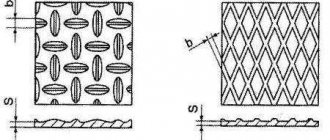

Corrugated aluminum sheet, distinguished not only by the texture of its surface, on which convexities of a certain configuration are specially formed, but also by its low weight, has recently become increasingly popular. This material is actively used not only by construction organizations, but also by designers, using it to create structures for various purposes.

Corrugated aluminum sheet is used for the manufacture of decorative, anti-slip and facing coatings

Classification

Sheets for special and general purposes from Al and Al alloys are produced:

- without applying a cladding layer, with normal (A), thickened (U) or technological (B) plating;

- without heat treatment, including these can be annealed (M) sheets - if they have satisfactory mechanical properties, after thermomechanical treatment: semi-work-worked (H2), cold-worked (H), as well as naturally aged after hardening (T), artificially aged after hardened (T1) and cold-worked after hardening with natural aging (TN),

- with normal, high (B) or increased (P) level of surface finish;

- with normal accuracy of dimensions of thickness, width, length, with increased accuracy of all three parameters, or selectively for two or one parameter.

The maximum permissible deviations in the thickness of rolled sheets are smaller for rolled products manufactured with increased precision.

Application area

AD1N alloy is used for the manufacture of a variety of industrial and household items. In the instrument making and electrical industries, aluminum sheets of this grade are used for the manufacture of:

- clamps, terminals, busbars for circuits with direct and alternating current;

- Due to their high electrical conductivity, elements made from AD1N aluminum sheet do not heat up when passing current through them. Therefore, cooling radiators are made from them for devices with power semiconductors, including transistors, thyristors, etc. In addition, the AD1N alloy has good thermal conductivity, which makes it possible to effectively remove heat from semiconductors, preventing parts from overheating;

- electrolytic capacitors used in radio electronics have a housing and fasteners made of AD1N aluminum;

- their low specific gravity and high corrosion resistance make it possible to use aluminum sheets in difficult or extreme conditions, making protective installations for electrical equipment from them: consoles, cabinets, panels.

Light weight, high ductility and resistance to corrosion, as well as to aggressive environments, make AD1N aluminum sheets an indispensable material for the aviation, space industry and shipbuilding, where they are used to make various complex structures and heat-reflecting screens. Aluminum sheets are also used in the production of electric vehicles and in the energy sector.

The petrochemical industry uses AD1N aluminum sheets in the construction of pipelines and ventilation systems, and in the manufacture of containers for storing products.

Aluminum sheet is also used in the food industry, where dishes are made from it using stamping machines. Such utensils retain their performance properties for a long time, are safe for humans and have a low cost. For the same reason, AD1N aluminum sheets are used in the manufacture of containers for transporting and storing products in meat processing plants, dairy plants, oil mills and distilleries, breweries and wineries.

The furniture and construction industries also cannot do without rolled aluminum. Partitions are made from AD1N aluminum sheets, they are used as sheathing or roofing material, and they are used to construct shelves and display cases.

To obtain a sieve with different cell sizes, perforated aluminum sheets are used. Such structures are used in the construction and agricultural sectors. In addition, aluminum sheets are used in catering establishments, as well as in medicine and pharmaceuticals.

Assortment

The dimensions of the thickness, width and length of Al sheets are indicated in relation to the technical characteristics of rolled sheets: the alloy used, the clad layer, thermal and thermomechanical treatment. Parameters with deviations within the tolerance must comply with the standards established by this GOST.

Table. Dimensions

| Al and Al alloy grades | Thickness, mm (from – to inclusive) | Length (from – to inclusive), mm | Width, mm |

| No heat treatment | |||

| A7, A6, A5, A0 | 5,0-10,5 | 2000 | 600, 800. 900,1000, 1200. 1400,1500, 1600,1800. 2000 |

| AD0, AD, AD1, AD00, | |||

| B95A, | 1000. 1200, 1425, 1500, 2000 | ||

| 1915 | 1200, 1500. 2000 | ||

| A5, A6, A7, A0, AD0, AD, AD1, AD00, AMtsS, AMts, AMg2, AMg5, AMg3, AMg3, AMg6B, AB, D1A, D16A, V95-1A, V95-2A, VD1A, VD1B, VD1, AKMA | 1000, 1200, 1400, 1500, 1600, 1800, 200 | ||

| After annealing, in a soft state | |||

| A5, A6, A7, A0, AD, AD0, AD1, AD00, | 0,3 – 10,5 | 2000 | 600, 800, 900, 1000, 1200, 1400. 1500,1600,1800, 2000 |

| D12 | 0,5 – 4,0 | 3000 – 4000 | 1200, 1500 |

| A5, A6, A7, A0, AD0, AD1, AD00, AD, AMtsS, AMts, AB, AMg2 | 0,5 – 0,7 | 2000 – 4000 | 1000, 1200, 1400, 1500, 1600 |

| 0,8 –10,5 | 2000 – 7000 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | |

| AMg6, AMg6B, AMg5, AMg3 | 0,5 – 0,7 | 1000, 1200, 1400, 1500, 1600 | |

| 0,8 – 10,5 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | ||

| AMg6U | 2,5 – 5,5 | ||

| 1565h | 0,5 – 0,7 | 1000, 1200, 1400, 1500, 1600 | |

| 0,8 –10,5 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | ||

| 1580 | 1,0 –10,5 | ||

| D1A, D16, D16A, D16B, | 0,5 – 0,7 | 2000 – 4000 | 1000, 1200, 1400, 1500, 1600 |

| 0,8 – 4,0 | 2000 – 7000 | 1000, 1200, 1400, 1500, 1600, 1800 | |

| 4,5 –10,5 | 2000 | ||

| D16U | 0,5 – 0,7 | 2000 – 4000 | 1200, 1500 |

| 0,8 – 4,0 | 2000 – 7000 | ||

| B95A | 0,5 – 0,7 | 2000 – 4000 | 1000, 1200, 1425, 1500 |

| 0,8 – 4,0 | 2000 – 7000 | 1000, 1200, 1425, 1500, 2000 | |

| 4,5 – 10,5 | |||

| V95-2A, V95-2B, V95-1A, AKM, AKMA, AKMB | 1,0 –10,5 | 1200, 1400, 1500 | |

| VD1, VD1A, VD1B | 0,8 –10,5 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | |

| 1915 | 0,8 | 2000 – 5000 | 1200 |

| 1,0 – 4,5 | 1200, 1500 | ||

| In a semi-hardened state | |||

| A5, A6, A7, A0, AD, AD0, AD1, AD00, | 0,8 – 4,5 | 2000 – 4000 | 1000, 1200, 1400, 1500 |

| AMts, AMtsS, AMg2, AMg3 | 0,5 – 0,7 | 2000 – 7000 | 1000, 1200, 1400, 1500, 1600 |

| 0,8 – 4,0 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | ||

| D12 | 0,5 – 4,0 | 3000 – 4000 | 1200, 1500 |

| In a hardened state | |||

| A5, A6, A7, A0, AD, AD0, AD1, AD00, | 0,3 – 10,5 | 2000 | 600, 800, 900, 1000 |

| 0,5 – 0,7 | 2000 – 7000 | 1000, 1200, 1400, 1500, 1600 | |

| 0,8 – 4,0 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | ||

| AMts, AMtsS, AMg2 | 0,5 – 0,7 | 1000, 1200, 1400, 1500, 1600 | |

| 0,8 – 4,0 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | ||

| VD1A, VD1B, VD1, AKMA | 0,8 – 4,0 | 1000, 1200, 1500 | |

| MM | 1,0 – 4,5 | 2000 – 4000 | 1000, 1200, 1400, 1500 |

| Naturally aged, after hardening | |||

| AB, D1A, D16, D16A, D16B, | 0,5 – 0,7 | 2000 – 5000 | 1000, 1200, 1400, 1500, 1600 |

| 0,8 –10,5 | 2000 – 7200 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | |

| D16U | 0,5 – 4,0. | 1200, 1500 | |

| D19A | 0,5 – 10,5 | 600, 800, 900, 1000, 1200, 1400, 1500, 1600, 1800, 2000 | |

| V95-1A, V95-2A, VD1A, VD1B, VD1, AKMA | 0,8 – 10,5 | 2000 – 7000 | 1000, 1200, 1500, 1600, 1800, 2000 |

| 1915 | 1,0 – 4,5 | 2000 – 5000 | 1200, 1500 |

| 5,0 – 10,5 | 2000 –7000 | 1200, 1500, 2000 | |

| Artificially aged, after hardening | |||

| AB | 0,5 – 0,7 | 2000 – 5000 | 1000, 1200, 1400, 1500, 1600 |

| 0,8 –10,5 | 2000 – 7000 | 1000, 1200, 1400, 1500, 1600, 1800, 2000 | |

| B95A | 0,5 – 0,7 | 2000 – 5000 | 1000, 1200, 1425, 1500 |

| 0,8 – 4,0 | 2000 – 7200 | 1000, 1200, 1425, 1500, 2000 | |

| 4,5 – 10,5 | 2000 – 7000 | ||

| Hard-worked, after hardening and natural aging | |||

| D16, D16A, D16B | 1,5 – 7,5 | 2000 – 7200 | 1000, 1200, 1400, 1500 |

Rolled sheets of unmeasured length must be cut within the limits established by these technical specifications. The intervals between length values are 500 mm.

Description of alloy AD1N

The first letters of the marking - AD - indicate that aluminum sheets of the AD1N brand are made of aluminum, which is easily deformable. The letter H at the end of the marking indicates that the material has undergone cold hardening. Hardening is one of the types of mechanical action, which is otherwise called cold hardening.

At the same time, a distinction is made between useful and harmful hardening. The latter occurs spontaneously as a side effect and requires subsequent treatments. Useful cold hardening (hardening), on the contrary, improves the quality characteristics of the metal. The word has German roots and is literally translated as solid, which describes the essence of the process.

During the cold-hardening procedure, the metal undergoes pressure treatment, during which its outer layers are compacted. As a result, the aluminum sheet becomes more durable, harder, does not crack and does not require additional processing. Hardening is carried out immediately during the production of aluminum sheets using the cold rolling method or in shot blasters.

After cold hardening, the level of ductility decreases, and topological defects (dislocations) may also occur. The latter can be removed by annealing - heating cold-worked aluminum to a temperature of about 345 °C. After annealing, the material regains its plasticity and softness, which is called recrystallization or return to its original state.

The concept of semi-hardening is also distinguished. In this case, the cold-hardening process takes place at reduced pressure, as a result of which aluminum retains a higher level of ductility while obtaining moderate hardness. Products that have undergone hardening are marked with the letter “H”, semi-fretted products are marked with the letter “H2”.

Designation

The symbol for rolled sheets made of Al and Al-based alloys includes information about metal products in the following sequence: alloy grade, cladding, heat treatment, dimensions: thickness x width x length, level of manufacturing accuracy. Next, indicate the number and year of this GOST. In conclusion, a letter is placed indicating the quality of the surface finish.

Example: Sheet AMg6 B N2 4.5 P x 1400P x 2500 GOST 21631-2019 P

Sheet of deformable Al alloy - AMg6, with technological cladding, in a semi-work-hardened state, 4.5 mm thick, 1400 mm wide, 2500 mm long, with increased accuracy of thickness and width dimensions, produced according to the technical specifications of GOST 21631-2019, with high quality surface finishing.

Order and delivery of aluminum sheet AD1N

Our company sells AD1N aluminum sheets to any region of Russia. Within Moscow and Moscow Region, delivery of products is carried out using our company’s transport. Products are delivered outside the Moscow region using transport companies specializing in large-sized cargo transportation.

Our warehouse always has a wide range of rolled aluminum and other types of rolled metal products. If necessary, before shipping we cut sheet metal to the required dimensions.

You can order products yourself on the company’s website or by contacting our operators at the phone number indicated at the top of the website page. To place an order, you need to decide on the brand, quantity, delivery time and assortment. The order is collected and shipped within 24 hours from the date of payment for the order.

All supplied products fully comply with state standards and technical specifications.

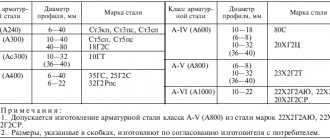

Requirements for the planned layer

The thickness of the cladding layer is a standardized value. It is set as a percentage of the thickness of the sheet before the cladding.

Table. Standards for the thickness of the cladding layer

| Sheet thickness, mm | 0,5 – 1,9 | 2,0 – 4,0 | 4,5 – 10,5 |

| Cladding | Thickness, depending on the plating method, % | ||

| Normal | 4 | 2 | 2 |

| Technological | 1,5 | 1,5 | 1,5 |

| Thickened | 8 | 4 | – |

The cladding layer is applied to the surface on both sides. Zinc-alloyed aluminum with a minimum content of impurities is used as a cladding material. The choice of material is made depending on the purpose of the sheet products. There is a clarification for the AMg6 alloy - the thickened cladding is at least 4% of the thickness.

Additional services from the Resurs company

To ensure a productive and pleasant cooperation with our company, we make sure that:

- a wide range of products was always available in our warehouse;

- the goods were shipped within 24 hours from the moment the contract was concluded and the order was paid for;

- to simplify the work, we offer additional services in the form of bending, cutting, perforating and other types of mechanical processing of aluminum sheets;

- We work with large and small wholesale, as well as retail sales;

- prices in our catalog correspond to the cost set by the manufacturer;

- You can pay for your order using any convenient option. For regular customers, benefits and individual terms of cooperation are provided;

- Our specialists are always ready to advise on technical and financial issues. Consultation is free;

- we deliver products anywhere in the Russian Federation;

- We have a large assortment of packaging materials that will ensure reliable safety of the cargo for any type of delivery;

- if necessary, we provide storage services in our warehouse, selected and placed orders;

- delivery to the transport company terminal is free of charge;

- Products are returned according to the schemes provided for by the legislation of the Russian Federation.

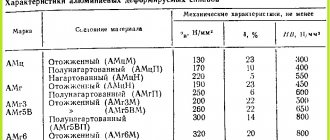

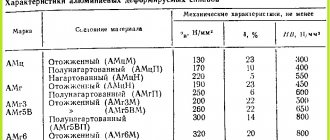

Mechanical properties requirements

Table. Indicators of mechanical properties under tensile force

| Al and Al alloy grades | Information about heat treatment (b/t - without treatment) | Yield strength, MPa | Tensile strength, MPa | Relative extension, % |

| AD0. AD1.AD00, AD, A7. A6, A5. A0, | M | – | 60 | A7. A6, A5. A0 – 20; AD0. AD1.AD00, AD – 25-30 |

| H2 | – | 100 | 6 | |

| N | – | A7. A6, A5. A0 – 145; AD0. AD1.AD00, AD – 130-145 | A7. A6, A5. A0 – 3; AD0. AD1.AD00, AD – 4-5 | |

| b/t | – | 70 | 15 | |

| AMts, AMtsS | M | – | 90 | 18-22 |

| H2 | – | 145 | 5-6 | |

| N | – | 185 | 1-4 (depending on thickness) | |

| b/t | – | 100 | 10 | |

| MM | N | Tests are not carried out | ||

| D12 | M | – | 155 | 13 |

| H2 | – | 220 | 2 | |

| AMg2 | M | – | 165 | 16-18 |

| H2 | 145 | 235-315 | 5-6 | |

| N | 215 | 265 | 3-4 | |

| b/t | – | 174 | 7 | |

| AMgZ | M | 80-100 | 185-195 | 15 |

| H2 | 195 | 245 | 7 | |

| b/t | 80 | 185 | 12-15 (depending on thickness) | |

| AMg5 | M | 130-145 (based on thickness) | 275 | 15 |

| b/t | 130 | 12-15 | ||

| AMg6, AMg6B | M | 140-155 | 305-315 | 15 |

| b/t | 155 | 315 | ||

| AMgBU | M | 130 | 275 | 15 |

| 1565h | M | 160-175 (based on thickness) | 335 | 15 |

| b/t | 175 | |||

| H2 | 265 | 360 | 10 | |

| 1580 | M | 260-280 | 360-380 | 12-15 |

| H2 | 310 | 400 | 10 | |

| AB | M | – | within 145 | 15-20 |

| T | – | 175-195 | 16-20 | |

| T1 | – | 295 | 8-10 | |

| b/t | – | 175- 295 (from aging) | 7-14 (depending on thickness) | |

| D1A | M | – | 145-235 | 12 |

| T | 180-195 | 365-375 | 15 | |

| b/t | 180 | 355 | 12 | |

| D16, D16B | M | – | 145-235 | 10 |

| T | 290 | 440 | 10-13 | |

| TN | 360 | 475 | 8-10 | |

| D16U | M | – | 135-235 | 10 |

| T | 230-270 (based on thickness) | 365-405 | 13 | |

| D16A | b/t | 255 | 415 | 10 |

| TN | 335-345 (depending on thickness) | 425-455 | 8-10 | |

| M | – | 145-235 | 10 | |

| T | 270-275 | 405-425 | 10-13 | |

| B95A | M | – | within 245 | 7 |

| T1 | 400-410 | 480-490 | 6-7 | |

| b/t | 410 | 490 | 6 | |

| AKMA | M | within 245 | 10 | |

| T | 315 | |||

| N | Tests are not carried out | |||

| b/t | 315 | 10 | ||

| AKMB, AKM, V95-2A, V95-2B, V95-1A | M | – | within 245 | 10 |

| T | – | 315 | ||

| b/t | Tests are not carried out | |||

| 1915 | M | – | within 245 | 10 |

| T | 165-195 (from the aging period) | 275-315 | ||

| b/t | 265-315 | |||

| VD1A, VD1B, VD | M | – | within 245 | 10 |

| N | Tests are not carried out | |||

| T | – | 335 | 12 | |

| b/t | – | |||

Surface Requirements

On the surface of sheets with a high and high finish, on both sides:

- Surface roughness of more than 125 microns is not allowed;

- must be completely absent, tears, marks from rollers, stripes and burn marks;

- may be present: small metal sunsets with an area depending on the width of the sheet;

- bubbles - for finishing quality B - no more than 20 mm² per 1 m², for finishing P - no more than 40 m²;

- Small dents, tarnished colors, notches no more than 4 mm long, light abrasion - no more than 1% of the sheet area are allowed;

- Traces of sunset spalling, single and group (less than 5) scratches, with a depth of no more than 0.02 for a rolled width of up to 1.2 m and up to 0.05 on sheets wider than 1.2 m are allowed.

The depth of permissible defects cannot be more than 50% of the maximum tolerance for deviations in thickness size. Scratches, notches, and dents should not disturb the layer of normal and thickened plating.

Impurities and composition of AD1N alloy

The content of pure aluminum in the AD1N alloy is about 95.5%. In addition, the alloy contains impurities, the composition and percentage of which is strictly standardized. For example, iron and silicon, which give the alloy its hardness, should not exceed 0.3% of the total mass of the substance. Deviation from the standard in a larger direction will lead to a decrease in the ductility of the alloy. Also present in the composition of the AD1N alloy in small quantities are:

- zinc – no more than 0.1%;

- manganese - 0.05%;

- titanium – up to 0.15%. This element increases the strength of the material and is responsible for increasing the anti-corrosion properties of the alloy;

- copper, magnesium – no more than 0.03% each;

- other additives in total may be contained in an amount of 0.03%.

Acceptance and technical quality control

The quality of the surface is determined on each product - visually, without the use of instruments. The depth of defects and roughness are checked with a profilometer and an indicator depth gauge. Roughness check - at the customer's request.

Flatness is checked for compliance with the standards by laying the sheet, alternately with each side on the plane of the control plate and measuring deviations with a template

Control of dimensional parameters is carried out by measuring: thickness - with a micrometer, length and width - with a tape measure. Every 10th product is checked.

The chemical composition is determined on samples taken from 2 products from the batch - by chemical or spectral analysis. Samples are taken in accordance with GOST 24231-80.

The microstructure is examined by metallography or the eddy current method, using methods developed by the manufacturer.

To control the mechanical properties, a flat, established, proportional sample is cut from a sheet selected from a batch (at least 1), transverse to the rolling direction. Test regulations: sheets thickness: 0.8-2.5 mm - GOST 11701-84, thickness: 3.0-10.5 mm - GOST-1497-84. The test report indicates the min and max values. Tensile strength, yield strength and relative elongation are not controlled for sheets produced using technology that meets the standards.

Storage and transportation rules

A mark with the alloy grade, heat treatment and plating mark, dimensions, batch number and technical control stamp is placed at a distance of up to 30 mm, along the side that is the width of the product. The batch may have: 1 top sheet branded, all sheets, or, as agreed with the consumer, without branding.

The manufacturer provides corrosion-protected storage. Sheets are packed in bundles. During transportation, each piece of cargo is marked in accordance with the rules of GOST 14192-96.

Table. Appendix A - theoretical mass

| Thickness (mm) | Estimated weight (kg) – 1 meter of sheet (average density), with rolled width (mm) | |||||||

| 600 | 1000 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | |

| 0,3 | 0,473 | 0,715 | – | – | – | – | – | – |

| 0,4 | 0,646 | 1,001 | 1,168 | – | – | – | – | – |

| 0,5 | 0,818 | 1,288 | 1,511 | 1,762 | 1,793 | 2,013 | – | – |

| 0,6 | 0,981 | 1,545 | 1,854 | 2,142 | 2.295 | 2,447 | ||

| 0,7 | 1,153 | 1.831 | 2.198 | 2.543 | 2,724 | 2,905 | ||

| 0,8 | 1,308 | 2.117 | 2,524 | 2,923 | 3,131 | 3,34 | 3.704 | 4,114 |

| 0,9 | 1,480 | 2.404 | 2,87 | 3,324 | 3,56 | 3,797 | 4,22 | 4,686 |

| 1,0 | 1,635 | 2.647 | 3,160 | 3,664 | 3, 925 | 4,185 | 4,681 | 5,20 |

| 1,2 | 1,98 | 3.22 | 3,846 | 4,465 | 4,783 | 5,10 | 5,659 | 6,286 |

| 1,5 | 2,453 | 4,006 | 4,774 | 5,506 | 5,898 | 6,30 | 7,05 | 7.83 |

| 1,6 | 2,625 | 4,292 | 5,117 | 5,906 | 6,327 | 6,747 | 7,562 | 8,40 |

| 1.8 | 2,970 | 4,864 | 5,804 | 6,707 | 7,184 | 7,662 | 8,591 | 9,543 |

| 1,9 | 3,142 | 5,151 | 6,147 | 7.108 | 7,613 | 8,12 | 9,105 | 10,114 |

| 2,0 | 3,314 | 5,437 | 6,456 | 7.488 | 8,021 | 8,554 | 9.594 | 10,657 |

| 2,5 | 4,131 | 6,796 | 8,105 | 9,43 | 10,101 | 10.772 | 12,089 | 13,428 |

| 3,0 | 4,95 | 8,155 | 9,788 | 11,332 | 12,14 | 12,945 | 14,533 | 16,143 |

| 3,5 | 5,81 | 9,586 | 11,470 | 13,314 | 14,262 | 15,21 | 17,08 | 18,971 |

| 4,0 | 6,67 | 11,016 | 13,136 | 15,296 | 16,385 | 17,474 | 19,625 | 21,80 |

| 4,5 | 7,531 | 12,447 | 14,853 | 17,298 | 18,53 | 19,761 | 22,197 | 24,657 |

| 5,0 | 8,35 | 13,806 | 16,553 | 19,28 | 20,653 | 22,025 | 24,744 | 27,486 |

| 5,5 | 9,24 | 15,267 | 18,31 | 21,32 | 22,835 | 24,35 | 27,354 | 30,381 |

| 6,0 | 10,104 | 16,63 | 19,943 | 23,226 | 24,876 | 26,526 | 29,801 | 33,098 |

| 6,5 | 10,967 | 18,063 | 21,663 | 25,232 | 27,024 | 28,817 | 32,376 | 35,96 |

| 7,0 | 11,831 | 19,496 | 23,367 | 27,217 | 29,151 | 31,085 | 34,926 | 38,791 |

| 7,5 | 12,694 | 20,93 | 25,09 | 29,223 | 31,30 | 33,375 | 37,502 | 41,652 |

| 8,0 | 13.515 | 22,292 | 26,74 | 31,15 | 33,361 | 35,574 | 39,975 | 44,398 |

| 8,5 | 14,378 | 23.725 | 28,46 | 33,154 | 35,51 | 37.865 | 42,55 | 47,26 |

| 9,0 | 15,242 | 25,16 | 30,164 | 35,14 | 37,636 | 40,133 | 45,10 | 50,091 |

| 9,5 | 16,105 | 26,592 | 31,884 | 37,145 | 39,784 | 42,424 | 47,676 | 52,951 |

| 10,0 | 16,926 | 27,954 | 33,553 | 39,111 | 41,90 | 44,668 | 50,226 | 55,783 |

| 10,5 | 17,79 | 29,39 | 35,274 | 41,117 | 44,038 | 46,96 | 52,802 | 58,644 |

Theoretical calculation of mass was carried out for Al and Al alloys, taking the average value of the material density - 2.71 g/cm. For reference: the density of AMg5 and AMg6 alloys is 2.65 g/cm