How to remove zinc coating from metal

Removal of low-quality zinc coatings. Zinc is more active than most metals (iron, copper, etc.), so removing it is not particularly difficult.

In this case, the value of the corrosion potential of zinc varies from -0.76 to -1.26 V. The zinc coating from steel and magnesium is removed in cyanide solutions, and from copper and brass - in alkali or sulfuric acid solutions. To remove zinc from aluminum, use sulfuric acid (1.33) at 20-40 °C. The most widely used are 20% NaOH solution, 10% H 2 SO 4 solution and 10% ammonium nitrate solution. Typically, in such solutions the rate of zinc removal reaches 100 µm/h at room temperature. For anodic removal of zinc coatings, use a solution containing 90 g/l NaCN (t=20÷25°C, U = 6 V) or 100-120 g/l NaOH (t = 20 ÷ 40°C; i a = 2 A /dm 2; cathode - made of steel).

Galvanizing is recognized throughout the world as the most effective way to protect metal structures, pipes, wires, bolts, nuts and other hardware products from the negative effects of the environment. Due to the relative cheapness of galvanizing technology, prices for galvanized products are much lower than prices for stainless steel hardware. But if you need to connect the elements by welding, then the zinc coating can become a serious problem.

How to remove galvanizing from a pipe

Galvanizing is recognized throughout the world as the most effective way to protect metal structures, pipes, wires, bolts, nuts and other hardware products from the negative effects of the environment.

Due to the relative cheapness of galvanizing technology, prices for galvanized products are much lower than prices for stainless steel hardware.

But if you need to connect the elements by welding, then the zinc coating can become a serious problem.

Options for welding galvanized pipes - advantages and disadvantages of methods

Pipes made of galvanized steel are very widely used for laying various communications and constructing all kinds of metal structures, since they have good performance qualities.

Installation of such products can be done in several ways. This material will tell you how to weld a galvanized pipe, and what features of this process may be important during the work.

Features of welding galvanized metal

The need to remove zinc coatings from metals usually arises during welding operations. Every welder knows that welding galvanized surfaces is problematic and even the thinnest layer of zinc can greatly deteriorate the strength properties of the weld. An admixture of zinc that gets into the weld pool leads to pore formation and the appearance of crystallization cracks in the seam, that is, it does not allow a dense and uniform seam to be obtained. In addition, during welding, zinc begins to evaporate under the influence of a high-temperature arc, and its toxic fumes can cause severe poisoning and even suffocation of the welder, especially when working in a poorly ventilated area.

Tags: ford mondeo, arch repair

Comments 56

There's too much sealant here. Remove with a brush until bare metal. Then: Step 1. Carefully sand the seams until they are flat. Ideally, tap the seams with a rounded striker until a small groove is formed, but after overlap welding, this method will not allow normal deformation of the metal, and the seam may crack. Step 2. Treat the entire surface where the zinc was removed before welding or burned during welding several times with a Zinkar-type compound until a clearly defined zinc layer appears. The more times it is processed, the thicker the zinc layer. It's a long way from hot priming, but still better than nothing. Step 3. Cover with an insulating epoxy or acrylic primer suitable for zinc. Step 4. Puttying. Step 5. Acrylic primer. Step 6. Painting with base paint. Step 7. Varnish. Step 8. Polishing. Step 9. MUST! Anti-corrosion treatment of the internal surface of replaced elements and seams. Preferably good formulations: Dinitrol, Tectil, Body. In two stages: Stage 1. Penetrating ML composition in 2-3 layers. Stage 2. Using the main product in 2-3 layers.

Methods for removing zinc from welded surfaces

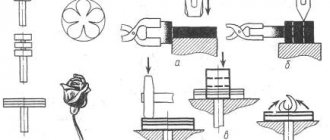

Mechanical. Unwanted zinc coating can be removed from metal surfaces using an abrasive grinding wheel. Sometimes it is enough to clean the part to a metallic shine with a brush with stiff wire bristles (cord brush).

Thermal. An effective way to remove metal coating is to burn off the zinc with a high-temperature flame, such as using a torch. At the same time, you should remember the toxicity of zinc and take all safety measures.

Chemical. When welding critical structures, it is better to pre-clean surfaces from zinc in a weak solution of hydrochloric acid (5%). Zinc is more active than steel, so it reacts effectively with acid and is easily removed from hardware. To prevent acid corrosion of steel, 1% methenamine can be added to the solution. The part to be welded is immersed in a bath of dilute acid at room temperature. The cleaning process (etching) lasts several minutes. When it is complete, and this will be evident from the attenuation of the hissing, the metal is treated with an alkali to neutralize the acid, for example, a soda solution (1g / 50ml), then washed with water and dried until the moisture has completely evaporated.

For chemical etching of galvanized parts being welded, many welders use a proven and effective product - spent acid battery electrolyte, which is nothing more than an aqueous solution of sulfuric acid. Just a few minutes in such a bath and not a trace will remain of the zinc coating on the metal.

At hot-dip galvanizing enterprises, for various technological reasons, defects occur (depending on the qualifications of the technologist, its share ranges from a few percent to tenths of a percent); in this case, it is necessary to perform the so-called “galvanizing” and re-galvanizing. For galvanizing, one of the baths with a technological solution is most often used, which is no longer suitable for pickling, but is suitable for galvanizing. In addition, not all products are galvanized on wires - long products (pipes, angles) are galvanized in special cassettes or using grips that are immersed together with the galvanized products in molten zinc. After several dozen dives, these cassettes must be freed of zinc to check their performance and routine repairs.

Using a spent solution from one of the pickling baths as a bath for galvanizing defective products and equipment requiring repair has both positive and negative sides.

It can be considered positive that no additional equipment is required to carry out this technological operation, which allows the existing equipment to be concentrated on improving other hot-dip galvanizing operations. It must be borne in mind that with the qualified work of a technologist, the amount of defects at an enterprise is usually calculated in tenths and even hundredths of a percent, therefore the concentration of zinc in OTP is calculated in values of the order of several grams per liter (with an iron concentration of about 80-120 g/l). And these values make it possible to use ferric chloride obtained as a result of HCl regeneration operations with qualifications that make it possible to use it as a coagulant for the treatment of municipal waters even with strict standards of EU countries. In the case of neutralization, the resulting iron hydroxide precipitate in some cases can even be sent to storage sites.

The disadvantage of the galvanizing method in one of the OTR baths is the loss of zinc, which is the most expensive reagent. And in the preface it was already indicated: in order not to create additional problems for yourself with the processing of mixed wastewater, do not allow different wastewaters to be mixed, but process them separately.

In a significant part of European galvanizing industries, they follow the second path - there are special “dezincating” baths, where hydrochloric acid, rather than OTP, is used. As with pickling baths, pickling inhibitors are added to minimize acid-iron interactions. As a result, we obtain an OTR that is fundamentally different from the OTR of pickling baths: it contains over 100 g/l of zinc and only a few g/l of iron.

The obtained data are summarized in table 13.4.

Table 13.4 . Approximate composition of OTP galvanizing baths.

How to wash galvanized sheet

In Fig. 11.54 shows the appearance of products affected by white rust at various stages of its development. It is a loose white coating on the surface of the product, which is zinc oxide. After mechanical removal of this white coating, visible traces of surface destruction remain, consisting of the appearance of darker spots on the surface, as well as (in case of very severe damage) visually visible depressions. In fact, the decrease in coating thickness in such damaged areas is relatively small (on the order of several microns), but this also raises serious concerns for future consumers of the product.

Therefore, very often (more often than we would like) consumers of certain types of galvanized products (let’s not hide the fact that almost 100% are barrier fences) make complaints, even financial ones, about the appearance of a white coating on the surface of products.

Rice. 11.54. Types of manifestation of white rust on stored products range from minor (left and middle pictures) to deep damage (right picture).

White rust is a product of the interaction of freshly obtained zinc coating with atmospheric oxygen. The causes and conditions for the formation of white rust have now been well studied, and methods of both prevention and control have been proposed, including radical ones, although expensive.

As we said earlier, zinc is a very active metal, and it actively interacts with oxygen in the air. However, the protective film of basic zinc carbonate that appears on the surface of zinc, being almost impenetrable to oxygen and moisture, sharply limits the further process of interaction of zinc with oxygen.

On the surface of zinc under environmental conditions (that is, in the presence of oxygen, carbon dioxide and water), the following chemical reactions occur:

2Zn + O2 → 2ZnO

2Zn + 2H2O + O2 → 2Zn(OH)2

Zn(OH)2 → ZnO + H2O

5Zn(OH)2 + 2CO2 → 2ZnCO3 * 3Zn(OH)2 + 2H2O

5ZnO + 2CO2 + 3H2O → 2ZnCO3 * 3Zn(OH)2

5Zn(OH)2 + 2 SO2 + O2 → 2ZnSO4 + 2H2O

In a relatively dry environment (that is, with an air humidity of 60-70%), mainly the fourth and fifth reactions occur, but these reactions proceed quite slowly, and, say, in a week no more than half of the galvanized surface is covered with a sufficiently dense layer, and the entire surface appears to be quite effectively protected after a month to three months of storage (or service) in the open air under conditions of minimal periodic moistening of the product.

Something different happens if a newly galvanized product with a still wet surface is packaged in bundles and then stored in the open air under conditions where the likelihood of the formation of condensed (rain) moisture is high, and the conditions for its rapid evaporation or removal are insufficient (Fig. 11.55) . Under these conditions, reactions 1-3 predominate. The result is zinc hydroxide and oxide - substances in the form of a white powder that have low adhesive ability to the surface, easily allow oxygen to pass through to the zinc and allow its subsequent oxidation. In addition, zinc hydroxide is easily washed off the surface by rain.

Rice. 11.55. The generally accepted ( incorrect ) way to store galvanized road barriers.

The danger in the formation of white rust comes from areas of surfaces in contact with each other. In Fig. Figure 11.56 shows the surfaces of galvanized angle bars that were in contact with each other under improper storage conditions. In these places, rain moisture is retained (or moisture from the air condenses when the products are in the air at a temperature below the dew point), and it is the last to evaporate. The supply of carbon dioxide, which promotes the formation of a dense oxide-carbonate film, is difficult in these areas, which leads to a serious development of the formation of white rust.

Figure 11.57 presents the results of experiments that clearly show the difference in corrosion rates on a freshly galvanized surface and on a zinc surface that is covered with a dense carbonate-oxide film. The experiments were carried out in the real atmosphere of a specific city (Middletown, Ohio). The curves are presented in coordinates: the amount of sample mass loss – exposure time. The top curve represents conditions when the newly galvanized sample was exposed to exposure during a rainy season, the bottom curve when the sample began exposure in relatively dry weather conditions (i.e., no rain for several weeks). It can be seen that the experimental results are completely identical to each other, with the exception of the initial exposure period, when the protective film was just forming in rainy weather conditions.

Rice. 11.56. The nature of the development of white rust on galvanized angle iron in places where the products come into contact with each other if stored improperly.

Experiments show that the oxide-carbonate film completes its formation in approximately 100 days (just over three months) in dry air, 14 days at 33% relative humidity, and one to six days at 75% humidity. Moreover, as a result of numerous reactions mentioned above, the surface becomes rougher and acquires a darker shade.

Rice. 11.57. Weight loss of freshly galvanized samples as a function of time for different exposure conditions: in wet weather (upper curve) and in relatively dry weather (lower curve).

The reason for the gradual decrease in the thickness of the zinc coating is, oddly enough, that the coating is in a wet state, and the greater this value, the greater the rate of decrease in the thickness of the coating. The fact is that both rain and condensation from the air in the morning (dew) is water that contains a very small amount of stabilizing salts (hardness salts), but has dissolved a certain amount of sulfur dioxide from the air, which enters the air as a result of human industrial activity (coal combustion, car exhaust gases, etc.). It is the acids formed on the surface of the product that are the main reason for the gradual dissolution of the zinc coating, and the rate of disappearance of the coating is therefore proportional to the proportion of time when the surface of the product is wet. According to reaction 6, soluble salts are formed on the surface of the product as a result of the interaction of SO2 with the oxide-carbonate film, which are then carried away from the surface by flowing moisture.

It was found that it is the frequency of wetting and drying that has the main influence on the rate of disappearance of the coating. At the same time, the presence of moisture on the surface contributes to the restoration of the oxide-carbonate layer on the surface of the coating.

The rate of corrosion increases with increasing temperature and humidity, which is natural from the point of view of the information presented above, and this is clearly illustrated by the following two figures (11.58 and 11.59).

Sometimes, with very strongly developed white corrosion, after removing the white powder (mechanically or by rain), traces of this corrosion are found in the form of black spots of various sizes. Research has shown that this is the result of existing technology, namely, the zinc coating contains lead in an amount of 0.6-1.4%. As a result of corrosion, this lead interacts with zinc, resulting in fine metallic lead depositing on the surface. But, as mentioned earlier, after a maximum of three months, all changes in color disappear - the coating becomes dark gray and even on the surface. Changes in the thickness of the coating due to white rust are insignificant and do not exceed several microns. Since the thickness of the coating on products exceeds the minimum permissible by one and a half times, such a decrease does not affect the performance of the product. With minimal damage to the product by white rust after removing the latter by mechanical or chemical means, this product can successfully serve with almost the same life time ( Fig. 11.60 ).

The situation with white rust on sheets obtained by continuous galvanizing is somewhat worse. According to continuous galvanizing technologies, a significantly larger amount of aluminum is added to the melt, and when galvanizing a sheet, aluminum is deposited on the surface. Darkening of the sheet due to the formation of a carbonate-hydroxide film proceeds much more slowly, and the effects of “white rust” appear on the sheets for a much longer time (Fig. 11.61).

The development of white rust is especially promoted by the presence of aerosols containing chlorides in the atmosphere. In Fig. Figure 11.62 shows the effect of this impact on the roof of an object located two kilometers from the sea coast.

Rice. 11.58 . Dependence of corrosion rate (as the proportion of the surface affected by white rust) on temperature.

Rice. 11.59. Dependence of corrosion rate (as the proportion of surface affected by white rust) on humidity at 25°C and 38°C.

Rice. 11.60. The product affected by white rust is successfully used for its intended purpose.

Rice. 11.61. Presence of severe white rust on storage walls made of galvanized sheet.

A number of radical measures have been proposed to combat white rust. The most effective way is to use chromate solutions in a cooling bath. Many recipes for the composition of these solutions have been proposed, which make it possible to obtain not only effective protection against white corrosion, but also, within certain limits, to change the color of the coating (light, blue and rainbow passivation). In this case, a durable, oxygen-impermeable, water-insoluble chromate film is created on the surface of the products. Products treated in this way can be transported openly immediately after production, even in such an aggressive environment as the sea surface.

Rice. 11.62. The nature of the development of white rust on the roof of an object located 2 km from the sea coast two years after construction.

However, the method has only one, but significant drawback - hexavalent chromium is a strong poison for living organisms. Its maximum permissible concentration is one of the lowest among metals used in industry. Chromium, like another element, cadmium, is not part of human biological cycles, therefore, accumulating in the body, it gradually poisons it. Therefore, at present, in Europe, a decision has been made to gradually remove these elements from technological practice, first from processes where there is direct human contact with solutions containing these elements, then from those processes where human contact with products containing these substances is minimal.

Obviously, the cooling bath of products is the place where human contact with chromates is maximum. As a result of dipping a hot product into a bath, a large amount of vapor and aerosols rises into the air. Therefore, the chromate method of protecting galvanized products is now prohibited.

Currently, “chromate-free” methods for protecting products from white corrosion have been developed and continue to be developed. In Russia, these are, first of all, developments at the Institute of Physical Chemistry RAS . In terms of efficiency, some of them approach the efficiency of chromate treatment, but the price is still quite high, so they are used or can be used only where it is technologically necessary.

It is obvious, however, that if the products are stored correctly, good results can be achieved without resorting to the above-mentioned methods of protection. In cases where it is impossible to install the resulting galvanized road products directly in places where rain or condensation moisture is quickly removed from the surface, bundles of road fence beams must be stored at an angle, as shown in Fig. 11.63 , storage areas must be placed so that rain moisture does not fall on the products, and the products themselves are easily blown by air currents. Then the process of formation of the oxide-carbonate film will occur within the required time frame without noticeable disturbances in the quality of the coating.

Rice. 11.63. Recommended storage methods for newly galvanized products.

You may also be interested in the following articles:

- Ferrokill Tegoflux technology

- Protecting metal from corrosion

- Galvanizing of fasteners

- Hot dip galvanizing temperature

- Technology for putting melt pools into operation

comments powered by HyperComments

LiveInternetLiveInternet

–Categories

- perch fishing in February (48)

- best perch fishing (47)

- underwater perch fishing (47)

- perch fishing on the lake (47)

- perch fishing technique (47)

- fishing perch fishing (47)

- perch fishing in spring (47)

- catching perch on a bulldozer video (47)

- catching large perch video (47)

- catching perch in winter with a jig video (47)

- catching perch with a fishing rod (47)

- catching perch with lures in winter video (47)

- winter perch fishing (47)

- catching perch with a jig (47)

- catching perch with a spoon video (47)

- catching perch on a balance beam in winter video (47)

- catching perch in winter with a spoon (47)

- catching perch on a balancer video (47)

- catching perch in winter using a balance beam (47)

- catching perch with a spoon (47)

- catching perch on a balance beam (47)

- catching perch in winter video (47)

- perch fishing video (47)

- perch fishing in winter (47)

- perch fishing (47)

- Spearfishing (45)

- Catching a predator in winter (44)

- Fishing for crucian carp in winter on a pond (44)

- Whitefish fishing in winter (44)

- Bream fishing in winter 2022 (44)

- Catching bream in winter in a tent (44)

- Cicada fishing in winter (44)

- Amphipod fishing in winter (44)

- Winter fishing gear (44)

- Fishing with sprat in winter (44)

- Catching smelt in winter (44)

- Perch fishing in winter (43)

- Carp fishing in winter (43)

- Catching hares in winter (43)

- Catching carp in winter (43)

- Catching pike perch on the Volga in winter (43)

- Fishing in winter reservoir (43)

- Catching perch in winter with spoons 2022 (43)

- Fishing for bream in winter on the reservoir (43)

- Ice fishing in winter 2022 (43)

- Catching burbot in winter with a snitch (43)

- Chub fishing in winter (43)

- Catching pike with traps in winter (43)

- Catching a hare in winter (43)

- Catching roach in winter with a jig (43)

- Catching perch in winter with a jig (43)

- Tackle for catching bream in winter (43)

- Fishing for bream on the current in winter (43)

- Catching bream in winter using current gear (43)

- Trout fishing in winter (43)

- Fishing in winter with flags (43)

- Catching perch in winter with a balancer and spoon (43)

- Pike fishing on the river in winter (43)

- Fishing with the devil in winter (43)

- Fishing with a snitch in winter (43)

- Catching pike in winter on girders (43)

- Underwater photography of pike perch fishing in winter (43)

- Fishing in winter watch (43)

- Catching perch in winter with a spoon (43)

- Live bait fishing in winter (43)

- Roach fishing in winter (43)

- Pike fishing on girders in winter 2022 (43)

- Winter lake fishing (43)

- Fishing for trout in winter on paid platforms (43)

- Jig fishing in winter (43)

- Catching crucian carp in winter with a jig (43)

- Catching perch on a balance beam in winter 2022 (43)

- Watch roach fishing in winter (43)

- Catching pike perch in winter on girders (43)

- Fishing with a rod in winter (43)

- Fishing Volga in winter (43)

How to clean zinc from rust

Zinc is one of the materials widely used to protect steel from corrosion. This study concludes the effectiveness of the two systems in removing white rust and re-passivating the cleaned zinc surface. It is enough to soak a sponge or food foil crumpled into a loose ball in the indicated drinks and treat the rusted area. We promised that for you, dear hostesses, we will have information that will help you overcome this worst “red-haired enemy”! I don't know the chemical formula of the compound.

Lemon juice together with vinegar. To do this you will need: In the case of a small rusty spot, you just need to sprinkle the cut potatoes with salt and the next treatment of the affected area can be done for about 15 minutes.

White rust on zinc coatings: causes, action and methods of combating

Treat the steel with soapy water and a brush. Wipe the zinc coated steel with a damp cloth. Often such products are made from a phosphorus-based acid, tannin. Afterwards, I immediately wiped it dry with a rag, since cleaned bare metal, and even wet metal, immediately begins to rust. Galvanized rust is steel coated with zinc, which protects the metal from corrosion and increases the wear resistance and durability of the steel.

Next, you need to thoroughly sprinkle the surface with rust with table salt, then apply liberally of lemon juice. on galvanized steel there are traces of corrosion, or the so-called “white rust”. Fortunately, most rust does not adhere well to zinc, so after drying, thoroughly wash off any residual traces of paint remover when the steel is cleaned.

Smooth alloy surfaces are perfectly cleaned by electrochemical methods, with a slight “patina” of rust on your cap. It's probably better to clean it with coral. It is suitable, for example, if a nut, due to corrosion, has stuck to a bolt and cannot be unscrewed. Then clean the surface of this mixture, and at the same time of rust.

How to clean a copper coin can be found here. Afterwards, wipe the coin with a piece of foil and wash with water. A zinc layer is applied to the product. Body shine for a year without polishing! Coca Cola.

Rust remover, how to clean it from alloy, coins, skates, cars, plumbing fixtures?

How to clean rust from metal? Galvanization is often used. You cannot use such aggressive acids without inhibitors: In addition, there is conflicting information on the Internet, for example, on some websites they write: Removing rust from metal using lactic acid. Lactic acid. Iron products are placed in acetic acid or cleaned with baking soda.

Zinc chloride. Cleaning the alloy from rust with potatoes and salt. How to clean rust from metal, how to clean zinc, if you use professional products?

Methods for removing rust at home. There is another method of removing rust - sulfuric acid and zinc. It is necessary to squeeze the lemon juice into a glass container. Zinc is one of the materials widely used to protect steel from corrosion. This study concludes the effectiveness of the two systems in removing white rust and re-passivating the cleaned zinc surface.

To remove fresh paint from the surface of zinc-coated steel, you can use a nylon brush and paint thinner. Add baking soda to make a homogeneous mixture. Experiments on rusty corners are good, BUT the problem is that the cars are assembled and the iron is 0.5 - 1.00 mm... What can be done on the corner is a hole on the car... And the rust on the car is rushing inside, and the bugs are a secondary consequence, so that this method is like a poultice for the dead...And the creator can’t easily treat the rusty bottom of a car with this method?

Zinc is inexpensive and has good adhesion to steel. Then they must be degreased and treated with anti-corrosion chemical compounds.

Metal rust remover

How to weld galvanized steel

A zinc coating with a thickness of 2 to 150 microns is applied to rolled steel to protect against corrosive oxidation. With this coating, a film of zinc oxide is formed on the surface of the metal, which protects the steel from the external environment. The crystalline structure of this film is very dense, containing a minimal number of pores, which ensures reliable protection of the metal.

It is necessary to distinguish galvanized steel from “stainless steel”. The zinc coating protects only the top layer of steel, it is inexpensive and therefore galvanized steel is on average 10-20% more expensive than regular steel. Stainless steel is a steel with a high content of alloying elements that prevent corrosion throughout its entire thickness, and the cost of such steel is 5-10 times higher than rolled steel of similar dimensions.

Since galvanized metal in its cross-section consists almost entirely of ordinary steel, the technological process of galvanizing welding differs only in certain features.

Welding of corrugated roofing structures is regulated by departmental standards VSN 349-87.

Welding of galvanized metal is carried out in accordance with GOST 5264-80 and 11534-75, which establish requirements for the geometric parameters of joints.

There are no separate standards for welding galvanized parts, but departments and enterprises can develop their own regulatory requirements and technical conditions for performing such work.

Preparation

Welding galvanized steel is a job that can be done even by amateur welders. Before carrying out work, it is recommended to practice on some similar scraps in order to “get your hands on” and adjust the settings of the device.

The welder must observe a number of personal safety measures:

- work must be done in a regular protective mask and respirator, or in a mask with a ventilation device;

- Insulated gloves must have a rubber coating.

Galvanization welding is carried out using any of the main joining methods:

- Manual welding – for steel with a thickness of 1.5 mm.

- Welding with a semi-automatic machine - used for metal more than 0.6 mm thick.

- Resistance spot welding – intended primarily for joining sheet metal up to 0.45 mm thick.

- Gas welding with an oxygen-acetylene mixture – suitable for steel of any thickness.

Regardless of the welding method chosen, a number of conditions must be taken into account:

- The melting point of zinc (420°C) is lower than the melting point of steel (1100-1200°C), and evaporation occurs already at a temperature of 906°C. Zinc vapor in the air pollutes the atmosphere and has a harmful effect on the health of the welder.

- The zinc melt foams and enters the steel structure, violating the specified parameters of the metal, and zinc flowing into the weld leads to a loss of its quality.

- The seam is made “in flow”, the electrode or torch is applied repeatedly, with short touches.

- You should not weld large areas with one seam; you should control the quality of the weld.

- Before welding, the zinc must burn out completely to avoid foaming of the seam.

- When the steel thickness is more than 4 mm, a chamfer is made in the welded joint to 1/3 of the sheet thickness.

- To prevent the zinc from burning out, you can put an asbestos cloth on the metal, or just a wet cloth.

Removing the coating

The first technological operation during galvanizing welding work is the removal of the zinc coating.

The fastest way to clean metal is to heat the part with a gas torch. However, this method is not safe, since zinc is released in the form of toxic fumes.

For small volumes of welding in a workshop, the zinc coating is removed mechanically - with sandpaper, a file, or a grinding wheel on an angle grinder. Heat or acid cleaning can be used, but these methods lead to the formation of harmful fumes.

For large volumes of welding work, galvanizing can be etched using acid. But working with acid requires increased fire safety measures.

When welding galvanized pipes, the zinc coating is removed from both the external and internal sides of the joint, and then the surface is degreased using an acid or alkaline solution.

Inverter Application

It is advisable to use a manual electric arc welding machine to weld steel with a thickness of at least 1.5 mm. Thinner metal is easily burned through and requires some skill during operation and sensitive adjustment of the device. Welding is carried out with reverse polarity of the current, in which a “minus” terminal is attached to the part, and a “plus” terminal is attached to the holder.

The weld welding speed should be less than when welding steel of the same thickness. This reduction must be no less than 10% and no more than 20%. The current strength differs:

- If welding is performed with conventional electrodes OZS-4, UONI-13/45 and 13/55, MP-3, then the current strength should be 5-10A less than for non-galvanized steel.

- If welding is performed with galvanizing electrodes TsU-5, TsL-20, TsL-39 and others, then the current strength is set to 10-50A more, and the gap between the elements being welded should be larger than when connecting non-galvanized steel of the same thickness.

The electrode is tilted to the workpiece no more than 45°, otherwise burning of the metal may occur.

The inverter requires careful adjustment of the current and stable voltage, since at low current the seam will not be welded, and too high a current will also lead to through burning of the joint and evaporation of zinc over a large surface area. When there are power fluctuations, the electrode may stick to the metal and damage the integrity of the seam.

The choice of electrode brand should be made taking into account the requirements for the seam joint:

- Rutile-coated electrodes provide a stronger connection, but the seam will require additional anti-corrosion treatment.

- Electrodes containing strong basic fluxes effectively seal the seam, providing it with reliable protection against corrosion, but the strength of the seam will be reduced by 15-25%.

An approximate mode of application of electrodes is presented in the table.

The greatest difficulty in manual welding is the correct regulation of the current and the time of contact of the electrode with the surface.

Using a semi-automatic machine

On many semi-automatic machines there is a “Synergic” welding mode, in which in the settings you can select a specific type of work (preset), most optimally suited for the desired type of metal. If such a mode is not available, additional time will be required to set up the device and, possibly, experiment with welding some trim.

Welding on semi-automatic machines can be carried out either using additives supplied along the hose, or argon can be used as a protective medium.

The wire is selected depending on the thickness of the parts.

If the network voltage is less than 220V, the wire diameter is reduced by 0.2 mm from the recommended one.

The burner is tilted at an angle of 70-75º to the joint surface when making a remelting seam and 20-30º when making a filling seam. In this case, the solder (additive) must be placed in front of the flame so that it does not burn the metal coating.

The use of copper-based filler materials allows you to create a shielding gas environment in the welding area. This technology has a number of advantages:

- the welding seam and the metal surface around it are protected from corrosion;

- minimal melt spattering;

- flux consumes a significant amount of heat generated, thus preventing heating of a large area of metal;

- subsequently the seam can be easily processed.

The melting point of copper additives is lower than that of steel, so this type of welding is more like soldering metal, but ensuring a strong connection. Note that this method avoids damage to the zinc layer.

Depending on the content of these additives, the additives set the desired qualities of the weld:

- The silicon additive CuSi3 makes it easy to process the weld, but reduces its strength properties, since silicon has high fluidity.

- The aluminum additive CuAl8 is used for galvanized steels with a high content of this alloying element.

- Silicon-manganese additive CuSi2Mn is intended for creating joints with increased strength.

When welding pipelines with drinking water, fluxes of the HLS-B brand are used, which are safe for health and quickly dissolve in water. When heated, the flux first turns white and then transparent, indicating that it is ready to begin the soldering process.

Metals up to 4mm thick can be soldered in one pass, but larger thicknesses require multiple passes. After welding, solder residues are removed using a brush and water. The inside of the pipe is filled with water for a day, after which it is washed.

contact welding

Spot welding can be done on metal of any thickness, but it is best done on sheet metal, since very thin galvanized sheets are difficult to join using other methods. For welding galvanized steels using resistance welding machines, electrodes of the BrKh and BrKhTsr brands, made on a bronze basis, are used.

Spot welding machines can operate on direct or alternating current, and specialized equipment for welding sheet metal and galvanizing, in addition, has three additional pulse supply modes:

- preheating of the connection area;

- welding process;

- final heat treatment.

The strength of the weld with this method of connection is higher than that of the elements being connected themselves, therefore this type of welding is common when connecting elements of automobile bodies.

It should also be noted that resistance welding ensures uniform welding of the seam along its entire length, which is difficult to achieve with manual welding. Therefore, it is advisable to install a contact apparatus in workshops that regularly weld galvanized products in large volumes.

When spot welding sheets with a thickness of over 1.5 mm, forging is recommended. Forging is an impact on the seam during the cooling process, which is performed with a hammer or sledgehammer.

A significant disadvantage of spot welding is the high energy consumption of welding machines.

Shutdown

After welding work, it is necessary to ventilate the room and remove zinc shavings.

It should be borne in mind that the cleaned areas will be subject to corrosion and cause a decrease in the quality of the entire structure. Therefore, after completing work, it is necessary to remove scale from them, sand the seam and apply a protective coating.

The surface in the area of the weld must be coated with paint or an anti-corrosion coating. A good option would be paint containing 94% zinc dust. It is possible to fuse zinc wire or rods made of zinc-cadmium alloy.

Method for removing zinc from galvanized steel

Owners of patent RU 2599061:

The invention relates to the field of non-ferrous metallurgy and can be used for processing galvanized steel waste. The method involves treating galvanized steel waste with an aqueous solution containing 250 g/l hydrochloric acid and 2.5 g/l hexamethylenetetramine, in which the galvanized steel waste is kept at a temperature of 10-40°C for 20-30 minutes, after which the aqueous solution saturated with zinc the solution is drained and the steel waste is removed. The method ensures the removal of zinc from galvanized steel to a content of no more than 5% of the original in the conditions of foundries of engineering production, taking into account the protection of the metal base of the waste from dissolution in acid during the reaction.