Marking the cutting line

Side cutters are also used to apply notches to thin metal parts, marking cutting lines with a hacksaw or jigsaw.

This function of this tool significantly makes the work of a mechanic easier if he needs to make a precise cut, but simple construction scissors do not bite a sheet of metal, but only slide off it.

Pliers

This instrument comes from our childhood. A large encyclopedic dictionary of technical terms defines pliers as a hand-held metalworking and assembly tool equipped with pyramidal jaws of rectangular cross-section, used for gripping and bending small metal parts . From the definition it is clear that with pliers you can:

- hold an object (metal strip, washer, nail, electrical wire);

- bend a metal strip or wire.

That is, their main purpose is capture and manipulation. The tool can only hold and bend. It is not for nothing that among its many relatives - pliers - the tool is now extremely rare in store windows. Domestic pliers must comply with GOST 7336-93, according to which they are:

- With short (25–55 mm) or long (50–63 mm) jaws. By the way, the criterion for belonging to one type or another is not the length of the jaws, but the ratio of their linear dimensions to the dimensions of the clamping handles.

- With plain or insulated handles. The latter are manufactured in accordance with GOST 11563-94, which regulates the requirements for hand tools for performing work under high voltage.

Dimensions of manufactured instruments: 125–220 mm (total length).

Domestic tools are made from tool carbon steel U7A with volumetric hardening up to 45 HRC units. Decorative coating for protection against corrosion is applied in one of 3 ways:

- Chemical oxidation. The color of the coating is dark gray with a black tint.

- Chemical phosphating. The surface of the instrument is matte gray, in various tones (from light to dark gray).

- Chrome plating. This coating is the most durable and corrosion-resistant.

Simple operating principle

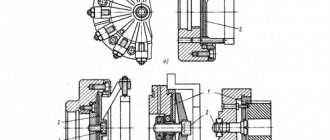

The design of side cutters is not much different from the design of pliers and wire cutters. The working components of this tool are connected by a special hinge.

A spring is placed between the handles. After the end of the compression period, it returns the handles to their original position. This happens immediately after biting an iron thread or cutting off a plastic edge.

Tips for quality sharpening

With constant use, the tool may become dull. You can take it to a workshop, or you can try to sharpen it yourself.

Before starting sharpening work, you should make sure that the cutting edges occupy the same position under any load. In other words, so that there is no gap between the hinge hole and the axle (or backlash, as it is also called). If such a problem exists, then it needs to be corrected. In the middle of the end it is necessary to make a hole with a drill measuring two times smaller than the diameter of the axis. Using gentle blows of a hammer, you need to push the metal apart.

If the metal in the axle is strong and the previous method does not bring success, you need to use a sharp center punch to make several shallow depressions at the end of the pliers with a gap of two millimeters and a millimeter of indentation from the edges. A hammer is also used here. You should hit carefully so as not to disrupt the ease of movement of the tool.

A file is used to grind off excess metal from the blades. Sharpening is best done using an abrasive rotating wheel. For a good result, you need to use only a smooth circle of the correct shape, otherwise you won’t be able to do the job well. If the circle is uneven, then you should either grind the existing one or use another one. You need to use both the end of the circle and its cylindrical surface. Then the sharpening will be of high quality. The metal must be removed carefully to ensure precise alignment of the cutting edges.

To increase the service life of the tool, proper operation is necessary. It is not recommended to cut thick wire or other solid iron materials with a tool that is not designed for such loads. Wire cutters are commonly used for cutting aluminum and copper wires. Other metals need to be cut with special reinforced nippers. Conventional ones can quickly fail when cutting steel or other metals.

Durability and comfort

Thanks to the indestructibility of the hinge joint, the master can press the handles of the side cutters as hard as he likes when processing metal workpieces. The strength of the cutting edges of the tool is ensured by the use of metals of increased hardness for their manufacture.

However, even the most durable side cutters must be very easy to use, which is necessarily taken into account during their manufacture.

What is the difference between side cutters and wire cutters?

Needle-nosed pliers are a metalworking pliers tool with pointed jaws. Needle-nosed pliers are designed for biting off wires, nails and wires of various diameters, as well as other materials. Let's look at the main types of needle nose pliers .

Types of needle nose pliers:

- Side cutters (side cutters) are a tool that has a sharpened inner side surface of the jaws.

- End cutters (straight side cutters) – the cutting edges are located perpendicular to the handles.

- Bolt cutters (rebar cutters) are a tool with a double lever system, elongated handles and replaceable cutting elements. Designed for cutting cables, hard wire and steel rods.

Side cutters

is a cutting tool that is used in electrical installation work and other fields of activity. Their main purpose is to cut cables and wires, small metal elements, parts, and wires. Another name for side cutters is “side cutters.”

Side cutters: features and the right choice

Side cutters have such a feature as the location of the cutting edges (jaws) in the same plane as the handles. There are models of side cutters, where the jaws are located at a certain angle.

The area of application of side cutters is industry, construction and installation work. Most often they are used in cutting cables, wires and wires (small diameter), somewhat less often in cutting metal and plastic (small elements).

Side cutter design:

- serrated tips for pulling out TPG from cable and wire products;

- hardened sharp blades;

- handle locking element and their return spring;

- handles.

All working parts of the side cutter are connected to each other by a special lock with reinforced construction. The spring between the handles is characterized by plasticity and is designed to instantly return the jaws to their original position. It is important to pay attention to the fact that the closure of the edges of the side cutters must be very tight. The movement of the blades is light and smooth, which is ensured by a hinged joint. Moreover, this feature reduces the effort required to operate the side cutter.

Read also: How much gold is in microcircuits

The quality of side cutters and their reliability have a direct impact on the result of the work. Therefore, you need to be extremely careful when choosing and purchasing side cutters.

The first thing you need to know is that wire cutters can be either single-jointed or double-jointed (double gear lock). Double-hinged models provide more convenient work with minimal effort and labor costs. Side cutters with a leaf return spring automatically return the edges to their original position. If the proposed work involves electricity, it is important to pay attention to the dielectric properties of the tool.

The material used for the production of side cutters is high-strength metal. During the development of the tool and its manufacture, the safety of further operation and ease of use are carefully monitored. The handles of all models of side cutters have an ergonomic shape and an insulating winding that provides protection against electric shock.

Nippers are either insulated or insulating, which depends on the materials used in production. For example, insulating side cutters are those that are made entirely of insulating material and have metal cutting inserts. Insulated side cutters are tools with a special coating.

Side cutters must have high characteristics in terms of moisture resistance, oil resistance, and gasoline resistance. For this purpose, the design of the tool includes pobedit and carbide brazing, which slightly increases the cost of side cutters.

Before side cutters are released onto the market, the tools must pass all quality testing checks.

It would seem that what could be difficult about using wire cutters? In fact, work using side cutters is characterized by certain requirements. For example, side cut pliers should be positioned over the work piece at a 90 degree angle. The tool should fit comfortably in the hand and be securely fixed in the hand. At the same time, you should not put excessive loads on the nippers.

Read also: What is connector pinout

The Planet Electric retail chain has a huge selection of different tools, which includes side cutters from leading manufacturers (HAUPA, Schneider Electric, DKC, KVT, etc.).

Ticks

Railroad workers have pliers for carrying railroad ties and also for carrying rails.

Use carpenter's pliers to pull out nails.

Plumbing pliers (pipe pliers) usually have a serrated groove for gripping pipes, angled jaws and an adjustable hinge mechanism for clamping pipes of different diameters.

Pliers also include a whole range of electrical installation tools: these are crimping pliers for terminals, pliers for stripping wires, pliers for connectors, pliers for cable entries, current clamps, insulating pliers for replacing fuses, etc.

In general, almost any pliers-joint tool can be called pliers, for example, pliers; in simplified terms, these are pliers with flat jaws.

Pliers

Combination pliers, sometimes called pliers, are a tool that includes pliers that have cutting edges for cutting wire and nails, and a notch with teeth for gripping tubes, nuts and various cylindrical parts. This is a multifunctional tool, on the one hand, capable of helping in various situations, on the other hand, special tools cope with specific tasks better. Therefore, combination pliers are a tool for a household tool set, and not for a professional one.

Round nose pliers

Pliers

Modern pliers, instead of several notches, have an adjustable hinge for pipes of different sizes.

Apparently, pliers differ from plumbing pliers in that they are smaller in size, or you can safely put an equal sign between them.

What many are accustomed to calling pliers, according to GOST 5547-93, are combination pliers. And it turns out that, on the one hand, this tool can be defined as pliers with pliers, and on the other hand, pliers with pliers.

Read also: How to dilute gasoline for a Husqvarna chainsaw

Wire cutters

When buying nippers, pay attention to what kind of material they are intended for cutting, since copper wire nippers may not be able to cope with nails, and the cutting edges will be damaged.

Nippers for cutting cables, ropes, fittings, and bolts have a particularly durable design, increased hardness of the cutting edges, and often several hinge units to provide increased compressive force.

Modern dielectric cases

For this reason, the handles of side cutters are given ergonomic shapes. At the same time, they are covered with polymer attachments that prevent the hand from fogging in case of prolonged use of the tool. If it is used by the same master for a long time, then the soft handles gradually take on the shape of the owner’s palm.

Modern comfortable polymer materials used for the manufacture of dielectric handle covers do not leave bruises, dents and abrasions on the hands, which can appear with strong compression of old-style hard plastic insulating attachments.

Tips for choosing a hair dryer

When choosing a specific model of a technical hair dryer, you should start from possible use scenarios. The most powerful option is not always optimal.

If a hair dryer at home will rarely turn on, there is no point in buying an expensive high-power model. In addition, when turned on, a high-power tool sharply increases the load on the electrical network. And for some jobs you will definitely need a hairdryer with a rotary handle to heat hard-to-reach areas of structures. It is important to have those elements that affect safety and ease of use:

- protective casing, closed handle and automatic overheating protection;

- smooth temperature control;

- the current temperature indicator is very convenient, like the Metabo HE 23-650 Control; Makita HG651C; Elitech TV 2000LCD

- the presence of a heel on the back of the hair dryer so that it can be placed vertically and give the hand a rest;

- as long as possible the power cord;

- variety of attachments included in the kit;

- Convenience of the handle and location of the power button.

But the main criteria remain power, temperature control and reliability of the tool. And the functionality of an industrial hair dryer can always be expanded by purchasing additional attachments.

Source: smelostroy.ru

Nippers and side cutters difference

Lever operating principle

Thick nozzles on the handles guarantee one hundred percent protection against electric shock. Thanks to the application of lever force to the jaws, this tool allows you to cut fairly thick wires and insulated cables.

Usually, to perform a working stroke, the force of one hand is sufficient, but if necessary, the side cutters can be squeezed with both hands, which allows you to cut a wide-section energy line.

What it is?

The main difference between side cutters and end cutters is that the jaws of the cutters are perpendicular to the handle, while the jaws of the side cutters are parallel or at a slight angle.

The main characteristic of the tool is the length of its jaws. As a rule, mini side cutters have blades that are 10-15 mm, which is quite enough for stripping wires and similar products. But the best side cutters, which are intended for processing large objects, can have a jaw length of 25-30 mm.

If you need high-quality side cutters, the price of which provides the opportunity to save money, you should use the catalog of the Anchor24 online store to purchase them.

What kind of lighting do you prefer?

Built-in Chandelier

Main Applications

Side cutters are most often used

- Electricians;

- Assemblers of exhibition pavilions, street kiosks, country and park small architectural forms;

- Representatives of housing maintenance organizations, theater decorators, adjusters of communication systems, ventilation, and air conditioning.

Conventional and electrical side cutters

The set of functions for which a particular type of tool is intended is determined by its design features. Standard side cutters are used primarily for cutting plastic, iron, and wires.

Analogues equipped with thick dielectrics are most often used for laying cables in apartments and offices.

How is a miter saw used?

Basically, the end plate is used for cutting wooden parts: moldings, boards, baseboards, platbands, decorative strips. But when replacing the saw blade, you can cut plastic pipes or profiles, as well as thin metal parts.

The process of cutting parts with a miter saw is as follows:

- The workpiece is fixed on the bed at the desired angle to the cutting plane;

- The operator turns on the saw;

- Using the handle, the rotating disk is lowered onto the workpiece and makes a cut;

- The machine is turned off and the trimmed element is removed.

The scope of application of such an installation is very wide: from laying floors or covering walls with clapboards, to making doors, windows or other wooden structures, for which parts often have to be cut.

Cutting thin and thick wires

The speed and quality of cutting largely depends on the correct use of side cutters. To cut through thin wire or nylon thread, it is enough to place them at the very tips of the blades.

If there is a need to cut through a wide-section wire, then it is placed at the very base of the blades.

Assessing the condition of cutting edges

Any home craftsman or professional installer who is puzzled by how to choose side cutters must first evaluate the quality of the metal from which they are made.

- You should also examine the condition of the blades, especially for nicks, dents, and chips.

- Used tools may well end up in the retail chain, and this fact will be determined by examining the condition of the cutting edges.

Types of wire cutters

Based on the type of design of the working parts of the tool, there are 3 types of cutters: end cutters, side cutters and bolt cutters. All types of presented wire cutters can be purchased in the GSM kit online store. You can choose the kuachki yourself on the page https://gsm-komplekt.com/category/kusachki-bokorezy-/.

End

End cutters

They are used during installation work, in construction, and when laying electrical networks. For the manufacture of the working element, reinforced steel with a chrome-plated surface is used. The cutting edges of this type of nippers are highly durable and are sharpened in a special way, which ensures high-quality performance of the work for which they are intended. The tool handles, made of dielectric, are resistant to high operating voltages.

Side cutters

The working element is at an angle relative to the tool head. The operating efficiency of the most powerful cutters of this type is ensured by additional reinforcement and hardening with high-frequency currents. Various models of products are available that can cut wires made of different metals and having different thicknesses, from aluminum to steel.

For diagonal wire cutters designed for cutting steel wires with a thickness of 1.2 mm, those made of mild steel - no more than 2.0 mm, and copper wires whose diameter does not exceed 2.6 mm, the heads are located at an angle to the surface of the handle. The hinge on the axis, which ensures the mobility of the working parts of the tool, is highly resistant to the constant impact of monotonous loads.

For the manufacture of professional side cutters, tool steel is used that undergoes heat treatment and multi-stage hardening. The handles of this type of nippers are comfortable to grip and can withstand impact forces of up to 75 kg.

Special nippers

One of the varieties of this type of cutting tool is bolt cutters. They are designed for cutting rods whose thickness does not exceed 12 mm. Representing a double lever in design and equipped with long handles, they first apply the applied force to an intermediate link that increases its value, and then to the cutting surface.

Another type of special cutters are products used for cutting small electronic parts. They have a mirror surface, open evenly, and are equipped with a device that removes static electricity. After watching the video presented to your attention, you can get acquainted with information about power cutters used for working with reinforcement.

Checking the tightness of the blades

It is also important to check if there is a gap between the edges. The more tightly the blades fit together, the higher the effectiveness of the tool when cutting thin threads and wires. In some cases, professionals use a microscope to assess the tightness of the edges.

It allows you to see not only the gap between the blades, but also the smallest defects on the cutting edges, as well as defects in the protective coating that will become sources of corrosion.

Rating of professional tools and price

Let's figure out which nail clippers are best to choose. Let's consider the most popular brands that represent this essential manicure tool on the market. Also read how to remove cuticles without cutting.

Zinger tongs

- The brand presents a huge range of wire cutters for household and professional use.

- You can purchase pliers with manually sharpened blades, which, unlike factory ones, are of higher quality.

- There are several design options, including silver or gold plating.

- Quite a high-quality tool, characterized by a long service life from sharpening to sharpening.

- Good compression/release mechanism.

- Several blade length options.

The average price of a tool of this brand is 300-800 rubles.

YOKO cutters

The cost of good wire cutters starts from 1000 rubles.

- The tool of this brand is made from cobalt steel, which is distinguished by its special quality.

- The blades do not have serrations, since the steel has increased hardness and practically does not become dull.

- There are several options for compression mechanisms. You can choose either a double spring or a single spring.

- Several blade length options - from 4 mm to 15 mm. This gives you room to choose a tool according to your skills and qualifications.

- Manual sharpening of blades.

The cost of a Yoko brand tool starts from 800 rubles, the average price is 1200 rubles. If you still prefer the European method, then pay attention to the Sally Hansen instant cuticle removal gel.

Brand Stalex

- The company offers a huge selection of professional manicure tools. Has an excellent reputation and the trust of most manicurists around the world.

- A variety of handle widths, blade lengths, and sizes of the nippers themselves allow you to choose a tool for any manicurist and for personal use.

- The nippers are made of surgical steel, so they do not rust and are very durable.

- Manual sharpening.

- The combination of high-quality sharpening and especially durable steel guarantees that the first sharpening will be required only after 5 years of active use. All this time, the blades will have excellent cutting properties - of course, subject to proper care.

- The blades have double-sided sharpening, which ensures their special sharpness. You will trim the cuticle gently with one light press. The main thing is to correctly calculate the distance of skin that needs to be removed.

- For all their positive qualities, the nippers have a reasonable price, which allows them to be used not only in beauty salons, but also purchased for home use.

Expert opinion

It-Technology, Electrical power and electronics specialist

Ask questions to the “Specialist for modernization of energy generation systems”

Wire cutters: a tool needed in every home They are designed to grab and manipulate objects, primarily wires, over a greater distance than conventional models. Ask, I'm in touch!

Main types of side cutters

There are currently two types of this tool on the market:

- Single-hinged;

- Double-hinged.

Selection of the required modification

When purchasing installation tools, the types and sizes of side cutters suitable for a particular craftsman are determined by the frequency and intensity of their future use. To work with a large number of workpieces, it would be better to purchase double-jointed side cutters.

Thanks to the presence of a leaf spring, they instantly return to their original state. At the same time, a double-jointed tool will allow you to spend much less effort on doing useful work.

How to choose a miter saw

Depending on the scope of application and load, it is necessary to take into account those parameters that may limit the master in his work. For example, more powerful miter saws will allow you to work longer without interruption and process larger workpieces.

We also recommend paying attention to elements that increase operator comfort. They provide not just comfort, but also greater precision and freedom in processing parts.

It will be easier for you to perform cross-cutting using a model with additional functions:

The cutting depth limiter simplifies the selection of grooves;

- Illumination of the cutting area and laser pointer allows you to accurately guide the saw blade even in poor lighting conditions in the workshop or on the street;

- The protective casing eliminates the possibility of injury to the operator. Models with automatically retractable casing are very convenient. For example, in Makita LH1201FL miter saws; BISON MASTER ZPT-210-1400 L

- The presence of additional clamps for fixing the workpiece on the table, clamps or expanding supports;

- The soft start mode extends the life of the engine and disk. This function is especially important when processing plastic profiles or pipes.

Also, when choosing a saw, you should make sure of the quality of the connection of all elements, the reliability of fixing the workpieces and the stable installation of the machine itself.

How to choose a hair dryer?

Professional options with dielectrics

While inexpensive standard models are quite suitable for a home craftsman, an electrician will need special dielectric side cutters that can easily withstand electric shocks of up to a thousand volts.

When choosing quality side cutters, the manufacturing company also plays a significant role. A long-known brand that has earned a good reputation among installers is a guarantee of reliability and durability.

If the brand turns out to be little-known or absent altogether, then this fact will give reason to doubt the high quality of the instrument.

Pliers. Everything is captured

If you put pliers and pliers side by side, the difference will become noticeable. Next to its humble relative, the pliers look more solid and are capable of more in their work. If you can only lightly grab the object being held with pliers, then pliers will clamp it much more securely. This works especially well when gripping cylindrical parts (rods, studs, bolts), thanks to the jaws, which are equipped with special recesses with a large notch . Some models have two pairs of grooved grooves of different depths, and sometimes they make an additional semicircular groove located on the side of the handles (can serve as a crimp). The ends of the jaws are flat and equipped with the same notches as those of pliers. Sometimes pliers are equipped with additional corrugated elements made on the inside of the handles, next to the hinge, resulting in a second-class lever.

In the standard version, all pliers have cutting blades (side cutters) located next to the hinge, which can be used to cut thin metal strips and electrical wires. Wire and thin nails can be cut through two cutouts on one side of the tool, which work on the principle of a guillotine. In this case, the cutting force pinches the part in the grooves, making it possible to squeeze the handles with both hands. The force increases even more due to the increased ratio of the lever arms - the cutting grooves are located close to the axis of rotation. Due to their additional working functions, pliers are often called combination pliers. They usually have one (fixed) axis of rotation of the handles. There are designs with an adjustable hinge - two- or multi-position, which expands the clamping range of the tool.

Pliers are made from stronger steel than pliers. Typically chrome-molybdenum or chrome-vanadium steel is used. The gripping jaws are hardened to 53 HRC, and the edges of side cutters are hardened to 60 units. A little about the handles. The amount of force applied depends on their shape and material. For this purpose, ergonomic pads are used to improve grip comfort. The material is rubber or a two-component coating (for example, thermoplastic rubber with santoprene linings). Dielectric handles (made of plastic) must have a confirmation inscription: work under voltage up to 1000 V.

Source: proinstrumentinfo.ru

Famous brands and fly-by-night companies

Naturally, tools of dubious quality will be offered at a much lower cost than side cutters from proven brands

- N.W.S.;

- Knipex;

- Bahco;

- Wiha;

- Kraftool;

- KBT.

However, this does not mean at all that cheap analogues will not break a week or two after purchase. With a high probability, their cutting edges will quickly become covered with deep dents, after which such a tool will be suitable only for chopping nuts.

How to find good metal cutters?

Selecting a quality tool means being able to effectively and easily complete the task of cutting cables and other elements. You can determine that the tool you decide to purchase is of high quality based on several criteria .

Signs of quality wire cutters

The cutting edges of these pliers should touch tightly in the middle.

Another important point is that the cutting edges should not overlap each other. The cutters may have a detachable type screw lock. However, instruments with such locks are very rare. Most often, wire cutters are offered with permanent locks.

According to such criteria as the presence of insulating materials, wire cutters are divided into:

A characteristic feature of insulated handles is their coating, which ensures safety when performing electrical installation work. The handles of insulating tools are made entirely of insulating materials. Only the cutting edge inserts in this tool are made of metal.

Requirements for materials for making tools

Manufacturers of these hand tools also ensure that wire cutters designed for electrical work have a good degree of electrical insulation and provide reliable protection against electric shock within the limits corresponding to the insulating materials used in the manufacture of the tool.

Expert opinion

It-Technology, Electrical power and electronics specialist

Ask questions to the “Specialist for modernization of energy generation systems”

8 Best Side Cutters – Rating 2022 To easily cope with this task, it is necessary to keep the wire very close to the hinges of the cutters when cutting cables. Ask, I'm in touch!