Characteristics

| Standard | EN 10253-4 - Butt welded pipe fittings. Part 4: Forged austenitic and austenitic-ferritic (duplex) stainless steels requiring special inspection EN 10222-5 - Steel forgings for pressure vessels. Part 5: Martensitic, austenitic and austenitic-ferritic stainless steels EN 10253-3 - Pipe fittings for butt welding. Part 3: Forged austenitic and austenitic-ferritic (double) stainless steels without special testing requirements EN 10216-5 - Seamless steel tubes for pressure service. Technical delivery conditions. Part 5. Stainless steel pipes EN 10217-7 - Welded steel pipes for pressure applications. Technical delivery conditions. Part 7. Stainless steel pipes | |

| Other names | European | X5CrNi18-10, 1.4301 |

| Classification | Elements for pipelines, welded pipes, seamless pipes, steel forgings | |

Stainless steel 1810 what is it - Metalworker's Guide

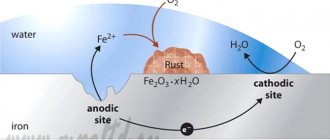

Corrosion-resistant (stainless) steels are steels that, in addition to iron, carbon and standard impurities, contain alloying elements.

These additives provide resistance to corrosion - the destruction of metal under the influence of negative factors (air, water, acidic and alkaline environments).

One of the dangers of corrosion is the likelihood of a sharp deterioration in the technical characteristics of the metal without external changes. The main component in the corrosion-resistant alloy is chromium (content not less than 12%).

Decoding stamps

The marking of alloy steels consists of letters and numbers. At the beginning there is a two-digit number that characterizes the amount of carbon in hundredths of a percent. The following are letters of the Russian alphabet, denoting a specific element:

- X – chromium;

- N – nickel,

- T – titanium;

- B – tungsten;

- G – manganese;

- M – molybdenum;

- D – copper.

After the letter designation of the alloying element in the decoding there is a number indicating its content in stainless steel, rounded to the nearest whole percent. If there is no such figure, then the additive in the alloy is in the range of 1-1.5%.

Grades of heat-resistant and heat-resistant stainless steels

Heat resistance, otherwise called “scale resistance,” is the property of a metal to resist gas corrosion at high temperatures in an unloaded or lightly loaded state.

Definition! To improve this characteristic, chromium, silicon and aluminum are introduced into the composition of stainless steels. These elements, combining with oxygen, form dense structures that increase the resistance of steel to temperatures above +550°C. Nickel by itself does not affect heat resistance, but in combination with Cr, Al and Si it increases their efficiency.

Heat-resistant steels are steels that function at high temperatures and loads without a tendency to short-term and long-term creep.

Table of areas of application of scale-resistant and heat-resistant steels

| Type | Brand | Temperature at which active reaction with air begins, °C | Areas of use |

| Chromium, scale resistant | X18 | +850…+900 | Equipment, products and structures operated at T up to +900°C without load |

| High chromium, scale resistant | Х25 Х25ТХ28 | +1100…+1150 | Metal products intended for operation without load up to T +1150°C, Х25Т – for the production of thermocouples |

| Silchrome, scale-resistant | Х25С3Н | +1100 | For heating units and heaters operating at temperatures up to +1100°C |

| Highly alloyed, scale resistant and heat resistant | Х23Н18 | Loaded products and structures intended for operation at T up to +1000°C | |

| Х20Н35 | Metal products operated at T +1000°C |

Stainless steel grades for the manufacture of chimneys

When purchasing modular chimney systems, you need to find out what kind of steel they are made of. On sale you can find chimneys that are about one and a half times cheaper than other products in this category. In their production, AISI 201 steel (12X15G9ND) is used.

According to international standards, it is necessary to use steel grade AISI 321 (08Х18Н12Т), the cost of which is approximately 2 times higher than the cost of AISI 201. It is impossible to visually distinguish AISI 201 from AISI 321, moreover, both alloys are non-magnetic.

They can only be distinguished by chemical analysis.

Differences in chemical composition

| Brand | WITH | Mn | P | S | Si | Cr | Ni | Cu | Ti |

| AISI 201 | Up to 0.15% | 7-9,5 | Up to 0.1% | Up to 0.03% | Up to 1.0% | 13-18 | 0,3-3,0 | 0,5-2,5 | — |

| AISI 321 | Up to 0.08% | Up to 2.0 | Up to 0.05% | Up to 0.03% | Up to 1.0% | 17-19 | 9,0-12,0 | — | Min 0.5% |

AISI 201 steel has low anti-corrosion characteristics, instability of the structure, and the risk of cracks during drawing. Its use will lead to rapid failure of the chimney due to rapidly developing corrosion. This steel is mainly distributed in China and India.

Well-known foreign and conscientious Russian manufacturers, in addition to AISI 321 steel, use high-alloy alloys stabilized by Ti. They are acid and heat resistant. The use of cheaper steels (AISI 409, AISI 430) for gas exhaust pipes that do not meet acid resistance requirements leads to their failure soon after the start of the heating season.

Stainless steels for the food industry

Corrosion-resistant steels are indispensable for industries producing equipment, tools and utensils intended for contact with food products. Their advantages:

- Resistance to various types of corrosion - chemical and electrochemical. In each specific case, it is necessary to select brands that are resistant to the environments with which they will come into contact during operation. These are normal atmospheric conditions, water, salt water, acidic, alkaline, chloride solutions.

- Good machinability. Modern tools make it possible to weld, cut, form and process corrosion-resistant alloys on lathes, milling and drilling machines in the same way as “ferrous” steels.

- Compliance with sanitary and hygienic standards. Thanks to various processing methods - grinding, polishing to a mirror finish - a surface is obtained that is practically free of pores and cracks into which dirt and pathogenic microorganisms can penetrate.

- Good mechanical characteristics. Thanks to them, it is possible to produce products and structures of smaller thickness and weight without compromising technical properties. Austenitic steels are more resistant to low temperatures compared to general purpose metals.

- Aesthetics. Electropolishing, satin finishing and other surface treatment methods provide a stylish look to stainless steel products.

Table of properties and areas of application of food grade stainless steels

| Steel grade according to GOST | AISI | Characteristics | Areas of use |

| 304 | 08Х18Н10 | It welds well, can be electropolished, retains high strength at normal and low temperatures, and is resistant to intercrystalline corrosion. | Equipment, tools, technological pipelines of food, petrochemical, pharmaceutical and medical industries, for utensils intended for high-temperature processing of products are not used |

| 316 | 03Х17Н14М2 | The presence of molybdenum increases the technical characteristics of the alloy at high temperatures | Installations, technological equipment, containers for the food and chemical industries |

| 321 | 12Х18Н10Т | Good weldability, maintaining performance characteristics at temperatures up to +800°C | Equipment for the chemical and oil refining industry |

| 409 | 08Х13 | Characteristics are satisfactory | Crockery and cutlery |

| 410 | 12Х13 | Heat resistance, resistance only to mildly aggressive environments | Winemaking equipment, alcohol containers |

| 420 | 20Х13-40Х13 | Versatility, ductility, wear resistance, increased corrosion resistance | Dishes, kitchen sinks |

| 430 | 08Х17 | Strength, thermal conductivity, good machinability, corrosion resistance | Utensils for heat treatment of products, including steam |

| 439 | 08Х13 | Possibility of use in various operating conditions | Alloy for mass use - production of refrigerators, sinks, washing machines |

Table of stainless steel grades used in the food industry

| Industry | Stamps |

| Dairy products – product sterilization and storage, cheese making, transportation tanks, ice cream and milk powder production | Austenitic steels – 304, 316, 321 |

| Fruit canning, juice production. In such industries, steel comes into contact with an environment containing sulfur dioxide | Grades containing molybdenum |

| Preparation of soups and sauces (these are aggressive mixtures with high acidity, containing chlorides) | Molybdenum-containing grades |

| Bakery, requirements - hygienic, smooth surfaces of tables and mixing equipment | Austenitic steels – 304, 316, 321 |

Stainless steel grades and their characteristics, 5.0 out of 5 - total: 3

Included area

Chrome-nickel steel 18/10, what is it?

Many housewives have stainless cookware in their kitchen, but most of them do not even know what it is made of, and are also unaware of the benefits it provides. All kinds of pots, stewpans and other attributes come into use for one simple reason - they are durable. But no one thinks that this is just one of the many advantages of such dishes.

Interesting facts about stainless cookware

Already in 1913, the world learned about the unique properties of steel and its resistance to corrosion.

Harry Brearley, having added 10% chromium to steel, realized that the alloy was now resistant to elevated temperatures, but society did not accept the new material, since it considered all these properties to be completely unfavorable.

Brearley tried his best to convince him otherwise and released the first ever batch of chrome steel knives.

The knives quickly became dull and this significantly affected the popularity of the products. Only ten years later, Brearley's successor, Hartfield, managed to correct this flaw. He discovered that by adding nickel, any mechanical stress on the material does not affect the material and thereby ensures long service life of kitchen appliances.

Mechanical properties

According to EN 10216-5, EN 10217-7, EN 10253-4 +AT

| Elongation, min., % | Transverse samples | 35 | |

| Longitudinal samples | 40 | ||

| Impact work KV at 20°C, min., J | Transverse samples | 60 | |

| Longitudinal samples | 100 | ||

| Minimum absorbed energy at 0°C [32°F], J (J) | Transverse samples | 35 | |

| Longitudinal samples | 47 | ||

| Impact work KV at -196°C [-320°F ], min., J | Transverse samples | 60 | |

| Brinell hardness, HB max. | 200 | ||

| Ultimate strength (temporary tensile strength), min., Rm, MPa | 500-700 | ||

| Yield strength, min., ReH, MPa | 195 | ||

| Nominal thickness, (mm) | < 60 | ||

According to EN 10222-5 +AT

| Elongation, min., % | Transverse samples | 35 | |

| Longitudinal samples | 45 | ||

| Impact work KV at 20°C, min., J | Transverse samples | 60 | |

| Longitudinal samples | 100 | ||

| Impact work KV at -196°C [-320°F ], min., J | Transverse samples | 60 | |

| Yield strength, min., ReH, MPa | 200 | ||

| Ultimate strength (temporary tensile strength), min., Rm, MPa | 500-700 | ||

All about stainless cookware: steel grades, care features and manufacturer tricks

Stainless steel cookware is certainly present in every kitchen - the housewife will have at least one saucepan.

And there’s nothing to say about ladle spoons - good kitchen utensils are made only from anti-corrosion alloys.

Well, let’s take a closer look at it: is it really that good in everyday life, what metals is it made from, and is it worth believing everything that the manufacturers themselves write on the packaging.

Peculiarities

Stainless steel cookware not only looks beautiful in the kitchen, it also has a number of undeniable advantages:

- Durability – and the count here goes on for decades. This is due not only to corrosion resistance, but also to the strength of the walls of the cookware. It will never crack from a strong blow, like cast iron, and it is very difficult to dent it, unlike copper or more affordable aluminum.

- Hygiene - the smooth surface of the steel and the absence of any pores allows you to ideally wash stainless steel pots and pans. Although this does not mean that the dishes can be scraped with impunity with a metal scraper, leaving scratches on the polish.

- Can be used with any oven (except, of course, microwave ovens). Most modern models initially come with a ferrite bottom, which allows them to be “friendly” even with induction cookers.

However, there are also disadvantages to such wonderful utensils. Due to uneven temperature distribution, food in thin-walled dishes often burns. A very thick bottom can partly solve the problem. Although it is cheaper to make it multilayer, hiding an aluminum or copper disk between two thin steel contours.

Keep in mind: nickel, which provides steel with its stainless properties, is harmful to the human body in large quantities.

Even if you are not allergic to this metal, it is highly undesirable to store food in stainless steel containers so that the nickel content in finished dishes does not exceed the norm. That is, if you have prepared something tasty, immediately transfer it to another, more suitable container.

Materials

But stainless steel is different from stainless steel, so you shouldn’t focus on mirror shine alone. Alloyed alloys for the production of cookware can be used in a variety of ways.

- 18/10 (or aisi 304) is an austenitic steel that is used to make only the best cookware. European manufacturers often use it for luxury cutlery.

- 201 or 202 - the so-called medical or surgical steel, suitable only for cheap utensils. These alloys contain much less nickel, which manufacturers partially replace with manganese. They make the best utensils that are not intended for cooking on the stove: bowls, gravy boats, cutlery.

- 430 is ferritic steel containing 17-27% chromium and is completely nickel-free. They do not make entire dishes from it, limiting themselves to making the upper part of the multi-layer bottom. However, it is also suitable for cutlery.

- 420 – martensitic steel is used to make knives because it is very hard, although due to its brittleness it is difficult to process.

Stainless steel cookware may also differ in the production method. Inexpensive utensils are made using the stamping method. But cast ones, although less in demand due to their high cost, will last you much longer.

Difficult choice

If you need really high-quality and safe cookware, it is better to go to a serious specialized store for it.

Here the chance to purchase original certified products of proper quality is much higher. When purchasing a set of cookware, be sure to check that the lids fit tightly onto the rims of the pots and pans.

Heat-insulating pads on the handles are also highly desirable, since stainless steel heats up quickly.

Be sure to consider sanding the surface of your chosen cookware in good light.

Here, no more than 3 spot polishing defects are allowed, and dents, protrusions, and scratches are completely unacceptable. The thickness of steel is one of the most important indicators of the quality of kitchen utensils. According to GOST, the walls should be no thinner:

- 0.5-0.8 mm for a saucepan, ladle or frying pan;

- 1-1.2 mm for a pressure cooker, saucepan or cezve.

Also, in all cases, it is necessary to have a thickened bottom of 3 mm or more, otherwise everything in your dishes will burn, and thin steel will simply go in waves due to constant thermal deformations. The problem is solved by soldering an additional heat distribution disk of appropriate height made of aluminum. If the inner layer is made of copper, its thickness may be less - from 1.5 mm.

In general, the encapsulated bottom of stovetop utensils is a case where the thicker the better. For example, stainless steel cookware with a thick inner layer of 4.5-5.5 mm a priori belongs to the premium class. In this matter, Zepter has traditionally proven to be the best - the bottoms of pots and pans with this brand can reach 8-10 mm. Indirectly, the high quality of such utensils is confirmed by its serious weight.

Also today you can find dishes made of steel using Tri-ply technology. Here, not only the bottom, but also the side walls are encapsulated, which allows you to get rid of some of the disadvantages of stainless steel utensils. However, so far manufacturers have not been able to achieve a layer thickness of more than 2 mm, so the problems can be called only partially solved.

By the way, there are a number of “tricks” that tableware manufacturers use to somehow stand out among competitors and advertise their products. But such innovations have no practical value, so you shouldn’t spend extra money if the seller explains the high price:

- The presence of a temperature sensor on the lid;

- Copper inserts-nickels on the inner surface of the steel bottom.

Manufacturers – decent and not so

Let’s make a reservation right away that this review includes only those brands that produce cookware that meet sanitary and epidemiological standards. Other “sins” may be more or less significant, but they do not pose any harm to health.

BergHoff

A well-known Belgian brand, whose products have been produced in a Chinese factory for some time now. However, the same high-quality steel 304 is used for its manufacture. The thickness of the walls of Berghof pans meets the basic requirements (0.7 mm), but the bottom unexpectedly turned out to be thinner than required by GOST - from 2.3 to 2.8 mm in different parts , although it consists of 5 layers.

Also disconcerting is the additional steel insert in the center of the aluminum layer, covered with a copper “penny”, which only serves to weigh down the utensils. However, thickening the bottom closer to the edges actually turned out to be a reasonable solution. This design prevents pans from deforming when heated and protects flat glass-ceramic surfaces from damage.

A good solution from BergHoff are lids with water seals, thanks to which you can cook dishes with a minimum amount of water or oil.

Rondell

Officially considered a joint German-Cypriot brand, although for some reason it is sold only in some CIS countries, Poland and the islands of Oceania.

The price tags in stores, where the manufacturer indicates the same China, are also confusing.

However, all product certificates confirm its compliance with sanitary standards, and participation in various competitions in the spirit of Product of the Year brings the company good places.

There are many specialized stores in Russia that sell the products of this “multinational” brand, and reputable hypermarkets are happy to sell them. In addition, Rondell stainless steel cookware comes with a 25-year guarantee. So, despite the confusing geography of the brand, which causes slight mistrust, the facts clearly speak in its favor.

KaiserHoff

Despite the clearly German name and even the occasional German flag on the logos, all the dishes of this brand are produced exclusively in China.

However, the manufacturer does not at all hide the origin of its products, so the external surroundings are rather used in an attempt to emphasize compliance with “truly German quality.” In addition, the design of stainless cookware is actually developed in Germany.

And the ideal steel chosen for its production is 18/10. Thermal storage bottom is also present, and a measuring scale is quite conveniently placed on the inner walls.

Gourmet

Very decent Russian-made stainless steel cookware is manufactured strictly in accordance with GOST and is mainly produced with a thick three-layer bottom. The range is quite wide: from pots and pans to measuring containers and kitchen accessories. In addition, here you can find many successful solutions for different series, for example:

- The lids are made of durable heat-resistant glass, which can be used together with the dishes even for cooking in the oven (the main thing is not to cool it sharply).

- The handles are made of heat-resistant plastic - they won’t burn your hands, but you can’t put such utensils in the oven. However, there are models with hollow, low-heating handles, all made of the same stainless steel.

In general, Gourmet dishes are distinguished by very high quality at an average cost.

Supra

Supposedly a Japanese (but actually Russian) brand that produces pots in factories in Asia. However, the price is very average, as is the quality, but Supra cookware does not go beyond the safety requirements. The steel used here is of a lower grade than the manufacturer claims - the nickel content is only 3.5%, and the wall thickness does not reach GOST standards.

Vinzer

Another marketing deception - the supposedly Swiss brand actually has Russian roots, but is, of course, produced in the Middle Kingdom. However, everything is in order with the safety of their dishes, which is confirmed by both Rospotrebnadzor and experts.

In our market, Vinzer stainless steel cookware is mainly represented by multifunctional sets. Copper plates 0.5 mm thick are placed on top of the bottom, and traditional 4 mm aluminum is placed in the middle of the capsule. The high class of 304 steel is also confirmed, so the manufacturer’s attempts to misrepresent the geography can be forgiven.

Vitesse

The same deception, but with a French pronunciation and far from being so harmless. Despite the sanitary and epidemiological certificates issued on the safety of the dishes, there is nothing good to say about their quality.

The steel grade 18/10 specified by the manufacturer is another scam, since in fact it uses alloy 201, which is not corrosion resistant in the full sense of the word.

And according to customer reviews, surface defects may appear already in the first days of operation.

Tescoma

Czech cookware of really good quality pleases not only with excellent stainless steel, but also with careful attention to design down to the smallest details.

This brand has a recognizable style of its own, so it is almost impossible to confuse its products with those of other manufacturers.

Teskoma even acquired a laboratory that allows the company to independently control the quality of finished products, and it uses it exclusively for the benefit of its customers.

Only after passing numerous checks are Tescoma steel products marked - a sign of impeccable quality that you can truly trust.

Konig

It is produced exclusively in the Middle Kingdom, and in several different factories at once.

Not the best 201 grade steel is used for it, although there are really good models made from austenitic 304. So when choosing, you need to be especially careful.

Otherwise, you will end up with utensils that will crack and corrode over time, despite all the sellers' claims.

The Konig brand produces cookware in two different price segments:

- Elite - here the pans have a fair wall thickness of 0.7-1 mm and a thick three-layer bottom with a 5 mm aluminum disk. The manufacturer assures that all high-end tableware can be trusted in a dishwasher.

- Economy - the thickness of the steel is slightly smaller, but fits into the basic requirements of GOST (0.6 mm on the walls and 3 mm in the bottom, only 3 mm).

Zepter

This is no longer just a brand, but a household name for the highest quality cookware. It is produced in Switzerland, Germany, France and Italy, and chrome-nickel Zepter steel may differ slightly in composition from the usual 18/10 due to the presence of silver and platinum in the alloy.

The bottom here is very thick, up to 1 cm, so dishes in pots and pans really don’t burn. The walls are also quite thick - about 1 mm. During the heating process, condensation forms on them, which allows you to cook dishes completely without water and fat - in their own juice.

But since the famous Zepter is most often counterfeited, the company has developed recommendations that allow customers to distinguish original products:

- The brand name should not contain any extraneous words - only the laconic “Zepter”. This company has no subsidiaries.

- A store that sells luxury tableware must have feedback contacts with the manufacturer - only after concluding a direct agreement, Zepter provides its products for sale.

- Each product in the set must come in an individual box. Moreover, sets cannot consist of more than 17 items.

Rules of care

Despite the enviable durability of stainless steel cookware, you also need to know how to care for it. Of course, you are unlikely to be able to ruin it to the point of being completely unusable, but if handled incorrectly, expensive kitchen utensils can lose their attractive appearance.

Firstly, it is not recommended to use steel wool and abrasives to clean such dishes, and secondly, you will have to completely avoid detergents containing chlorine or ammonia.

And be sure to wipe polished surfaces dry so that they retain their shine longer.

Stainless steel utensils can only be washed in the dishwasher if the manufacturer has specifically indicated this in the instructions.

Under no circumstances should you leave pans and pots on the fire empty. Otherwise, they will become covered with tarnished spots, which will be very difficult to get rid of.

And if something is still burnt, it is better to first soak the product for several hours in a soda or soap solution, and only then clean off the carbon deposits.

If possible, use special stainless steel dishwashing detergents, especially if you have purchased an expensive set and want it to delight you with its shine for a long time.

Tests at elevated temperatures of material X5CrNi18-10 - 1.4301

| Temperature, °C | Ultimate strength (temporary tensile strength), min., Rm, MPa | Yield strength, min., Rp0.2 in N/mm3 |

| 550 | — | 90 |

| 500 | 360 | 92 |

| 400 | 380 | 98 |

| 350 | 380 | 104 |

| 300 | 380 | 110 |

| 250 | 390 | 118 |

| 200 | 400 | 127 |

| 150 | 420 | 142 |

| 100 | 450 | 157 |

| 50 | — | 180 |