The marking implies a special license plate that describes the main functional characteristics of the hardware. This degree of discrimination is necessary for applying fasteners to a drawing or for recording some information for documentation. By using fastener markings, confusion due to incorrect reading of the markings disappears.

Digital designations printed on fasteners are determined in accordance with the approved GOST R52627-2006. Marking of hardware can contain such information about the element as:

· Trademark;

· Strength class.

Fasteners include all types of hardware, including nuts, bolts, studs, screws and washers.

Strength class in marking

One of the main indicators used in marking is the strength class. Such indicators can be defined by the following symbolism:

| Strength class | 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.6 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 |

| Marking symbol | 3.6 | 4.6 | 4.8 | 5.6 | 5.8 | 6.6 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 |

The “a” indicator corresponds to the number 12 on the watch dial. This is the control mark. It looks like a dot and defines the trademark.

The “b” indicator corresponds to the strength class and is indicated by a double stroke. To highlight the strength class, the dot designation is used.

Conventional designations of coatings

All coatings have their own markings, which are marked on the packaging, but understanding the intricacies of technical symbolism is not easy. You need to know the numerical designation of the coating:

| Zinc, chromated | C. hr | 01 |

| Cadmium, chromated | Kd. xp | 02 |

| Multilayer: copper-nickel | M. N | 03 |

| Multilayer: copper-nickel-chrome | M. N. H. b | 04 |

| Oxidized, oil-impregnated | Chem. Oks. prm | 05 |

| Phosphate, oil impregnated | Chem. Phos. prm | 06 |

| Tin | ABOUT | 07 |

| Copper | M | 08 |

| Zinc | C | 09 |

| Oxidic, filled with chromates | An. Oks. NHR | 10 |

| Oxidic from acidic solutions | Chem. Pass | 11 |

| Silver | Wed | 12 |

| Nickel | N | 13 |

In addition, the thickness of the spraying is of great importance, which is also written on the packaging and is calculated in microns. It is always noted after the type of spraying.

Examples:

- Nut М12×1.25-6Н.05.40Х.016 GOST 5915-70;

- Screw A2M12×1.25-be x60.58.S.019 GOST 17473-80.

The numbers 016 and 019 are general information about the coating and its thickness. 01 - zinc chromated coating. And the third number (6 and 9) indicates that these types of spraying have a thickness of 6 and 9 microns, respectively. There are also letter variants that would look like “Ts.khr6” and “Ts.khr9” in these cases.

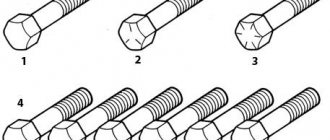

Star and hex head on fasteners

This type of fastener is marked with a strength class and the manufacturer’s trademark. These are the necessary indicators that should be on the product.

Functional designations are applied to the side of the fastener. The place of application is the head. If it is not possible to apply numbering on the head of the element due to its absence, then the markings are applied to the flanges of bolts and screws.

Hex bolts have their own marking characteristics. Especially if their diameter is higher than 5 mm. Marking the head of such fasteners is mandatory during their manufacture.

a— Trademark. b— Strength class.

Structural forms of fasteners

Basic Fasteners

Figure 1. Types of fasteners for threaded connections of various designs: a) bolt, nut and washer; b) screw; c) stud, nut and washer; d) screw, insert and washer

Among threaded parts, the most common are the following basic fasteners :

- screws (including bolts ),

- hairpins,

- nuts,

- inserts,

- washers.

A bolt (Figure 1, a) or a screw (Figure 1, b) is understood as a rod with a head and one threaded end.

A screw is a fastener that has a rod with an external thread and a head. The screw connects to a nut or mounting hole.

Figure 2. Stainless steel bolt DIN 933

Screws are classified according to purpose into two types:

- fastening screws used for detachable connections of parts (for example, for detachable flange connections of pipelines);

- installation screws used for mutual fixation of parts.

A bolt is a fastener that has a male threaded shank at one end and a head at the other. A bolt forms a connection using a nut or threaded hole in the product being connected. Unlike a screw, a bolt necessarily has a head to transmit torque.

The hairpin (Figure 1, c) has two threaded ends and does not have a head.

Figure 3. Stainless steel nuts.

The insert (Figure 1, d) is shaped like a helical spring made of rhombic wire, screwed under tension into a threaded hole.

A nut is a fastener with a threaded hole and a structural element for transmitting torque.

A washer is a fastener with a hole placed under a nut or the head of a bolt or screw. The washer serves to increase the supporting surface or to prevent them from unscrewing themselves.

In our country and abroad, standards have been developed for the most common types of parts for general purpose threaded connections.

Hairpins

As for bolts and screws with a diameter greater than 5, as a rule, the strength class corresponds to 5.6 or 8.8. Sometimes the strength class can be higher. The marking of such products necessarily includes strength class indicators. Numbering is applied to any place on the product that does not have a thread.

If there is not enough space on the product, other symbols may be used.

| Strength class | 5,6 | 8,8 | 9,8 | 10,9 | 12,9 |

| Marking symbol |

Fastener materials

According to the fastening standard GOST 1759.4-87 “Bolts, screws and studs. Mechanical properties and test methods" (“Bolts, screws and studs. Mechanical properties and test methods”), the mechanical characteristics of carbon and alloy steels used for the manufacture of bolts, screws and nuts, as well as the steel grade, must correspond to those indicated in Table 1.

Table 1. Mechanical characteristics of corrosion-resistant (stainless), heat-resistant, heat-resistant and heat-resistant steels (at normal temperature) for the production of screws, bolts, studs and nuts.

| Fastener steel grade | tensile strength σв, MPa | yield strength σt, MPa | relative elongation δ5, % | impact strength, aH, J/cm2 | |

| Bolts | Nuts | no less | |||

| 12Х18Н10Т | 12Х18Н9Т, 10Х17Н13М2Т | 520 | 200 | 40 | 40 |

| 20Х13 | — | 700 | 550 | 15 | 60 |

| 14Х17Н2 | 20Х13, 14Х17Н2 | 650 | 12 | 60 | |

| 10Х11Н23Т3МР 13Х11Н2В2МФ | — Х12Н22Т3МР | 900 | 550 | 8 | 30 |

| 25Х1МФ | 25Х2М1Ф 20Х1М1Ф1ТР | 750 | 10 | 30 | |

The use of Bessemer steels for the manufacture of fasteners is prohibited, since such steel fasteners have increased brittleness due to the high content of phosphorus and nitrogen absorbed from the air during purging.

When there are strict requirements for corrosion resistance, strength, dimensions and weight of the connection, fasteners made of titanium and beryllium alloys, high-strength and heat-resistant steels and alloys are used.

Marking of high-strength bolts according to GOST 22353-77

Strictly speaking, GOST 22353-77 today has already lost force in the Russian Federation. Instead, bolts are now made according to GOST R 52644-2006, which we will talk about below.

But, since bolts manufactured according to this GOST are still found in practice, let's see what markings were made on them and what it means.

It consists of two parts: at the top there are some alphabetic symbols, at the bottom there are numbers.

So what do the numbers and letters on the head of the bolt mean according to GOST 22353-77?

1. The letter designation at the top, which comes first, is the manufacturer’s mark (D, OC, L, Ch, WT, etc.)

2. A series of numbers following the letters is the temporary resistance of the bolt in MPa, divided by 10

3. Climatic version HL (for cold climates)

4. Melt number.

If the thread on a bolt is left-handed, then such a bolt is additionally marked with an arrow (counterclockwise), if the thread is right-handed, then the bolt is not marked with any arrow.

APPENDIX 1 (for reference). Weight of steel bolts (version 1) with coarse thread pitch

APPENDIX 1 Reference

| Bolt length, mm | Theoretical weight 1000 pcs. bolts, kg, with nominal thread diameter , mm | ||||||||||||||

| 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 42 | 48 | |

| 8 | 4,306 | 8,668 | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 10 | 4,712 | 9,394 | 16,68 | — | — | — | — | — | — | — | — | — | — | — | — |

| 12 | 5,118 | 10,120 | 17,82 | — | — | — | — | — | — | — | — | — | — | — | — |

| 14 | 5,524 | 10,850 | 18,96 | 27,89 | — | — | — | — | — | — | — | — | — | — | — |

| 16 | 5,930 | 11,570 | 20,10 | 29,48 | 43,98 | — | — | — | — | — | — | — | — | — | — |

| 18 | 6,336 | 12,300 | 21,23 | 31,12 | 46,21 | 65,54 | — | — | — | — | — | — | — | — | — |

| 20 | 6,742 | 13,020 | 22,37 | 32,76 | 48,45 | 68,49 | 95,81 | — | — | — | — | — | — | — | — |

| 22 | 7,204 | 13,520 | 23,51 | 34,40 | 50,69 | 71,44 | 99,52 | — | — | — | — | — | — | — | — |

| 25 | 7,871 | 14,840 | 25,22 | 36,86 | 54,05 | 75,87 | 105,10 | 133,3 | — | — | — | — | — | — | — |

| 28 | 8,537 | 16,330 | 26,92 | 39,32 | 57,40 | 80,29 | 110,60 | 140,2 | — | — | — | — | — | — | — |

| 30 | 8,981 | 17,120 | 28,52 | 40,96 | 59,64 | 83,24 | 114,30 | 144,8 | 193,0 | — | — | — | — | — | — |

| 32 | 9,426 | 17,910 | 29,43 | 42,59 | 61,87 | 86,19 | 118,00 | 149,4 | 198,6 | 237,0 | — | — | — | — | — |

| 35 | 10,090 | 19,090 | 31,28 | 45,34 | 65,24 | 90,62 | 123,60 | 156,3 | 207,0 | 246,9 | 340,6 | — | — | — | — |

| 38 | 10,760 | 20,280 | 33,18 | 48,00 | 68,59 | 95,04 | 129,20 | 163,2 | 215,4 | 256,9 | 353,3 | — | — | — | — |

| 40 | 11,200 | 21,070 | 34,36 | 49,78 | 71,25 | 97,99 | 132,90 | 167,8 | 221,0 | 263,5 | 361,8 | 474,8 | — | — | — |

| 45 | 12,310 | 23,040 | 37,45 | 54,22 | 77,30 | 105,70 | 142,10 | 179,4 | 235,0 | 280,1 | 373,0 | 500,9 | — | — | — |

| 50 | 13,420 | 25,020 | 40,53 | 58,67 | 83,35 | 113,60 | 152,40 | 190,9 | 249,0 | 296,7 | 404,1 | 526,9 | 834,5 | — | — |

| 55 | 14,530 | 26,990 | 43,62 | 63,11 | 89,39 | 121,50 | 162,40 | 203,7 | 263,1 | 313,3 | 425,3 | 553,0 | 872,1 | 1304 | — |

| 60 | 15,640 | 28,970 | 46,70 | 67,55 | 95,44 | 129,40 | 172,40 | 216,0 | 278,9 | 329,9 | 446,5 | 579,0 | 909,8 | 1356 | — |

| 65 | 16,760 | 30,940 | 49,79 | 71,99 | 101,50 | 137,30 | 182,40 | 228,4 | 293,8 | 348,8 | 467,7 | 605,1 | 947,4 | 1407 | 2009 |

| 70 | 17,870 | 32,910 | 52,87 | 76,44 | 107,50 | 145,20 | 192,40 | 240,7 | 308,8 | 366,5 | 491,1 | 631,1 | 985,0 | 1458 | 2076 |

| 75 | 18,980 | 34,890 | 55,96 | 80,88 | 113,60 | 153,10 | 202,40 | 253,0 | 323,7 | 384,3 | 513,6 | 659,7 | 1023,0 | 1509 | 2143 |

| 80 | 20,090 | 36,860 | 59,04 | 85,33 | 119,60 | 161,00 | 212,40 | 265,0 | 338,6 | 402,1 | 536,1 | 687,5 | 1061,0 | 1561 | 2211 |

| 85 | 21,200 | 38,840 | 62,13 | 89,77 | 125,70 | 168,90 | 222,40 | 277,7 | 353,6 | 419,8 | 558,6 | 715,2 | 1098,0 | 1612 | 2278 |

| 90 | 22,310 | 40,810 | 65,21 | 94,20 | 131,70 | 176,80 | 232,40 | 290,1 | 368,5 | 437,6 | 581,0 | 743,0 | 1141,0 | 1663 | 2345 |

| 95 | — | 42,790 | 68,30 | 98,64 | 137,80 | 184,70 | 242,40 | 302,4 | 383,4 | 455,4 | 603,5 | 770,8 | 1181,0 | 1715 | 2412 |

| 100 | — | 44,760 | 71,38 | 103,10 | 143,80 | 192,60 | 252,40 | 314,7 | 398,3 | 473,2 | 626,0 | 798,5 | 1221,0 | 1766 | 2479 |

| 105 | — | — | 74,47 | 107,50 | 149,90 | 200,50 | 262,40 | 327,1 | 413,3 | 490,9 | 648,5 | 826,3 | 1261,0 | 1826 | 2546 |

| 110 | — | — | 77,55 | 112,00 | 155,90 | 208,40 | 272,30 | 339,4 | 428,2 | 508,7 | 671,0 | 854,1 | 1301,0 | 1880 | 2614 |

| 115 | — | — | 80,63 | 116,40 | 162,00 | 216,30 | 282,30 | 351,8 | 443,1 | 526,5 | 693,5 | 881,8 | 1341,0 | 1934 | 2690 |

| 120 | — | — | 83,72 | 120,90 | 168,00 | 224,20 | 292,30 | 364,1 | 458,1 | 544,2 | 716,0 | 909,6 | 1381,0 | 1989 | 2760 |

| 125 | — | — | 86,80 | 125,30 | 174,00 | 232,10 | 302,30 | 376,4 | 473,0 | 562,0 | 738,5 | 937,4 | 1421,0 | 2043 | 2831 |

| 130 | — | — | 89,89 | 129,70 | 180,10 | 240,00 | 312,30 | 388,8 | 487,9 | 579,8 | 761,0 | 965,2 | 1461,0 | 2098 | 2903 |

| 140 | — | — | 96,06 | 138,60 | 192,20 | 255,80 | 332,30 | 413,5 | 517,8 | 615,3 | 806,0 | 1021,0 | 1541,0 | 2207 | 3045 |

| 150 | — | — | 102,18 | 147,50 | 204,30 | 271,60 | 352,30 | 438,1 | 547,6 | 650,8 | 850,1 | 1076,0 | 1621,0 | 2315 | 3187 |

| 160 | — | — | 108,38 | 156,40 | 216,40 | 287,40 | 372,30 | 462,8 | 577,5 | 686,4 | 895,9 | 1132,0 | 1701,0 | 2424 | 3329 |

| 170 | — | — | 114,58 | 165,30 | 228,50 | 303,20 | 392,30 | 487,5 | 607,4 | 721,9 | 940,9 | 1188,0 | 1780,0 | 2533 | 3471 |

| 180 | — | — | 120,68 | 174,20 | 240,60 | 319,00 | 412,30 | 512,2 | 637,2 | 757,5 | 985,9 | 1243,0 | 1860,0 | 2642 | 3614 |

| 190 | — | — | 126,88 | 183,10 | 252,70 | 333,80 | 432,30 | 536,9 | 667,1 | 793,0 | 1031,0 | 1299,0 | 1940,0 | 2751 | 3756 |

| 200 | — | — | 133,08 | 191,90 | 264,70 | 350,60 | 452,20 | 561,5 | 697,0 | 828,6 | 1076,0 | 1354,0 | 2020,0 | 2860 | 3898 |

| 220 | — | — | — | 209,70 | 228,90 | 382,20 | 492,20 | 610,9 | 756,7 | 899,6 | 1166,0 | 1465,0 | 2180,0 | 3077 | 4182 |

| 240 | — | — | — | 227,50 | 313,10 | 413,80 | 532,20 | 660,3 | 816,4 | 970,8 | 1256,0 | 1576,0 | 2340,0 | 3295 | 4466 |

| 260 | — | — | — | 245,20 | 337,60 | 445,40 | 572,20 | 709,6 | 876,1 | 1042,0 | 1346,0 | 1687,0 | 2500,0 | 3513 | 4751 |

| 280 | — | — | — | — | 361,50 | 476,90 | 612,20 | 759,0 | 935,9 | 1113,0 | 1436,0 | 1798,0 | 2660,0 | 3730 | 5035 |

| 300 | — | — | — | — | 385,70 | 508,50 | 652,20 | 808,3 | 995,6 | 1184,0 | 1526,0 | 1910,0 | 2820,0 | 3948 | 5319 |

(Changed edition, Amendment No. 5).

Full symbol

The full designation of bolts, screws, studs and nuts is standardized by GOST 1759.0-87 “Bolts, screws, studs and nuts. Technical specifications"

In the post-Soviet space, in accordance with GOST 1759.0-87 and GOST 18126-94, the following symbol scheme has been adopted for bolts, screws and studs and nuts made of carbon steels and non-ferrous alloys:

For washers, a slightly different symbol scheme is used according to GOST 18123-82 “Washers. General technical conditions":

The above diagrams have a general appearance, with all possible elements. Depending on the type of fastener, the designation may contain more or fewer elements. It should also be noted that some types of bolts, studs, nuts and washers have their own specific symbols, standardized by a specific standard (for example: foundation bolts GOST 24379.1-80, studs for flange connections GOST 9066-75, etc.)

Types and types of anchors and methods of their fastening

Anchoring for concrete structures can be very diverse, using a single or multiple influencing forces - support, a molecular link in the stage of adhesion, friction, fracture, contraction, etc.

According to their intended purpose, the types of anchor bolts for concrete structures are made: frame, ceiling, support and multifunctional. According to the configuration - curved and straight, with an installation or integral system. The type of anchor can be wavy or smooth.

According to the assembly method, a foundation bolt can be through fastening, wedging, driving in, screwing in, etc.

Significant meaning is contained in the substance from which the product is made. In the case of steel, the strength level is 6.8 or higher, treated with an anti-corrosion agent, then it will withstand much longer. Brass will not withstand severe vertical stresses.

Spacers

Expansion anchors for building concrete are often used with nuts; Ftr works in this method. They look like a not very large rod with a thread, a sleeve-shaped cap and a cone.

If the fastener is screwed into the foundation, it spreads out and holds the element firmly in the concrete block.

Spacer anchors installed in walls will not be able to be used next time.

Spacer anchors are also sleeve and sleeve anchors. Used for dense foundations of concrete structures. A small contact zone sometimes with a small caliber model provides an option to withstand significant overloads.

The anchor bolt with nut can be electro-galvanized, hot-dip galvanized, and has acid-resistant properties. This includes helical anchors made of stainless steel.

Drivers

Drive-in anchors are selected for strong concrete.

The foundation bolt is mounted using this type of pins - when assembling boxes, upper air intakes, and placing technical equipment.

Before driving the staple into the stone wall, first drill a suitable hole. Later, the metal product is hammered in, the rim is pulled apart, and a threaded rod of the required length is screwed in. A similar foundation bolt touches the dowel rod and the upper (on the ceiling) anchor.

It is practical to strengthen Armstrong suspensions, supports, and ceilings on them. Typically, the fastening element is used as a fire safety element or against vandalism, since the pin is permanent and cannot be removed.

Frame

They are used to separate openings where window and door frames are installed. The quill is made with a cut along the length; a small release coupling during tightening effectively supports the opening of the system, passing to a suitable place.

In order to protect it from displacement and screwing near its point, there are accents at the top of the quill.

Self-tapping screws for concrete

Here, the strength of the installation occurs through a thread made along the entire length of the pin. During the stage of screwing into a concrete support, a massive resistance to tearing off or displacing the mechanism is formed. When using such a fastener sample, the load-bearing capacity is quite large (up to 100 kg).

Expanding

Can be used to secure cornices, shelving, light sources, canvases and other objects into hollow structures with low load-bearing capacity. The clamp on the screw or pin is designed as a diverging skirt; when the pin is screwed into the foundation, it sticks into the inside of the base.

Along the outer part of the clamp, special needles are immersed in wood concrete to prevent the pin from moving or turning during assembly.

Chemical anchor

This concrete anchor bolt is a semi-liquid part and hardens easily. It is with this part that the pin is wedged into the block of concrete. In view of this composition, it is possible to guarantee a strong adhesion of the base and the pin with a uniform load order along the full length of the fastening material.

Chem. anchors for a building monolith do not induce hidden loads, significantly reducing the risk of collapse and destruction.