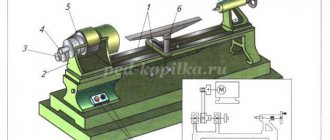

An important element for fastening a part in lathes is the lathe chuck. With its help, reliable fixation and safe processing are ensured. To use a lathe cutting tool correctly, you must have a good understanding of how a lathe chuck is designed.

Structurally, they are combined into two large groups. The first includes cam, the second collet. The lathe chuck used in wood lathes has certain differences in design.

Faceplates

A faceplate is a round metal plate with holes for fastening with self-tapping screws, mounted on the machine shaft using threads or bolts. They differ in diameter, presence or absence of teeth and additional fasteners. Used for turning plates, bowls and other similar products. Often made by hand. Working with the faceplate is thought out so that part of the wood into which the screws are screwed is subsequently removed.

Faceplate for 4-jaw chuck

Jaw chucks

The most convenient and functional. They work both in compression and expansion, so they can grip the workpiece both from the outside and from the inside. They differ in the number of cams and their drive mechanism. Unlike metalworking, two- and three-jaw chucks are practically not used for turning wood. Options with a spiral drive and non-removable cams are also not popular. The most common type of lathe chuck for woodworking is self-centering four-jaw, with a rack-and-pinion transmission mechanism and replaceable jaws. They are supplied to the Russian market by the brands Axminster, Jet, Barracuda and other, less well-known companies.

Jaw lathe chuck

4-jaw lathe chuck Ø150 mm

4-jaw lathe chuck Ø100 mm

Types of cams

According to their shape and purpose, replacement jaws for wood lathe chucks are divided into several types, which have special markings:

- A, G, M – for compression, differ in size and depth of grip;

- D and F – act on unclenching;

- C and H are universal. Different shapes of sponges;

- To work with soft, compression-sensitive wood, cams with rubber fastenings are used.

Basic dimensions and designations

The adopted system of standards provides detailed data for each type of lathe chuck. It shows the dimensions of each element. The tables show the main parameters: flange diameter, size and shape of the cams, diameter of the internal hole in the housing, hole size and method of fastening, permissible rotation speed. The lathe chuck is calculated based on the requirements specified in the technical specifications for the machine.

The main parameters can be determined by the accepted markings. It is established by a unified notation system. It includes eight digits. The designation ends with a lowercase letter. The numbers indicate the following dimensions:

- number of cams;

- outer diameter of the product;

- basic dimensions established by standards;

- method (type) of attachment to the spindle;

- the shape of the fists.

For example, marking 3-200.33.14 P allows you to set the following. The product has three cams. The outer diameter is 200 mm, the standard version is 33. It has modification number 14 and an increased accuracy class “P”.

Additional accessories

When turning thin-walled products or working with fragile wood, metal fastening rings are used. Having the skill of handling metal, you can make them yourself. Also paired with type C cams, screw inserts can be used that screw into a hole pre-drilled in the part. Chucks designed to solve specific woodworking problems:

- cam with independent adjustment - for eccentric turning;

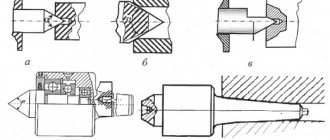

- collet - clamps round workpieces when tightening the petals of a conical collet with a coupling nut. Has a small capture range;

- cylindrical - a tube with three or more threaded fasteners around its circumference; vice - for gripping rectangular workpieces. The parallel jaws are compressed by a screw;

- vacuum – for finishing. It works due to the difference in air pressure created by the pump;

- drilling – for fixing drills. Attached to the tailstock quill.

Set of driving cartridges MK2

Making a lathe chuck for wood with your own hands

The manufacture of jaw chucks requires high-precision industrial equipment and it is hardly possible to make them in a home workshop. However, there are simpler designs that are not difficult to build with your own hands.

Homemade wood turning faceplate with adjustable clamps

You will need a flat sheet of steel with a thickness of at least 10 mm, a steel angle 50x50 mm, eight M8x30 bolts with nuts and washers. You should think in advance about how the device will be mounted on the machine and, if necessary, make or purchase an appropriate threaded bushing. After this you can proceed:

- Mark on the existing plate a circle of the required diameter and two axes passing through the center and intersecting at right angles.

- Cut out the faceplate blank using a jigsaw according to the markings and sand it thoroughly.

- Cut through grooves along the resulting axes, stepping back a few centimeters from the center and not reaching 2 - 3 cm to the edges. This can be done easier by pre-drilling holes slightly larger in diameter than the stocked bolts.

- Saw off four identical sections from the corner and drill one of the shelves of each with the same drill.

- In the second shelf of the corners, cut an M8 thread and screw in the bolts.

- Weld or solder a threaded bushing for mounting on the shaft.

- Screw the corners to the faceplate with bolts through washers.

- Attach the resulting wood chuck to the lathe.

To fix it with such a homemade cartridge, the corners are moved to the desired position and secured by tightening the nuts; the part is finally tightened with bolts screwed into the threaded shelves.

Principle of operation

The main task of such a device is to accurately and reliably hold the workpiece being processed. The principle of operation depends on two factors: how the chuck is attached to the lathe and the drive used.

The accuracy of workpiece fastening depends on the number of jaws used. They must provide uniform pressure on the surface of the workpiece. With proper adjustment, the center of its position relative to the horizontal processing axis is ensured.

To solve this problem, the following cam drive methods are used:

- manual;

- pneumatic;

- hydraulic;

- electromechanical.

The first method is done manually using a special key. Reliability and accuracy are largely determined by the experience of the turner working on the machine. The remaining three drives completely mechanize the process of fixing workpieces. They are used on automatic lathes, numerically controlled machines and machines for processing large parts. The cams are mounted on a flange. Moving to the center, they grasp the installed workpiece.

To ensure the fixing parameters, a backpressure system of the lathe chuck is used. It allows you to create the required pressure on the surface of the workpiece.

The clamping force of a part in pneumatic or hydraulic structures is provided using a special rod located in the coupling. Compressed air or liquid (usually oil) is supplied into it under pressure.

This design ensures free movement of the cams over a distance of up to 10 mm. This distance is quite sufficient for quickly changing workpieces.

DIY vacuum chuck for wood

If your lathe's headstock spindle has a through hole for knocking out the gear center, you can add a homemade vacuum chuck to your arsenal. For this you will need:

- Powerful vacuum cleaner

- Closed bearing, approximately equal in outer diameter to a vacuum cleaner hose

- A piece of thick rubber hose for connecting the vacuum cleaner and the bearing

- Clamp

- Standard faceplate with hole in the center

- A small piece of MDF or thick plywood

- Textolite for adapter

A bushing is machined from the textolite, one side of which should be equal in diameter to the internal size of the bearing, the other - to the spindle. This homemade adapter is pressed into the bearing using glue; it will be held in the machine due to the tightness of the fit. The resulting structure is connected with a piece of hose to the vacuum cleaner and secured with a clamp.

A disk is cut out of MDF or plywood, attached to a faceplate and ground. It is better to make the surface slightly concave. To ensure a tight fit, linoleum or thin rubber is glued on top. The disk is drilled through the center to remove air. A similar self-made chuck provides a pressing force of 40 - 50 kg, sufficient to hold medium-sized parts during finishing.

AliExpress - Products from China at wholesale prices - Opt-aliexpress.ru

For Yamaha YZF-R1 YZF R1 2007-2008 Front Rear Axle Fork Wheel Sliders Protection

Sale

Vivobiniya Free Shipping Child Swimwear Shorts Baby Boys Beach Swimsuit Kids Bathing Suits 3pcs Summer Clothing Split |

Sale

Children's clothing dresses for children toddler girls solid leather low shoes with

Sale

Summer Dress for Girls Summer 2022 Princess Sleeveless Floral Embroidery with

Sale

Japanese Cartoon Les Barbapapa Barbamama Pink Smile for Samsung Galaxy A5 A6 A7 A8 A9 J4 J5 J7 J8 2022 2018

Sale

2020 Fashion Sail Boat T-shirt Men Summer Style Cotton Short Sleeve T Shirt Funny Tee Mans Tops Clothing | Men's clothing

Sale

Dildo Rabbit Vibrator Sexy Masturbation Toy for Women G-Spot

Sale

Boots women's shoes women's knee-high suede boots with crosses

Sale

Real Natural Colorful Roses Necklace Tourmaline Quartz Bracelet 12 2mm

Sale

For Blackview BV7000 Battery Case Cover 5.5" Hard Bateria Protective Back Replacement With Figerprint Rrcognize |

Sale

Emmababy Baby Soft Sole Crib Casual Shoes Cute Toddler Boys Girls Anti-slip Prewalker 0-18 Months Infant Newborn |

Sale

SHENGPALAE 2022 New Spring Long Dress Women Vintage Loose High Waist Slim Was Thin Elegant Black Shirt Pleated ZA2410 | Women's clothing

Sale

Original 20 pieces/TTP223-BA6 223B SOT23-6 | Electronic components and accessories

Sale

08-12 LP-570-4 2012 Super Style Carbon Fiber Recessed Front Bumper |

Sale

2018 New Fashion for Jiayu G5S Luxury Cool Floral Pattern 100% Special Made

Sale

2018 Swimsuit - Women Push Up Bow Bikini LC410186 Bathing Suit Beachwear

Sale

9344 9531 chipset Wi-Fi repeater Lange Bereik 300 Mbps 2.4G3KMOutdoor AP Router CPE Brug Client |

Sale

South Bend GOLD ROADS Rainbow City Map Print United States Poster Canvas Wall Art Black Pictures for Living Room | A house and a garden

Sale

Slowpoke Animal Dolls 19cm Baby Plush Toys Children Pocket

Sale

Full Size/Round 5D DIY Diamond Painting 5pcs sea turtle

Sale

Newborn Photography Props Blanket 55x55cm Woven Square Carpet

Sale

Ninja Drawstring Bags Kids Toy Organizer Sundries Storage Tools Bag Travel Large Capacity Portable | A house and a garden

Sale

Multi Colors Bag In Makeup Handbag Organizer Insert Functional Women Cosmetic Travel Bags | A house and a garden

Sale

2 pcs. baby boys socks and hat set toddler girls clothes

Sale