Anyone who grows oilseeds needs to purchase special equipment for the production of raw materials. It is an oil press. Such devices come in different types, differ in characteristics, and have their own advantages and disadvantages. In today’s article we will analyze popular options for such equipment, and also tell you how to make the simplest but working device yourself at home.

Dimensional press for extracting oil Source marcato.com.ru

Homemade oil production

Let's tell you a little about how you can make oil dishes for obtaining olive or sunflower oil with your own hands and what features there are in these matters.

- Mini oilers for pressing allow you to produce oil that is suitable for consumption for two years. You can assemble the device yourself or buy special presses for household use.

- Homemade oilers are designed to produce products from sunflowers, olives or seeds with nuts. It all depends on what kind of oil you need.

- The easiest way to make wringer oilers with your own hands is to adapt a mechanical press. Previously, they sold a hand press, with the help of which they squeezed juice out of grapes and apples. To obtain olive oil using the pressing method, you don’t even need to change attachments. The holder is replaced with a device with increased power. This will allow you to use the unit as a press for squeezing sunflower oil or olive oil, beloved by many.

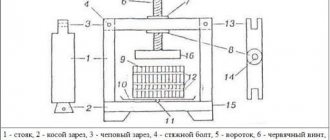

- If you can’t purchase a manual squeezing press, you can make the device yourself using improvised means. A homemade press involves the use of a worm screw for pressing. The pressure generated depends on the power of the beam risers and the diameter of the worm nut. It is recommended to make a beam with a power reserve. The best option is an oak mechanism. If you cannot assemble an oak unit, you can use a metal structure.

- The design provides for a cylinder without a bottom. It is made or made from part of a barrel. It is recommended to strengthen the structure from below with an additional metal hoop. The main thing is that the material is dry and made from hardwood. An oak cylinder would be the ideal solution.

- Peeling spin rollers. This is a pair of replaceable rollers that rotate due to gears. The gears are mounted on metal racks and buckets - upper and lower - are fixed to them. There is also a handle for rotation or a toggle lever. All this is assembled from scrap metal. Only the rollers are made of wood and lined with grater cloth.

How does he work

Having a ready-made design and replaceable squeezing attachments, you can start making sunflower or olive oil.

- A seed is poured into the ladle;

- The handle sets in motion the mechanism that acts on the seeds with a grater;

- The seeds end up in the gap between the rollers, due to which the peeling process occurs;

- The kernels and husks end up in the lower bucket;

- The mixture is collected and winnowed;

- Roller attachments are replaced with smooth spin devices;

- The mixture is again placed in the upper ladle for rolling;

- The corresponding lever is moved to the second position to disengage the gear. Now it will rotate freely in the direction of the second gear, pressing and squeezing the seeds;

- As a result of rolling, a mushy mass is formed, which is sent for pressing.

The output percentage of finished products is not as high as with specialized equipment. This is due to the fact that the nozzles of a home oiler operate with insufficient pressure. This can be corrected using a hydraulic press or an electric motor.

Important advantages are the minimal cost of constructing an oiler and obtaining a high-quality natural product by pressing.

For home use, you can purchase a wooden unit or an auger. Both the wooden and screw type oilers have excellent efficiency. A screw unit will cost approximately 13-15 thousand rubles, and for a wooden hydraulic press you will have to pay at least 50 thousand rubles. But if you use the resulting oil not only for yourself, but also sell it to friends or acquaintances, over time, buying an oil can will completely justify itself.

Even with a mini oiler, you can organize a small business producing cold-pressed olive oil or the most popular sunflower oil.

Homemade oil press – Homemade machines

I received a question from Instagram about the cold-press technology of EcoFarm YAKUSHEV. A good question deserves a good answer and gratitude, so we provide a link to the author’s profile: rodnoy_medok

Question from rodnoy_medok: Tell us how you can fry using extra cold-pressed oil?) After all, there are only three methods of extraction - an oak barrel, a screw press and extraction. You can buy it from a screw press in a store - “cold” pressing and the smell of roasted seeds. Do you have the same?

The answer was prepared with the support of Alexey Yakushev: Dear rodnoy_medok, thank you for the wonderful question, because many people only know about the existence of refined and unrefined oil, and even unrefined oil can be different. So let’s put harmful refined oils aside and consider the technologies for the production of unrefined vegetable oil.

Like presses made from other types of wood, oak presses are very beautiful, and during the production process they emit an incomparable aroma and the oil flows so deliciously that you can admire it, but everything is so rosy only before they begin to be actively used.

The main disadvantages of wooden oil presses:

- low performance. On average, 1-3 liters per hour, which means even with a 12-hour working day you can’t get more than 36 liters of oil

- low oil yield - about 20% of the weight of the seed

- rancidity, drying and fungus. When the cash press is idle, it must be cleaned and treated with beeswax. If this is not done, then the oil remaining on the surface of the wood will dry out, go rancid, and the new smell will no longer be eradicated from the old barrel. If the press is not dried, then mold may grow on wooden surfaces, which also will not make the oil useful and environmentally friendly.

- High cost or low quality oil. If the equipment is used regularly, without downtime and is cleaned and dried in a timely manner, then problems with its damage can be avoided, but who can vouch for an unknown manufacturer, especially when every preventive maintenance means equipment downtime, a waste of time, and therefore an increase in cost.

Screw oil presses are more technologically advanced and can operate in continuous mode for a long time. They also require cleaning, but metal is easier to clean than wood. However, screw presses have no fewer pitfalls than wooden ones.

DIY cold pressed oil press

A business idea for the production of sunflower oil is based on an oil mill. From an investment perspective among professionals, the idea has not lost its popularity and is still in demand and profitable.

However, for many, the issue of income in this area is quite controversial, which is in vain. Let's take a closer look so as not to rely on the opinions of the majority, but to base our own conclusions on specific numbers and facts.

In this business you won’t be satisfied with just butter.

The profit from its sale is hardly enough to reach the cost level.

But we must not forget about the additional products obtained from the creamery, which bring a significant net profit.

Spin methods

Before choosing oil extraction devices, you need to decide what type of oil product you are targeting. There are two ways to obtain this sought-after liquid.

- Hot pressed oil. Before squeezing, the mushy mass is heated to a temperature of 110 degrees Celsius. At the same time, the mint is moistened and mixed in roasting pans. After this, the screw mechanism compresses the raw materials. The hot-pressed product has the taste of roasted sunflower seeds. This oil is darker, has an attractive color and an amazing aroma.

- Cold pressed oil. Cold-pressed products are considered more useful, since some properties and useful components of the raw materials are not lost when heated. The essence of cold pressing is the absence of the stage of heating the raw materials. Cold-pressed liquid retains all the beneficial substances and vitamins. But the shelf life is lower. Over time, the oil darkens and acquires a bitter taste.

How to care for the wooden parts of the press

In order for the oak press for producing cold-pressed oil to retain its positive properties over a long period of time, the equipment should be properly maintained after each use:

- Wash all wooden parts of the press after use with water and detergents, and then vacuum treat with linseed oil, which has bactericidal properties. In addition, beeswax can be used to treat the surface of an oak mold. After such treatments, the wooden surface will not be exposed to temperature changes, moisture and fungi.

- Parts of the oak press should be stored disassembled, wrapped in linen cloth soaked in linseed oil.

- During the cold season, wooden parts of the press should not be kept in cold rooms where the temperature drops below 0 degrees. If oak parts were stored in the cold, and then you decided to squeeze them, you should first let the wood thaw in natural conditions, holding it for several hours at room temperature so that it warms up evenly to a temperature of + 20 degrees.

Features of modern devices

Having decided between the cold and hot pressing method, you can proceed directly to the selection of equipment for production.

In our country, the production of olive oil is problematic, since there is no access to a large amount of appropriate raw materials. The production of olive oil is less profitable than sunflower oil. But the choice is yours.

For active production of these products, appropriate equipment will be required. The optimal solution with an eye to the future is the purchase of modern production complexes. The uniqueness of modern developments lies in the fact that they have different attachments and functionality. At the same time, the device, which is a production line, takes up minimal space.

This mini complex for the production of sunflower oil performs the main stages of raw material processing without the need for additional devices.

- First, the raw materials go through the mandatory stage of drying and removing all kinds of contaminants. Appropriate attachments remove foreign objects from the seeds.

- Next, the raw material goes to cleaning, where nozzles separate the kernels from the husks. After this, the products are crushed.

- The resulting pulp is steamed and fried if we are talking about the hot pressing method.

- When the pre-treatment is completed, the prepared mass is pressed.

- The resulting oil then passes through filter devices. This allows you to obtain the purest and highest quality oil possible.

- After pressing, the liquid is packaged in appropriate containers and sent for storage for further sale.

It is not difficult to obtain oil by pressing even at home. To do this, you can build a special device or purchase factory equipment aimed at producing oil by cold or hot pressing.

Source: tvoistanok.ru

Homemade oil press

To obtain oil industrially, the seeds are filled with gasoline fractions. Hexane, for example. When oil is formed from the seeds, this hexane is removed using steam, and its remains are removed with alkali. At the exit, various undesirable substances appear in the finished product: resins and pigments. Residual solvents are rarely completely evaporated.

Before the oil obtained by extraction can be consumed as food or used in medicine, it needs to go through several more stages of purification: refining, then hydration, then bleaching, then deodorization and finally a couple more filtration steps.

Cold pressed oil press: DIY and home use

To process oilseeds, special equipment is used - an oil press. By using such a simple device, which some craftsmen make with their own hands, at home or in small-scale production, you can obtain an environmentally friendly product that is superior in taste and healthiness to oils sold in stores. The technical characteristics and design of the equipment used depend on which plant crops and in what quantities the oil must be obtained.

To obtain oil for your needs, it is enough to acquire a device whose design is quite simple

Rating of the best options

There can be many models that fit the criteria discussed above. We still recommend choosing options from the prepared rating, since it is based on real user reviews and the popularity of purchases.

Screw manual oil press Piteba

A practical hand-held device that can perform hot and cold oil extraction. It will be an ideal purchase for those who support an extremely healthy diet. The device is capable of working for a long time without rest. There are no difficulties in using the unit.

Press for squeezing oil, manual screw type Source vsesoki.ru

Advantages:

- the most simple design;

- fast heating when using hot mode;

- continuity of work;

- light weight.

Minuses:

- no additional components;

- may become clogged if processed too intensively.

The design of the device contains all the necessary regulators and mechanisms to achieve optimal spin quality.

Design Features

Producing vegetable oil at home using a purchased or self-made press has a number of features that must be taken into account.

- When producing oil at home, the finished product has a two-year shelf life. A home press can be purchased in a serial version or made by yourself.

- Using a household squeeze press, you can extract oil from sunflower seeds, olives and even nuts.

- One of the simplest and most cost-effective ways to make a device for extracting oil is to remake a serial household press designed for squeezing juice from grapes and apples. In such equipment there is no need to change working attachments - it is enough to replace the holder with a device of higher power. This modernization will allow the unit to be used not only for processing olives, but also for squeezing oil from sunflower seeds.

- A home oil press, the basis of which is a worm screw responsible for pressing, can be made using improvised means. When designing such a press, keep in mind that the pressure it will be able to develop will depend on both the diameter of the worm nut and the power of the beam risers. To provide the created device with higher reliability, the beam that serves as the basis of its structure should be made more powerful. These requirements are fully met by a wooden oil press, the mechanism elements of which are made of solid oak. A budget alternative to such a unit is a press, the structural elements of which are made of metal.

- A household press (like any other) used for squeezing oil requires a cylinder without a bottom in its design, which can be used as an ordinary metal barrel. To increase the rigidity of such a cylinder in its lower part, you can take a metal hoop. If a wooden barrel is used as a cylinder, the material from which it is made must be dry and highly hard. The ideal material in this case would be solid oak.

- Important design elements that an oil press should be equipped with include the peeling rollers, which are a pair of replaceable rollers. Their rotation is ensured by gears mounted on the metal racks of the device. On the racks, in addition to the gears, the upper and lower buckets are fixed, as well as a handle, which ensures the rotation of the mechanism elements, or a toggle bucket. Peeling rollers are usually made of wood, and their working surface is lined with a float cloth.

Operating principle

Once the wooden oil press (or metal) is assembled and equipped with replaceable attachments, you can begin to use it for its intended purpose. To extract oil using such a unit (for example, from sunflower seeds), you must perform the following steps:

- Raw materials are poured into the loading ladle of the device.

- The rollers, the surface of which is covered with a grater cloth, are driven into rotation by means of a handle.

- Due to the rotation of the rolls, the raw material is drawn into the gap between them, where the peeling occurs.

- After peeling, the sunflower kernels and the husk from which they are freed end up in the lower bucket.

- The mixture consisting of sunflower kernels and husks is winnowed.

- Rollers with a grater cloth are replaced with rollers with a smooth surface, with the help of which vegetable oil will be squeezed out.

- The cleaned seed kernels are placed in the upper bucket and sent to rolling.

- To reduce the size of the gap between the rollers, which is necessary so that the seed kernels passing between them are compressed with the required force, a special lever of the hand press, which is moved to the second position, allows.

- The result of rolling is a mushy mass, which must be pressed to extract the vegetable oil from it.

Manual type wooden hydraulic oil press for squeezing oil from seeds and nuts

Since a manual squeezing press is not able to provide the high pressure exerted on the raw materials used, the percentage of oil yield is lower than when using specialized equipment. If you use an electric motor or a hydraulic press to drive such equipment, you can correct this shortcoming.

A manual oil press has a number of advantages. We present the most significant of them.

- Due to the simplicity of the design, such a press can be made by hand.

- The finished product has excellent taste and high nutritional value.

Manual screw press for home oil extraction

At home or in a small production workshop, you can use both a wooden and a screw press to produce vegetable oil, which are highly efficient. It should be kept in mind: if you do not make such devices for extracting oil yourself, but purchase ready-made models, then a wooden press based on a hydraulic mechanism will cost much more than a screw press. If you take such a unit to organize a small business producing and selling environmentally friendly vegetable oil, it will pay for itself quickly enough. Such equipment will pay for itself even faster if you use it to produce not only sunflower, but also olive or even cedar oil.

Household oil press Rawmid Dream Modern ODM-01

for obtaining cold and hot pressed oil from nuts and seeds Today, the iXBT.com test laboratory received another interesting and non-trivial household appliance from the Rawmid company. We have previously tested professional blenders and a seed germinator from this company, and Rawmid's kitchen appliances made the most favorable impression and performed well in all our tests. The Dream Modern oil press allows you to produce fresh “live” oil from various seeds and nuts, using both hot and cold pressing. In this article you can get acquainted with the characteristics of this device, our impressions of operation and, most importantly, the results of testing a household oil press.

Table of contents

- Specifications

- Equipment

- At first sight

- Instructions

- Control

- Exploitation

- Testing

- conclusions

Specifications

| General characteristics | |

| Manufacturer | Rawmid |

| Model name | Dream Modern ODM-01 |

| Type | household oil press |

| Rated power | 200 W |

| Thermal power | 120 W |

| Rotation frequency | 50 rpm |

| Case color | white / green / red |

| Material of main block with motor | plastic, aluminum alloy |

| Accessory material | food grade ABS plastic |

| Screw material | stainless steel AISI 304 |

| Accessories | main unit with electric motor, grinding chamber and auger, funnel for small seeds, containers for oil and cake, mesh filter, heat-protective glove, cleaning brush (the copy sent to us had a spare clamp for the grinding chamber) |

| Manufacturer's warranty | 1 year from date of purchase |

| Control | |

| Control type | electronic |

| Speed Modes | one mode and reverse mode |

| Temperature | from 30 to 180 °C with adjustment increments of 10 degrees |

| Cord length | 1.10 m |

| Weight and dimensions | |

| Packaging (W×H×D) | 38×30.5×26 cm |

| Dimensions of the assembled device (W×H×D) | 41×28×18 cm |

| Weight with packaging | 7.4 kg |

| Device weight | 5.5 kg |

Equipment

Oil press Dream Modern ODM-01 is supplied in a parallelepiped cardboard box. The box is designed in a minimalist style: graphic images of the oil press and its components are placed on a white background. On one of the sides the technical characteristics of the device are given, on the second side a number of seeds and nuts are listed that the oil press works with.

When packaged, the device is protected from impacts by foam inserts in which the components of the oil press and its accessories are located. Assembling the device into a package is not difficult. The box is equipped with a carrying handle, which facilitates manual transportation of the device in the package.

Opening the box, inside we find:

- main unit with electric motor;

- grinding chamber and grinding auger;

- oil container;

- sieve for straining oil;

- container for pulp with a lid-nozzle;

- funnel for small seeds;

- mitten;

- a brush for cleaning the grinding chamber and auger;

- cord;

- advertising brochure with Rawmid products;

- instructions;

- warranty card.

Accessories

Two containers (for oil and cake) are made of impact-resistant food-grade ABS plastic. They look laconic, without frills. The material is transparent and quite durable in appearance. The straining sieve is tightly installed on the oil container, i.e. the oil is filtered immediately upon squeezing. The filter also protects the oil from cake, which can bend and end up in an unintended place. The cake container is equipped with an additional lid, which allows you to get rid of splashing and scattering of the cake during the oil preparation process. Initially, this decision seemed very correct and necessary to us. However, during testing, this accessory was removed, since when processing half a kilogram of seeds or nuts, it is often necessary to compact the cake in the container.

A device with a spare clamp for the grinding chamber was sent to our laboratory. Perhaps the manufacturer was afraid that we would test the device in such harsh production conditions that this part of the oil press would break. It is worth paying tribute to the quality of the device - a spare clamp was not needed.

The main working part of the device - the motor block - is made of plastic, rubber and metal. It looks noble, the corners are rounded. The unit does not give the impression of a massive and impressive device, which can be considered a plus when storing the oil press in an ordinary kitchen. The loading opening is wide and made of ABS plastic. The size of the loading bowl allows you to pour a large amount of raw materials into it.

For small seeds, it is proposed to use a special metal funnel, which is inserted into the product supply opening and limits the rate at which the product enters the grinding chamber. It is assumed that medium-sized seeds and nuts will enter the grinding chamber through the existing standard opening.

The lower part of the block is equipped with rubber feet. This solution allows you to achieve stable adhesion to the table surface and reduce the level of vibration.

The control panel, structurally located on the top side of the block, is extremely simple.

The grinding chamber and grinding screw are all-metal and made of stainless steel.

The holes for the resulting oil to flow out in the grinding chamber are quite small, which allows you to obtain relatively clean oil with a small amount of sediment.

Additionally, the kit includes a heat-protective glove and a brush for cleaning the device. Such little things allow us to note that the manufacturer cares about its customers and their convenience when using the device.

At first sight

At first glance, the Rawmid Dream Modern ODM-01 oil press gives the impression of a reliably made and well-designed device. All parts are made from modern, durable and environmentally friendly materials. Everything is logical and convenient.

Steel parts are pleasant to hold in your hands - they are heavy, smooth, without jagged edges. There were also no problems with assembling the device. It is probably incorrect to say that the device is as simple as an iron, but these two devices have something in common.

Instructions

The instructions are in A4 format and printed on thick paper. The document consists of 5 pages, the information is in one language - Russian. The instructions contain information about the structure of the product (the same diagram is shown on the side of the package), recommendations for installation and operating procedures. In many sections, the information is illustrated with photographs. An entire page is devoted to safety precautions when operating an oil press.

In general, the usual instructions provide the most general, but also the most necessary information about the operation and maintenance of the device. It is clear that there is not and cannot be any recipe book for this device. However, I would like to find recommendations, for example, on temperature conditions when squeezing oil from various types of raw materials. You are also interested in the approximate yield of oil during cold and hot pressing. It is worth noting that information about the performance of the oil press is available on the manufacturer’s website. There are also a number of videos demonstrating the process of obtaining oil from various seeds and nuts.

Control

The control panel of the Rawmid Dream Modern ODM-01 oil press is an LCD display with three buttons: on/off, start/pause and reverse. Using the same buttons, you can set the temperature. By default, the device has a temperature of 180 degrees. This means that when the oil press is turned on, it starts to heat up. If you need to reduce the temperature, you need to keep the power button pressed for a few seconds, then, when the value on the display starts flashing, set the desired temperature using the middle and right buttons. The temperature changes in 10 degree increments.

While the device is operating, the display shows information about heating, the current temperature and the direction of movement of the auger (forward or reverse).

As we wrote above, assembling the device is quite simple. Assembly begins with installing the grinding auger on the electric motor shaft. Then the grinding chamber is installed on the auger. After this, the auger and chamber are secured to the engine by turning the locking ring.

Having attached the front part of the device to the motor block using three grooves and clamps on the sides, and placing containers for oil and cake, you can start working. You need to insert a sieve into the container for collecting oil, and a funnel into the loading bowl if you are going to crush small seeds or nuts.

The device heats up quite quickly. The maximum temperature is reached in 3-5 minutes. Using the device is intuitive; no special training is required. Since the appliance is very hot in some areas, certain safety precautions must be observed when operating it. The rules are standard and do not cause inconvenience or difficulty.

Exploitation

Preparation for use

The instructions do not contain any recommendations for using the oil press for the first time. To avoid deterioration in oil quality or short circuits, before starting work, the manufacturer advises checking the grinding chamber and auger to ensure they are free of moisture. Before the first use, the parts of the device that will come into contact with food were traditionally washed: the chopping auger and grinding chamber, containers and their parts.

Purpose of the device

The ODM-01 oil press is positioned as a household one; the manufacturer warns that industrial use of the device leads to a reduction in its service life. This model is suitable for squeezing oil from nuts and seeds: sunflower, pumpkin, mustard, sesame, flax, poppy seeds, walnuts, almonds, peanuts, etc. Low-oil crops such as soybeans and corn are not suitable for this type of squeezing.

The device can operate continuously for an hour, after which it must be turned off and the motor rested for at least 30 minutes. In an hour, an oil press can process from 1.5 to 3 kilograms of raw materials. The performance of the device depends on several factors:

- varieties and quality of raw materials;

- humidity of raw materials;

- oil press temperature.

This device is ideal for people who adhere to the principles of a healthy diet and want to eat high-quality pure oil, for vegans and vegetarians. The oil press allows you to obtain cold-pressed oil, which retains all the vitamins and microelements. This oil can be used not only for food and culinary purposes, it can also serve as a basis for homemade cosmetics, for creating mixtures of aromatic oils and for soap making.

Caring for the device

The device should be cleaned after use. It is necessary to wait until the oil press has cooled down, and only then disconnect the screw and grinding chamber. To clean these parts, the kit contains a special brush-brush. Note that the parts can be easily cleaned with a simple toothbrush. Due to design features, you should not put the grinding chamber and auger in the dishwasher without first manually cleaning it from residual nuts, seeds and cake. So, the grinding chamber simply will not be washed from the inside. All plastic parts (containers and oil strainer) can be washed in the dishwasher.

It is not recommended to wet the main unit with the motor and the front detachable part of the device containing the loading bowl. The manufacturer recommends wiping them with a clean cloth. Note that during the tests, the loading bowl and the area around and inside it became quite dirty. However, it was not possible to wash it, because it is in this part that the heating element and electrical contacts are located. Therefore, we wiped the dirty parts first with a damp cloth with cleaning agent, and then with a dry cloth.

The photo below on the left side shows the removable front part of the device with the heating element. It is this part, which is slightly contaminated during operation of the device by splashes of oil and cake, that cannot be washed.

Testing

Objective tests

Laboratory measurements of energy consumption using a wattmeter recorded a maximum of 180 W. These figures are obtained when the device simultaneously squeezes out oil and heats up. During cold pressing, that is, when the oil press only squeezes out the oil, its energy consumption is 80 W. Interesting figures were obtained when heating the device before the spinning process began: energy consumption is maximum at the beginning of heating (at 30 °C - 175 W), then, with increasing temperature, it decreases (125 °C - 120 W; 150 °C - 100 W; 180 °C - 81 W). The data obtained during the measurements allows us to draw a conclusion about the low energy consumption of the device, and therefore, about its efficiency.

In order to test the capabilities and performance of the Rawmid Dream Modern ODM-01 household oil press that was included in the iXBT.com test laboratory, we decided to obtain oil from the following oil-containing crops:

- sunflower seeds;

- pumpkin seeds;

- Flaxseed;

- mustard seeds;

- sesame;

- peanuts;

- walnut;

- pine nuts;

- almonds

Rawmid Dream Modern ODM-01 oil press performance table

| Raw materials | Weight, g | t, °С | Raw material processing time, min:sec | Oil yield, g | Oil yield percentage, % | Productivity, kg/h |

| Sunflower seeds | 500 | 30 | 9:20 | 175 | 35 | 3,1 |

| Sunflower seeds | 500 | 180 | 9:20 | 250 | 50 | 3,1 |

| Pumpkin seeds | 500 | 140 | 16:00 | 216 | 43 | 1,9 |

| Flaxseed (brown) | 500 | 180 | 9:20 | 98 | 20 | 3,1 |

| Mustard seeds | 490 | 150 / 60 1 | 7:20 | 70 2 | 14 | 4,1 |

| Sesame seeds | 500 | 180 | 8:55 | 266 | 53 | 3,3 |

| Peanuts (unroasted) | 500 | 150 | 16:25 | 240 | 48 | 1,8 |

| Walnut | 300 | 180 | about 15 minutes 3 | 184 | 61 | about 1.2 |

| Pine nuts | 250 | 110 / 180 4 | 5:25 | 90 | 36 | 2,7 |

| Almond | 250 | 130 | 8:45 | 115 | 46 | 1,7 |

Notes on the table:

1 We started pressing at a temperature of 150 °C, then reduced it to 60 °C. The extraction process went very quickly, so they decided that lowering the temperature would help slow down the extraction of oil. 2 The small amount of oil may be due to the fact that we did not insert a funnel into the loading bowl. As a result, the seeds entered the grinding chamber too quickly, which led to oily cake and low oil yield. 3 During the tests, the timer did not work, so the time is given according to subjective feelings. 4 We started pressing the oil at a temperature of 110 °C; approximately halfway through the process, it was decided to increase the temperature to 180 °C in order to obtain the maximum amount of oil.

Test results are excellent.

The device operates quietly, no vibration was noticed. The oil press perfectly presses oil from all oil-containing seeds and nuts. The highest oil yield can be obtained by pressing at maximum temperature. Sunflower showed a 15% difference in performance when pressed at 180°C. In this case, the temperature of the resulting oil itself rises to approximately 40 degrees, the temperature of the cake - about 55 degrees. Let us immediately note that these measurements are approximate, since they were made using a simple kitchen thermometer.

Walnuts showed the highest percentage of oil content in the feedstock. I was pleasantly surprised by sesame with 53% oil yield. Mustard seed showed the lowest percentage. This may have been due to errors during testing, or perhaps due to poor quality raw materials (old or dry mustard, not intended for oil production).

During cold pressing, the pulp has a finer structure and scatters in all directions; in this case, the attachment to the container with the pulp is indispensable. When pressed hot, the cake becomes more elastic, curls into even, fairly long spirals, and is easy to pick up and compact. We used a regular teaspoon for this. Note also that the cake may fly into the container for collecting oil. In this case, a butter sieve most often helps - pieces of cake end up in it. During testing, the cake got into the finished oil only once.

We will write separately about the use of cake. This is a rather interesting topic, because throwing away such a valuable product seems irrational. The cake can be crushed into powder using a blender, coffee grinder, or even manually in a mortar, because the substance is quite fragile and dry. So, we plan to make halva from sunflower seed cake. We will use pumpkin seed cake in baking. When squeezing flaxseed oil, we obtained excellent low-fat flaxseed meal as a by-product. It can be used in baking, added to various types of dough, and porridge. We will make tahina from sesame cake and traditionally use it to make hummus. You can also make tahini halva. By grinding mustard cake in a coffee grinder, we got an excellent aromatic mustard powder. We plan to use it to make mustard, various sauces and marinades. If we suddenly catch a cold, then, remembering our grandmother’s recipes, we will soar on our feet. It's a pity that the photo doesn't capture the smell of freshly ground mustard powder.

Pre-ground nut cake turns into excellent nut flour. Area of application: all confectionery products, nut butters, dietary cakes and sweet pastries. We have special plans for the walnut cake: we want to mix it with sugar and a small amount of butter. We will use the resulting mass as a filling for buttery nut rolls. We admit that in some ways it is even more interesting to work with cake than with oil.

Now let’s briefly go over the observations during testing and the characteristics of the resulting oils.

Sunflower seed oil

There were no difficulties when squeezing out the oil. The oil obtained by cold pressing is cloudy, with a faint smell of fresh seeds. The color is light gray, a few hours after preparation there is little sediment, the oil is cloudy. Hot-pressed oil is light yellow in color, more aromatic, settles faster, and after additional filtration is almost transparent. Both oils have a distinct seed flavor. Oil from pre-roasted sunflower seeds is clearer than from raw sunflower seeds, has a bright aroma, and has a nicer color. If you are primarily interested in the culinary properties of the oil, we recommend pressing it from roasted seeds and nuts.

The photo below shows the resulting oils: on the left is cold-pressed oil, on the right is hot-pressed.

In order for the readers of our review to see, and at the same time hear, the operation of the oil press, we made a short video:

Pumpkin seed oil

There were no particular difficulties when squeezing out the oil. It took a long time. This may be due to the size of the seeds, which entered the grinding chamber more slowly than sunflower seeds. We started pressing at 180°C, but at this temperature the seeds were fried and stuck in the grinding chamber, so the temperature was reduced to 140°. Hot-pressed oil is dark green in color, with a bright smell of pumpkin seeds, thick, cloudy even after sediment has settled, which has settled after several hours. The oil is very tasty and aromatic. Ideal for salads made from fresh vegetables and herbs.

Pumpkin oil is beneficial for its high content of easily digestible proteins, vitamins A, E, F, C, P, group B. Indispensable for diseases of the gastrointestinal tract.

Flax seed oil

The manufacturer writes in the instructions that flax seed does not need to be heated. However, when trying to press the oil in a cold way, the auger began to creak and grind. Previously, having studied videos from other manufacturers of similar equipment, we learned that it is always recommended to press flax seed at a high temperature, so we set the oil press to 180 °C and subsequently did not experience any difficulties when squeezing out oil. The oil turned out to be light brown in color, settled easily, and after additional filtration was absolutely transparent. The oil has a specific taste.

Extremely beneficial because it is the richest source of heart-healthy alpha-linolenic acid (ALA), an omega-3 polyunsaturated fatty acid. Lowers cholesterol levels and is a preventative against heart disease, reduces high blood pressure, and increases the absorption of iodine. Can be used in salads, snacks, porridges, when baking bread and other dough products.

Mustard seed oil

In the notes to the performance table, we have already noted that we made mistakes in the manufacture of this oil. However, the error only led to a low oil yield, but did not affect its quality in any way. There were no difficulties when squeezing out the oil. Rather, on the contrary: the raw materials were processed too quickly. The cake came out quite greasy, and there was a lot of it. Hot-pressed oil is light green-brown in color, with a bright aroma, thin, cloudy even after sediment has formed, which has settled after several hours. In our rating, this oil took first place in terms of taste. We highly recommend dipping freshly baked white bread into this oil; it is incredibly delicious.

Mustard oil is widely used not only in cooking, but also for medicinal purposes. Mustard oil improves blood composition and the functioning of the cardiovascular system. It is used as a means of preventing atherosclerosis and as part of the complex treatment of hypertension. This oil is widely used in cosmetology and dermatology.

The photo shows the yield of mustard seed cake.

Sesame seed oil

There were no difficulties when squeezing out the oil. A small seed funnel has been inserted. Sesame showed the highest percentage of productivity among all seeds. Hot-pressed oil is light yellow in color, settles quickly, and after additional filtration is almost transparent. The oil has a pronounced taste and aroma.

Sesame oil contains many essential amino acids, polyunsaturated fatty acids, vitamins (E, A, D, B1, B2, B3, C) necessary for the human body, macro- and microelements (potassium, calcium, phosphorus, zinc, magnesium, manganese, silicon, iron, copper, nickel, etc.) and other valuable biologically active substances. It finds its use in cooking, especially in the preparation of Indian, Japanese, Korean, Chinese and Thai dishes. It is also used to treat diseases of the digestive tract, to support the health of the cardiovascular system, etc.

It should be separately noted that unrefined sesame oil cannot be used for frying. It should be added to ready-made dishes to enrich the aroma and taste. Note that the oil from roasted sesame seeds has an even more pronounced sweetish-nutty odor and is darker in color.

Peanut butter

There were no difficulties when squeezing out the oil. The oil was made from raw peanuts, which greatly influenced its taste. Hot pressed oil is light in color, cloudy and thick. The oil has a pronounced nutty taste and a sweetish aroma.

Peanut butter contains 50% to 60% omega-9 monounsaturated oleic acid and 15% to 30% omega-6 polyunsaturated linoleic acid. It finds its use in cooking, especially in the preparation of exotic and oriental dishes. This oil is used in the baking, confectionery and pharmaceutical industries. Peanut oil is even used in soap making. Used in cosmetology and dermatology. Improves the functioning of the cardiovascular and nervous systems, is used for diseases of the organs of vision, diabetes and blood diseases.

Walnut oil

Walnuts, like all large nuts, must be crushed into small pieces no larger than 5 mm in size. This is the only inconvenience when squeezing oil from large nuts. The oil turned out yellow, settled easily, and after additional filtration was absolutely transparent. The oil has a pronounced taste and aroma of walnuts. There is a pleasant bitterness in the taste.

The composition of this oil is also extremely rich. It is believed that the fatty acids in its composition support the nervous system and hormonal levels, help reduce stress levels and provide a good mood. The oil has anti-inflammatory properties. Can be used for both culinary and medicinal purposes. Used in cosmetology and dermatology.

Pine nut oil

There were no difficulties when squeezing out the oil. The oil turned out to be light yellow, cloudy and thick. The oil has a pronounced taste of pine nuts. Let us note right away: we don’t know who, under normal conditions, would think of squeezing oil out of pine nuts - they can be eaten just fine anyway. But, in fairness, we note that the oil has a concentrated taste; This oil is the quintessence of the taste of pine nuts. However, we had difficulties with the culinary use of this oil. Apparently, this oil should be used specifically for medicinal purposes, since cedar oil is a real natural storehouse of useful biologically active substances.

Almond oil

Almonds also need to be crushed into small pieces no larger than 5 mm. The oil turned out to be light yellow in color, settled easily, and after additional filtration was absolutely transparent. The oil has a pronounced sweet-nutty taste. The aroma is not very strong. We see the scope of application of this oil primarily in baking and making cakes and desserts, flavoring confectionery products, dough and creams. Almond oil is widely used in cosmetology.

conclusions

Based on the results of testing, we got the impression that Rawmid Dream Modern ODM-01 is a high-quality and easy-to-use device that opens up completely new horizons in a hobby for a person who is interested in cooking.

The device turned out to be very interesting, pleasant and easy to use.

The advantages include the laconic design of the product, the presence of rubberized feet that dampen vibrations and provide good grip on the surface. The undoubted advantage of the oil press is its low noise level.

The device copes with the assigned tasks perfectly. The power turned out to be sufficient for all test tasks - all available seeds and nuts were safely processed into aromatic and healthy oils.

There were no foreign odors when using the device. It only smelled of processed food. There were no problems with heavy splashing of the cake. Note that the cake must be compacted in the container, otherwise the container will quickly overflow. No vibration was noticed during operation of the device. Separately, it is worth noting the presence of a “reverse” mode, which allows you to freely remove the chopping auger and solve problems with clogging and compaction of raw materials.

Perhaps we did not find a single drawback of this product. It works quietly and presses effectively. The oil at the outlet does not overheat, so all useful vitamins and microelements are retained. The pulp can be used to prepare a range of wonderful dishes.

The materials from which this product is made are very stable, reliable and environmentally friendly. Separately, we note the presence of additional accessories that make the cooking process safe: a heat-protective glove and a cleaning brush.

pros

- Extremely easy to operate and assemble

- Low noise level

- Availability of cold and hot spin modes

- Obtaining high-quality fresh oil from any oil crops at home

- Making high-quality nut, low-fat sesame and flaxseed flour at home

Minuses

- Occasionally: cake gets into the finished oil

- Relatively high price

| Household oil press Dream Modern ODM-01 provided for testing by Rawmid |

What methods are used to extract oil from vegetable raw materials?

Vegetable oils, depending on the extraction method, are divided into two main types, each of which involves the use of a specific technology and appropriate equipment. These types, in particular, are:

- oils obtained by hot pressing;

- cold pressed oils.

Oil extraction area using double hot pressing

If the oil is produced using hot-pressing technology, then the pulp obtained after rolling is placed in special fryers, where it is heated to a temperature of 110° and at the same time moistened. At the same time, the mass is constantly stirred. After such preparation, the raw materials are placed in a screw device, where pressing is performed, as a result of which the oil is released. Vegetable oil obtained using hot-pressing technology is distinguished not only by its beautiful dark golden color, but also by a very bright aroma, as well as the taste of fried seeds.

Meanwhile, cold-pressed vegetable oil is considered more useful, since the raw materials for its production are not subjected to thermal effects, and accordingly, the product retains all its beneficial properties. For cold pressing of oil, a technology similar to that described above is used, only it does not include the stage of heating the pulpy mass that has passed through the rollers. Vegetable oil obtained using cold-pressing technology, although it has more beneficial qualities, has a shorter shelf life, and over time acquires a darker color and a bitter taste.

The main disadvantages of wooden oil presses

The disadvantage of a wooden press is its low productivity and low yield of finished products compared to a metal screw mechanism due to insufficient pressure on the raw materials during the pressing process. In an hour, using such equipment made of oak, you can get from 1 to 3 liters of live oil.

In addition, this form, when manipulated manually, makes it possible to obtain from raw materials no more than 20% of the total volume of a seed or nut. This shortcoming can be corrected by a hydraulic pump or electric motor, which can be connected to an oak mold to increase the performance of a home oiler.

When using one oak mold, it is difficult to obtain high-quality oil from different oilseeds, since the smell of one type can be transferred to another. To create a line of cold-pressed oil, you will need several oak molds for each type of raw material.

In order for the oak press to retain its qualities, it should be thoroughly cleaned after each use to avoid drying of the surface, rancidity and fungus on oil residues.

If you follow all the manufacturer's recommendations when working with an oak mold, you can obtain high-quality cold-pressed oil with a pleasant taste and preservation of all the beneficial properties of the finished product.

Production equipment

Even high-performance equipment designed for producing vegetable oil in industrial conditions is small in size and, accordingly, does not require much space for installation. Modern models are often mini-complexes for the production of vegetable oil, equipped with various working modules, which significantly expands their functionality.

Screw oil press, designed for cold continuous extraction as part of a production line or as an independent device

Thus, a typical sunflower oil production line operates according to the following principle.

- The raw materials must be dried, cleaned of various contaminants, and foreign impurities are removed from them.

- In a special module, the seed kernels are separated from the husks and crushed.

- The crushed seed kernels are steamed, and if we are talking about hot pressing, they are also fried.

- The oil is squeezed out from the prepared mass.

- The oil obtained immediately after pressing goes through a filtration stage, which significantly increases its purity.

- After filtration, the finished oil is poured into containers and sent for storage.

Do-it-yourself cold-press oil press - Metals, equipment, instructions

A business idea for the production of sunflower oil is based on an oil mill. From an investment perspective among professionals, the idea has not lost its popularity and is still in demand and profitable.

However, for many, the issue of income in this area is quite controversial, which is in vain. Let's take a closer look so as not to rely on the opinions of the majority, but to base our own conclusions on specific numbers and facts.

In this business you won’t be satisfied with just butter. The profit from its sale is hardly enough to reach the cost level. But we must not forget about the additional products obtained from the creamery, which bring a significant net profit.

Equipment for the production of vegetable oil

The production of vegetable oil at home is limited by financial resources. This type of business is attractive for its flexibility of rapid development.

You can start with a minimum set of production workshops, and then expand with additional equipment for the production of by-products. Thus, the range expands, and profits grow progressively.

A full-fledged plant for the production of vegetable oil must be WASTE-FREE!

The minimum configuration of the line consists of the following equipment:

- Mini oil press. The power of such an oil press is 2 kW. per hour, 220 V. Capacity = 13 liters per hour. Press weight 45 kg. The average cost is $800.

- Food filter. The oil must be cleaned using a special filter with a capacity of 0.5 m2. at one o'clock. Productivity = 5 liters per hour. Filter weight 100 kg. Cost 1100-1300 dollars.

By and large, these two components are already quite enough to produce and sell two products: good sunflower oil and meal. By the way, meal from oilseeds is widely used to feed animals and birds in agriculture. Therefore, it sells much faster than the main product. In addition, there is much more of it at the output of processed raw materials - 65%.

But if you plan to earn more, then you should think about expanding production. Additional technological equipment for the production of vegetable oils allows us to obtain several products from one oil mill at once:

- Sunflower oil, raw.

- Fried sunflower oil.

- Technical drying oil.

- Circles of the crown.

- Shrot.

- Biochar from fuz.

- Biofuel briquettes made from husks.

A creamery, even at home, can produce 7 types of products if the necessary equipment is available. It is worth paying attention to other advantages of business.

Storing vegetable oil in production does not require special conditions. A dry room, protected from sunlight, with an air temperature ranging from +5 to +15 degrees, can store unrefined products for 5 months.

You can use different raw materials to produce vegetable oils. For example, seeds: sunflower, soybean, flax, pumpkin and many other oilseeds. This advantage also has a positive effect on expanding the range and increasing sales. You can repurpose your business for other products without upgrading the line.

Technology for the production of vegetable oils by pressing

Production flow diagram:

The technological line for the production of vegetable oil is equipped with:

- Separator for coarse and fine cleaning of grain and seeds.

- Hulling machine for sunflower seeds and other oilseeds.

- Twin-screw oil press extruder with heating elements for mint up to +50C (for a quick start).

- Filter for purifying vegetable oils from fuses (food grade).

- Press for squeezing fuses (fusodka).

- Press for forming crown circles.

- Press for briquetting sunflower husks and other seeds.

- Auxiliary equipment, structures and devices: bunker; pneumatic loader; weight; buckets, shovels, etc.

We will conduct a simple training workshop on the technology of production of vegetable oils.

Waste-free production using the cold pressing method during squeezing occurs in several successive stages:

- Rough cleaning of oilseeds (raw materials). From coarse impurities that can damage technological equipment (stones, wire, etc.).

- Fine cleaning of raw materials. From small premiums that may affect product quality (dust, weed seeds, etc.).

- Peeling of the seed coat. This process is carried out immediately before cold pressing. In the waste-free production of vegetable oil, the husks are used as biofuel, and the kernels are used as oil and fluff. The shell of oilseeds can be removed using different types of equipment in different ways: rubbing the shell on a specially corrugated surface; splitting the shell by impact; compression under pressure.

- Pressing kernels through a screw oil press to obtain oil and flour. At this stage we get 2 semi-finished products.

- Filtration. The process of filtration of the crude product obtained only from the press occurs using filters based on filter fabrics. For example - lavsan. Under air pressure, the liquid hits the surface of the fabric and passes through it, leaving fuses on the surface.

- Fuzz extraction. The fuzz itself, obtained after filtration with lavsan, contains 80% fat content. It is rational to squeeze it out in the same way. The production of vegetable oils by pressing ends at this stage. Then by-products are produced.

- Hot pressing of the top. It is better to press the flour immediately upon exiting the oil press, while it still retains the temperature from the pressure.

- Briquetting. In order to profitably and quickly sell seed husks, you need to produce a popular product from them - biofuel. Naturally, this process will require special equipment.

As for the organization of labor in production on such a line, everything depends on the workload of the workshop with raw materials for processing and the timing.

If the load is minimal (for example, 1 ton per day), then even 1 employee is enough.

As soon as the sales market for all types of goods produced at the oil mill is established, additional labor will be needed in order to invest on time with good production volumes.

Vegetable oil production waste and its use

A homemade butter churn for sunflower oil production pays for itself faster if all its advantages are rationally used. Don't underestimate the importance of waste management.

At the exit from the oil press we obtain vegetable oil that is unrefined and black in color. It should either be settled or filtered from the fuses in a special way.

Fuzz is small particles of husk and dust with a large content of residues of the produced product, which remains after filtration. The best method for removing waste is considered to be a fabric filter.

You should not spare money on the filter, and then it will efficiently clean the product and prepare it for presentation. When the oil is cleared, the collected fuses can be pressed on a fusodushka. From it we can still get 20% bio-coal + 80% vegetable oil.

Homemade oil press

Questions can only be asked after registration. Please login or register.

Dear forum users. In the “Homemade Agricultural Equipment” section there is a topic “homemade feed extruder” in which a question was asked about an oil press. For me, setting up a homemade oil press is currently a sore subject. In this new topic, I propose to combine all ideas and thoughts regarding oil presses, as well as discuss all the problems that the owner of a homemade oil press faces.

Dear forum users. In the “Homemade Agricultural Equipment” section there is a topic “homemade feed extruder” in which a question was asked about an oil press. For me, setting up a homemade oil press is currently a sore subject. In this new topic, I propose to combine all ideas and thoughts regarding oil presses, as well as discuss all the problems that the owner of a homemade oil press faces.

Yes, I support it, at one time I also made an oil press (screw) on my own. Even though it was not my invention, but simply a copy of the factory one, but it was made with my own hands and has been working for many years, over time I will be able to share the drawings if anyone is interested.

My channel - https://www.youtube.com/user/pppatriot You are welcome to join the viber group “Farmers of Ukraine”, write in private.

Good afternoon, Alexander. Then I want to ask you, as a person who has assembled a working copy of the oil press. I have a screw with a diameter of 85 mm, the internal diameter of the squeezing chamber is approximately 85.9 mm (that is, the gap between the screw and the chamber on each side is almost 0.5 mm). Oil holes - 5 mm. There is a spiral groove inside the squeezing chamber (for oil). Problems that arise: the cake is wound on the auger in a pigtail and does not come out of the oil press, the seeds are not taken out of the hopper by the auger, and as a result the press becomes very hot. At the end of the oil press there is a conical exit for the cake (like on an extruder, the diameter of the hole is adjusted with a bolt). Of course it’s difficult without a photo (but I still can’t figure out how to post it on the forum), but the general picture is outlined. Tell me, what's the problem? Ready to send a photo with dimensions.

Good afternoon, Alexander. Then I want to ask you, as a person who has assembled a working copy of the oil press. I have a screw with a diameter of 85 mm, the internal diameter of the squeezing chamber is approximately 85.9 mm (that is, the gap between the screw and the chamber on each side is almost 0.5 mm). Oil holes - 5 mm. There is a spiral groove inside the squeezing chamber (for oil). Problems that arise: the cake is wound on the auger in a pigtail and does not come out of the oil press, the seeds are not taken out of the hopper by the auger, and as a result the press becomes very hot. At the end of the oil press there is a conical exit for the cake (like on an extruder, the diameter of the hole is adjusted with a bolt). Of course it’s difficult without a photo (but I still can’t figure out how to post it on the forum), but the general picture is outlined. Tell me, what's the problem? Ready to send a photo with dimensions.

How hot does it get? Before starting, I heat my press with a blowtorch to 100 degrees or more (the water bounces off and evaporates), but it’s very difficult to start it when it’s cold. I don’t remember the dimensions, but somewhere within the same limits, the output is also within 5-6 mm and is adjustable with a bolt. In a couple of days I’ll be in the village and I’ll be able to clarify (the drawings are also there)

Source: fermer.ru

Make your own oil press

Since the market for wooden oil presses is just beginning to emerge in Ukraine, I think it is important to know what you, as consumers, would like to receive. Therefore, I invite everyone here to speak out about the desired characteristics of the press: desired price, size, weight, performance, etc. etc.

In this regard, I provide here information about the various configurations and designs of an oil press that are possible today. Let's start with the fact that oil presses, depending on the desired performance, can be manufactured with 1.5 l, 3 l and 6 l press barrels. Everything is clear here: the larger the volume of one bookmark, the greater the productivity of the press. But a larger barrel volume leads to a larger piston diameter and, as a result, the required press pressure increases as a quadratic function of the piston diameter. So for a 1.5 liter barrel with a piston diameter of 100 mm, 12 tons of pressure will be sufficient for most crops, for 3 liters - 30 tons and for 6 liters - at least 50 tons. I’ll say right away that a 3L barrel, in my opinion, based on my operating experience, is optimal both for home use and for small industries, and also the entire press installation with such a barrel will have the best price/performance ratio. Another very important parameter is the type of hydraulics that will be used. Two versions are possible - using a hydraulic jack and using more professional hydraulics consisting of a hydraulic cylinder with a pressure gauge and a hydraulic pump (with manual, electric or pneumatic drive). The use of a jack allows you to make a press installation cheaper by almost 50% than with professional hydraulics and, in principle, I do not see any obstacles to using a press in this design for home purposes, as well as for small production. The main advantage of the jack is its low cost (it is 4-5 times cheaper than a hydraulic pump/hydraulic cylinder pair of similar load capacity). At the same time, the main disadvantage of using a jack is the overall dimensions, the weight of the press installation, and in some cases it is necessary to apply more physical pressure to its handle than to the hydraulic pump (which, however, can be easily eliminated with the help of an additional lever). The use of a hydraulic pump/hydraulic cylinder pair makes it possible to make the installation as compact, lightweight and more convenient to use (the presence of a pressure gauge, the ability to change the applied force on the handle). The question about the lifespan of the jack and the hydraulic pump/hydraulic cylinder pair largely depends on the manufacturer of a particular product, but other things being equal, the hydraulic pump/hydraulic cylinder pair will most likely initially have a longer life, since it is specifically designed for presses, which implies more regular use than using a jack. However, the use of a jack is more than compensated by its low cost and the low cost of its maintenance (for example, the cost of replacing all seals, oil seals, cleaning valves, changing the oil on a 30t jack costs about 400 UAH and after that the jack becomes like new).

Source: vk.com