The problem arises when the welding technology itself is violated or at the preparatory stage. Generally, there are three places where lack of penetration can occur.

- Along the edge separating the base and deposited metal;

- Between layers of adjusted seams;

- At the root of the seam.

Below we will describe 5 problematic issues in which lack of penetration may occur at different stages of work, its causes and practical ways to combat it.

Heat supply

Low voltage and incorrectly set parameters of the welding machine often cause lack of penetration, when the formation of sufficient heat for full penetration is not ensured. If such a welding defect occurs at the end of the weld or at its beginning, then this indicates a decrease in the penetration depth and instability of the thermal process.

Lack of penetration can be caused by moving the electrode too quickly. At high welding speeds, the edges do not have time to melt. Ultimately, the shape and outline of the seam will not completely match the shape of the groove.

Incorrect welding sequence when applying multi-layer welds also provokes lack of penetration. If you do not completely remove the slag between the individual layers, you are guaranteed to get such a defect and a weak weld.

Refractory oxides

The likelihood of lack of penetration increases when welding alloy steels and alloys containing elements that form refractory oxides, which are in a solid state at the time of upsetting and, for one reason or another, remain in the joint.

If the welding mode is incorrectly selected, slags and oxides do not have time to float to the surface and remain in the weld metal in the form of non-metallic inclusions.

The ductility of welded joints is greatly influenced by the characteristics of oxide inclusions. For defective connections consisting of low-carbon steel, oxide inclusions (for example, Fe3O4) at fracture sites have rounded outlines (see figure) due to the relatively low melting temperature. When testing joints with such oxide inclusions for bending (dark areas in the figure), a sharp decrease in the bending angle is observed.

Rice. Electronic microfractograms of fractures of joints welded by continuous reflow. Steel 20. Solid dark areas of oxides are visible

In addition, welds may be subject to atmospheric contamination. The ingress of moisture or the presence of an oxide film can interfere with the process of fusion of metals and can greatly deteriorate the quality of the weld. Therefore, thorough preparation of edges before welding is recommended.

Correct angles

The angle of the electrode and the torch play an important role in achieving good weld quality. During operation, make sure that the electrode is at the correct angle and that the torch moves at a moderate pace. These are important components of success. Otherwise, a large displacement of the edge of the electrode from the axis of the junction of the edges in one direction or another will cause an uneven distribution of the molten metal. In this case, one of the edges does not melt, but is only covered with melt on top.

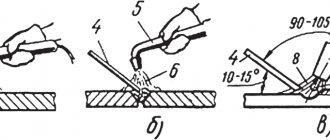

Often you have to deal with fillet welds. To avoid lack of penetration during welding, the edges of the welded product are welded “in a boat”, and when tilted at an angle of 30 or 60° - in an asymmetrical “boat”. Welding is carried out at increased values of welding current, both in direct and reverse polarity of the current. Welding with reverse polarity is performed with a short arc, which may result in undercuts. The position of the electrode when welding should correspond to that shown in the figure below.

Rice. Position of the electrode when welding “in a boat”: a - welding in a symmetrical “boat”; b - welding in an asymmetrical “boat”; c - spatial position of the electrode

An important point: a large diameter electrode, as well as incorrectly selected polarity, very often result in slag getting into the gaps between the edges.

Preparation of joints

Well-prepared, clean edges of the parts being welded are an integral part of a perfect weld. If the parts to be joined are not aligned in the same plane, negative changes in the form of lack of penetration occur in the root zone of the weld. Too small a gap between the welded edges, distortions and banal displacement provoke such a defect. Therefore, it is necessary to understand what type of cutting to use, observe the geometric dimensions of the edges, and make the appropriate blunting (if necessary). Do not forget about the need to degrease and remove traces of dirt, paint, rust, and scale.

Correct voltage and inductance

One of the most important reasons for lack of penetration is incorrect welding mode. The inexperience of the welder, violations and errors when setting up welding equipment are manifested in the low strength of the welding current for this thickness or type of metal being welded.

Welding with direct current may be accompanied by instability and deflections of the arc due to the influence of magnetic fields arising from excessive induction. In addition, under the influence of electromagnetic pressure, oxide films partially remain on the surface of the edges, preventing their full penetration.

To reduce the likelihood of lack of fusion and splashing of molten metal, a compressive force is required. It appears in the conductor during a short circuit during MIG / MAG welding. To minimize such defects, appropriate adjustments to the voltage parameters and the introduction of controlled inductance into the welding current source are required.

In addition, the operation of old or faulty welding equipment leads to fluctuations in the current and voltage of the welding arc during welding.

Elimination of defects of this type usually occurs by increasing the power of the welding arc, reducing the length of the arc and increasing its dynamics. To identify and eliminate a defect, a preliminary inspection is first carried out, followed by internal control. If necessary, it is possible to completely remove defective areas of seams with lack of penetration. They are cut down or planed, cleaned and prepared for re-welding.

Reasons for lack of penetration

The most common cause of lack of penetration is considered to be improper welding mode. This could be either insufficient welding current or increased welding speed. It is clear that in both cases there is a lack of energy for high-quality melting of the edges. Such conditions most often contribute to incomplete penetration of the weld root.

In cases where the electrode is displaced from the center line of the joint, insufficient fusion of the weld edge occurs. The seam reaches the root, but one of the edges does not touch it. Cases of lack of penetration between layers occur when each layer is not thoroughly cleaned. Lack of penetration can be caused by improper cutting of the edges of the parts being joined: small gap, small bevel angle, large bluntness.

Weld Porosity

You don't need to be a deep theorist to understand the detrimental effect of porosity on the mechanical strength of a welded joint. Some products, in addition to mechanical strength, have increased requirements for impermeability. These are all kinds of vessels, technological baths, ship hulls. For such products, a special approach begins when the metal is stored in warehouses. They try in every possible way to avoid cases of contamination or corrosion of both metal sheets and welding wire. The quality of the electrodes and the presence of welding slag can affect the occurrence of porosity in the welded joint.

To eliminate the influence of electrodes on the porosity of the weld, it is recommended to calcinate them before welding. This procedure reduces the amount of moisture in the coating and promotes charring of organic matter. High-quality electrodes must have the following qualities:

· manufactured in strict compliance with the recipe;

· manufactured without violating the requirements of technical documentation in relation to the components;

· calcined before use.

Electrodes with a basic type of coating are calcined at a temperature of 380 – 420 C0. It is recommended to cook them 2 – 3 days after calcination. Exposure is necessary to stabilize the moisture content of the coating. Welding is carried out with a short arc, which provides sufficient protection from atmospheric oxygen.

Most often, porosity is caused by the presence of hydrogen, carbon monoxide and nitrogen in the metal. The development of porosity is facilitated by an increase in gas dissolved in the metal as the temperature of the melt increases. If the amount of gas in the metal exceeds its amount in equilibrium, it will begin to be released into the atmosphere. Gas bubbles from the lower layers of the metal do not have time to escape into the atmosphere before solidification and remain in the weld metal.

Lack of weld penetration

Author:

Igor

Date of:

13.01.2018

- Article

- Photo

- Video

In the technological process of welding, lack of penetration of the weld appears, which worsens the technological properties of the material. Assessing the acceptance of work requires checking welded joints, where high quality surface treatment of the connected planes is necessary. All formations on the surface that have a non-uniform structure and shape are referred to as a weld defect of lack of penetration. In turn, there is a division of degrees and levels of lack of penetration, which have the following characteristics of defects:

- Hot or cold microcracks.

- Hot or cold macro cracks.

- Lack of penetration of the root of the weld.

- Visible pores.

- Inclusion of various groups.

In general, welding work, regardless of the level and complexity, allows for the appearance of lack of penetration, but at the same time, it is necessary to eliminate existing defects using available means and technologies.

Example of lack of penetration of a weld

Content

- Internal and external defects in welds

- External weld defects

- Internal weld defects

- Seam formation defects

- Lack of weld penetration

- Weld undercuts

- Weld burns

- Weld beads

- Craters and shrinkage cavities

- Pores in welds

- Lack of fusion of welds

- Slag inclusions in deposited metal

- Cracks in welded joints, types of cracks

- Types of defects in welded joints, depending on their shape

- Types of welding defects, depending on the reasons for their occurrence

- Acceptable and unacceptable defects in welds

Defects in welds are, first of all, various discontinuities in the weld metal that impair its quality. When assessing the weldability of steel, it is mainly based on the fact that the weld metal must be solid. And all formations that make the weld inhomogeneous are considered to be defects. The following types of weld defects are distinguished: micro- and macrocracks (hot and cold), lack of penetration, pores, various inclusions.

Methods for checking for defects

It is possible to visually determine the location only if the welder has sufficient experience in this field and knows the reasons for the lack of penetration of the weld. Defects can appear anywhere, and the technician needs to correct the problem in a timely manner using approved methods for welding technology. The presence of a defect can subsequently cause destruction, reduce the mating of welded areas, and also lead to failure of the structural element.

The main reasons for the lack of weld penetration of the problem that has arisen are the following criteria:

- The welding current is low.

- The electrode moves quite intensively and at high speed.

- Very large length of the arc size range.

- For the edges there is a small bevel angle.

- There are obvious flaws in the edges with a large angle of bluntness.

- The welding elements for the edge are either moved incorrectly or significantly displaced.

- There is a small gap between the located edges.

- During the welding process, an electrode with a large diameter is used, which is not intended for the welding stage.

- Slag flows between the welded edges.

Thus, lack of penetration of a weld is a defect that poses a particular threat and danger when carrying out further work on structural products.

Lack of Cooking Terminology

Among specialists, there are special interpretations that indicate what it means to lack fusion of a weld - this is a visible or hidden area of the joint where there is no fusion effect, which is mandatory in this situation. Most often, structural lack of penetration of a weld can be found in the root part of the joint, in the edges between joints, and between adjacent parameters of the layers of the weld being deposited along the edge.

Visible lack of penetration on the part

Further, the determination of lack of penetration of a weld indicates that the working cross-section of the structural joint of the seam is significantly reduced. In turn, this leads to a natural decrease in the performance of the existing welded joint.

Technological illumination of welds is recognized as a kind of stress concentrator, as a result of which cracks of varying depths and hardness appear. A decrease in the corrosion resistance of the finished welded joint is revealed.

Porosity, main points of defects

An equally important element of the defect of lack of penetration of a weld is the identification of its porosity. The appearance of this structure is caused by small bubbles that form as gases in the metal. As a rule, the structure has a spherical, or approximately circular structure. For carbon steels, lack of penetration in these places is not spherical, but tubular in shape. Initially, spherical formations appear in the liquid metal during welding. During a certain welding time, or rather intense gas formation, not all involved bubbles of the technological process have time to reach the surface. Some part remains inside the welded joint structure. The overall volumes and sizes of such “balls” vary in various ranges, from microscopic to full-fledged large spheres with a diameter of 2-3 mm. If gas diffusion occurs, the spheres begin to grow even larger inside the welded joint until complete solidification.

Such defective phenomena can form chains, groups and other textures. In general, in order to correctly use the recommended method for eliminating lack of penetration of a weld, we pay attention to the following causes of the problem:

- The presence of gas compounds that do not have time to escape, and crystallization of the structure occurs.

- The interaction of iron oxide with carbon, resulting in the formation of carbon dioxide and carbon monoxide.

- There is moisture in the flux or during the automatic welding process.

- The occurrence of rust, both at the ends of welded technological connections and on the wire.

Appearance of cracks

This is an additional defect of lack of fusion; the criterion is associated primarily with the formation of microscopic or macroscopic components of intercrystalline destruction, as a result of which small cavities with microscopic opening parameters are formed. The presence of residual stress phenomena in the connected areas leads to the fact that in the future cracks can expand at an unprecedented speed to unprecedented sizes. This process is very dangerous, and in some cases can lead to disastrous consequences for the operation of significant metal assemblies and components. Causes of cracks:

- There is a place of increased shrinkage stress where the tensile strength of the metal is exceeded.

- There is a rigid mode of fastening of the metal elements being welded.

- The so-called martensite effect occurs in the metal, which is characteristic of the phenomenon of structural stress.

- All metals have a high content of sulfur, phosphorus, and carbon.

- Welding activities took place at very low temperatures.

- A large number of seams are concentrated in one area, which cause complex conjugation.

Groups of lack of penetration according to GOST

There is a unified classification of standards for lack of penetration of defects in welds, which are reflected in the current regulations GOST 30242-97, which defines 6 main groups or zones characteristic of each process and metal

Hello student

Defects in welded joints are those shortcomings that reduce the strength of the joint and, consequently, the reliability of the entire structure. The main types of defects in welded joints are lack of penetration, incomplete seam, burnout, penetration and burn-through, undercuts, sagging, porosity, cracks.

Lack of penetration.

Lack of penetration is the lack of connection between the base and deposited metal or insufficient penetration of the deposited metal into the base.

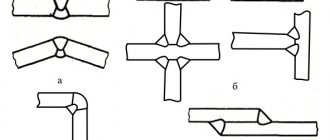

An example of lack of penetration is shown in Fig. 395, a, b.

The cause of lack of penetration in all types of welding can be contamination of the surface of the parts being welded; in arc and resistance welding, insufficient welding current; in gas welding, the use of an inappropriate torch tip; in gas and arc welding, premature introduction of filler material into the weld pool or too high a welding speed. Lack of penetration is the most serious defect in welds.

Incomplete seam

. The weld seam may be below the surface of the sheets being welded. Insufficient filling of the seam with metal is sometimes called under-welding (Fig. 395, c). The reason for under-welding in arc and gas welding is uneven welding speed or a violation of the uniform supply of filler material. An incomplete weld can be easily corrected by additional surfacing.

Burnout

in welding, they call strong oxidation of the deposited and adjacent base metal; As a result of burnout, the strength of the seam decreases. The cause of burnout in gas welding is excess oxygen, while in arc welding it is an excessively long arc. Overburning is the result of a completely incorrect welding mode and is as serious a defect as lack of penetration.

Melting and burning.

Penetration is the through melting of the base metal with good connection of the welded parts. The reason for penetration in all types of welding is excess heat supplied to the welding site.

Local melting of the base metal by an arc, accompanied by the formation of an empty cavity or without the formation of one, is called burn-through. Burns are observed when welding parts of small thickness.

Undercuts.

Melting or burning out of metal along the boundaries of the weld is called undercutting (Fig. 395, d). Undercut weakens the strength of the welded joint, especially under dynamic loading. The reason for undercuts is the retention of the arc or flame of the burner in one place or uneven supply of filler material.

Beads are the absence of a connection between the edge of a weld and the base metal when there is good connection throughout the rest of the weld. The reason for the sagging may be the dense melting of the filler material.

Porosity

weld seam is called the presence of gas bubbles, fistulas, and slag inclusions in it. The cause of porosity is contamination of the base and filler material.

Cracks

are caused by large internal stresses arising in the base and deposited metal. The cause of large internal stresses can be improper welding: lack of a gap between the parts being welded, a large number of welds in a small area of metal, lack of heating and heat treatment to soften internal stresses. In some cases, cracks can be corrected by welding or covering with overlays welded to the product.

Craters

are called depressions in the weld seam during arc welding. Craters are caused by arc breaks. Unwelded craters in the middle of seams made by manual or automatic welding (due to arc breakage) are also serious defects, since they can serve as sources of crack formation during the operation of the welded structure.

Welding control methods

Technical control of welding work cannot be limited to assessing the degree of quality of work already performed, but should be extended to the work process itself and even to preparation for it. Therefore, with the correct formulation of the matter, technical control should be preliminary, operational - during the welding process itself, and acceptance - after the completion of welding work.

Preliminary control

consists of checking the quality of the base and filler metal, coatings and fluxes, checking the correctness of the seams, the accuracy of the edges and compliance with the required gaps. Preliminary control also includes checking the qualifications of the welder.

Control during the welding process

(operational). During the welding process, it is necessary to monitor the strength of the welding current or the use of appropriate torches, the thickness of the deposited layer, the cleaning of the weld surface from scale and slag in the case of applying the next layer, and the correct conduct of the process as a whole.

Control upon completion of work.

To identify welding defects, external inspection, X-ray examination, magnetic testing, mechanical testing, and metallographic examination are used.

Visual inspection. After tacking and welding, the products are inspected. Inspection checks the correct dimensions of the seam, as well as its quality. If places suspicious for cracks are found, such places are washed with alcohol and etched with a 10% aqueous solution of nitric acid, after which the surface of the seam takes on a matte appearance. The seam surface prepared in this way is viewed through a magnifying glass.

Transillumination with X-rays. This control method is based on the property of X-rays to penetrate differently through different media. In a weld, X-rays are absorbed by the metal to a greater extent than by slag inclusions, gas bubbles, and cracks; also, the thicker the metal layer, the more rays are absorbed by it.

There are two methods of X-ray inspection - visual and photographic. The first is to observe the transmission pattern on the screen, the second is to photograph this pattern. The photographic method gives a more reliable result.

A benign suture gives an even darkening of the film, and various defects create deviations from this character of the radiograph; Thus, lack of penetration is revealed by the sharpness of the boundary between the deposited and base metal; slag inclusions and base bubbles appear on the negative as darker than the base metal, etc.

In fig. 396 shows an X-ray image of a V-shaped weld with lack of penetration in the lower part.

X-ray testing is used to establish the correct welding conditions for parts that produce a large percentage of defects, as well as in cases where it is difficult to judge the quality of welding by external inspection; It is also advisable to use this control method during trial welding of complex and especially critical parts.

The length of the visible section of the seam usually does not exceed 300 mm. In some cases, X-raying of 10, 20% or more of the welds of a given product is required.

Magnetic control.

In magnetic testing, the weld seam is covered with paper on which magnetic iron powder is sprinkled. When a magnetic flux is passed through the welded joint under study, the powder particles will be located in the direction of the magnetic lines. If there are slag inclusions, lack of fusion, or cracks in the weld seam, the resistance of the seam to the magnetic flux in places of such welding defects will be greater than in solid metal, and the distribution of magnetic lines will be uneven. The uneven distribution of field lines in the material under study is reflected in the distribution of powder particles on the paper and makes it possible to determine the presence of defects in the seam under study.

Magnetic testing is also carried out using devices whose effect is to magnetize the test compound with an electromagnet. The presence of defects (lack of penetration, slag inclusions, gas bubbles, cracks) is reflected in the degree of magnetization and is detected by the sound strength in the handset or by the indication of the arrow on the device.

Magnetic testing gives good results in the case of butt joints of sheets up to 25 mm thick; It is not used for overlapped and tee seams.

Mechanical tests.

The deposited metal and welds are subjected to tensile, impact and bending tests, for which samples are prepared, the shape and size of which must comply with current GOSTs. Mechanical tests of finished products must be carried out under loads that provide the necessary margin of safety of the welded part during its operation, but without unnecessary overloads. As a result of loads significantly exceeding the load of the part in operation, small cracks may appear that are not visible during testing, but can lead to destruction of the product during its service.

Welded vessels, boilers, pipelines are tested for strength by hydraulic pressure. Leaks detected by such tests should not be eliminated by caulking, since the caulking areas subsequently quickly corrode; areas of the seam with detected leaks must be cut out, welded and subjected to a new test.

Metallographic control.

Examination of macro- and microsections of the metal of a welded joint makes it possible to judge the quality of the welded metal and identify the structure of the transition zones. This method also detects all types of welding defects.

Systematically carried out metallographic control is a reliable means of establishing a rational welding regime under certain conditions of welding production.

Safety precautions during welding work

Safety precautions during welding work are regulated in detail by relevant instructions and rules; We will focus only on the most important and general requirements.

When gas welding, proper handling of oxygen cylinders is necessary. Cylinders should not be allowed to be used if their periodic testing period has already passed; this period must be indicated by a mark applied by the technical inspection. Gas-filled cylinders should not be subjected to shock or heat, as sparks generated upon impact can cause the cylinder to explode. The reducer screwed onto the oxygen cylinder must be free of traces of oil and grease. Cylinders should not be carried by hand to avoid shock if the cylinder is dropped. The gearbox must be kept clean, since the friction of dust particles and rust can also cause a spark, which leads to the ignition of the gearbox metal in an oxygen atmosphere. Heating of the valve and gearbox can only be done with hot water or steam, avoiding the use of burner flames.

Acetylene generators must be kept clean and kept at least 10 m away from the burners. Gas supply hoses must not leak gas. The water seal must always be filled with water and be under constant supervision of the welder. The welder must ensure that the torch taps are closed tightly and must not let go of the burning torch or place it anywhere.

All parts of electric welding installations that are energized must be reliably grounded with a copper wire with a cross-section of at least 6 mm2. Touching live parts of the welding machine with bare hands is only allowed when the switch is turned off. For all electric welding work inside vessels, tanks and reservoirs, it is recommended to use rubber mats or rubber galoshes.

To protect your eyes from damage from light rays during gas welding, you must use glasses with dark-colored protective lenses; When arc welding, protective glass must be reinforced in a shield or helmet that protects not only the eyes, but also the welder’s face from burns.

To protect against drops and splashes of molten metal, the welder must use gloves and wear protective clothing that fits tightly to the body.

In rooms intended for welding work, it is necessary to arrange ventilation to ensure the removal of harmful gases, and the storage of flammable materials must not be allowed.

Workers involved in cleaning seams from scale and slag must be equipped with glasses to protect their eyes from contamination.

Welding work should not be allowed on products under pressure from liquids or gases.

Live welding wires and gas hoses must not be laid together.

The place where welding work is carried out must be fenced with partitions or portable shields.

Download abstract: You do not have access to download files from our server. HOW TO DOWNLOAD HERE

Archive password: privetstudent.com

What are the types of weld defects, classification by groups

When carrying out welding work, it is necessary to take all measures to increase the quality of the formed seam. The service life of the product depends on the degree of quality. Defects in welding seams can occur under the influence of a number of factors, including such as non-compliance with technology, lack of necessary welder qualifications, negligence, and incorrect operation of equipment. Depending on the degree of deviation of parameters from the norm, acceptable and unacceptable defects are distinguished. All standards are defined by GOST 30242-97.

Types of defects in welded joints, depending on their shape

Existing weld defects can be divided into two types based on their shape. These are plane defects and spatial defects. Planar defects include hot and cold cracks and lack of weld penetration.

Spatial include various slag inclusions, pores, gas bubbles and all types of incorrectly executed welds (undercuts, burns, incorrect configuration, displacement, etc.).

Planar weld defects pose the greatest danger to the joint as a whole. And the existing types of cracks, depending on the temperature at which they appear, can be divided into several more types, which are mentioned above in the text.

Group 1. Cracks

Defects of type 100 or “E” are considered unacceptable. In the zone of crack formation, the structure will certainly collapse. The rupture occurs in the seam itself or in the immediate vicinity. When a crack occurs, the opening may be minimal, but the action of loads leads to rapid destruction. According to statistics, this type of defect appears when welding alloy and carbon steels. The risk of cracks increases when the weld cools quickly.

The reason for the formation of cracks is the presence of carbon, silicon, sulfur, nickel or hydrogen in the metal. If the technology is not followed, excessive stress occurs in the seam area. To eliminate cracks that have already formed, you must first drill their ends. Then the crack is removed by planing, and the place where it is located is cleaned and welded again.

Cracks can be classified by origin; they are divided into cold and hot.

- Cold cracks form after the seam has cooled, when the temperature is 300°C degrees. Such defects can manifest themselves after quite a long time. Phase transformations that occur during metal crystallization sharply reduce strength indicators. Atomic hydrogen does not completely evaporate and causes cracks to appear. This can only be avoided by ensuring protection of the weld pool.

- Hot cracks occur at high temperatures (1100-1300°C degrees). During crystallization, a process occurs that is the opposite of linear expansion. Pulling the metal together causes it to rupture. This type of crack is directed not only along the seam, but also across it. Discontinuities form at the boundaries of crystal grains.

Cracks can be divided by size. Macroscopic cracks (100; E) are assessed visually. Microcracks (1001) appear only when using magnifying devices. Often it is necessary to use fifty times magnification to observe the defect.

Group 2. Pores

Pores in metal are cavities that are filled with gas. They begin to form when the metal is in a liquid state. At this time, the process of gas formation is observed, but only some of the bubbles come out. The size of the cavity varies from micrometers to several millimeters. Sometimes entire clusters of pores are observed, forming shells. Usually the cavity has a round shape.

Pores can appear for a number of reasons. The first of them is the low quality of cleaning surfaces from contamination. Particles of rust, scale, and oil may remain on the edges. At high welding speeds, the gas simply does not have time to leave the liquid substance, remaining in it in the form of bubbles. As already noted, the tendency to form pores is especially pronounced when working with carbon steels.

Violation of welding technology will lead to negative consequences. Particular attention should be paid to climatic conditions. High humidity affects the state of the flux. The appearance of pores leads to the fact that after preliminary gouging the surfaces have to be cleaned and welding repeated.

The cavity (200; A) can be of any shape with rounded corners. The bubble contains hydrogen, nitrogen or carbon monoxide. Gradually the metal hardens and a pore forms. Often these two concepts are separated, since the pore has a spherical shape, and the cavity is irregular. But in this classification these defects are identical. A series of pores distributed evenly (2012) is a defect observed when working with non-ferrous metals. Its variety is a chain (2014) and a cluster of pores (2013).

A special case of a pore is a fistula (2016; Ab). The index shows that this is a defect of the same type, but the fistula is represented by a tubular cavity that penetrates the suture right through. The reason for its occurrence is high humidity. The shape of the fistula depends on the gas released. Sometimes a fistula occurs when the metal overheats or an accidental short circuit caused by contact of a tungsten electrode with the surface. Such a defect must be corrected by complete removal of the metal followed by overcooking.

A crater, marked as defect 2024 or “K,” forms a shell at one edge of the weld bead. Usually appears as a result of a sharp detachment of the electrode. If in appearance the crater does not have cracks, then upon closer examination they most often appear, so such a defect must be eliminated.

Types of welding defects, depending on the reasons for their occurrence

During fusion welding, defects in welded joints that arise, depending on the reasons for their occurrence, can be divided into two types. The first type of defects is associated with metallurgical processes during welding and with thermal phenomena that occur as a result of the formation and crystallization of the weld pool and cooling of the welded joint. These defects include hot and cold cracks in the metal and heat-affected zone, pores in the metal, non-metallic inclusions, as well as non-compliance of the properties of the deposited metal and the heat-affected zone with the specified parameters.

The second type of defects includes their types, the cause of which is a violation of the selected welding modes, violations during the preparation of welded elements and during their assembly, malfunctions of welding equipment, insufficient professionalism of the welder, as well as other violations of welding technology. Defects of this type include the discrepancy between the actual dimensions of the seams and the required ones. These are defects such as lack of fusion, undercuts, unfilled craters, burns in the metal being welded.

Group 3. Solid inclusions

Foreign particles reduce the strength of the seam and act as localization sites for excessive stress. If solid inclusions are detected, gouge until healthy metal appears, and then repeat the welding process. Defect 300, which consists in the entry of metal particles into the weld zone, in the presence of at least one acute angle, is called an acute inclusion. An example of such a defect is a slag inclusion (301; Ba), a flux inclusion (302; G), an oxide inclusion (303; J) and a metal inclusion (304 H).

The slag inclusion is divided into linear (3011), isolated (3012) and others (3013). Slag, which is formed as a result of melting of an additive or flux, always floats to the top. But if the technology for guiding the electrode is violated or at high welding speeds, it often remains inside the molten metal. For work in a protective gas environment, the phenomenon of slag inclusions is rare. There are established standards for particle sizes at which the operation of a part is allowed. If this norm is exceeded, the seam is cut out and digested.

Flux inclusions are divided into the same types (3021, 3022 and 3023, respectively). They arise from flux residues that have not had time to react with the metal. It usually floats to the surface, but parts may remain inside, forming a defect.

A similar situation occurs when the flux is selected incorrectly. For example, if it is presented in the form of large granules. Excessive welding speed can also provoke the occurrence of inclusions.

Oxide inclusion is oxide trapped in the weld metal. It is formed as a result of the reaction of a metal with oxygen. The oxide film is refractory and difficult to dissolve, so when it appears, a defect is sure to form. To avoid the formation of a film, it is necessary to protect the welded zone with active or inert gases. Particular attention should also be paid to surface preparation. Oxide inclusions are usually located in the form of a layer in the massif, which leads to the destruction of the seam.

Metallic inclusions of tungsten (3041), copper (3042) and other elements (3043) can occur if the weld pool is not properly protected. In most cases, such defects can be observed during an accidental short circuit of the tungsten electrode. The situation can be recognized by the characteristic crackling sound and sharp arc flashes. Tungsten has a high melting point, so it does not dissolve in liquid metal.

Group 4. Lack of fusion and lack of penetration

A characteristic sign of non-fusion is a poor connection between the weld elements and the workpiece metal. Varieties of the defect are lack of fusion on the side (4011), between the rollers (4012) and at the end of the seam (4013). Defects such as lack of fusion are characteristic of arc welding. Its essence lies in the fact that the metal of the edge did not melt completely, so the joint turned out to be of poor quality.

This is often preceded by incorrect cutting of the edges or errors in choosing the position of the electrode. The situation is aggravated by the chemical heterogeneity of metals. The welder must accurately set all welding parameters (current strength, speed of weld formation).

Defect 402 or “D” - incomplete penetration. Lack of fusion is technically similar to lack of fusion. The difference is that in this type of technology violation, areas are observed where the metal was unable to penetrate the root of the connection. Lack of penetration can be observed between the base material and the weld metal, as well as between the layers of the weld in multi-layer welding. Lack of penetration is observed during double-sided welding in the middle of the section. You can notice the defect visually, because there is a crack at the end of the zone.

Lack of penetration can lead to a decrease in the strength of structures. Seams with lack of penetration are especially sensitive under vibration loads. Even small areas with a defect reduce performance by 40%. Lack of penetration of the root impairs the strength of the connection by 70%. As with non-fusion, in this case the reason lies in the incorrect choice of welding mode. A defect between layers occurs when surfaces are poorly processed. The defect is corrected by removing the seam and re-welding.

Description of the defect

Many novice welders wonder what is called lack of penetration. Lack of fusion and lack of penetration are an identical phenomenon that occurs when welding at the root or cross section of a seam. You can notice it when the product being welded is broken or sections are cut out for inspection. The defect appears as a black stripe between metal joints.

External cracks and pores on the outer surface of the weld will visually indicate the presence of a flaw. And x-rays, gamma rays, and ultrasound will help detect internal cracks.

Group 5. Violation of the seam shape

Before performing welding work, preliminary design takes place, as a result of which the geometry of the future seam is established. Deviation of the shape from the established standards is qualified as defect 500. Violation of the shape of the seam not only negatively affects its strength, but also worsens the aesthetic appearance. Reasons include possible power surges, uneven wire feeding or incorrect electrode angle.

The most common defects of this type include various undercuts. They weaken the resistance of the structure to loads. Undercutting occurs when the current is exceeded or when the gas burner flame increases.

Modern semi-automatic machines allow you to control the welding mode, so recently undercuts have become much less common, however, if the welder is insufficiently qualified, this defect does occur.

Undercuts are corrected by reapplying a thread stitch. If aesthetics are lost, then the strength of the connection returns to normal. When working with thin sheets of metal, burns occur. Presence of burn-through (510). It is visually identified in the form of through holes and indicates that the welding current is set too high on the inverter. Elimination of burns involves cleaning the places where they are located and re-welding.

Group 6

All other defects that are not included in the previous groups are positioned as defects 600. These include random arcing, spattering, scuffing and reduction in metal thickness. Despite the wide variety of welding seam defects, very specific recommendations have been developed to prevent them.

It will be difficult for a novice welder to comply with all the requirements, but professional welders can easily avoid poor-quality results. It is necessary to initially develop a welding technique. To do this, it is necessary to resolve such issues as the choice of equipment, the choice of consumables, proper surface treatment, and welding techniques.