Why laser cutting of metal, although an expensive operation, is still in great demand today. It's all about the quality of the cut and the high speed of the process. At the same time, cutting metals with a laser is practically carried out without waste, because the thickness of the cut is very thin. The advantages include smooth edges, which practically do not require mechanical modification; the metal workpieces being cut are not subject to deformation (only the areas adjacent to the cutting zone are slightly heated). In fact, with the help of laser cutting, a finished product is obtained that can be used in the future for its intended purpose.

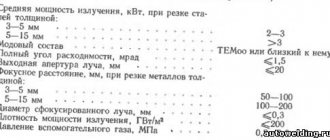

Technical characteristics of the process:

- metal cutting speed: 0.167-12.5 m/s;

- deviation of parts of standard sizes: 0.05-0.2 mm;

- cutting width of steel with a thickness of 0.5-5 mm: 0.1-0.3 mm;

- There may be a small layer of cut metal left on the edges, which can be easily separated.

Laser cutting of metals can cut any metal profiles: sheets, pipes, corners, etc. In addition, metal products made using different technologies are subjected to cutting: casting, stamping, rolling, and so on. The power of the laser used depends on the thickness of the workpiece. For example, to cut a part with a thickness of 12-15 mm, a laser with a power of 1.5 kW is needed. To cut a workpiece 4-5 mm thick, a 0.5 kW laser is required. In this case, there is no need to clean the metal workpieces, that is, to prepare them for the process. The only thing is the removal of anti-corrosion grease, which is applied at the factory to some profiles.

Description of technology

When using laser cutting, the rolled metal is influenced by the effects of reflection and absorption of radiation from the laser. Changes in the dimensions and shape of elements during laser processing are achieved due to the influence of two radiation results: melting and evaporation. The description of the process is as follows:

- The laser beam affects the iron at a certain point.

- First, the elements are melted to the optimum temperature, then the process of melting the metal begins.

- In the melting phase, depressions appear.

- The influence of laser radiation energy leads to phase 2 of the process - the metallic substance boils and evaporates.

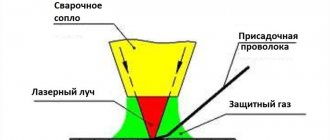

However, the latter mechanism requires high energy consumption and is feasible only for fairly thin metal. Therefore, in practice, cutting is performed by melting. In this case, in order to significantly reduce energy costs, increase the thickness of the metal being processed and the cutting speed, an auxiliary gas is used, blown into the cutting zone to remove metal destruction products. Typically the auxiliary gas is oxygen, air, inert gas or nitrogen. This type of cutting is called gas laser cutting .

Modes

Laser cutting of metal workpieces depends on the following factors:

- beam diameter;

- drive power;

- processing materials with protective compounds;

- number of lenses, their location;

- the type of metal or alloy that is processed;

- workpiece thickness;

- preliminary cleaning of metal from rust and dirt.

The speed of separation of parts is also affected by the inert gas used. For example, if you replace oxygen with regular air, the performance of the device will decrease by half.

The quality of the cut depends on the selected cutting mode. The main factors that influence the state of the finished cut are the speed of movement of the working head and the thickness of the part. It is advisable to cut metal slowly so as not to spoil the cut.

Types of laser devices

The laser consists of elements:

- A special energy key (pumping system).

- A working object capable of stimulated emission.

- Optical resonator (set of specialized mirrors).

Whether the treatment belongs to one or another variation is determined by the method of the laser used and its power. Currently there is the following classification of lasers:

- Solid state (power no more than 7 kW).

- Gas (power up to 22 kW).

- Gas-dynamic (power from 110 kW).

For production purposes, iron processing with a solid-state device is more popular. Light emission can be supplied in pulsed or continuous mode. Ruby, glass with the addition of neodymium or CaF2 (calcium fluorite) are used as the working body. The main advantage of solid-state lasers is the ability to create a powerful pulse of energy in a few seconds.

Gas lasers are used to process iron for technological and scientific purposes. The active catalyst is a mixture of nitrogen gas, carbon dioxide and helium, the elements of which are activated by an electrical discharge and give the laser beam monochrome and directionality.

Gas-dynamic devices are distinguished by their enormous power. The working fluid is carbon dioxide. First, the gas is heated to the highest temperature, then it is passed through a small channel, where expansion and subsequent cooling of carbon dioxide occurs. As a result of this procedure, energy is released that is used for laser processing of iron.

Gas-dynamic devices can be used to process iron with any surface. Due to the low consumption of radiation energy, they can be placed at a distance from the part being processed and at the same time preserve the quality of iron cutting.

Gas lasers for cutting hard materials

As the name implies, the active medium of these lasers is gas. Carbon dioxide, CO2. Under the influence of a powerful current, this gas becomes excited and begins to emit light.

However, chaotic gas, of course, emits it haphazardly, in all directions - and for it to work, it still needs to be collected into a beam. A complex system of mirrors and lenses is responsible for this. It concentrates the beam and directs it to the desired point. This is one of the problems with gas lasers - to work, you need all these mirrors to be intact, there are enough of them, and this whole system is precisely tuned. An optical system adjuster is an expensive specialist, whose regular work is naturally included in the cost of gas laser cutting, which is paid by the customer.

However, gas lasers still remain extremely common - they deserve it, over the many years of their existence they have confirmed that they produce a high-quality beam and are quite powerful.

In terms of power, however, there is a nuance. The power of common gas lasers is quite enough to cut wood, various plastics, glass, even stone - but metal is difficult for them. The question here is their efficiency. Even a concentrated CO2 laser beam is significantly larger in diameter than a beam from, for example, a fiber laser. This means that the same energy is distributed over a large surface - and, most likely, it will not be enough to effectively heat the metal to the melting point.

So it is not profitable to use gas lasers in metalworking.

And here is an example of a case produced by Metal-Case:

Audio equipment housing with silk-screen printing (4 photos)

Equipment

Laser devices for cutting iron consist of elements:

- A specialized emitter (solid-state or gas device). Must have the required energy and optical properties.

- Beam and gas shaping system . Responsible for supplying the beam from the radiation target to the part being processed, and changing the indicators of the working gas arriving at the point.

- A device for movement (coordination) of both the iron itself and the laser beam acting on it. It also includes an electric actuator, drive and motor.

- ACS (automated control system). Regulates the laser beam and controls the coordinate mechanism and the system for transporting and forming the beam and gas. Equipped with a variety of sensors and subsystems.

A modern iron cutting device is capable of performing any difficult tasks, even artistic cutting. Both Russian and foreign enterprises (German) are engaged in their production.

What reduces accuracy

Laser cutting equipment, regardless of cost, loses the accuracy of laser beam positioning during operation. Reasons for such failures:

- violation of the alignment of the optical system;

- abrasion of coating on mirrors;

- contaminated focusing lenses;

- violation of structural rigidity;

- changing the angle of the working surface.

If an adjustment violation is detected, re-adjustment is performed to align the center of each reflector. Damaged and worn lenses are replaced with new ones. Focusing lenses and mirrors are carefully wiped and cleaned of dust as a preventative measure. When the tension of the drive belts is loosened, they are aligned. Before work, check the strength of the lens in the emitter (to avoid vibration).

Laser cutting of thin iron

Industrial manufacturers find it more convenient to use sheet metal for cutting than unprocessed thick parts. At the same time, you can save energy and use methods for cutting sheet iron with greater power.

Methods for cutting iron , the sheet of which is prepared for processing, are oxygen cutting (burning), cutting with a group of gases (argon, nitrogen) and compressed air. Among the advantages of laser cutting of sheet iron over other types of processing, it is possible to highlight:

- Greater accuracy of recoil and cutting of the laser beam.

- There is less dust on the plane of the part.

- Low probability of causing damage to the iron sheet.

- Reduced energy costs.

- Formation of three-dimensional simple structures with high speed and the smallest area of the finished material.

Due to its advantages and the use of precise advanced equipment, iron cutting is used to create:

- Parts of mechanical engineering equipment.

- Decorative stands, shelves, racks and equipment for the retail industry.

- Components of boilers, tanks, chimneys and furnaces.

- Door and gate links, forged fences.

- Personal design of cabinets and cabinets.

- Unique signs, letters and stencils.

The use of cutting has many advantages over other types of metal finishing. That’s why more and more enterprises are using laser processing of iron in their production.

What is meant by metal cutting?

Sheet metal cutting is a procurement operation. They are carried out with the aim of forming parts suitable for welding and installation. In essence, this is the production of fragments of metal structures. Enterprises often operate entire procurement departments where cutting, processing of cut edges, bending, etc. are performed. The result is either workpieces that require additional processing or finished parts. It all depends on what technologies and equipment are used at this stage.

Before cutting begins, you need to rationally place the “patterns” on the sheet. The workpiece can be of any shape, but the easiest way, of course, is to work with rectangular ones. During the cutting of sheet metal, waste is generated - returnable and non-returnable. The amount of these residues is directly related to the technology used.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

Cutting sheet metal is a difficult and very responsible operation. The quality and cost of parts and the entire structure as a whole depends on it. Modern enterprises prefer efficient high-tech cutting methods.

Innovative laser complexes

The global machine tool industry keeps up with the times and provides its consumers with all kinds of electrical equipment for cutting iron. Multi-axis devices are designed to replace loud and low-productivity mechanical cutters. The laser energy depends on the specificity of production and the financial justification of the selected unit. The latest generation of CNC precession cutting machines allow finishing of materials with accuracy up to 0.005 mm. The processing area of individual laser machine models reaches many square meters.

A huge advantage is the minimization of the human factor contained in the high automation of the industrial process. The geometry of the components is specified in a macro-program unit that controls the laser and the work table with the blank. Focus adjustment systems automatically select the appropriate distance for effective cutting.

Specific heat exchangers regulate the temperature of the laser unit , providing the operator with control information about the current state of the instrument. The laser mechanism is equipped with valve devices for connecting a gas supply to supply spare gases to the working part. The smoke collection system is designed to improve exhaust hood costs by turning it on right at the time of treatment. The processing area is completely shielded by a safety casing to protect the operating personnel.

Cutting sheet metal on modern equipment is transformed into an easy process of specifying numerical characteristics and obtaining a finished component at the output. Equipment productivity directly depends on the characteristics of the machine complex and the qualifications of the operator generating the program code. The iron cutting technique fits proportionally into the concept of robotic manufacturing, designed to completely relieve humans from hard work.

Manufacturers offer different types of laser machines:

- Multipurpose.

- Special.

The cost of the former is higher, but they make it possible to perform a certain number of operations and produce parts of more complex shapes. A considerable number of market services provide a choice for interested buyers.

Mechanical engineering professionals understand the potential of using the technology provided to produce precision parts with superior surface finish. The scope of use is wide: from ordinary cutting of sheet metal to the acquisition of complex car body parts.

The visible advantages of cutting iron come down to several aspects:

- High quality finished surface.

- Thrift of material.

- Ability to work with fragile materials and small workpieces.

- Probability of obtaining components of complex configuration.

Among the disadvantages:

- High price of equipment.

- And consumables.

Cutting iron and non-ferrous metals is in huge market demand. Laser technologies are intensively used in decorative arts to create designer jewelry and unique souvenirs.

The decision to use processing should be made taking into account the calculation of the payback of equipment and the amount of operating costs. Currently, such installations can be afforded mainly by large enterprises with a rather large production cycle. With the advancement of technology, the cost of machines and the amount of energy consumed will decrease, so in the future laser units will displace their competitors.

Crystal lasers for metal cutting

The active medium of such lasers is a crystal. The most commonly used crystals are:

- Nd:YAG (yttrium aluminum garnet doped with neodymium ions),

- Nd:YVO (yttrium vadanate doped with niodymium ions).

The crystal does not glow on its own; it only “accelerates” the light directed at it from the pumping system. The pumping system is:

- flash lamps are an outdated option, which has largely given way to a new technological level, but can still be used in some places,

- diodes are a modern option that powers most crystal lasers currently produced.

Such a laser is already quite capable of effectively dealing with metals.

However, there were some nuances here too. Even modern pump diodes create economic difficulties. On the one hand, they deteriorate relatively quickly and need to be replaced. The appropriate service life of pump diodes is from 8 to 15 thousand operating hours. On the other hand, these diodes are expensive. And, naturally, the cost of their wear and tear naturally falls, again, on the shoulders of the laser cutting customer - production workers have to include the costs of the future purchase of new diodes in the cost of orders currently being carried out.

Here's what we offer:

Production of housings for industrial equipment

Advantages and disadvantages of technology

Cutting iron products has many significant advantages compared to other cutting methods. Of the many advantages of this technology, it is worth noting the following:

- The thickness range of products that can be successfully engraved is quite wide: steel - from 0.2 to 22 mm, copper and brass - from 0.3 to 16 mm, aluminum-based alloys - from 0.3 to 22 mm, stainless steel - up to 55 mm.

- When using laser devices, the need for mechanical contact with the component being processed is eliminated. This allows you to cut easily deformable and fragile parts without worrying about them being damaged.

- To obtain a product of the required configuration using cutting, simply load a drawing made in a special program into the control unit of the laser unit. Everything else with the smallest degree of error (reliability up to 0.2 mm) will be carried out by equipment equipped with a computer control system.

- Cutting units can process thin steel sheets, as well as hard alloy products, at high speed.

Laser processing can completely replace the expensive scientific and technical operations of casting and stamping, which is appropriate in cases where it is necessary to produce small batches of products. The initial cost of production can be significantly reduced, which is achieved due to a higher speed and development of the processing process, a reduction in the volume of residues, and the absence of the need for subsequent mechanical processing.

Along with high power, laser processing devices have extraordinary versatility, which makes it possible to calculate problems of any level of complexity with their help. At the same time, laser processing also has certain disadvantages.

Due to the high force and significant energy consumption of laser cutting equipment, the initial cost of products manufactured using it is higher than those produced by stamping. However, this can only be attributed to those situations when the cost of the stamped element does not include the cost of production of technological equipment.

How to make a laser cutter in the garage

Laser cutting of steel is carried out using purchased and homemade devices. If you can’t buy a machine, you can make it yourself. To do this you need to prepare materials and tools:

- powerful battery-powered flashlight;

- laser pointer;

- DVD-ROM drive;

- soldering iron, screwdrivers.

Step-by-step instructions for assembling a laser cutter:

- Initially, you need to disassemble the drive to remove the working head. This must be done carefully so as not to damage the lens.

- Pull the diode out of the pointer. In its place, solder the working part from the drive.

- The insides of the pointer need to be pulled out to assemble a new housing for them. Secure all elements into the flashlight body. Remove the protective glass and power the device with batteries.

Additionally, you can strengthen the body with tape and glue.

Strengthening a homemade installation

Craftsmen experiment with a set of lenses to enhance the power of the beam. Additionally, you can power it from a battery charger. To make it more convenient to carry out technological processes, a structure is assembled to hold the homemade installation. It is installed above the desktop on guides.

Laser cutting is a modern technological process that allows you to separate metal sheets of different thicknesses. Depending on the size of the workpieces being processed, you need to select the drive power.

Purpose and selection criteria

This method of work is also used for processing plywood, linoleum, polypropylene, and rubber. Even artificial stone and glass can be subjected to this treatment. This type of cutting is used in the construction of cars, ships, numerous electrical appliances, as well as agricultural machines. This processing option is also suitable for making signs, signs, tokens, and interior decorative elements.

Laser cutting machine GCC LaserPro FMC280 200 W

- Dimensions, mm 1125 x 720 x 1800 mm

- Maximum power consumption 1800 W

- Display 4-line LCD panel

- Max. motor speed 500 mm/s

- Maximum load size 786 x 542 x 120 mm

- Laser tube power 200 W

- Memory capacity 32 MB

- Axes 3

- Emitter manufacturer Germany

- Working field 712 mm x 370 mm

- Resolution, DPI 3000

- Laser type: optical fiber 1070 nm

- Laser tube cooling type: air

Go to product

When choosing the type of processing, you need to rely on the material being processed. For example, carbon dioxide lasers are more suitable for welding, engraving and cutting metal, glass, rubber and plastic.

But solid-state machines process metal perfectly, but are not at all suitable for non-metals.

Reviews about our work

Maksim

29.07.2021

I needed to make a case for one project, so I became interested in laser cutting of metal. The specialists created the cutting according to the specifications and quickly cut the parts on the machine. Separately, it is worth noting the high quality of the finished elements.

Egor

07/21/2021 It was necessary to use the services of a company to manufacture a certain metal structure. I was pleased with the professionalism of the company's employees and the affordable prices for services. I was pleased with the quality of the final result.

Philip

07/15/2021 High precision metal parts were needed. Friends recommended this company. Specialists designed the necessary elements and cut them out as quickly as possible. When checking the dimensions of the final products, everything turned out to be as specified without deviations.

Alexei

07/13/2021 Aluminum elements were needed. The specialists received the task, discussed all the nuances, and specified the deadlines for completion. As a result, the quality of the finished product was excellent, therefore, I confidently recommend the company to everyone.

Victor

07/03/2021 Ordered metal construction elements with further powder coating. When discussing the details, we chose the material for production and the appropriate color. After that, the craftsmen began work and after a couple of days I picked up the finished elements. I'm pleased with the quality of the painting.