Any welder, whether a beginner or a professional, has encountered thin sheet metal. Thin-sheet (or simply thin) is metal up to 2 mm thick. It is used everywhere. Most often you encounter it when working with profiled pipes.

To weld thin sheet metal, you do not need a powerful welding machine and large-diameter electrodes. For this reason, working with thin metals is not that difficult. However, there are a number of features that need to be taken into account when performing such work. And if they are not taken into account, then most likely the seams will be defective.

In this article we will tell you in detail how and with what to weld thin metals, what welding technologies are best to use, what brands of electrodes are suitable and how to work with thin galvanized steel.

Difficulties when joining thin metals

- The main difficulty in joining thin metal is that when it gets too hot, it burns out and holes form in it. When working with thin metal, you need to follow the principle: “The faster, the better.”

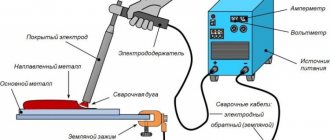

- The current strength should be small, that is, the arc should be short. A short arc easily goes out even with a small separation, so it is recommended to use machines with good current-voltage characteristics when welding.

- When metal sheets are exposed to high temperatures, they can change their shape: they bend in a wave-like manner. It is very difficult to say goodbye to this minus. The only way out is to try to prevent overheating or remove heat.

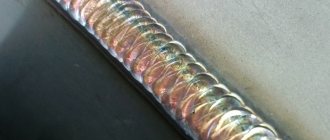

Thin metal is usually welded using manual arc welding. It is recommended to weld metal 1 mm-1.5 mm thick with 2 mm electrodes. The choice of electrodes for welding metals must be made, including taking into account the type of metal product. The connection of thin metal is carried out continuously throughout the entire length of the weld. The average welding current is about 40-60 A.

The main goal when joining thin metal is to prevent burning. Other defects are rare when working with thin metals.

Methods for welding profile pipes

To weld metal profiles at home, you can use several methods that differ in their cost. When performing welding work, the following difficulties arise:

- When a separate section of the edges is heated, the workpieces being welded change their location.

- End connections create high stress points at the corners.

- A thin-walled profile often burns out when welded by an inexperienced welder.

Rice. 3 Devices for resistance spot welding

contact welding

Resistance welding is the pressure connection of two metal parts heated to a high temperature by electric current. There are the following varieties, mainly used in industrial production:

- Spot. From the name it is clear that the connection of metal parts occurs at separate points.

- Butt. With this method, the ends of the products are strongly heated by electric current, after which they are pressed against each other under pressure. As a result of diffusion, the mutual penetration of metals into the structure of the parts occurs - this leads to the formation of a strong butt joint. With other types of butt welding, melting of the ends occurs when the parts are connected or they periodically come into contact until the specified melting temperature is reached, after which they settle.

- Embossed. In this case, welding occurs at points with pre-formed protrusions.

- Suture. With this method, a disk-shaped electrode is rolled over the surface of compressed workpieces and heats them to the melting temperature, after which they are firmly connected due to mutual diffusion.

- Contact-arc. It is one of the most popular types of resistance welding, widely used in industry, repair services and small-scale production. With this method, parts are welded by heating their surfaces with an electric arc; the heating process itself takes tenths of a second.

Rice. 4 Gas resistance welding - diagram

Gas welding

The essence of gas welding is to heat the surfaces of the parts being joined and supply a filler rod to the weld zone, which, when melted, fills the gap between the edges. Gas torches are indispensable when connecting copper pipes by soldering in refrigeration, heating and air conditioning equipment; they are convenient to use for cutting metal.

With this method of carrying out work, you should use protective equipment in the form of special glasses, welder’s gloves or gauntlets; the following equipment is used for gas welding:

- Gas cylinders. The flame is formed by supplying propane, butane, hydrogen or acetylene to the burner; oxygen is additionally supplied to increase the combustion temperature. A typical standard cylinder has a volume of about 40 liters.

- Gearboxes. Devices are necessary to regulate pressure and, accordingly, gas flow; they are installed on acetylene and oxygen cylinders.

- Pressure gauges. The device is used to control and set the operating pressure in lines with acetylene and oxygen.

- Burner. It is selected taking into account the ratio of combustible gas and oxygen, and can have various replaceable nozzles in the form of attachments.

- Filler rods. The main requirement is that the composition matches the material being welded.

- Gas supply hoses. Typically, rubber hoses are used to work under a pressure of at least 6 bar (category 1) for supplying acetylene, and a rubber hose designed for pressure up to 20 bar (category 3) for supplying oxygen.

Types of thin metal joints in manual arc welding.

- Using a continuous welding arc. In this case, the electrode must be directed at medium speed. If you move the electrode too quickly, not the entire seam will be welded, but only its upper part. If you move the electrode slowly, you can burn through the metal.

- With the cessation of the arc. This method is the most popular for joining thin metal.

- Spot welding.

As with manual arc welding, and when welding metal with an inverter, thin metal must be welded very quickly to prevent it from cooling.

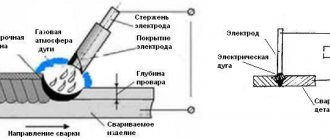

Coating of electrodes

The core coating is a solid composition, a kind of flux, designed to protect the molten metal from the harmful effects of oxygen, which, when it enters the liquid metal, forms oxides that deteriorate the quality of the connection.

Another function of the coating is to thermally insulate the melt to delay the solidification time (so that harmful gas and non-metallic inclusions have time to escape from it). Modern electrodes use several types of coating. The main ones are basic (in the marking of electrodes, indicated by the letter “B”) and rutile (letter “R”).

How to choose the right electrode? What electrode should you use to weld metal? What determines the choice of diameter?

One of the arc welding modes is the diameter of the welding electrodes. The choice of welding electrodes of a certain diameter is influenced not only by the position of the seam, but also by the thickness of the material.

The choice of electrode diameter depending on the thickness of the metal being welded is shown in the table below.

Table: electrode diameter depending on the thickness of the metal being connected.

| Metal thickness, mm | 1-2 | 3-5 | 6-11 | 12-24 | 25 or more |

| Electrode diameter, mm | 1,6-2 | 2.5-3 mm | 4-5 | 5-6 | 6 or more |

Electrode diameter and their most popular models.

Among the huge variety of electrodes, many of them have similar technical characteristics.

Diameters of electrodes for welding LB-52U

| Diameter, mm | 2.6 | 3.2 | 4 | 5 | |

| Length, m | 0,35 | 0,35 | 0,4 | 0,4 | 0,4 |

Diameters of electrodes for welding ANO-21

| Diameter, mm | 1.6 | 2 | 2,5 | 3 | 4 |

| Electrode length, m | 0,25 | 0,25 | 0,3 | 0,3 | 0,35 |

OZS-12

| Rod diameter, mm | Rod length, m |

| 2 | 0.3 |

| 2.5 | 0.35 |

| 3 | 0.35 |

| 4 | 0.45 |

| 5 | 0.45 |

For welding carbon and low-alloy steels, MTG electrodes 01k or MTG 03 are used. They are also called LEZ MR electrodes.

How do electrodes differ besides diameter? The choice of welding electrodes also depends on the material of the surfaces being welded. This is necessary, among other things, to ensure that the melting temperature of the electrode and the material used coincide.

In this case, the elementary laws of physics apply: the more metal that needs to be melted, the higher the temperature required. Therefore, to increase the temperature, a higher current is required.

| Metal thickness, mm | Electrode thickness, mm | Current, A |

| 1-2 | 1,6 | 25-50 |

| 2-3 | 2,0 | 40-80 |

| 2-3 | 2,5 | 60-100 |

| 3 and 4 | 3 | 80-160 |

| 4-6 | 4 | 120-200 |

| 6-8 | 5 | 180-250 |

| 10-24 | 5-6 | 220-320 |

| 30-60 | 6-8 | 300-400 |

The peculiarity of the MP-3C electrode is that it can cope with welding even metal that is poorly cleaned of oxides or other contaminants, with rust or when the surfaces are wet. The selection of these particular electrodes is indispensable during installation work and when welding fixed pipe joints. However, there is still a difference between welding prepared metal and poorly prepared or unprepared metal.

| Surfacing productivity, g/min | Relative yield of deposited metal, % | Material consumption per 5 kg of weld weld, kg |

| 23,5 | 90 | 8,5 |

Metal preparation and joining

- Before butt welding thin metal sheets, they must be cleaned and processed. It is not advisable to leave rust or dirt behind. The better you prepare the metal, the better the quality of the seam. Remove traces of paint, oil, and dirt using a solvent. Using a grinder, sandpaper or file, clean the surface to a shine.

- The sheets must be placed next to each other without any gaps.

- Secure them with clamps. You can use any type of clamp, including magnetic ones.

- Using short seams, tack elements at intervals of 7-10 cm. This is done to ensure that the parts do not move and to reduce the likelihood of bending.

Connecting thin metal with an inverter

An inverter comes in handy when working with thin metals. With experienced use, you can achieve excellent results with it. It is important to set up the device correctly to avoid errors.

The positive feature of inverters is expressed, first of all, in the fact that you can cook using reverse polarity. That is, the electrode will heat up more, and the metal less.

When welding with an inverter, you need to use electrode sizes from 1.5 to 2 mm with a high melting coefficient, then the weld will be of high quality. The current strength is set to small: approximately 30-45 amperes for a 1.5 mm electrode and 40-60 amperes for a 2 mm electrode.

In order to minimize the degree of heating of thin material, the parts must be placed vertically and cooked from top to bottom. The tilt angle is approximately 30-40 degrees.

Rutile coating

Rutile is titanium dioxide. In addition to it, the coating contains silicon and oxygen.

Rutile coating is characterized by the following properties:

- formation of a high-quality seam at any spatial position of the electrode;

- stable arc burning;

- minimal splashing of melt and coating;

- possibility of welding on both direct and alternating currents;

- possibility of welding rusty and dirty parts;

- quick and easy ignition of the electrode;

- easy removal of slag.

Techniques and methods for joining thin metal sheets

In each specific case, it is important to determine which technique should be used when joining thin-walled material.

electrodes for thin-walled materials

The flanging method involves bending the edges of the sheet to the required angle and fastening it with transverse seams every 5-10 cm. Then you need to lay a continuous seam from top to bottom.

However, it is not always possible to weld a continuous seam without burning through the material. In this case, you can try to tear off the arc for just a few moments and lower the electrode back to the same place, moving it a couple of millimeters. This is done so that the metal has time to cool during arc separation. The most important rule when carrying out such actions is not to let the metal cool too much.

Butt welding of thin iron is difficult to achieve. It is better to overlap it.

When butt welding, wire can be placed between the sheets. In this case, the arc must be drawn along it. It takes on the entire thermal load, while the sheets themselves do not overheat.

Instead of wire, copper plates can be placed between the sheets. Copper has good thermal conductivity, about 7 times higher than steel. The plates are placed under the welding site, and it “takes” the heat to itself, preventing the metal from overheating.

Calcination of electrodes

Coating of electrodes requires tightness during storage, but this condition is not met everywhere. The sharp edges of the rods, as a rule, break the tightness of the plastic packaging already during the first transfer of packs. Thus, by the time of purchase, the electrodes are saturated with excess atmospheric moisture.

In this condition, due to the danger of obtaining a poor-quality seam and the possibility of too much metal spattering, welding cannot be performed with them. The electrodes need to be dried. The manufacturer gives clear recommendations regarding process parameters, setting drying time and maximum temperature. It usually does not exceed 260 ºС.

Galvanized connection

Galvanization, that is, galvanized steel, is ordinary steel, most often in sheets, only coated with zinc. When working with galvanizing, many craftsmen encounter difficulties due to which they are unable to form a high-quality seam.

The thickness of the electrode coating with zinc can be different. If you need to weld it, all the zinc must be removed from the edges. This can be done in the following ways:

- Remove mechanically using a grinder, grinder, sandpaper or wire brush

- Burn it out by welding. However, in the process, zinc evaporates, the vapors of which are poisonous. Therefore, such work should be carried out outdoors or indoors where there is a properly functioning hood.

Thus, joining thin plates of metal products requires a specialist to have certain knowledge and practice. It is very difficult to carry out such a process correctly the first time. You can make the right choice of electrodes for welding using the tables above. It is important to remember that the diameter of the electrode, depending on the thickness of the metal being welded, should be selected wisely. Thus, you need to understand what conditions are chosen from and what indicators need to be followed in order to connect thin-walled metal efficiently.

Welding current strength: what parameters should be taken into account

In addition to the electrode diameter, it is important to pay attention to the following parameters:

- welding and metal thickness. This is a mandatory factor that will help determine the diameter of the electrode;

- welding position. Only in the lower position you will not be able to weld parts, there are no other restrictions;

- multilayer welding. If you need to boil in several passes, then you will have to experiment with the strength of the currents;

- electrode brand. Most often, professional welders who work with load-bearing structures, in which mistakes cannot be made, pay attention to this point. In this case, there are certain requirements for the brand of electrode;

- types of currents. Gender can be variable or permanent. Since certain electrodes can only work with specific shooting ranges, this can be important;

- what is the polarity?