Epoxy composition Abro Steel is an indispensable assistant for motorists and mechanics. Cold welding is used in emergency situations at home, in the country, in the garage. The glue is suitable for wood, plastic, ceramics, metal. American manufacturers have created a composition that users recognize as a reference. Over the past years, the product has remained a bestseller.

Features and Specifications

Although manufacturers keep the Abro Steel recipe secret, it is clear from the name that the composition is based on epoxy resin and contains metal powder. Like all epoxy mixtures, cold welding after polymerization hardens and becomes dense. The steel filler forms a connecting layer that can be drilled, cut, ground, bringing it to the required accuracy.

Physico-chemical and mechanical characteristics of Abro Steel cold welding:

- After mixing the layers for a couple of minutes, a hot viscous substance is formed.

- The mixture uses an actively oxidizing hardener; cold welding quickly hardens in air. 5...7 minutes are enough until a layer forms.

- Machining begins after an hour, by which time a diffuse layer similar to a weld seam has formed.

- Epoxy glue expands during polymerization, fills microcracks and pores, and acts like a cork or sealant.

Cold welding requires 24 hours to fully harden.

What it is?

The method of joining parts is based on the action of strong solvents . The surfaces of the workpieces are lubricated with the composition and allowed to sit for some time. The glue increases the plasticity of the surface layers of two parts, and upon compression, mutual penetration of their molecules occurs.

An intermediate layer is created in which interatomic interaction occurs between these molecules. When the composition hardens, the two parts are combined into a single whole, the layer resembles a frozen hot weld seam.

In order for the method to work, a number of conditions must be met:

- thorough preparation of workpiece surfaces - they must be cleaned of mechanical contamination and degreased;

- strong compression of parts to ensure interpenetration of softened surface layers;

- strict adherence to the soaking time of lubricated surfaces, compression time and hardening time specified in the instructions before use.

The method is widely used for express repair of plumbing equipment, vehicles, and household repairs.

Application area

For emergency repairs using the Abro Steel composition, 10 minutes is enough. The mass is used for sealing pipes, gluing wood, ferrous and non-ferrous metals, ceramics, glass, and plastics. The composition is used for the repair of cars, watercraft, furniture, plumbing, restoration of concrete, natural stone, and other materials.

Cold welding Abro Steel AS-224 is universal

Advantages

The versatility of Abro Steel lies in the fact that it can be used for almost any material and under any conditions - this is its main advantage. Thanks to the composition, which is based on epoxy resins, the drug is high-temperature and can withstand up to +204°C and has a high degree of adhesion to any materials.

According to the manufacturer, it can even be used to repair the hull of marine vessels, since the welding is sealed and is not subject to destruction by sea water. Also, the product does not react with engine oil and other liquids, so it can be safely used when repairing cars in any part.

Separately, it is worth mentioning such an important characteristic as the ability of Abro Steel to harden during direct exposure to water. This is especially true for emergency repairs of boats and ships during navigation, as well as cars and other vehicles in rainy and snowy weather

At least one welding tool is necessary in every home, as it will help to quickly solve the problem of leaking pipes and batteries at any time. Fish lovers also note that this product can safely patch holes in aquariums.

Most cold welding products come in a dirty gray shade, but the Abro Steel line is much wider. To save money on paint and time on additional operations, you can purchase a product in black or white, as well as metal shades, among which the most popular are steel or bronze.

After hardening, the welding site can be leveled with sandpaper or a file, drilled and cut, if it is necessary to repeat the relief of the surrounding surface on it.

This is interesting: Wooden lining - varieties and finishing options in the interior

Customer Reviews

The composition of cold welding is considered universal, users leave positive reviews. Abro Steel paste is capable of sealing water containers, aquarium seams, and aluminum boats. The leak can be eliminated. The product cuts well, you don’t need to have a knife for this, it kneads quickly in your hands. True, women complain about the high temperature of the plastic mass. You need water to avoid burns on your hands.

It is recommended to always keep the packaging in the glove compartment and seal it tightly, otherwise the glue will dry out and deteriorate. Another advantage of Abro Steel is its rapid hardening. In emergency situations, you don’t need to spend a lot of time on repairs. A useful property is the flexibility of hardened cold welding to mechanical processing.

Many people write that in comparison with similar compounds of the previous generation, Abro Steel is more convenient. There is no need to measure the amount of hardener, it is air. There is practically no waste; low consumption is considered a positive quality. One container lasts a long time.

How to use

Like any epoxy compound, Abro Steel requires surface cleaning and degreasing before application. In emergency cases, this moment is omitted, but then the quality of the repair deteriorates sharply, since maximum adhesion is not achieved.

Execution steps:

- Open the container lid. It is hermetically sealed, which allows the material to be reused.

- The instructions are extracted and carefully studied.

- The repair surface is cleaned, leveled if necessary, and degreased.

- Remove the composition and cut off the required part.

- Apply it to the surface to be repaired and give it the required shape.

- Pack the remaining material back.

- Wait until completely hardened.

How to use welding

The instructions for use always describe in detail the process of mixing the components and applying the product. The proportions of hardener and resin must be strictly observed or the adhesion of the adhesive will decrease. The rules for surface preparation cannot be ignored. They need to be cleaned of dirt, treated with sandpaper, then degreased - wiped with alcohol and acetone. Without removing fat, it is impossible to reliably join the elements.

Next, the order of work will be as follows:

- mix the resin and hardener or mix the thick components together (the amount of mass must correspond to the area of the hole, defect, gluing area);

- knead solid components only with thick rubber gloves moistened with water; when ready, the mass will acquire a bright brown color;

- apply the product to the parts to be fastened, use a clamp, tourniquet, cord or elastic band to secure them;

- press the parts, leave for an hour;

- then wait for the time according to the instructions or immediately begin further processing of the product (carving, painting, drilling).

Advantages of the welding method

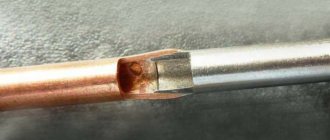

The method helps to reliably fasten metals (copper soldering, cable cores). There are a great many areas of application.

Below are the advantages of this option for connecting materials:

- it is not necessary to have welding experience;

- no need to purchase additional tools;

- environmentally friendly process, no fire or smoke;

- no waste;

- you don’t have to spend money on electricity (meaningful financial savings result);

- the ability to easily make an even seam;

- there is no deformation of the connected parts, everything remains intact;

- the only way to repair metal containers for storing explosive substances.

There were some shortcomings. This method cannot be used to repair products that come into contact with food during operation. Ignoring the requirement may lead to poisoning.

Security measures

When using adhesives, safety precautions must be observed. To prevent skin irritation and allergic reactions, you need to wear gloves when mixing the components of the liquid composition. If the composition gets on exposed skin or mucous membranes, they should be immediately rinsed under a stream of clean water.

Do not load glued objects until the seam has completely hardened. If the composition is heated, it hardens faster. Seams formed by this method are less strong than those obtained during conventional welding and have a reduced value of permissible tensile stress. This means that the part cannot be subjected to tensile stress.

Formulation options

It may include 3 main components:

- Filler. Metal powder, the purpose of which is to ensure the reliability of a tensile-resistant seam joint.

- Epoxy resin. Connecting component. The task is to ensure molecular strength and durability.

- Additives. These include silicon, sulfur and other elements intended to form individual qualities.

In essence, it is the amount of additives that differentiates one brand from another. There are other divisions in composition, but they are not so significant globally. Under standard conditions of use, they can be completely neglected.

Summarizing

So, how long it takes for cold welding to dry is now clear. The article also discussed the principles and rules for its application.

Finally, we will consider the rules for storing glue that can make it last for a long time:

- Avoid ultraviolet exposure. The packaging should be kept in a cool, dark place. Direct sunlight is the worst enemy of safety.

- The packaging must be hermetically sealed. Some formulations are sold in mini-containers with a lid or in tubes. It is worth choosing one of these if you understand that the entire composition will not be used at once.

As an alternative, you can buy glue, the packaging of which contains a kind of sealed honeycomb. You can conveniently take as much as you need and not worry about the safety of the leftovers.

Types of Abro sealants

All mixtures produced under the Abro TM are multi-purpose. Therefore, they are divided into several types, according to their component composition.

High temperature

Red silicone sealant is considered high temperature. Abro red sealant contains a reddish-yellow fine pigment. It is this that helps the mixture withstand high temperatures. During the drying process, no odor appears and no acetic acid is released.

Main characteristics:

- Operates at temperatures up to +370 degrees.

- The applied layer should not exceed 6 mm.

- When dry, a flexible, uniform seam is obtained.

- Dries within 24 hours.

- Retains its shape during pulsations and destruction.

Red high-temperature acriplast is available in packages of different weights (42.5; 85; 226; 310 g), which is convenient when choosing a product.

Silicone acid

Abro black on silicone is suitable for restoration work on changing gaskets, insulation, and seals among elements of car parts.

Advantages of silicone Abro:

- Operates at temperatures up to +260 degrees.

- The layer thickness is optimal.

- Maintains configuration during pulsations and destruction.

- When hardened, a flexible, durable seam is obtained.

- Ease of use.

- High adhesiveness.

- Final drying is achieved within a day.

This composition is available in packages weighing 42.5 g and 226 g.

Silicone neutral

Abro 999 is necessary when replacing any type of gaskets on a car. Advantages:

- Operates at temperatures up to +343 degrees. New types have added copper dust and such compositions can withstand temperatures up to 371 degrees.

- Compatible with any liquids other than fuel.

Abro 999 is available in gray and black in 42.5g, 85g and 310ml packs.

Series 1100 and 1200

Abro 1100 is suitable for different surfaces. Characteristics:

- Suitable for insulating and protecting duralumin, wood, rubber, metal, clay surfaces.

- Operates at temperatures from -50 degrees to +200 degrees, so it can be used for internal and external work.

- The composition contains components that prevent the formation of mold and mildew.

Abro 1100 is available in white, transparent and black in packs of 70 g and 280 ml.

The structure of Abro 1200 has similar properties. It is available in white, transparent, black, with a volume of 85 g or 310 ml. It is distinguished by its water resistance and moisture resistance. Remains flexible when stretched up to 25 percent.

We recommend watching the overview video:

Tips for using cold welding

Most often, cold welding is used for car repairs and heating installations, but each application of glue has its own subtleties: repairing a gas tank with cold welding is a good solution to extend its life without an expensive replacement.

Before starting work, you need to provide convenient access to the damaged area. There is a simple method to make your task easier if the hole is small: use a screwdriver to bring it to a round shape, screw in a bolt of suitable diameter and secure it in this way.

Cold welding for a car radiator is another popular way of using such compounds. You can determine where the radiator is damaged by blowing it under water with a compressor; the location where bubbles appear will indicate the location of the damage.

It should be taken into account that this method in this case will only be a temporary solution - a radiator repaired in this way cannot withstand long-term operation.

Whether it is possible to cold weld a muffler depends on what temperature the composition can withstand. Be sure to take a high-temperature modification; before gluing, the surface must be thoroughly cleaned and prepared, in this case the muffler will last quite a long time after repair.

Cold welding for radiators must be of very high quality - the cost of repairs is too high if the weld fails. Therefore, it is better to take compositions that can withstand high temperatures, and only compositions intended for constant contact with water.

If the damage is small, this method will solve the problem; if the hole is large, it will only be a temporary solution. For serious repairs of metal products, it is better to use an inverter or semi-automatic welding machine.

Cold welding can be a good way to repair metal parts. But you should always put safety first, so you shouldn’t use glue to repair key components that bear a lot of stress.

The way this method works is simply gluing two surfaces together; such a seam does not withstand pull-out forces very well. Therefore, traditional welding or part replacement is more suitable for repairing important parts.

Manufacturers

The leading positions in the market are occupied by imported products. Domestic analogues, if you believe user reviews, do not demonstrate the same high quality and strength of the seam.

The most durable welding, according to professionals, and also based on examination data, is produced under the brands Hi-Gear, Abro, Poxipol.

- The version from the first brand is a universal composition suitable for working with metal, as well as stone and plastic surfaces. Demonstrates heat resistance and chemical inertness.

- Abro is a two-component welding, also characterized by versatility of use. Withstands heating up to 260°C, suitable for use in chemically aggressive environments.

- Domestic analogues that are close to them in quality are Polymet and Almaz.

- For water supply and heating pipes, it is better to use Mastix products, but only on condition that the coolant in these systems has a temperature of no more than 120°C. This makes the compound an excellent option for home welding, but does not allow it to be used for repairing production systems with higher heating temperatures.

- For heat-resistant systems, it is better to choose Kerry “Thermo” adhesive, which is characterized by increased viscosity and the ability to withstand heating up to +900°C. This composition has proven itself well when working with cast iron, steel and titanium bases, and is widely used in car repairs.

- Henkel’s “Moment SuperEpoxy” product for universal use, which can withstand heating up to 140°C, demonstrates good quality. The composition of Adefal Trading SA Poxipol demonstrates similar properties, but the heating temperature when using it can only reach 120°C.

Application in car repair

Cold welding is often used for express repairs of various vehicle parts in the field. It is much easier for them to knead two pieces that look like plasticine, or mix liquids from two tubes, faster than taking a welding machine to the site of a breakdown.

Most often, cold welding is used to repair leaky pipelines, radiators, mufflers, gas tanks, gluing a broken crankcase into place with a fragment, etc.

An important advantage of cold welding over hot welding is that:

- no need to remove the part from the car,

- there is no need to ventilate the gas tank and fuel lines to remove gasoline vapors from them,

- You can continue driving under your own power after repairs.

You need to understand that the service life of a gas tank or radiator repaired in this way in conditions of constant vibration is exactly until the nearest service center, where a full sealing or replacement of the unit will be required.