Welding an engine with argon includes a whole range of work, since this technology allows you to weld almost all metals used in this unit: from aluminum to stainless steel or cast iron. Thus, the list of engine elements that can be repaired by welding is very extensive and includes:

- cylinder blocks;

- cylinder head;

- intake and exhaust manifolds;

- pipelines;

- valve guides, seats and inserts;

- pumps;

- pistons and piston pins.

How to weld an aluminum engine block yourself

In the article, we can see several damages to the aluminum alloy cylinder block in the car.

From them you can see how, in some cases, restoration work is carried out on a cylindrical block. Damage to the cylinder block of the ZMZ-24 engine

The damage consists of a crack in the outer cooling jacket at the corner of the block. One end of it goes to the thread hole for the head mounting pin.

The technical requirements for welding are to ensure the strength and tightness of the welding joint.

The most appropriate solution would be to repair the damage using argon arc welding. It is necessary to cut a groove along the crack and clean the metal surface until the oxide film is completely removed, that is, completely clean metal should appear before welding. Immediately before starting welding around the crack, it is required to heat it to a temperature of 250 - 280 degrees Celsius. This operation can be carried out using the flame of a gas burner, on which a tip number 4 or number 5 is installed. The metal can be heated to the required temperature in 1.5 - 2 minutes. To prevent possible warping of the metal under the cylinder liner, a technological sleeve is inserted into the hole.

For welding, torch number 2 is used, in which a tungsten electrode with a diameter of 5 - 6 millimeters is installed. The welding process is carried out at a current of 240 - 280 Amps. The crack can be welded from either end, but it is best to start welding from the threaded hole and then move to the side surface of the block.

The possible formation of pores in the weld metal is a consequence of the ingress of scale into the weld pool, sucked from the internal cavity of the block. A weld containing pores must be remelted without adding filler material. In this case, the torch is given crescent-shaped movements across the seam or loop-shaped movements perpendicular to the plane.

Having finished welding the cylinder block, the welding site must be covered with asbestos to slowly cool the metal, thus avoiding sudden temperature changes. In order to fully ensure the tightness of the welding joint, the cylinder block should be crimped on a hydraulic stand, applying pressure to it under a pressure of 0.3 - .4 MPa.

In this case, the cylinder block was restored until all its operating functions were restored. The work required the use of argon arc welding, as well as the skill and experience of a welder, which are an indispensable tool when carrying out any welding work. From this example you can see that welding a cylinder block is not such a difficult job, but it does require care and effort, due to which the weld will become strong and durable.

Source

Repairing the cylinder block part 6 - glue instead of welding

(published in abbreviation)

ALEXANDER KHRULEV, candidate of technical sciences?

“I missed the oil” - this is how one of the drivers described his case. If you missed it, it means you didn’t check it in time. And the engine was left without oil. The consequences are clear: the connecting rod bearing “knocked”. It ended up that the connecting rod broke off and, falling between the crankshaft and the block wall, punched a good hole in the cylinder block.

This block, of course, needs to be changed. But it costs money, and a lot of it. So, although there are options, they do not always provide a real way out of the situation.

But what if you don’t change the block? Should I try to repair it? Well, it’s a good thing, but it’s not easy, requiring knowledge and some experience.

To cook or not to cook?

In principle, it is possible to repair a cylinder block with any damage. The whole question is how economically justified it is.

Of course, before starting to correct such complex damage as holes, it is necessary to outline a repair technology. The most important question is how to seal the hole. The complexity of the work, the need for special equipment and tools, and ultimately the reliability of the engine after repair depend on this.

The traditional method of repairing holes in the cylinder block is welding. However, it is difficult to simply take and weld a hole. Local heating in the weld zone always leads to the occurrence of large stresses when the block cools. And this is dangerous - cracks may form. But even if there are no cracks, the strong heating will still not go in vain, and after cooling the block may turn out to be deformed.

Of course, the result greatly depends on the qualifications of the welder and the equipment used. For example, if the block is heated before welding and then slowly cooled, the stresses will be noticeably reduced. This means that deformations will decrease and cracks will most likely not appear. True, such a process requires a special oven, and this is not so cheap. By the way, good welding equipment is also not cheap. Welding has other disadvantages related to the materials from which the engine blocks are made. Thus, alloying elements present in the metal often interfere with obtaining a high-quality weld.

When the hole is welded, the strength and rigidity of the block, damaged as a result of the breakage, will be restored. But this does not mean at all that the repaired block will regain its former tightness. It must be checked and, if necessary, the seam must be additionally sealed, for example, using various adhesive compositions.

So it turns out that in many cases welding is a rather complicated and not the most successful method of repair. Which one is better? There is no definite answer, but there is still an alternative to welding.

How to seal a hole

So, the technology used should be accessible and inexpensive, that is, it should not require expensive equipment, tools and materials; it must be performed by semi-skilled personnel and ensure high engine reliability after repair. All of the above requirements are fully satisfied by the repair method using adhesive compositions.

Are you surprised? In vain. The technology of gluing blocks has long been tested and is successfully used by a number of specialized engine repair shops.

Any adhesive composition, like welding, cannot be applied simply, as they say, directly. It is imperative to comply with the requirements, which have already been worked out quite well. Let us briefly formulate the task: it is necessary to repair the hole in the block, ensuring high strength and tightness of the wall after repair. Its solution is available to any workshop or service station.

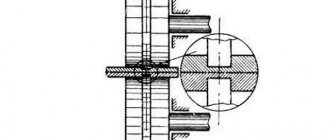

As always, we need to start with preparation. It is necessary to thoroughly clean the surface around the hole (both inside and outside the block) to a width of 20-25 mm. Next, you should cut and fit the linings from sheet steel with a thickness of 0.7-0.8 mm. In order to close the hole with an overlap of 15-20 mm on both sides - inside and outside. Since the shape of the overlays will most likely be complex, repeating the “relief” of the block’s surface, it is better to first make cardboard templates, and only then cut out the overlays using them.

The linings are adjusted into place by tapping them with a hammer to ensure their precise fit to the block. Where there is a complete fit, holes are marked and drilled. To do this, the overlay is pressed against the block, and with a 5.0-5.2 mm drill, through drillings are made through the overlay in the wall of the block. The holes should be located evenly along the contour of the hole with a pitch of 40-50 mm. The holes in the plates are drilled to 6.5 mm, and M6 threads are cut into the holes of the block. Where the walls of the block are thin enough (less than 8-10 mm), you can drill holes in the block up to 6.5 mm, and then use one bolt to tighten both linings - both outside and inside.

It would be useful to pre-assemble the structure - install and tighten all the bolts in order to check how the linings fit on the block and how the bolts are tightened. All that remains is to thoroughly clean the surfaces of the linings, degrease everything with acetone and proceed to the final stage of repair - applying the adhesive composition. What should I apply?

Indeed, the epoxy resin that was widely used in the past is no longer suitable today. For example, without filler it will leak out of the gaps between the pads and the block. Without a plasticizer, nothing will work either - the hardened resin will crack, since the cylinder block constantly experiences heating-cooling cycles, leading to stresses that are dangerous for the resin.

Compositions such as “cold welding” are more successful. Their base, as a rule, is the same, epoxy, but the properties due to additives are better - strength, ductility, and adhesion. Some of these materials can withstand high temperatures - up to 250-3000C, which will not be superfluous for the engine.

But from the available options, we chose the composition of the American company Belzona.

For the repair of cast iron parts, the company's program includes compositions with fine cast iron chips, ideal for cylinder blocks. And, of course, many years of experience in using these compositions to repair blocks is also worth a lot. In our opinion, the only drawback of Belzona materials is the relatively high price (more than $100 per kilogram).

Having mixed the components in the required proportion (1:3 by volume), apply them to the block wall along the contour of the hole and press one of the pads. After this, the hole is filled with the composition and a second overlay is installed. There should be enough composition between the linings that when the bolts are tightened, some of it is squeezed out along the entire contour of the linings.

When the composition has hardened, all that remains is to cut off the protruding part of the bolts (for aesthetic reasons or if they interfere with something) and paint the block.?

www.motornn.ru

How to weld an aluminum engine block

The cylinder blocks of the ZMZ-53 engine are made of AL-4 aluminum alloy . Welding this alloy has many features that create some difficulties during welding. The main difficulty is that during the welding process, aluminum, when interacting with oxygen, combines and forms an oxide film, which has a higher melting point, unlike pure aluminum. Being on the surface of the weld pool, aluminum oxide makes welding difficult . It is also worth paying attention to the fact that welding aluminum alloys can be difficult because the metal has high thermal conductivity, and at elevated temperatures is quite fragile, which, if certain requirements are not met, can lead to the formation of cracks on its surface.

Welding of the engine cylinder block must be done with the neutral zone of an oxy-acetylene flame. You can also use a flame with excess acetylene.

Welding work on the cylinder block is carried out by drilling into the surface of the metal edges . The crack area is cleaned of various types of contaminants using an abrasive wheel or a special metal brush. After this, the cylinder block is heated to a temperature of 250 - 300 degrees Celsius. To carry out this process, the block can be placed in a special oven for heating or heated using a burner flame. When heated, the crack should be in a horizontal position.

On both sides of the crack there are pieces of filler material, which are rods of aluminum alloy AL-4 , from which the block itself is made . The burner flame is directed at the cracks, into which a steel hook is inserted. After the metal begins to melt, the hook is immersed into the depth of the metal and with its help the molten metal is mixed.

Thus, the film of refractory oxides is destroyed, and the oxides themselves are removed from the weld pool, which makes the weld seam strong and durable. After heating the weld pool, filler material is introduced into it. It is introduced without removing the burner flame, and fluxes are used to dissolve the formed oxides.

Let's sum it up

As you can see, the cylinder block is welded with argon most often for sale. This is not the most reliable option for repairing a power plant. But there are masters who can do everything quite efficiently. Often, after a visit to them, the owners decide to sell the car, as they are constantly worried about the presence of handicraft interference in the operation of the engine. Any sound becomes scary, it seems that the engine is now going to shatter into small pieces. Therefore, when repairing a car for your own further use, it is much better and easier to perform a normal repair with replacement of the cylinder block.

When making repairs for sale, it is better to refuse any work altogether, simply discounting the price to the buyer for the amount of repair work. If the new owner wants to cook the engine with argon, that will be his problem. You will come out of this situation fairly honestly with an untarnished reputation. You should not carry out cheap argon welding in a garage car service, and then quickly go to the car market in the hope of selling the car and forgetting about all these problems. Through mutual scams, car owners have already made the car market a dangerous place where they can lose all their money. How do you feel about repairing unit housings and gearboxes using argon welding?

What are internal combustion engine blocks

The engine cylinder block is cast from cast iron or aluminum alloy. The body has holes for liners or there is a monolithic insert with those for pistons. Inside the part there are ducts for antifreeze and oil; on the lower part there are beds for the crankshaft bearings. The unit absorbs force loads and has bosses for installing cushions necessary for installation in the engine compartment. On the outer part there is a platform on which the serial marking is stamped or otherwise applied (information about this is entered into the PTS and traffic police information databases).

Features of the material

For the manufacture of parts use:

- Aluminum alloys cast under high pressure (containing silicon, copper, manganese and magnesium), allowing to reduce the weight and dimensions of the power unit. Inside the body there is a cast iron insert with cylinder mirrors. It is impossible to restore aluminum components with thin walls using thermal methods. In case of mechanical damage, the purchase of a new unit is required.

- Gray cast iron (iron with a carbon content of 2.14% and with alloying additives). The metal is used for some engines of domestic and foreign production. The crack can be welded with special electrodes. If the damage has affected the crankshaft bearings, the mounting surface of the head or the mirror, then repair is impossible.

Properties and weldability of cast iron

Due to the increased carbon content in welds, pores filled with carbon monoxide are formed. Voids reduce the mechanical strength of the cast iron structure, in which cracks appear. The metal is characterized by rapid cooling. Due to temperature differences, internal stresses arise and various modifications of crystal lattices are formed, leading to the appearance of faults. Welding requires special electrodes and requires uniform heating and cooling of the cylinder block.

The main reasons for the formation of cracks

Common causes of damage to a housing part during operation:

- a broken connecting rod that pierces its side surface;

- freezing of water poured into the cooling system;

- overheating of the internal combustion engine, leading to thermal deformation and destruction of structural elements;

- cyclic shock loads (for example, due to operating a vehicle with damaged support pads).

One of the main reasons for the formation of cracks is damage to the connecting rod.

When welding, cracks form when the walls of a cast iron part are suddenly heated or cooled. To prevent defects, the block is slowly heated and heat is supplied to it during welding. To prevent a decrease in the concentration of carbon, which combines with atmospheric oxygen and forms gas, a protective environment (for example, argon or fluxes) is used. To prevent hydrogen from entering the seam (from air or electrode coating), a protective gas atmosphere is used. Cracks can also form if the flux is incorrectly selected.

ICE welding methods

Several technologies are used to restore damage:

- hot processing;

- semi-hot exposure;

- welding without preheating.

hot

The hot process means welding with pre-heating of the workpiece with a gas torch to +600°...+700°C. After the seam is formed, the block is slowly cooled in an oven, minimizing the risk of bleaching (the appearance of a hard and brittle phase) and the formation of gas pores. To perform the work, special equipment is required, so the technology is not used in domestic conditions. The seam is characterized by increased mechanical strength (if the requirements are met). It is allowed to repair damage in hard-to-reach areas.

Semi-hot

For massive body parts, complete heating is difficult, so they are processed using semi-hot welding technology. The area around the seam is heated to a temperature of +300°...+400°C, and then cooled evenly. Increased wall thickness and greater weight of the structure reduce the risk of new cracks due to thermal stress or the formation of white cast iron crystals. The technique is designed for the use of special equipment and is not used in domestic conditions.

Stress relief and cooling

Strengthening the weld is also highly recommended to relieve stress. This is done by lightly tapping the bead with a medium-heavy hammer, such as this ball hammer.

The last critical part is cooling. Cast iron needs to cool very slowly. Ideally, it should be buried in sand or wrapped in thermal blankets, but on a normal summer day a few regular blankets will suffice. This part is a little annoying as catastrophic failure is possible at this stage. In any case, we never heard the characteristic "ringing" sound of cast iron splitting.

Preparation before the welding process

At the preparatory stage, it is necessary to clean the mating surfaces from traces of paint and oil to improve the visibility of the material. Sharp corners, which act as stress concentrators, are not allowed. The edges must be cut with an abrasive tool (for example, files or an electric carbide cutter). The recesses for the future seam should take on a U-shaped configuration with rounded transitions. At the ends of the cracks, it is necessary to drill holes to the entire depth of the wall (channel diameter - 5-6 mm).

If the cracks are located in hard-to-reach places, then it is necessary to cut out technological channels to provide access (additional ones reduce the rigidity of the cylinder block). After completing the work, the holes must be sealed (welded or closed with a screw plug). Before work, it is important to assess the labor intensity and cost-effectiveness of restoring the unit. In some cases, it is advisable to purchase a new part and make appropriate adjustments to the documents (indicate the changed identifier of the license plate unit in the PTS).

Welding technology for internal combustion engine blocks

For cold welding you need:

- Install the assembly on the mounting table. To weld a fragment, you need to combine the parts and secure them with clamps. There is no need to clean the surfaces from traces of oil or antifreeze: foreign liquids will burn out under the influence of high temperature from the burning arc.

- Fuse the metal with an electrode along the edges of the fracture, avoiding overheating of the main part of the block to a temperature above +80°C.

- Use short stitches to fill the seam, hammering the roller over the hot material. The sections should be up to 40 mm long and located at a distance from each other (to prevent overheating of the unit).

- Turn the product over and weld using a similar technique.

Point technology

This technology, which involves overlapping aluminum parts, is the most common method of cold welding of this metal. The workpieces to be joined are compressed at individual welding points, for which a special punch is used. According to this technology, parts are predominantly connected by several welding points located at a certain interval relative to each other.

Cold spot welding diagram

The quality of cold welding performed using spot technology directly depends on the degree of deformation of aluminum in the area of the weld spot. In numerical terms, this parameter characterizes the relationship between the thickness of the parts being connected and the depth to which the punch is pressed into the metal. There are standards according to which this parameter for aluminum should be 60–70%, and for alloys based on this metal – 75–90%.

Cold spot welding, which can be used to join fairly large sheets of aluminum and alloys based on this metal, has a number of advantages.

- The parts to be connected do not require preliminary fixation in special clamping devices.

- Aluminum is deformed in very small local areas - weld points.

If you have a mechanical device capable of creating significant pressure, cold welding using this technology can be performed at home.

Welding mode parameters

Welding current parameters are selected depending on the type and diameter of the electrodes. Information about this is indicated by manufacturers on the packaging. For example, for 3 mm the parameter ranges from 65 to 80 A for TsCh-4 products, and when using OZZHN-1 the value increases to 100-120 A. When using electrodes with a diameter of 5 mm, the current strength is 130-150 A and 160-180 A respectively. If the regime is violated, material is ejected from the weld pool and the workpiece overheats, leading to the appearance of cracks.

Selection of electrodes for welding

Common types of electrodes for welding cast iron (according to Russian standards):

- TsCh-4, designed for welding without heating the structure. They have a diameter of 3, 4 and 5 mm. The composition of the deposited metal includes up to 0.25% carbon, manganese, vanadium and silicon are present. The products have a base coating; surfacing 1 kg of material will require 1.4 kg of electrodes. It is allowed to use DC or AC equipment (reverse connection).

- OZCh-2, having an acid coating. They are designed for sealing cracks and surfacing material on products made of gray or ductile iron. Designed for welding with short beads (length from 30 to 50 mm) with forging immediately after extinguishing the arc and cooling under the influence of atmospheric air. Before work, they require calcination at a temperature of about +200°C for 1 hour. The rod consists of copper with the addition of iron and nickel (10% and 2% respectively), it contains manganese and a small amount of silicon.

- OZZHN-1 with basic coating. They provide a deposited material that matches the shade of gray cast iron. Designed for cold welding with short beads with forging and gradual cooling. Designed for direct current equipment with direct polarity of connection. To seal large faults, such electrodes are used in conjunction with MNC-2. Their rod consists of an alloy of nickel with iron and additives (carbon, manganese, silicon and traces of aluminum).

- MNC-2 are designed to operate without preheating the workpiece. They are used for welding defects in gray cast iron blocks. Provides a weld material with increased hardness. Welding requires DC equipment with reverse polarity.

In addition to Russian brands, there are analogues produced by the Swedish company Esab or the German factories Kjellberg or Zeller. For example, Zeller's 855 electrodes have a bimetallic core (nickel-iron alloy) and a graphite-based base coating. They are designed for welding cast iron without heating the edges (connecting steel elements with a cast iron base is allowed). Initially created for the restoration of crankcases of power units or transmission units.

Safety precautions

During the welding process, safety precautions must be observed:

- use a protective shield, clothing and gloves made of non-flammable materials;

- connect the equipment to a working AC network;

- use a welding machine with a grounding loop;

- do not use cords with damaged or missing insulation (the length of connecting wires should be no more than 10 m);

- equip the workplace with ventilation and provide protective screens;

- when welding in a room with high humidity, use a rubber mat;

- do not work where flammable liquids (for example, motor fuel or oil) are stored;

- Use special clamps to hold parts.

Equipment and materials for welding

Work must be carried out in a protective suit.

To carry out the work you will need:

- standard welding machine or inverter with the function of adjusting the current in the circuit;

- ferronickel electrodes (for example, model 855 manufactured by Zeller);

- metal brush and hammer to remove scale and remaining protective coating;

- protective shield and welder's suit to prevent burns from flying drops of metal and scale.

We recommend that you read

Muffler welding

Possible difficulties

Problems that arise when restoring parts:

- The damage affects the threaded holes intended for mounting the sensors. After repairing the fracture, it is necessary to drill the channel and restore the thread, but mechanical stress can destroy the seams. In this case, you will have to refuse to install the sensor or purchase a new unit.

- The crack runs through the cooling jacket or the engine oil supply passages. When carrying out welding work, complete or partial overlap of sections occurs. Such repairs lead to accelerated engine failure (due to local overheating or oil starvation).

- The resulting weld is not airtight, so a layer of epoxy resin must be applied. Before treatment, clean the surfaces from carbon deposits and degrease (for example, with paint solvents). After polymerization, epoxy resin does not allow liquid to pass through, but cannot withstand vibration loads and temperatures above +120°C. After welding with a ferrocopper electrode, the seam is treated with a 10% ammonium chloride solution for sealing. The reaction products fill the pores and reduce the risk of liquid leakage.

Difficulties of welding aluminum

The main difficulties encountered when welding aluminum.

During welding work, the work product heats up to a certain temperature and begins to change its color.

This happens with copper or iron - the most popular metals for the production of household items. Changing the shade helps the performer to correctly regulate the process, understand whether the heating is sufficient, determine whether the seam has been “sealed” or whether heat treatment needs to be continued. But aluminum does not change color .

Therefore, the welder cannot visually evaluate the result. The high thermal conductivity of this metal requires a limitation on the duration of thermal exposure. Exceeding the duration of exposure to high temperatures can lead to deformation, cracks, bulges and other defects.

The peculiarities of welding aluminum and its alloys are explained by a whole range of special properties that the metal has:

- The surface of this material is always covered with an oxide film , which has a high melting point - about 2000°C. The metal itself melts at 660°C.

- Drops molten aluminum

, formed during welding in the working area, are immediately covered with an oxide film, which prevents the formation of a continuous seam. To prevent this effect, it is good to use argon gas, which reliably protects the welded zone from interaction with air. - The high fluidity of aluminum in the molten state seriously complicates the formation of a weld pool. Therefore, the technology for welding aluminum requires the use of special linings that remove heat from the welding zone.

- Aluminum contains dissolved hydrogen , which tends to escape into the atmosphere. This promotes the formation of pores and crystallization cracks.

- Aluminum has a fairly high coefficient of linear expansion . Because of this, significant shrinkage occurs when the metal hardens.

- Due to the high thermal conductivity of this material, welding should be carried out using significant amounts of current.

- An important feature is that welding aluminum is often complicated by the fact that it is difficult for the performer to determine the brand of alloy from which the welded products are made. This complicates the choice of connection mode and method of its implementation.

burns on the back side

For household aluminum welding, MMA and TIG . Welding workpieces 5-7 mm thick. performed by direct current of reverse polarity. For thick-walled parts, preliminary preparation will be required. Welding aluminum with an electrode at home includes the following steps:

- thorough cleaning of workpieces from the oxide layer;

- degreasing is carried out using a solvent;

- to obtain a more durable and uniform connection, edges of products with a thickness of more than 5 mm. need to be removed at an angle of 45 to 65 degrees;

- the coating of electrodes for aluminum is characterized by active absorption of moisture, so calcination should be performed before welding;

- the surface to be welded must be heated to 250°C , which promotes more efficient melting of the oxide film;

- The current strength depends on the thickness of the walls of the product, the parameters of the seam, as well as the composition of the base metal.

Important! The weld seam should not be thick, otherwise it will be porous and cracked. Therefore, when working with massive parts, several passes should be made.

More detailed information is presented in the article “Welding aluminum with electrodes”.

Argon arc welding with a non-consumable electrode requires large financial costs. However, the quality of the seam is much better compared to the MMA connection. Home TIG welding technology includes the following operations:

- the device must be equipped with an oscillator (a device that ensures excitation and stability of the arc), which improves the parameters of welding and melting of the oxide layer;

- To avoid excess gas consumption, it is necessary to set the tungsten electrode to 5-6 mm. from the tip;

- argon is supplied at a flow rate of 5-8 l/min, after which current is supplied with a slight delay;

- after the formation of the weld pool, the welding wire melts progressively;

- welding is carried out using pulsed alternating current.

There are also general rules for welding aluminum that are recommended to be followed for any method:

- welding is performed from right to left ;

- the arc length should be 1.5-2.5 mm;

- the filler material is fed in short, progressive and reciprocating movements ;

- an angle of 90 degrees between the electrode and the wire

- It is not allowed to perform transverse vibrations with a tungsten electrode;

- Thin aluminum is welded with a copper or iron backing to dissipate heat and prevent burns.

burn-through

Is it worth trying?

Welding aluminum at home has a number of advantages :

- saving financial resources, this advantage is especially important for performers who have the necessary equipment at their disposal;

- instant results that can be checked immediately;

- the ability to use improvised means;

- no special requirements for seam quality.

However, it is worth noting the disadvantages :

- when welding aluminum at home, the performer will receive a connection of lower quality;

- sometimes difficulties arise when choosing filler material;

- at home it is difficult to use advanced technologies that are used in modern industries;

- it is more difficult to comply with safety regulations;

- electrodes may be stored in inappropriate conditions, they may become damp or deteriorate;

- lack of precise methods for quality control of the finished connection.

Help from specialists

If difficulties arise, it is recommended to contact specialized companies engaged in the restoration of parts made of ferrous and non-ferrous metals. After analyzing the damage, the repair price is calculated. It is necessary to compare the cost of restoration with the cost of a new unit. For a number of mass-produced car models (for example, from the VAZ plant), it is more cost-effective to install another unit (with simultaneous replacement of piston rings, liners and revision of the gas distribution mechanism) than to pay for repair services from a third party.

Butt method

When using this cold welding method, aluminum parts are connected by their end parts, which are first thoroughly cleaned and degreased. In order to make a connection using this method, the workpieces are fixed in special jaws with a small release of the end parts, which will be subject to compression. After the parts are securely fixed, axial pressure is applied to the clamping jaws, which compresses the end parts of the workpieces being connected, which is accompanied by the formation of a reliable permanent connection.

Scheme of butt cold deformation welding

This cold welding method, despite its simplicity, has a number of significant disadvantages and limitations in application.

- The dimensions of the clamping devices used to perform such welding limit the length of the joint formed.

- When aluminum parts are compressed, not only the ends being connected are subjected to plastic deformation, but also the part that is clamped in the jaws.

- After obtaining a permanent connection, the workpieces are quite difficult to remove from the clamping jaws.

Additional Information

After completion of the work, the surfaces must be treated (for example, if any unit is being installed). In a workshop setting, a milling machine is used to level the plane; in a domestic situation, an angle grinder is used. At the same time, it is important not to damage the mating surfaces with high precision processing (for example, for installing a clutch bell, front cover or head).

Welding an automobile cylinder block requires a highly qualified worker. Mistakes made lead to a decrease in the strength of the assembly; with cyclic temperature changes (the part warms up to +90°...+95°C and cools down to ambient temperature), new cracks may appear. In case of a large area of damage, it is possible to install patches from a sheet of steel, which are welded into cast iron. The decision on the method of restoration and the feasibility of repair is made by the master, based on the qualifications and equipment available.

Source

Replacing the cylinder block and abandoning welding is the right decision

Any welding, even by the most professional performer, will not be as high quality as installing a new cylinder block. When there is a crack in this unit, the component parts of the unit quickly break down and everything fails. Even with professional welding, it is impossible to maintain all factory dimensions down to the last micron. The cylinder block is replaced as follows:

- Based on the make and model of the engine, the specialist searches for spare parts, selects all peripheral parts that will also have to be changed, and forms a budget;

- Also added to this budget is the cost of work, which each master evaluates in his own way, but it is better to contact a professional car service station;

- Next, the engine is disassembled, the problem and its effect on all other parts, such as pistons, connecting rods, rings and seals in the unit, are studied;

- a new cylinder block is installed, the necessary parts are assembled in the right place, and at each stage several checks are performed, which proves the quality of the part;

- After assembly, it is necessary to diagnose the power unit in different planes, then test drive the car with an understanding of all extraneous sounds and noises in the engine.

If a used cylinder block is being installed, special care must be taken during the engine testing and inspection processes. However, with professional selection of the part, no negative features of the operation of the power unit should arise. That is why replacement is the optimal process for such a breakdown. But welding is not always suitable, even if done professionally.