Cold welding for heating pipes is an adhesive for eliminating leaks in a pipeline that does not have heavy loads, high pressure, or elevated temperatures. This type of heating system repair has nothing to do with inverter welding. Leaks are eliminated due to the high adhesion of the adhesive to the surface. After cold welding has set, the final result is not inferior in quality to a classic seam.

Application of the product does not require any specific skills, so repair work can be easily done with your own hands. This method is appropriate in situations where hot welding is dangerous or causes technical difficulties. It is suitable for spot sealing plumbing fixtures, radiators, pipes, expansion tanks and other structural elements of the heating system.

Advantages

- reliable elimination of cracks, chips and leaks in household pipelines;

- safe use, no deformation or stress on the metal;

- When forming a seam, no heating is allowed, no additional tools are needed;

- does not melt the material, suitable for repairing metal-plastic and plastic structures;

- repairs do not take much time, are suitable for sealing leaks in an emergency, you must strictly follow the manufacturer’s instructions;

- The most cost-effective way to repair water pipes.

Methods and means for repairing PVC pipelines

During pipeline operation or installation work, it is impossible to completely eliminate the possibility of leaks. In this case, you need to find a solution for urgent repair of products or restoration of tightness in connecting nodes. Let's consider which adhesive or sealant for polypropylene is suitable for such purposes.

Leakage in the hub connection with the fitting Source tumentoday.ru

Causes and consequences of leaks

Identifying root causes is often helpful in finding problems and solutions. More often this is a depressurization of the connecting seam. To prevent or minimize the risks of “gaps” appearing, you need to monitor:

- temperature conditions during the soldering process;

- degree of reliability of fixation of nut fasteners or crimp fittings;

- correct preparation of elements for soldering, welding or other connections (cut angle, evenness of edges, cleanliness of walls);

- the applicability of the adhesive for a specific section of the pipeline;

- admissibility of the use of sealing and sealing materials.

It is not difficult to identify problems in polymer pipelines in a timely manner. In places of depressurization, condensation (dew), leaks appear, or the pressure in the system changes downwards. Without urgent intervention, the situation may turn out to be an emergency. This applies not only to the water supply or sewerage system itself, but to neighboring premises, apartments, houses, furniture and interior items, household appliances, and electrical wiring.

Consequences of failure to detect a leak in a timely manner Source ytimg.com

Review of methods and materials for pipeline repair or restoration

The action algorithm includes three stages: turning off the water, troubleshooting, testing the system for serviceability. Only after this can you return to full operation of communications.

To stop the transportation of liquid, it is not always necessary to turn off the central riser in a particular house. Today, plumbers are trying to create separate circuits or bypasses by integrating shut-off valves or tap fittings into the system. This way, it will be possible to de-energize only part of the pipeline and continue to use the rest as before.

Before carrying out restoration measures, you need to decide how to seal the plastic water pipe. Here are the main criteria for choosing funds:

- efficiency;

- performance;

- ease of use.

More often, connections of polymer products are made with the creation of conditions for polymerization. In this case, it is impossible to disassemble the monolithic assembly and create it back. Therefore, it is necessary to cut out part of the contour and insert a new one using a similar technology (which was used previously).

Replacing a damaged section of a pipeline Source homify.com

Flaws

- used only for minor repairs of pipe damage in places where there is no load;

- requires careful adherence to application technology, otherwise it will not stick;

- during the welding process it is necessary to maintain the specified temperature;

- Unlike inverter welding, the seam is not durable, it is only a temporary measure.

Cold welding pipe repair

Review of properties and methods of fastening PVC pipes

Products made from unplasticized polyvinyl chloride are characterized by rigidity and high strength. Hollow materials with a round cross-section are also distinguished by their tightness, with a service life of over 50 years (reaches a century-long figure). For installation of communications, glue for polypropylene pipes is often used.

Brief technical description

PVC pipes are inert to corrosion, most chemicals and biological activity. Such properties are in demand in the construction of water supply and sewerage systems. Other characteristics are also useful here, such as:

- mechanical resistance to water hammer and pressure up to 1.6 MPa;

- maintaining quality at temperatures from -15 to +66 degrees Celsius (CPVC up to +100 degrees);

- resistance to environmental conditions (ultraviolet radiation, changes in humidity, temperature within acceptable limits);

- the smoothness of the walls determines low hydraulic resistance, absence of plaque and build-up from salts and fats (it is easy to clean the outside);

- safety for humans, animals and plants.

Plastic water supply in a residential area Source sakh.com

It is also worth noting the affordable prices and easy installation. The latter implies easy cutting, elasticity and a method of fastening individual elements. Here it is enough to have a set of inexpensive fittings and glue for PVC sewer or water pipes.

Product installation

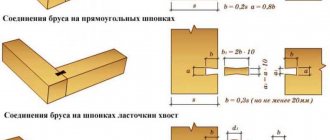

The assembly of communication lines is carried out in three ways: using sockets, bolts or using related parts. In the first case, pipes for sewer systems are used. On one side they are made with a thickening, the inner diameter coincides with the outer diameter of the main part. That is, channels or corners with tees are simply inserted into each other. To ensure the tightness of the connections, the walls are additionally coated with glue for plastic pipes.

In the case of ventilation systems, gluing is not necessary; you can limit yourself to sealing agents. Another relevant connection here is a flange connection. The technique is applicable to large-diameter pipes (entry into the building, installation of valves, valves, taps).

Flange connection of polymer channels Source techfabinternational.com

The second technique applies to plumbing products of relatively small diameter. Fittings are additionally used here. These include connectors (at different angles), tees, adapters with different end diameters. Here, for installation, you may need not only glue, but a special iron for working with polymer pipes and a bevel remover. Due to the strong and tight connection (subject to the rules), the method is otherwise called chemical welding.

Types of adhesives

Cold welding is in demand for spot repairs of pipes. Glue from foreign and domestic brands is available for sale. It differs not only in cost, but also in quality. The following materials have proven themselves well:

- Abro and HI-Gear - imported;

- Almaz and Polymet are domestic.

The main element is epoxy resin, which gives the ingredients a uniform composition and plasticity. Mineral additives are used as additional components: iron oxide, sulfur and others that affect the quality of adhesion. Each manufacturer determines their name and quantity independently. A metal component is used to enhance strength after hardening.

Review of the best brands

In all ratings of adhesives for PVC pipes, the leading brands are Tangit (Germany), Genova (USA), Griffon (Netherlands), Gebsoplast (France). Buyers speak well of the adhesives “Phoenix” , “Vinilit”, “Mars” and others, but they are not so in demand and popular.

All types of glue for polymer pipes operate on the same principle, are available in packages of various sizes, and the appropriate composition should be selected depending on the purpose and technical characteristics.

Image gallery

Photo from

Reliable “pair” - glue and Tangit solvent

Genova glue - composition from the pipe manufacturer

Griffon universal adhesive in 1 liter package

Gebsoplast adhesive for water supply and sewerage

Criteria for choosing pipes and type of glue

Cold welding for pipes varies in consistency and composition. Liquid glue is produced in two components - in the form of an adhesive mixture and a hardener. They are combined in a certain proportion immediately before use. When choosing a material for sealing defects, you need to take into account the composition and purpose. The plastic analogue has a consistency similar to plasticine. It is sold as a one-component or two-component mixture. It is made in the form of a bar, which is thoroughly kneaded before use. Manufacturers offer the following types of cold welding:

- for metal - suitable for temporarily sealing leaks in low-pressure metal pipelines, tanks, carburetors and car radiators;

- for plastic pipes - a specialized composition for plastic and plastic parts, eliminates cracks in the body well, suitable for PVC pipes, seals joints well;

- universal - can be used for plastic, metal, polypropylene, glass and ceramic products, glues worse compared to specialized compounds;

- for plumbing – eliminates cracks and leaks on sinks, toilets and other porcelain and earthenware plumbing fixtures.

Types of cold welding adhesives

Rules for working with adhesives

When working with glue, you should always read the manufacturer's recommendations. Many compounds cannot be left open for more than a few minutes, because... they set quickly, making their further use difficult. The average time during which the glue can remain open is 4-5 minutes.

In summer and winter, the compositions harden the fastest: at high ambient temperatures, the glue may become unusable after 1-2 minutes, and at low temperatures, the viscosity increases. Therefore, you should pay attention to the manufacturer’s instructions regarding operating temperature conditions.

When purchasing a specific brand of glue, you should pay attention to its preparation for use. Some types are easy enough to mix, but two-component compositions have to be combined correctly and their consistency must be monitored.

There is a risk of incorrect mixing, which leads to loss or change in adhesive properties.

You should pay attention to the solvent for degreasing surfaces. It is best to choose a composition from the same company as the glue. Even if the packaging of the adhesive composition states that degreasing is not necessary, it still makes sense to wipe the surfaces to be glued with a high-quality solvent.

Color and viscosity matter. Experienced plumbers prefer compositions of medium viscosity. They are easy to apply, and when joining parts, such glue does not spread, so you do not have to remove it with napkins.

As for color, the colorless composition is suitable for white and colored pipes. It is not visible, even if the drops protrude beyond the glued area and freeze.

Using Cold Welding to Repair a Leaking Pipe

Before starting welding work, it is necessary to turn off the shut-off valves, drain the water, and ensure good access to the problem area. The area with cracks and chips is cleaned of dirt and degreased. Be sure to remove old layers of paint. Old paint at the leak site can be cleaned with coarse sandpaper or a grinder using special attachments.

If repair work is carried out during the heating season, it is not always possible to drain the water from the system. Defects are repaired on a functioning main line. In this case, you should not count on high-quality adhesion between materials. The flowing liquid does not allow the glue to adhere well to the area.

Step-by-step instructions for using the composition

Before you start gluing plastic pipes, you should make sure that there is normal air circulation in the room and the temperature is between 5-35°C.

In addition to materials, the work will require some tools:

- for marking - marker and measuring tools;

- for cutting pipes - pipe cutters, jigsaw or hacksaw;

- for cleaning surfaces - sandpaper;

- for degreasing – solvent;

- to apply the composition - the glue itself, a brush made of natural bristles (some glues, including Tangit, are immediately equipped with a suitable brush) or a glue gun.

Surface preparation is an extremely important stage in gluing parts. They should be perfectly smooth and fat-free. If contaminants remain on the pipe, the glue will only stick on top of them and form a film, but there will be poor contact with the surface itself. This may cause leaks to develop over time.

PVC pipes are prepared for upcoming gluing in several steps:

Image gallery

Photo from

Step 1: Purchase socket fittings

Step 2: Fitting and marking pipes

Step 3: Marking pipes for preparation

Step 4: Cold Welding Rules

Pipeline bonding technology:

- Pipe marking . Before starting the installation of the pipeline, a design and detailed diagram must be prepared. The pipes are measured and marked using them.

- Cutting pipes . The next stage is preparing sections of the required length. It is best to use pipe cutters, but other tools will work. The main thing is that the cutting areas are level. The edges are cleaned with sandpaper.

- Bonding system elements . The most convenient way is a glue gun. With its help, you can evenly and accurately distribute the composition over the surface. If you don't have a gun, you should use a brush. The glue is applied so that in the selected area there are no areas free from it.

- Connecting parts . To connect, the system elements are pressed against each other for at least 20-30 seconds. During this time, the composition thickens and becomes more viscous. Then the part can be put aside for a day. It is important that the compression force is sufficient, otherwise the joint may leak during operation.

- Pipe cleaning . No matter how carefully the glue is applied, it may extend beyond the intended area. It is removed immediately before it hardens. A damp cloth, rag or sponge is suitable for this.

- Polymerization of the composition . It takes 20-24 hours for the glue to harden, so it is better not to touch the system before. You cannot move, separate or reconnect parts, or run water through pipes.

When the glue polymerization process is complete, you should check the efficiency of the system. It is launched in operating mode and all joints are carefully examined.

If it doesn't leak anywhere, everything is fine. If leaks are detected, the connections are additionally sealed.

Image gallery

Photo from

Stage 1 – straight cutting of the pipe

Stage 2 - chamfering the pipe

Stage 3 - applying adhesive composition

Stage 4 – process of gluing parts

An important nuance: when gluing parts you need to work extremely clearly. The pipeline section is inserted into the fitting in one motion. It should not be sharp, but fast. When the pipe is inserted, it should not be wiggled or twisted so as not to reduce the strength of the connection.

Is it possible to repair a heating battery using cold welding?

For metal heating circuits, specialized glue is purchased that allows repair and operation of the pipeline at high temperatures. Cold welding for steel radiators allows you to eliminate fistulas in hot water supply circuits. This method of sealing defects is used temporarily. At the first opportunity, it is recommended to weld this fragment using an inverter.

Repair of heating batteries by cold welding

This method is not recommended for use on complex structural elements of heating and water mains. Using an adhesive composition, only surface repairs of cast iron, steel and aluminum pipelines, radiators, and expansion tanks are performed, provided that there is free access to the defect site. The adhesive mixture is not a complete weld. It eliminates the defect by sealing the crack, so that mechanical action disrupts adhesion. The connection is not “pull-off” stable.

How to Seal a Hole with Sealing Tape

Using this modern material, you can efficiently eliminate small leaks in pipes located in bathrooms. Externally, it is an adhesive fabric impregnated with special substances. Most often, joints and connecting elements are sealed with sealing tape. As for straight sections, they can also be repaired using this method.

READ ALSO: Service life of polypropylene pipes: material properties, scope of use, operating conditions of polypropylene pipes

When using sealing tape, it is important to follow the following sequence of work:

- The damaged area must be thoroughly cleaned and dried.

- After stretching a small piece of tape, it is wrapped around the pipe. It is important that this procedure is accompanied by constant tension in the tape, otherwise folds will appear.

- When winding, each new turn should be laid on half of the previous one. It is best to pack the pipe with two layers of sealing tape.

The main disadvantage of this method is the insufficient resistance of the repair material to sunlight. To achieve a good service life, the wound tape is coated with additional protection.

Suitable brands

Adhesive for plastic takes up a significant part of production, since in this segment the requirements for the composition are not as strict as, for example, for means for joining metals. There is a wide selection of products from both domestic and foreign manufacturers on sale. Let's look at the most popular products in the mid-price segment:

- Hi-Gear Super putty for plastic HG6505 . Country of origin: USA. A universal product for joining products made of plastic, glass, PVC, ceramics, and metal. It has high water resistance parameters. Not soluble in petroleum products. Complete polymerization time is 1 hour. Maximum operating temperature – +204 degrees Cº. Tensile strength – 500 kg/cm².

- DoneDeal DD6659 Super adhesive for plastic . Another American made product. Indications for use: plastic, polypropylene, polyvinyl chloride, glass, plexiglass and other polymers. Complete polymerization time is 24 hours. Heat resistance ranging from -50 to +94 degrees Cº. Tensile strength – 204 kg/cm².

- Mannol 9827 . Product made in Lithuania. One-component adhesive for universal use. High polymerization speed – 15 minutes. Operating temperature range – from -10 to +80 degrees Cº.

- Cold welding Universal LAVR Ln1721 . Product from a Russian manufacturer. It is a high-temperature and water-resistant two-component adhesive with universal properties. Can be used on wet or oily surfaces. Ultimate strength is achieved after 2.5 hours. Operating temperature from -60 to +150 degrees Cº.

- Adhesive cold welding for plastic “ASTROhim” AC-9321 . Russian product. According to its technical characteristics, it is an analogue of the previous product. The manufacturer recommends for use in the automotive industry. For example, weld a hole in the expansion tank of the cooling system.

Important! Buy cold welding from trusted manufacturers. Beware of low-quality products of questionable manufacture. Pay special attention to the expiration date of the product.

Radiator repair

The technology for working with radiators is similar to that used when repairing pipes. The surface is also prepared - cleaned, washed, degreased.

Knead the required amount of welding (usually a ball about 20 mm in diameter) until a uniform color is obtained and the temperature of the material rises, and then press and smooth it on the damaged area, fixing it with a clamp or rag.

The water must be turned off in advance. Fistulas in radiators are eliminated using fiberglass - it is wrapped around the damaged area and the patch is impregnated with a liquid adhesive.

The composition usually polymerizes in a period of 30 to 40 minutes, but it is worth waiting a day before using the repaired battery again.

The cold welding method will help gain time until the end of the heating season in case of leaks and create reliable temporary seams simply and quickly.

Safety at work

Regardless of the composition: waterproof or high temperature, liquid or plasticine, etc., safety precautions must always be observed.

In order not to harm your health and get a reliable connection, it is important to know and not violate the following points:

- After drying, heat the mixture near the battery for about half an hour.

- Protect the skin from contact with adhesive. For these purposes, manipulations should be carried out in special clothing and seals. If the adhesive does end up on the skin, it is immediately washed off with water. If an allergic reaction occurs or something bothers you, you should definitely seek advice and treatment from a doctor.

- You should not use glue in cases where repairs are necessary to cutlery or those items that interact with drinking water or human food.

- Wear a respirator to avoid damaging the respiratory tract. Also, all manipulations should not take place in a stuffy room.

- Do not leave the adhesive or the part being repaired under direct sunlight.

In most cases, the seam is heat-resistant and does not emit a toxic odor, so the product can be used for household use.

Description and distinctive features

Liquid welding for plastic is a polymer adhesive mixture for joining parts of the same and different structures. The main distinguishing feature of this repair technique is that there is no need to subject the material to heat or melting.

The plastic sticks together thanks to the components contained in the adhesive. After the mass dries, the connection is close in reliability to the material that was restored.

The components of cold welding on plastic are:

- additives (mineral);

- epoxy and amine resins;

- a piece of metal.

This glue can be used not only in cases where plastic repair is required. It can also be used to restore the surface of materials such as wood, metal alloys, etc.

Adhesives can be universal. In this case, they can be used for gluing various materials. However, they form a less reliable connection than specialized compounds for a specific surface.

Application area

Plastic refers to synthetic polymer materials .

It is widely used in various industries, science, and everyday life. The wider the scope of application of polymers, the greater the demand for methods of its repair. Currently, cold welding for plastic is successfully used to repair the following materials:

- plastic piping and plumbing;

- internal and external plastic of the car: bumpers, door cards;

- housing and parts of household appliances;

- plastic products;

- linoleum and other flooring.

- fishing gear.

How to fix a leak in your home heating system

If the leak is strong and a simple clamp cannot be used to close it, the heating circuit with liquid will have to be turned off. It doesn’t matter where the leak is found - on a heating or water supply pipe - eliminating the leak will only be possible by turning off the water supply. A disconnected circuit gives scope for repairs: you can at the same time check the entire route and repair (replace) all suspicious areas.

Let's start with the simplest ways to fix a leak in a heating pipe:

Seal the gap or hole with a fabric (fiberglass) patch liberally coated with epoxy glue. The patches (there should be 2-3 of them) are cut twice as wide as the diameter of the pipe; the length should allow the pipe to be wrapped 5-7 times. The metal around the violation is cleaned with sandpaper, a file or a grinder, the area is well dried, and epoxy resin is applied to it. The fabric can be soaked with glue in advance, or you can coat it as you wind it onto the pipe - whichever is more convenient on the spot. The last fabric layer is not saturated with glue, and the end of the fabric is secured with cord or wire. Epoxy dries on a pipe in different ways: at a temperature of 20 0 C-25 0 C, a few hours are enough; at a temperature below 18 0 C, even a day is not enough.

If you have repaired a central heating pipe, then the system operates under higher pressure than individual heating, and when water is initially supplied to the circuit after the repair, a noticeable water hammer may occur, which can simply rip off the patch. Therefore, the supply valve should be opened slowly, tracking the area with the patch visually.

You can increase the strength of the patch by adding bronze or aluminum powder to the epoxy glue. If you were unable to buy powder, you can make it at home by grinding off the surface of any non-ferrous metal part with a small file or needle file. By adding such powder, you can make not 5-7 turns of fabric, but 2-3, and repairing such an area will become easier and faster.

Factory materials

From ready-made solutions, adhesives and liquids, you can use a heat-resistant, waterproof sealant to seal the leak. Such adhesive compositions are produced specifically for the repair of heating systems. When purchasing, make sure that the word “neutral” is on the label - this means that your glue will not corrode non-ferrous metal and adjacent materials.

Cold welding is also good for eliminating leaks:

- A liquid epoxy substance that is convenient for impregnating fabric patches that are applied to a hole in a water pipe. Some compounds can also work on a wet surface;

- Semi-solid plastic compositions. This cold welding looks like a small piece of plasticine consisting of two different component strips. Knead the plasticine in your hands until the substance becomes plastic (your palms should be wet - moisten them in water), cover the hole in the pipe with a small piece, and spread it over the cleaned surface. It takes 10-15 minutes to harden, after which the patch becomes so hard that it is difficult to take even with a file.

Both liquid and solid cold welding contain toxins, so it is recommended to use rubber gloves when working with it.

Sealing connections on pipes and between radiator sections

If connections at the junction of pipes or fittings are leaking, then, depending on the difference in diameters, you can immediately seal the pipeline with a metal clamp or first wrap rubber in place with a smaller diameter. The rubber band is easily wound even under pressure, stopping severe leakage.

BF-2 glue works well for sealing the threaded connection in the place where tow or FUM tape is wound. The tow is first soaked in alcohol, then coated with glue. The glue dissolved in alcohol impregnates the winding, and after drying it forms a dense waterproof layer.

What else can the winding be impregnated with and what can you wrap the pipe with so that it does not leak: in most cases, ordinary oil-based (not nitro) paint is used. To do this, wrap the tow around the thread, apply the paint with a brush, and after tightening the thread, paint this area 2-3 more times. You can turn on the heating or water supply only after 2-3 days.

If you can’t fix the leak with your own hands, you need to turn off the heating or water supply and redo the threaded connection: completely remove the old winding, clean the threads and degrease them. New tow or FUM tape must be wrapped with preliminary impregnation with sealant or paint.

- When a metal-plastic fitting leaks, it is easier to eliminate a water supply network leak: you can stop the leak by simply tightening the thread. In 90% of cases this helps;

- To stop the leak, the copper circuit only needs to be soldered;

- Propylene pipes on the heating circuit are repaired by replacing the cracked section with a new section of pipe - this requires a special welding machine for welding PP products - there are no other ways to weld propylene.

If you don’t know what to do if there is a leak between battery sections, then the most common repair is replacing the gasket between the radiator elements, or replacing the nipple. To do this, the system is turned off and the failed part is replaced with a new one. There are no other options other than temporary repairs - applying a patch using the method described above. This is a rather complicated process, since aluminum radiators have a very small distance from section to section.

To seal a leak on an aluminum surface between sections, you need to somehow manage to clean hard-to-reach places. To do this, you can use a cable - you need to wrap it around the leak and pull the ends one by one until all the paint is erased. A clean aluminum surface is sealed with epoxy mixed with aluminum powder or by cold welding.

Few people know, but you can coat a heating pipe with regular table salt! A small hole in a water supply line or heating pipe will immediately stop flowing if you rub it with a pinch of salt. If the hole is rather large, then salt is used together with a regular bandage - rewinding the leak area, sprinkle the bandage with salt.

If an aluminum radiator is leaking, then repair is a temporary measure for one season. To get through next winter, the radiator needs to be changed - it will definitely leak in another place.

How to fix a leak on a radiator

Not between sections, not on the threads, but simply on the body of the radiator - such cases occur mainly with cast iron or steel devices due to cavities that occur in the casting. Temporary repairs can be carried out as follows:

- The easiest and fastest way to stop a leak if the hole is small is to hammer a wooden plug (plug) into it. Level it with the surface of the product, cover it with sealant or cold weld;

- In addition to wood, a self-tapping screw or press washer will work well. The hardware also needs to be lubricated with sealant before screwing it into the hole.

Leaking hidden pipes

It is clear that this is the biggest nuisance that can be imagined in a newly renovated apartment. There are two options for how to seal to prevent pipes from leaking in the wall or under the floor:

- If this is a heating route, then add 100 grams of dry mustard to the expansion tank. 2-3 hours are enough for small holes to heal. The next day, you need to drain the mustard water from the system and fill in with new, clean coolant. This is done to prevent the filters in the heating circuit from becoming clogged;

- Mustard is a popular household method, but factory sealants that need to be poured into the coolant to prevent the pipe from leaking also work. The principle is the same - the next day the liquid is drained and replaced with clean one.

Causes of defects in adhesive joints

The use of glue ensures durability and reliability of fastening of polypropylene pipes, but sometimes water leaks occur. The reasons are:

- Poor surface preparation, presence of significant irregularities;

- Presence of dirt and grease;

- Incomplete sizing of the seam, actions must be carried out quickly, otherwise a film may form on the glue, which will no longer allow obtaining a strong adhesion;

- Poor mixing of the solution, no bubbles are left;

- Low compression force of materials, violation of compression time;

- Inappropriate adhesive composition.

Glue for PVC pipes and fittings is an excellent option for joining them yourself. The method will help save your budget, but the solution must be chosen carefully. And the work is carried out in compliance with the rules.