Registration process

Coated metal rods come in a wide variety, and each type is used strictly for specific purposes, therefore the preparation of certification documentation has significant differences.

For one type of electrodes, confirmation of compliance with developed quality and safety requirements is required; for another type, certification in the system of state standards is required, and some require a separate registration certificate from the Ministry of Health, which is called a passport for electrodes , where the minimum toxicity value must be indicated.

To complete the documentation, the manufacturer applies to a certification center accredited in the city where he lives, submits an application and all the necessary documents, as well as samples of manufactured products. During laboratory tests, the center’s specialists determine whether the presented products comply with the norms and standards that apply in the state, and the result is recorded in the protocol.

A certificate for electrodes is issued only in case of full compliance with all current standards.

Quality certificate for electrodes E42

Welding is considered one of the most reliable methods of joining steel parts. There are several methods for performing this work using different brands of electrodes.

Home craftsmen prefer to use manual arc welding technology and E42 electrodes. Judging by numerous consumer reviews, this type is in very high demand. Information on the technical characteristics of E42 electrodes is contained in the article.

Acquaintance

Electrodes E42 (GOST No. 9466, 9467) are metal rods equipped with a special coating. During welding operations they are used as auxiliary filler materials.

The range of these products on the modern market is quite wide. The consumer can purchase E42 electrodes with a diameter of 1.6 mm, 2-3 mm and 4-6 mm. Standard sizes of auxiliary products vary between 250-400 mm. The length of E42 electrodes with a diameter of 4 mm can reach 450 mm.

The necessary information about the filler material can be gleaned from its markings:

- The letter “E” indicates that these electrodes are intended for electric arc welding only. The filler material can be used for both manual and automatic modes.

- The designation “42” indicates that the deposited material has a strength of 420 MPa.

Purpose

E42 electrodes are used to work with parts made of carbon steel. The products are used both by home craftsmen in everyday life and by professional welders in repair shops and in many areas of industry to create connections of reduced responsibility.

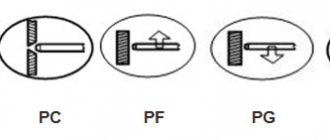

Welding work can be carried out in almost any spatial position. The exception is vertical welding “from top to bottom”. This is due to the fact that the deposits created by these electrodes are not able to withstand heavy loads.

Therefore, it is undesirable to use E42 electrodes to connect those steel parts that are subject to constant pressure from a large weight.

Chemical composition

The following chemical elements are used in the production of E42 electrodes:

- Carbon. Its content in the filler material does not exceed 0.12%.

- Manganese – 0.7%.

- Silicon – 0.3%.

- Sulfur – 0.03%.

- Phosphorus – 0.03%.

Specifications

E42 electrodes have the following properties:

- The indicator of temporary tensile strength is 420 MPa.

- “Surfacing” - 10 g/Ah.

- The rod size does not exceed 400 mm. Electrodes E42 with a diameter of 4 mm and 6 mm can have a length of 450 mm.

- Welding is performed at temperatures from -20 to +20 degrees.

- Consumption: 1 kg of auxiliary material per 1.6 kg of float.

- The seam has an impact strength of 150 J/cm. sq. at a temperature of +20 degrees. Viscosity at –40 degrees is 35 J/cm. sq.

- Seam elongation does not exceed 22%.

Safety requirements

The variety of materials for welding and methods of its implementation determines the wide use of electrodes, but each type must meet the following requirements:

- Ensure stable burning of the welding arc, minimal radius of spattering of molten metal, stable performance of welding work.

- Create optimal conditions for the formation of high-quality seam joints.

- When welding, maintain all the technological, chemical and physical properties listed in the quality certificate for the electrodes.

N. I. Novogradov, education: vocational school, specialty: welder of the sixth category, work experience: since 2001: “Inexperienced welders sometimes work with electrodes, among which many products do not meet the usability criteria due to improper storage or have expired, etc. etc. etc. You shouldn’t put your health at increased risk because business executives have decided to save money.”

Benefits of obtaining a certificate

By issuing a quality certificate for electrodes, you have the opportunity to participate and win public procurement competitions, obtain profitable cooperation with foreign brands, and strengthen consumer confidence. The document opens the door to the sales market and helps increase competitiveness and investment attractiveness.

Need instant expert advice? Just call the toll-free number or use the feedback form:

Or write to us in messengers and get an instant response from an expert:

Voluntary certification

During the issuance of a voluntary certificate, testing is carried out to determine the compliance of the main characteristics and parameters of the products manufactured by the entrepreneur with the requirements of state standards GOST R ISO numbered: 2560-2009, 3580-2009, 3581-2009 and GOST 9466-75, 9467-75, 5.1215-72, 10051-75, 10052-75.

If the applicant wishes to obtain product certification on a voluntary basis, he is provided with the benefits of selective testing of certain properties, and on the basis of which documents it will be carried out.

Order of conduct

The certification procedure on a voluntary basis has a certain standard and is not much different from the mandatory process. The main stages are:

- a written application and a package of necessary documentation are submitted to the body responsible for certification, which contains basic information about the applicant and the product;

- All documents are analyzed and a certification scheme is selected;

- samples are selected and transferred to a testing laboratory for research;

- if necessary, production assessment is carried out;

- If the research results are positive, based on the protocol received from the laboratory to the center, a certificate of conformity is issued.

If the result is negative, the applicant is offered a set of measures to eliminate inconsistencies with GOST requirements . After the changes have been made, the products are sent for re-examination.

National Welding Control Agency and its role in the certification of electrodes as a welding material

The control carried out by this organization is aimed, first of all, at identifying the correct adherence to the technologies of all welding processes carried out within the construction part. In order for these processes to be carried out without deviations from existing welding technologies, NAKS, as the main regulatory body, has quite serious mechanisms of influence.

One of these mechanisms, the purpose of which is to prevent the use of welding materials that do not meet the conditions of special welding technologies, is the certification of such materials. It is carried out in relation to welding electrodes, flux, wire and other filler elements that are used in welding processes.

Until the type of electrodes, as a welding material, passes the certification procedure with the assignment of a certificate of conformity, it will not be approved for use in production processes.

In the case of unauthorized use, this may result in the organization that has violated the NAKS requirements having to conduct an extraordinary certification to identify the percentage of defects.

Verification of documents

Certificates of conformity for electrodes of any brand are issued on a specially designed form confirming that the specified products have been tested and meet the requirements of regulatory documents on safety and quality. For example, a certificate of conformity for E42 electrodes must meet the requirements set out in GOST-9567-75-E42:

- linear parameters of the product;

- diameter of the metal rod and thickness of the coating layer;

- total weight;

- consumption for seam formation in kg;

- impact characteristics and relative elongation of the seam.

In addition to the listed parameters, the document may also contain additional information specific only to the verified type.

Certificate for electrodes

In general, electrodes are part of a conductive structure, elements of a galvanic circuit in the form of a metal plate or rod. Main parameters for electrode classification:

- scope of application – there are welding electrodes, biomedical electrodes, reference electrodes, indicator electrodes, etc., each of these types has its own application options;

Tab. 2. Purpose of welding electrodes according to GOST 9466-75

| Steel type | Designation (letter) | GOST |

| low-alloy structural and carbon steels with certain parameters (up to 60 kgf/mm² (600 MPa) tensile strength | U | 9467-75 |

| similar in parameters, but alloyed structural steel | L | 9467-75 |

| heat resistant alloy steels | T | 9467-75 |

| highly alloyed with special properties | IN | 10052-75 |

| surface layers (surfacing) | N | 10051-75 |

Tab. 1. Electrodes by material of manufacture

| Non-metallic | Metal | |

| Non-melting | Melting | |

| Covered | Uncoated | |

|

| in its modern version it is a continuous welding wire for working in shielding gases |

Tab. 3. Types of coating of welding electrodes

| Coating | Designation | |

| ISO | GOST 9466-75 | |

| Basic | B | B |

| Sour | A | A |

| Rutile | R | R |

| Pulp | C | C |

| Mixed coatings | ||

| Rutile-cellulose | R.C. | RC |

| Rutile-basic | R.B. | RB |

| Acid-rutile | AR | AR |

| With iron powder rutile | R.R. | RJ |

| Others | S | P |

Is a certificate of conformity required for electrodes?

The Unified List of Technical Regulations (PP No. 982, 2009, Section II) includes only electrodes that measure biometric potentials (9331 OKP); they require a declaration. For other types of electrodes, a letter of refusal is issued or, as an alternative, a certificate of conformity for electrodes issued on your initiative, i.e. voluntarily. You will need a certificate when joining an SRO, and when seeking a government order, in any tender, innovative project, etc.

Certificate for NAKS electrodes

This is the abbreviation of the “National Welding Control Agency” - a specially created non-profit partnership within the framework of a professional SRO, with its own standards, rules and certification system. NAKS is represented in almost all regions of the Russian Federation and is involved in, among other things,

certification of various elements of welding production. NAKS electrodes is the most convincing confirmation of their quality in Russia.

The system enjoys well-deserved authority - for example, QMS NAKS has an ISO 9001-2008 certificate from DVS ZERT.

Certificate for electrodes Uoni 13/55

Electrodes of this brand differ from others in impact strength, bending angle, etc., i.e. Can be used to work with both carbon and low alloy steel or when a ductile weld is required.

These electrodes are used to cook at extremely low (≤ -40°) and very high temperatures, in almost any position and with reverse polarity of direct current.

Voluntary certification allows you to choose evaluation criteria, so the certificate obtained at the request of the supplier for electrodes Uoni 13/45 or 13/55, OZS-12, ANO-21, MP-3 and any others is a unique opportunity to officially confirm their strengths and advantages.

Where to order a certificate of conformity for electrodes

In addition to the above certificates, you can order from us:

- certificate for LB (recommended by VNIIST), for repair of main pipelines and construction;

- certificate for electrodes OK 46 , which are used to weld carbon steels, incl. galvanized, galvanized, marine and automotive steel;

- a certificate for E42 electrodes will confirm the special parameters of the weld; as with OK46, welding is possible with any, etc., but they are also used for low-alloy steel.

Regulations

Consumable electrodes are manufactured in accordance with GOST standards and are divided into the following groups:

- Y - for carbon and low carbon steels.

- L - alloyed structural steels.

- G - for processing heat-resistant alloy steel.

- B - only high-alloy steels with special properties.

The main task of the electrode is to ensure stable combustion of the welding arc and obtain a seam with predetermined parameters . Coating or spraying is designed to protect the molten metal from oxidation, slowing down its cooling and solidification so that gases and non-metallic components evaporate.

Required documents

To certify electrodes you must provide:

- copy of TIN, OGRN;

- GOST, TU or STO, which served as the basis for creating the product;

- description of the product item (name with type, technical characteristics, range, scope of application);

- a copy of the rental agreement;

- delivery agreement.

Depending on the situation, other documents may be required. For example, this could be a notarized form of power of attorney if the application is not submitted by the owner of the company, and his interests are represented by another person.

Product certification

This technique appeared to protect the domestic market of the Russian Federation and prevent the emergence of products unsuitable for use, while manufacturers are held accountable for producing illiquid goods. Certification of types of industrial goods meets international requirements and is based on in-depth testing, as well as assessment of production conditions.

Therefore, a certificate of conformity for electrodes is a reliable guarantee of product compliance with GOST, as well as an effective incentive for manufacturers to improve quality . In addition to the certificate, a special sign is applied indicating that the product has been tested and meets the requirements of GOST.