A spring can be called any plate or spiral that is capable of springing, that is, capable of changing its original position under the influence of a certain force and restoring it after the force ceases. According to their shape, springs are divided into cylindrical, conical and spiral, and according to the type of work - into springs that work in compression, tension and torsion. In Fig. Figure 5.32 shows the most common springs - cylindrical, conical and special.

Rice.

5.32. Springs: a - cylindrical, working in compression; b - conical, tensile; c - a special spring that works for torsion; d —wire diameter; D^H

- internal diameter of the spring;

/)ts - outer diameter of the spring; t - spring pitch

A cylindrical spring is measured in two ways: by the internal diameter, if it must be seated on a rod or rod (the internal diameter of the spring must also be known to select the diameter of the mandrel when winding the spring), and by the external diameter, if the spring must be enclosed in a pipe or into any hole. The outer diameter of the spring is equal to the inner diameter plus two diameters of the wire from which the spring is made.

The average diameter of the spring is practically not measured; it serves only for technical calculations.

Springs have a pitch and length.

Step by step

is the distance between the middle (axial) lines of two turns, measured along the axis of the spring, or, in other words, the distance between the beginning and end of one turn when the spring is in a free position.

Spring length -

the distance between its ends.

When counting spring coils, only the working coils are counted.

For compression springs with unpressed ends, the number of working turns is determined by subtracting from the number of all turns one turn from each end, and 3/4 turns from each end if the outer turns are pressed and ground to form a supporting plane.

Before making a spring, determine the length of its workpiece using the formula

where / is the length of the wire blank;

D, is the average design diameter of the spring; P -

number of spring turns.

Example 1.

Determine the length of the cylindrical spring blank if the wire diameter

d =

3 mm, the internal diameter of the spring D>, is equal to 20 mm, and the number of turns of the spring is 12.

First we determine the average diameter of the spring:

Therefore, the length of the workpiece:

Example 2.

Determine the length of the cylindrical spring blank if the wire diameter is 2 mm, the outer diameter of the spring /)n is 22 mm, and the number of turns of the spring is 10.

Example 3.

Determine the length of the workpiece for a conical spring if the inner diameter of the spring at one end is 22 mm, and the outer diameter at the other end is 32 mm, the number of turns is 16, and the wire diameter is 3 mm.

Average diameter at one end:

Average diameter at other end:

Average design diameter:

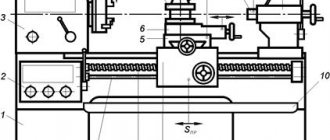

Rice.

5.33. Winding the spring: a - in a vice using a hand vice or using a curved rod; b - on a lathe; c - on a drilling machine

Coiling of cylindrical springs is done in a vice (Fig. 5.33a), on a lathe (Fig. 5.336) and drilling machine (Fig. 5.33

Source: studref.com

Cold coiling technology with quenching and tempering

The first stages of the technology coincide with the previous process. Changes begin at the heat treatment stage. It is carried out in several stages:

- Hardening. The workpiece is heated to a given temperature and held for 2 to 3 hours. Next, it is subjected to rapid cooling by immersing it in a container with mineral oil or saline solution. During the hardening stage, the workpieces must be in a horizontal position. This will avoid deformation

- Vacation. The workpiece is heated to 200-300° and kept for several hours to relieve internal stresses and improve elastic properties.

Further measuring and control operations are also carried out. The workpieces that have passed the inspection are sent for sandblasting to remove scale. If necessary, shot blasting should also be done to increase the strength of the surface layer of the metal.

The process is completed by applying a protective coating.

How to make and harden a spring at home

Almost every home craftsman knows that it is possible to make a spring from almost any wire and successfully use it in everyday life. Basically, there are no problems with making the part yourself. However, sometimes situations arise in which it is necessary to either make a spring of non-standard dimensions, or give it increased strength and elasticity. To do this, you should resort to heat treatment operations. It is quite possible to harden a spring at home. It goes without saying that a homemade part should not be used in particularly critical devices operating under increased load. For such purposes, it is recommended to use factory-made springs. But for home use in a device operating in a lightweight mode, the technology in question is quite suitable.

Required tools and materials

In order to make and harden a wire spring with your own hands, you need:

- Steel wire. The diameter is selected based on the necessary characteristics of the future product.

- Ordinary gas burner.

- Metalworking tools: pliers, hammer, etc.

- Vise.

- Stove. This may be, if available, a special one or an ordinary household one.

Additional devices that are selected individually in accordance with the size and stiffness of the spring can facilitate the process of winding the spiral.

If the use and hardening is intended to be made from wire with a diameter of less than 2 millimeters, then it may not be preheated. It will bend without any problems without this operation. However, before starting winding, it is recommended to straighten it along its entire length and completely level it.

When using wire with a diameter of more than 2 millimeters, it should be burned before starting work. Without this operation, aligning and winding it will be problematic.

Features of the operation

- The right foundation is the key to success. In factory conditions, an alloy of non-ferrous metals (65G, 60HFA, 60S2A, 70SZA, Br. B2), alloy or carbon steel is used for production. During home production, the optimal base will be an old spring of the required diameter.

- A special furnace is best suited for annealing. If this is not available, brick or metal will do.

- For cooling after heating, it is recommended to use transformer oil. If it is not available, a spindle will do.

Sequencing

1. Before tempering the spring wire, you should check the base material and make sure that the wire used is carbon steel.

2. The annealing procedure, as mentioned earlier, can add plasticity. This will make the process of alignment and winding onto the mandrel easier. You can use a special oven or any suitable oven for this. In everyday life, it is possible to harden in the most suitable structure (metal or brick). To do this, a regular fire is lit and then the future spring is placed in the coal. After heating the workpiece red-hot, the wire must be removed and allowed to cool naturally. The cooled wire will be much softer and you can work with it comfortably.

3. The softened wire should be completely aligned and begin winding onto a mandrel of a suitable diameter. During the procedure, you need to control the tight arrangement of the turns to each other. To make it easier, you can use a screwdriver.

4. To impart the required elasticity, hardening will be required. Thanks to this heat treatment, the part is harder and more durable. Hardening springs involves heating them to a temperature of 830 to 870 degrees. To do this, you can use a gas burner. Earlier we talked about hardening metal at home.

It is unlikely that you will find a suitable thermometer at home that can accurately determine the temperature of a part. Therefore, you can navigate by the color of the metal. When the required temperature is reached, the workpiece will turn light red. We recommend watching a video with a detailed description of the heating temperature. After this, the spring is placed in a cooling medium (oil).

5. Afterwards, the hardened spring must be kept in a compressed state. This requires from 20 to 40 hours.

6. Finally, process and adjust to the required dimensions.

Correct implementation of such hardening will allow you to successfully use the spring in home mechanisms.

Winding - spring

Winding of springs onto a mandrel is carried out on special (Table 6) or screw-cutting lathes.

The coiling of springs can be radial or beam-shaped.

Springs are wound onto them without preliminary cutting into blanks. At the same time, productivity increases by 6–7 times compared to manual winding.

Winding of springs onto a mandrel is carried out on special (Table 6) or screw-cutting lathes.

Springs are wound onto them without preliminary cutting into blanks. At the same time, productivity increases by 6–7 times compared to manual winding.

Winding springs from blanks of rectangular cross-section ( txs ) when placing them with their long side t perpendicular to the spring axis is very difficult (in this case, the condition I tjs 4 must be met, where s is the width of the section), and severe bending deformation on the mandrel leads to a significant thickening of the inner part sections, so that instead of a rectangle in the section, a trapezoid is obtained. The circular cross-section almost does not change its shape when wound. In order to obtain a cross-section of the coil of the correct shape (square, rectangle) after inflating the spring, the cross-section of the workpiece must first be given a special shape.

The spring is wound in a cold state on a mandrel, the diameter of which is selected taking into account the increase in the outer diameter of the spring pitch after removing it from the mandrel.

The spring is wound in a cold state on a mandrel, the diameter of which is selected taking into account the increase in the outer diameter of the spring pitch after removing it from the mandrel. After bending the outer coils and stripping the ends, valve springs are tempered at a temperature of about 300, and then compressed 5–10 times until the coils touch.

The spring is wound in a cold state on a mandrel, the diameter of which is selected taking into account the increase in the outer diameter of the spring pitch after removing it from the mandrel. After bending the outer coils and stripping the ends, valve springs are tempered at a temperature of about 300, and then compressed 5–10 times until the coils touch.

Electromotor winding of gland springs is allowed for material with a diameter of up to 1–8 mm.

The coiling of springs is carried out on screw-cutting lathes on the left turns of the spindle. A mandrel is attached to the three-jaw chuck of a lathe, the end of which is pressed by the center. The diameter of the mandrel is selected experimentally. The end of a wound wire passed through wooden clamps fixed in the tool holder is inserted into a hole pre-drilled in the mandrel of the chuck.

Winding of springs with initial tension (with tight coils) is carried out both on automatic machines by simple adjustment, and on lathes using a special device.

Winding of springs is carried out on screw-cutting lathes using a special device; small springs are made on automatic machines.

Winding of springs is carried out on screw-cutting lathes using a special device.

After coiling, the springs are subjected to heat treatment according to the following regime (for steel 50HFA): normalization at 720 - 730 C for 15 - 20 minutes with cooling in air; quenching in oil at 850 - 860 C and tempering in a salt bath at 400 - 420 C with holding for 30 - 38 minutes or in a lead bath with holding for 25 - 30 minutes. Then the springs are subjected to shot blasting and grinding of the ends, after which, by compression, the compliance of the spring characteristics specified in the drawing is checked.

Production

According to the established GOST rules, wire is created by pulling or drawing initial blanks through holes arranged in order of decreasing section diameter. To increase the tensile strength, thermal hardening is carried out at the end. When drawing, a special form for calibration is installed at the last outlet hole of the machine - a die. It is installed in the case when the material must be manufactured already calibrated and not have defects on the surface.

Next comes the tempering of the wire at a temperature of 400-480 C. The hardness of the web is 35-45 units (from 1300 to 1600 kilograms per 1 square millimeter of plane). To improve technical properties such as load suppression, carbon or high-alloy steel is used. Typically, manufacturers make it from alloy grades - 50KhFA, 50KhGFA, 55KhGR, 55S2, 60S2, 60S2A, 60S2N2A, 65G, 70SZA, U12A, 70G.

Features and Requirements

The most popular diameter is 6-8 millimeters. To make spring wire, steel wire rod is used. Technical requirements are established in accordance with GOST 14963-78 or GOST 9389-75. Sometimes deviations from the norms to the requirements of spring wire are allowed. For example, at the request of the customer, the amount of manganese in the composition can be changed, but only if chromium and nickel were not used in manufacturing.

During operation, the load will be created in places that are not resistant to flaws. Therefore, all raw materials are tested before producing springs.

The strength of the spring web directly depends on the size of the diameter; the strength of a small diameter is much higher. For example, a cross-sectional size of 0.2-1 millimeters is almost twice as strong as a wire with a cross-section of 8 millimeters. The form of release of the finished spring wire can be in the form of coils, skeins (permissible weight 80-120 kilograms) and coils (500-800 kilograms).

Required tools and materials

In order to make and harden a wire spring with your own hands, you need:

- Steel wire. The diameter is selected based on the necessary characteristics of the future product.

- Ordinary gas burner.

- Metalworking tools: pliers, hammer, etc.

- Vise.

- Stove. This may be, if available, a special one or an ordinary household one.

Additional devices that are selected individually in accordance with the size and stiffness of the spring can facilitate the process of winding the spiral.

If the use and hardening is intended to be made from wire with a diameter of less than 2 millimeters, then it may not be preheated. It will bend without any problems without this operation. However, before starting winding, it is recommended to straighten it along its entire length and completely level it.

When using wire with a diameter of more than 2 millimeters, it should be burned before starting work. Without this operation, aligning and winding it will be problematic.

Device for winding coil springs

Helical cylindrical single-core springs are widely used in various machines and devices.

Most often, springs are made from round wire, since the stresses and deformations in them are distributed fairly evenly, and their cost (compared to other springs) is the lowest. The proposed device is used for winding cylindrical springs with a diameter of up to 11 mm from wire with a diameter of 1.5 mm. Of course, the dimensions of the device can be changed to produce springs from wire of a larger diameter.

All parts of the device are made of steel. The left and right posts are cut from 5 mm thick steel strip. A groove 8 mm wide is cut into each rack. In these grooves, a handle rod 4 is installed, as well as prisms 5, which support the handle rod from below, pressing it to the upper edge of the groove.

The prism has a slider that moves in the groove of the stand, ensuring the desired position of the stand relative to the handle rod.

When replacing a handle rod of one diameter with another, the prism has to be moved. The prism with the slider can be machined entirely, or you can make the slider separately and press it into the prism itself, as was done in this case.

In the upper part of the left rack there are holes for the guide sleeve 1 and for a short threaded rod 2, on which a pedometer plate 3 is secured with a nut to adjust the pitch of the wound spring. Please note that the hole for the wire in the guide bushing is drilled after installing the bushing on the stand, and a similar hole in the threaded rod is drilled after attaching the pedometer plate to it. A 12 mm steel strip measuring 20x110 mm was used as the base for the device. Racks 6 are attached to the base at both ends using two bolts.

Before work, clamp the device in a vice or secure it to a workbench with a pair of clamps. Pass the wire through a series of holes: in the guide sleeve, in the pin, through the slot at the end of the handle rod and secure it by wrapping it around the slot in the rod.

Rotating the rod, place turns of wire on it with the required pitch. Adjust the size of this step with a pedometer plate, turning it on a pin, i.e. setting the corresponding working sector of the plate to the desired position.

Having wound the required number of turns, stop the handle. Be careful: the unloaded spring can turn the handle in the opposite direction several times. In addition, when the load is removed from the spring, the number of turns will decrease and the diameter will increase slightly. So the diameter of the rod should always be less than the required internal diameter of the spring.

The surface of the finished spring is hardened, so it is better to release it at a temperature of 260-300 ° C (heating is carried out in oil). The duration of exposure at this temperature is 5 minutes for each millimeter of wire diameter.

Cold manufacturing method

The technology of winding springs on lathes in Russia is considered more preferable. This is due to the fact that the hot method requires serious costs associated with the purchase of expensive additional equipment. The cold method has restrictions on the wire diameter; it does not exceed 16 mm. The equipment for this process consists of mandrels adapted to guide the metal thread on a rotating spool.

The type depends on the shape of the spring (cylindrical, barrel-shaped or conical). The device for tensioning and directing the wire is presented in the form of two rotating rollers. Moreover, the top one has a screw that allows you to adjust the tension and direction. When cold curling springs, metal with the necessary qualities is taken and the required part is made from it. At the end, heat treatment is carried out in order to get rid of internal stresses.

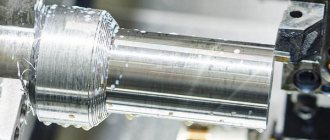

The technology itself looks like this. The steel wire is fed through a bar mounted on the equipment support, and the end is fixed with a clamp on the mandrel. The roller device exerts tension on the metal thread, which is important in the manufacture of the product. After turning on the machine, the winding of the spring begins, and the speed, depending on the diameter and material used, is in the range of 10 - 40 m/min. The number of turns is counted visually or with a counter. Upon completion, the craft is subject to mechanical processing.

This can be a technology for trimming compression springs with abrasive wheels on special machines or on industrial sharpeners. On products of other profiles, the technological ends must be trimmed or trimmed using a special device and an appropriate tool. The finished product is heat treated in electric ovens.

The technology for heat treatment of parts depends on the material. For some grades of steel, tempering and hardening are used; for others, including bronze, it is low-temperature tempering, after which the items acquire spring properties.

Finished products are checked and tested for compliance with technological parameters (tension, compression, bending, torsion). If necessary or with the consent of the customer, additional processing (galvanic, paint or other coating) is performed.

Hot manufacturing method

Winding springs on lathes using this method is available for the manufacture of products from bar material with a diameter of 10 mm or more. The technological process consists of a number of stages:

- trimming and subsequent heating;

- guying and rolling of ends;

- reheat;

- winding made of heated material;

- the ends of the workpiece are cut off;

- layout and straightening of the product, subsequent heat treatment;

- sharpening and grinding of ends, corrosion protection, dimensional control and testing (strength, wear resistance, etc.).

The workpiece is heated in a short time, and a mandatory condition must be met - uniform heating throughout the entire volume. Hot coiling requires tools and equipment (mandrel, hammers, pliers, wedges, etc.). The coiler needs to have all of the above on hand when performing work on the manufacture of springs. The mandrel is needed for winding springs on lathes, and the workpiece is secured to it using a wedge. The pliers have the shape of sponges that provide holding, installation and rotation of the part.

During the work process, you need to be guided by technological instructions that will ensure the production of high-quality products. In order to reduce waste when producing short products, a long spiral is laid on the mandrel, i.e., a blank is made for several parts. The process of winding springs on large lathes involves almost the same operation steps that are used for medium and small workpieces.

Tactics for catching crucian carp using a spring feeder

When using a spring for catching crucian carp, both loose and viscous bait is suitable. The feeder is filled with it and several casts are made for the starting feeding. Leashes with hooks are not attached. When feeding is done, you can install a smaller spring with leads.

The bait is compacted in the feeder so that it is washed out no faster than 10 minutes. All that remains is to attach the bait to the hooks and throw the equipment into the feeding area.

The fishing rod is placed on a stand, the fishing line is tensioned, and a bite alarm is mounted. The friction brake is weakened, and if there is a baitrunner, it should be turned on. Now you can sit comfortably and wait for the fish to bite.

To catch crucian carp at shallow depths and short distances, it is better to use small springs made of thin wire 1-2 mm. If you need long casting with a large depth at the fishing point, then it is better to install large models made of 2.5-3.5 mm wire. Having a wide range of feeders, the angler can easily select the optimal spring for fishing in a particular fishing area.

Especially for Homemade FISH – Sergey Viktorovich Shchetko, Belarus, Stolbtsy

Material requirements

The strength parameters and fault tolerance of a product are largely determined by the material from which it was decided to be made. Metallurgists distinguish special spring steels in the classification of steels. They have a specific crystal structure, determined both by the chemical composition and the heat treatment of the products. Highly alloyed alloys of increased purity and high metallurgical quality provide high elasticity and ductility, and are able to retain their physical and mechanical properties after repeated deformations.

Spring alloys 60S2A, 50HFA and stainless steel 12Х18Н10Т have gained popularity among mechanism designers.

Where is it used?

The production of springs can be done using cold or hot methods. For cold coiling, special spring-coiling machines and machines are used. The wire must be carbon steel because the final part will not be hardened. In Russia, the cold method is used more often, since it is not so expensive and costly.

Process description.

- The spring wire is prepared for work and checked for defects.

- The wire sheet is threaded through the bracket in the caliper, and the end is secured with a clamp on the frame.

- The upper shaft adjusts the tension.

- The winding roller turns on (its speed depends on the wire diameter).

- The fabric is cut when the required number of turns is reached.

- The last stage is mechanical and thermal treatment of the finished part.

The hot method can produce parts only with a cross-sectional diameter of 1 centimeter. During winding, rapid and uniform heating occurs. The process looks like this.

- A piece of wire, heated red-hot, is pushed through the clamp and the ends are secured with clamps.

- The upper roller sets the tension.

- The rotation speed is adjusted (also everything depends on the diameter), and the machine is turned on.

- Afterwards the workpiece is removed.

- Next comes thermal hardening - cooling in an oil solution.

- Mechanical processing of the finished part and application of an anti-corrosion compound.

During the hot winding method, cutting the spring into pieces is not provided if the desired size has already been achieved, that is, winding occurs over the full length of the web. After this, it is cut into pieces of the required length. In this method, the last heat treatment is needed to relieve internal stress on the part. It is recommended to work with an oil solution rather than water, so that cracks do not appear on the steel during hardening.

See below for what spring wire looks like.

Quality and technologyHOT SPRING COILING TECHNOLOGY

Technological process for manufacturing springs

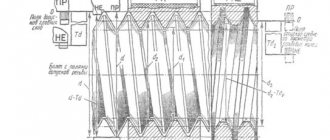

Hot coiling has a number of features. For hot coiling of springs, rod material with a diameter of 10 mm or more is used. The manufacturing process of such springs includes the following basic operations: cutting the workpiece; heating the workpiece; pulling or rolling the ends of the workpiece; heating the workpiece; hot spring coiling; cutting off the ends of the spring with heating to a certain temperature; hot spring wiring and straightening; heat treatment of the spring; sharpening and grinding of spring ends; testing and control of spring dimensions. When cutting workpieces intended for winding heated springs, it is necessary to take into account the ends along the length of the 3D coil. The length of the drawn end is calculated by the formula:

The formulas given earlier allow you to calculate the necessary parameters for the spring sizes. Preparation of the source material consists of checking the grade of steel or alloy, the condition of the surface of the rods and their straightness. The material is cut into blanks in various ways, the use of which depends on the number of springs being manufactured. In serial and mass production, the material is cut using eccentric presses, scissors and mechanical saws. The specified length of the workpiece during cutting is ensured by advancing the rod until it stops. When cutting single workpieces, marking the rods into measured workpieces is done manually, and cutting (cutting) is performed without a stop. The ends of the workpieces are pulled back on hammers, presses or forging rolls using, respectively, a backing tool, stamps or rolls with tools in the form of sectors with streams. The ends of the workpieces are heated in flame slot furnaces, in induction heaters, and sometimes in forges, which are located at a short distance from the main equipment. The heating temperature of the ends of the workpieces should be 950–1150°C. Heating above 1150°C leads to grain growth in steel, deterioration of its structure and a decrease in mechanical properties. When heated below 950°C, steel has reduced ductility, as a result of which cracks form at the ends of the workpieces when pulled back. Depending on the profile of the workpiece, the drawn ends have different cross-sections. The drawn ends must be positioned so that during winding the parallelism of the end planes of the spring is ensured. This implies certain requirements for the cross-sectional shape of the drawn ends of the workpieces. The rectangular cross-section of the drawn ends of the workpieces transforms into a trapezoidal one during the coiling process of the spring, so the ends of the spring are not parallel and do not fit tightly to the horizontal plane. To eliminate this defect, additional machining of the ends of the spring is necessary. The trapezoidal cross-section of the drawn ends of the workpieces, compared to the rectangular one, ensures better parallelism of the planes of the end turns. When winding the spring, the trapezoidal cross-section, as a result of plastic deformation, becomes rectangular (Fig. 59), due to which the labor intensity of processing the ends on sharpening machines is reduced.

It is very important to determine the relative position of the cross sections of the drawn ends, since when winding a spring on a mandrel, it is necessary to ensure that the second drawn end is parallel to the plane of the first end of the spring. Very often, the most favorable relative arrangement of the cross sections of the drawn ends of the workpiece is established experimentally during experimental winding of the springs. The shape of the drawn end of the workpiece is important. The rational form of the drawn end is considered to be one (Fig. 60, a), in which the outermost coil does not extend beyond the outer diameter of the spring. If the drawn end of the workpiece after winding extends beyond the outer diameter of the spring (Fig. 60, b), the shape is considered irrational, since it requires additional mechanical processing. Heating of blanks for winding springs should be carried out in the shortest possible period of time. In this case, uniform heating of the workpieces throughout the entire volume must be ensured with minimal scaling and decarburization of the top layer of metal. When heating blanks for winding springs, a single-stage heating mode is used, since it is believed that the cross-section of blanks for springs with a diameter of 8 to 40 mm is thin and large internal stresses cannot arise due to the temperature difference between the surface and the center of the blank. Workpieces with a diameter of 8 to 40 mm and a length of 3-6 m are heated using the contact method. Contact heaters are automated; the heating time by this method is very short and depends on the diameter and length of the workpiece.

The heated workpiece is fed with tongs, or in the mechanized method with a device, to the receiving table of the coiler, who quickly installs and secures it on a special mandrel. When making individual springs, the simplest devices and smooth mandrels of the required diameter are used. The workpiece is secured by tightening the wedge in the groove of the mandrel. The coiling pitch of the springs is adjusted by the movement of the caliper. Some corrections to the end coils of springs are made with a crochet hook. After this, the spring is quickly removed from the mandrel (for convenience, the tailstock of the machine should be hinged). Winding of large springs using the hot method is carried out on powerful spring-winding machines, and in individual production, large springs can be made on large screw-cutting lathes using mandrels on which clamping devices are mounted for fastening the drawn end of the workpiece. Special spring-winding machines make it possible to wind springs of any pitch, change the rotation correction and spindle speed, and due to this, the outermost pressed coils of the spring are automatically obtained. In addition, these machines are equipped with a special device for securing the workpiece and removing the spring from the mandrel after winding. When hot winding large springs, it is necessary to take into account that the linear dimensions of the heated workpiece are increased by 1.2-1.5% compared to its length in the cold state. Due to changes in size during cooling, the wound spring must be quickly removed from the mandrel, since during cooling, contracting in size, the spring has difficulty coming off the mandrel. When winding large springs, the winding speed should be 12 - 20 m/min. If you wind at a lower speed, significant cooling of the workpiece on the mandrel leads to the formation of cracks and the appearance of high residual stresses, and also makes it difficult to remove the cooled spring from the mandrel. High speeds do not produce high-quality winding, as they distort the profile of the turns. When tested, the spring settles by a certain amount. In order for the spring to have a given height size after settling, the free height of the spring is increased by the amount of settlement. Therefore, when winding, the free height and winding pitch of the spring are made somewhat larger than required. The increased winding pitch can be selected experimentally or calculated using the formula

where t is the increased coiling pitch of the spring, mm; Н0 — free height of the spring according to the drawing, mm; b is the amount of settlement after testing the spring for settlement, mm; c is a value that takes into account non-working pressed turns (c = 1.5 d, where d is the diameter of the workpiece); i is the total number of turns according to the drawing. Typically, the free height of the spring is 5 - 10% greater than the specified height according to the drawing.

The hot spring is removed from the mandrel and placed in a container or directly at the workplace for cooling. The wound springs are supplied for subsequent operations of wiring, straightening and preloading of non-working coils.

Heating for wiring and straightening of springs is carried out in a flame furnace or in a lead bath. A large heated spring is installed on a mandrel, which is fixed on a massive cast-iron plate, and the non-working coils of the spring are routed, straightened, and preloaded. Hot straightening of the springs is carried out on a mandrel between the plates (Fig. 61). By editing, the uneven pitch of individual turns and the non-perpendicularity of the end plane of the non-working turns of the spring axis are eliminated.

It is recommended to straighten springs in the temperature range 700–850°C. Straightening at lower temperatures causes residual stresses in the metal, which lead to upset and bending of the spring during heating for heat treatment. The wiring and straightening operations may not be performed if the winding accuracy ensures the required pitch and height of the spring with preloaded non-working coils. Springs that have undergone hot working operations are supplied for mechanical processing of the ends, which may include preliminary processing and, to more accurately ensure the perpendicularity of the end planes of the spring axis, final grinding of the ends on special mandrels.

Return to contents

For questions regarding placing orders for the production of springs, please contact:

| Moscow | Saint Petersburg | Voronezh |

| Ekaterinburg | Novosibirsk | Krasnodar |

| Krasnoyarsk | Nizhny Novgorod | Kazan |

| Tolyatti | Volgograd | Ufa |

| Permian | Rostov-on-Don | Samara |

| Tyumen |

© 2015-2018 Spring and Coiling Plant LLC. Production and sale of metal springs: production of torsion springs, coiling of compression springs, disc springs. We offer pipeline hangers and supports, as well as retaining rings.

Coil compression springs

Elastic elements can have different spatial forms. Historically, the first springs mastered by man were leaf springs. You can still see them today - these are springs on heavy-duty trucks. With the development of technology, people have learned to make more compact coil springs that work in compression. In addition to them, spatial elastic elements are also used.

Design Features

During operation, such springs take a load along their axis. In the initial position, there are gaps between their turns. The applied external force deforms the spring, its length decreases until the coils touch. From this moment on, the spring is an absolutely rigid body. As the external force decreases, the shape of the product begins to return to its original shape until it is completely restored when the load disappears.

The main characteristics describing the geometry of the part are:

- The diameter of the rod from which the spring is wound.

- Number of turns.

- Winding step.

- External diameter of the part.

The external shape may differ from cylindrical and represent one of the figures of rotation: cone, barrel (ellipsoid) and others

The winding pitch can be constant or variable. The winding direction is clockwise and counterclockwise.

The cross-section of the turns can be round, flat, square, etc.

The ends of the turns are ground down to a flat shape.

Operating area

Cylindrical coil springs of constant outer diameter and constant pitch are used more widely than others. They are used in areas such as

- Mechanical engineering.

- Instrumentation.

- Vehicles.

- Mining industry.

- Appliances.

and in other industries.

Infinite spring

January 25, 2014 admin

It's hard to believe that you can wind a spring as long as a train on a lathe. After all, the length of the spring with this manufacturing method is limited by the length of the mandrel on which it is wound.

What does this have to do with a lathe, they ask? There are special machines that literally shoot out springs: small ones - hundreds of pieces per minute, larger diameters - dozens. But when you need a few springs, of different diameters, with different pitches, it is not profitable to keep machines for each type. You clamp a mandrel into the chuck of a lathe and, repeating the old-fashioned technique, pass a wire for tension between two boards clamped in the tool holder of the machine.

The cartridge rotates, the caliper crawls along the lead screw, and the wire lies in even turns on the mandrel, to the end of which the last turn creeps up after a couple of minutes. But what is it? Instead of the specified 40 mm in diameter, all fifty, and the step turned out to be “free”. Maybe the wire was clamped loosely, without proper tension? Let's try again. Now they went too far in the other direction: the diameter turned out to be smaller than necessary. You can carry on like this for an hour. Having finally selected the required tension, we obtain the desired spring. But there is no guarantee that the second and third springs will repeat the result. And a long spring - how to wind it?

The inventor offers a universal device for winding springs on a lathe.

Productivity... If you do not stop the machine in time, it will fill the entire workshop with a spring like foam. Instead of a cylindrical mandrel, there is a steel cone on which springs can be wound in a wide range of diameters. In areas of the cone that are closer to the top, springs of small diameter are obtained, and closer to the base - large ones. A certain spring pitch is provided by the separating knife, and the wire is wound by a pressure roller during planetary movement along the generatrix of the cone. They turn on the machine, and a spring crawls out of the device, writhing like a snake. And it can be as long as a fire hose, if necessary.

Setting up the device is very simple. For example, if a spring has a smaller diameter than needed, the winding location moves closer to the base of the cone. That's all. In a few minutes you can adjust the device to any diameter within one cone, and having several interchangeable cones, you can wind a spring of any diameter and pitch within the nominal range.

(2 votes, average: 4.00 out of 5) Infinite spring ← Honey gingerbread with cherriesOrganization of labor in the apiary →

bdjola.com

Where should I start?

Experts recommend using wire from an old spring whose diameter does not suit the owner. The craftsman will only have to align it and wind it onto a mandrel with a cross-section of the required size. To do this, the wire must be absolutely straight. It will be much more plastic if it is processed in a special oven. If you don’t have one, any other device that can be heated with firewood will do. According to experienced craftsmen, birch provides sufficient heat for firing. After lighting the stove, you need to wait for the wood to burn in it. Only coals should remain. You should put the old spring in them. If the product is hot enough, it will turn red. Now the spring can be moved to the side so that it cools in the air. After this procedure, the metal will become plastic and easy to work with.

Step-by-step instruction

The first thing you need to do if you are going to make a spring with your own hands is to select the material for such a product. The optimal material in this case is another spring (the main thing is that the diameter of the wire from which it is made matches the cross-section of the coils of the spring that you need to make).

By selecting material from an old spring, you will be sure that the wire is made of hardened high carbon steel

Annealing the wire for the spring, as mentioned above, will allow you to make it more flexible, and you can easily align it and wind it on the mandrel. To perform this procedure, it is best to use a special stove, but if you do not have one at your disposal, then you can use any other device that heats wood.

In such a stove you need to light birch wood and, when it burns down to coals, put a spring in it, the wire from which you are going to use. After the spring is red-hot, the coals must be moved to the side and the heated product allowed to cool along with the stove. After cooling, the wire will become much more flexible, and you can easily work with it at home.

Read also: Camry in Lexus style

The wire that has become soft should be carefully aligned and begin to be wound onto a mandrel of the required diameter. When performing this procedure, it is important to ensure that the turns are located close to each other. If you have never winded springs before, you can first watch a training video, which is easy to find on the Internet.

You can use a screwdriver to wind a small spring.

In order for your new spring to have the required elasticity, it must be hardened. Heat treatment such as hardening will make the material harder and more durable. To perform hardening, the finished spring must be heated to a temperature of 830–870°, for which you can use a gas burner. You can determine that the required hardening temperature has been reached by the color of the hot spring: it should turn light red. To accurately determine this color, also rely on the video. After heating to the required temperature, the spring must be cooled in transformer or spindle oil.

Heated steel colors

After hardening, the spring should be kept in a compressed state for 20–40 hours, and then its ends should be processed on a sharpening machine to make a product of the required size.

After completing all the above procedures, you can begin to use the spring you made with your own hands for its intended purpose.

Springs are elastic structural elements that serve to accumulate or dissipate mechanical energy. They surround us on all sides - under the keys of the computer keyboard, in the car suspension and in the lifting mechanism of the sofa. The most common are coil compression springs. There are several ways to make them.

Spring manufacturing technology and requirements for them

Spring manufacturing technology plays an important role and is of great importance for their trouble-free long-term operation. Elastic elements are high-tech products that require qualifications and experience from design engineers and technologists, as well as a good fleet of equipment at the manufacturing enterprise.

The operation of the entire unit, where this part will be a component, depends on how correct the calculations of the spring were, the selection of material taking into account the required characteristics and features of its application, as well as the technologies used and manufacturing accuracy.

Twisted compression springs: design and operation features

During operation, this type of spring absorbs loads applied in the longitudinal-axial direction. Compression springs initially have gaps between the coils; the application of external force leads to deformation, characterized by a decrease in the length of the product, and is limited to the moment when the coils touch. When the impact is canceled, the spring must restore its shape and geometric dimensions to what they were before the load was applied.

The main dimensions that determine the type of individual part are:

- — Diameter of wire (rods).

- — Number of turns.

- — Winding pitch.

- — Product diameter.

The most common are cylindrical helical compression springs, in which the diameter of the product is the same along the entire length. These parts are widely used in various industries: instrument and mechanical engineering, mining, gas and oil production, and others.

In general, compression springs can have not only a cylindrical shape, but also a conical, barrel-shaped, or more complex one. The pitch of the turns can be constant or variable, and the winding can be clockwise or counterclockwise.

This introduces features into the generally accepted technology of their manufacture.

Spring requirements

To do their job effectively and correctly, these elements must have good strength, ductility, elasticity, endurance and relaxation resistance.

Achieving these qualities is possible subject to many factors, including:

— Correct choice of material. — Competently carried out calculations. — Compliance with manufacturing technology.

High-quality springs must meet the requirements of GOST and the technical specifications of a specific customer.

According to the standard, there are three accuracy groups for controlled deformations:

- — With permissible deviations up to 5% (+/-).

- - To 10%.

- — Up to 20%.

In accordance with this, three groups of accuracy according to geometric parameters are defined.

An important requirement for these parts is a clean surface; scratches and other defects are not allowed here, as they lead to a decrease in strength and reliability

Technological process for manufacturing springs.

Springs and leaf springs typically operate under conditions of repeated, repeated loading. Such parts must have high elastic properties and withstand a large number of repeated loads during operation without breakage and without settling. The latter means that when the load is removed, the spring or spring must completely restore its original dimensions and shape. Numerous studies have established that the durability of springs and springs is greatly influenced by the quality and cleanliness of surface treatment. Risks, hairlines, scratches and other surface defects are unacceptable, since they sharply reduce the performance of such parts. Small springs are wound from solid cold-drawn wire with a diameter of up to 6-8 mm. The wire is made of carbon steel and strengthened by special heat treatment - patenting. Essentially it is a combination of isothermal hardening and cold drawing. After such hardening, the wire acquires a sorbitol structure and is then pulled sequentially through several holes (dies). The diameter of the hole is slightly smaller than the diameter of the wire pulled through it. As a result, the wire gradually thins to the desired size. The reduction in wire diameter occurs through plastic deformation, which is accompanied by cold hardening. Thanks to this, the wire acquires high elasticity and strength properties.

After winding springs from such wire, heat treatment is needed only to relieve the stresses that arose during winding. For this purpose, tempering is carried out at 200-250 ° C with exposure for 20 minutes.

To produce springs of small and medium sizes, along with patented wire, wire obtained by the strain hardening method, which was developed at the Gorky Automobile Plant, is used. It consists in the fact that wire made from steels 45, 65G, etc. is first subjected to normalization and then cold drawing. Springs are made from such wire by winding, and then they are heated to 280–300 °C and held for 20–40 minutes. In this case, a process called strain aging occurs, which results in the necessary strengthening of the wire. In a similar way, springs can be produced by cold rolling sheets instead of drawing.

Springs of medium and large sizes, as well as springs, are made from alloy steels 50G, 60S2, etc. Carbon steels are not used due to their low hardenability. Silicon steels have increased hardenability, but are prone to decarburization. Manganese steels also have increased hardenability, but at the same time are prone to cracks during hardening.

Springs of medium and large sizes are wound from hot rods. This is followed by heat treatment.

In this case, it is recommended to follow the following rules:

1) heating of the springs for hardening should be carried out in a horizontal position or suspended on a herringbone-type device; otherwise, the spring may settle under the weight of its own mass;

2) extension springs with coils adjacent closely to one another must be clamped or tied so that they do not spread apart when heated;

3) long springs of small diameter must be placed on a mandrel before heating to avoid warping;

4) springs must be immersed in a vertical position in the quenching liquid to avoid warping;

5) regardless of the grade of steel, hardening is carried out in oil;

6) to obtain uniform properties, it is better to temper the springs in saltpeter baths, and if in chamber electric furnaces, then always with fans;

7) tempering for hardness HRC 40-47.

The technological process for manufacturing large springs includes the following operations: hot coiling; routing of turns at a given pitch; hardening; vacation; grinding of ends; cleaning In the mechanized production of springs, it is possible to combine heating for winding and hardening.

The main difficulty in the manufacture of springs is preventing warping during hardening. For this purpose, mandrels are used. In the manufacture of small-sized springs, the mandrel is used during tempering. If: such a spring becomes warped during hardening, then when mounted on a mandrel before tempering, it straightens, and under heating conditions during tempering, its dimensions are fixed on the mandrel. A large spring, warped during hardening, is difficult to fix on the mandrel before tempering. In such cases, hardening should be carried out on a mandrel. However, the design of the mandrel must provide sufficiently complete access of the quenching liquid to the spring.

Cold coiling technology without hardening

First you need to do preparatory operations. Before a workpiece is wound from wire, it is subjected to a patenting procedure. It consists in heating the material to the plasticity temperature. This operation prepares the wire for the upcoming change in shape.

During the winding operation the following parameters must be maintained:

- External diameter of the product (for some parts the internal diameter is standardized).

- Number of turns.

- Winding pitch.

- The total length of the part, taking into account subsequent operations.

- Compliance with the geometry of the end turns.

Cold coiling without tempering

Next, the end turns are ground down to a flat state. This must be done to ensure high-quality support for other structural parts, to prevent their destruction and the spring from slipping out.

The next stage of the technological process is heat treatment. Cold coiling of springs involves only tempering at low temperatures. It allows you to increase elasticity and relieve mechanical stresses that arise during winding.

After heat treatment, it is necessary to carry out test and control operations.

Further, if necessary, protective coatings can be applied to prevent corrosion. If they were applied by galvanic method, the products are reheated to reduce the hydrogen content in the surface layer.

Cold coiling technology without hardening

First you need to do preparatory operations. Before a workpiece is wound from wire, it is subjected to a patenting procedure. It consists in heating the material to the plasticity temperature. This operation prepares the wire for the upcoming change in shape.

During the winding operation the following parameters must be maintained:

- External diameter of the product (for some parts the internal diameter is standardized).

- Number of turns.

- Winding pitch.

- The total length of the part, taking into account subsequent operations.

- Compliance with the geometry of the end turns.

Next, the end turns are ground down to a flat state. This must be done to ensure high-quality support for other structural parts, to prevent their destruction and the spring from slipping out.

The next stage of the technological process is heat treatment. Cold coiling of springs involves only tempering at low temperatures. It allows you to increase elasticity and relieve mechanical stresses that arise during winding.

After heat treatment, it is necessary to carry out test and control operations.

Further, if necessary, protective coatings can be applied to prevent corrosion. If they were applied by galvanic method, the products are reheated to reduce the hydrogen content in the surface layer.

Features of the curling process

The springs obtained after coiling during operation are subject to numerous repeated loads. Therefore, they must have high elasticity characteristics and withstand a large number of repeated loads during operation without settling or breaking. The first means that the springs, after loading, must quickly restore their intended shape and size. Practice shows that the durability of a product made on a machine directly depends on the quality and cleanliness of wire processing. The surface of the springs should not have scratches, hairs, marks or other defects, as they lead to a sharp decrease in the performance of the product.

An important point for winding springs is the use of mandrels (devices), they prevent warping during hardening and tempering. Even if the part is warped during hardening, the situation can be corrected by placing it on a mandrel before the tempering procedure. For large springs, the defect obtained during hardening is difficult to correct, since in this case fixation on the mandrel is difficult. To prevent this from happening, it is necessary to carry out heat treatment of the workpiece already on it.

Device for winding springs on a lathe

With any of the two methods of winding springs on lathes, the following parameters must be ensured:

- inner, middle or outer diameter of the product;

- general and working turns, their number;

- height and pitch of the spring, taking into account subsequent processing.

If you find an error, please select a piece of text and press Ctrl+Enter.

Source: stankiexpert.ru

Hot coiling technology with quenching and tempering

Before winding, the workpiece is heated to plasticity temperature using one of the following methods

- muffle furnace;

- gas-burner;

- high frequency heating.

Heat treatment schedules are constructed based on the properties of the material and the dimensions of the workpiece.

To make an elastic element, specialized equipment is required. These are winding machines. You can make a part on a regular lathe, but it will require additional equipment with special equipment. Medium and large series are produced on semi-automatic machines that operate with minimal operator intervention. You can also make a spring from wire by hand. This will also require special equipment.

At the next stage of machining, the ends are ground on face grinding machines. For single production or small series, this can be done with a grinding wheel.

Heat treatment is carried out using mandrels that prevent product deformation in specialized furnaces for hardening and tempering. Both operations can be done in a universal oven.

For quality control, load installations and measuring systems are used. In case of single production, measurements can be made with a universal tool.

A spring that will serve for a long time and perform its tasks as efficiently as possible can be made not only in production. Yes, there is an opportunity to fully comply with the entire production process, all its parameters, and correctly select the characteristics of all technological processes (for example, hardening temperature). However, you can make a simple spring for a mechanism that operates in a gentle mode with your own hands.

To do this you will need the following materials:

- directly a spring and wire of a size suitable for the intended unit;

- gas-burner;

- metalworking tools;

- vice;

- household or thermal oven.

Coil compression springs

Elastic elements can have different spatial forms. Historically, the first springs mastered by man were leaf springs. You can still see them today - these are springs on heavy-duty trucks. With the development of technology, people have learned to make more compact coil springs that work in compression. In addition to them, spatial elastic elements are also used.

Coil springs

Design Features

During operation, such springs take a load along their axis. In the initial position, there are gaps between their turns. The applied external force deforms the spring, its length decreases until the coils touch. From this moment on, the spring is an absolutely rigid body. As the external force decreases, the shape of the product begins to return to its original shape until it is completely restored when the load disappears.

The main characteristics describing the geometry of the part are:

- The diameter of the rod from which the spring is wound.

- Number of turns.

- Winding step.

- External diameter of the part.

The external shape may differ from cylindrical and represent one of the figures of rotation: cone, barrel (ellipsoid) and others

The winding pitch can be constant or variable. The winding direction is clockwise and counterclockwise.

Spring device

The cross-section of the turns can be round, flat, square, etc.

The ends of the turns are ground down to a flat shape.

Operating area

Cylindrical coil springs of constant outer diameter and constant pitch are used more widely than others. They are used in areas such as

- Mechanical engineering.

- Instrumentation.

- Vehicles.

- Mining industry.

- Appliances .

and in other industries.

Use of springs in everyday life

Device for winding springs on a lathe

Quality and technology

Working tools and devices for winding springs

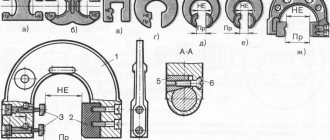

For hot coiling you need forging tongs, hammers, smooth cylindrical mandrels, wedges, etc.

steering devices and other devices.

Pliers are used to hold, rotate and install heated spring blanks onto smooth mandrels during winding. In Fig. 19, and shows the most commonly used pliers. Depending on the cross-sectional shape of the workpiece, the pliers have an appropriate

the shape of the jaws with which they compress the workpiece. The pliers must match the cross-sectional dimensions of the workpiece. To hold heavy workpieces in the jaws of the pliers, rings or clamps are used, which are put on the end of the pliers that the worker holds.

Hammers (Fig. 19, b) are used to install and secure the workpiece with a wedge on a smooth mandrel. The hammer, having a mass of 0.5-1.5 kg, is mounted on a handle made of durable and tough wood, such as birch or maple. The hammer handle must be carefully wedged to prevent the hammer from jumping off it when struck.

The mandrel is necessary to actually wind the spring, and the wedge is needed to secure the workpiece to the mandrel.

Small and medium springs are wound in a cold state. Springs can be wound manually using simple devices, as well as on lathes equipped with special equipment, and on automatic cold-winding springs.

For the manufacture of small batches of springs, the simplest devices are used. A device for winding springs operating in compression and tension (Fig. 20) consists of a cylindrical fixed mandrel 4 installed in a sleeve 5 and secured with a locking screw 3. The mandrel has a groove for fastening the end of the wire. The handle / with bushing is installed on mandrel 4. The bushing has a protrusion with a guide groove. Wire 2 is tucked into the groove and the spring is wound by rotating the handle around the mandrel. The spring tension is produced by the protrusion of the bushing.

The equipment used for winding springs on lathes consists of smooth mandrels, devices for guiding and tensioning the wire onto smooth mandrels, and a rotating spool. Smooth mandrels can be cylindrical, conical or barrel-shaped. The material for the mandrels is structural carbon steel. The shape of smooth mandrels depends on the shape of the springs. One of the ends of the smooth mandrels has a blind center hole, which serves to install the center of the tailstock. The end of the wire is secured by the chuck cam of the headstock of the lathe. To safely wind the spring, the smooth mandrel is pressed by the center of the tailstock of the lathe.

The device for guiding and tensioning the wire when winding springs on lathes consists of two pairs of rotating rollers. The upper rollers can be moved vertically by rotating the screw.

direction. The screw provides the necessary pressure of the rollers on the wire, increasing the friction forces between them. The device ensures constant wire tension when winding the spring.

The rotating reel is a carousel (Fig. 21). The reel consists of a massive base with a bearing, in which a vertical stand is installed, freely rotating around its axis. A coil with a coil of spring wire is placed on the stand. The end of the wire is passed through a stand installed in front of the lathe, which, when cutting the wire, does not allow it to tangle on the reel.

The main tools and equipment of spring coiling machines of models PN-1, A520, A521, A-522A, A524, A524A and others are: rotating rollers of a straightening mechanism for straightening the spring wire

input, middle and output guide bars of the feed mechanism (see Fig. 39), a winding pin (Fig. 22), a fixed mandrel of the winding mechanism (Fig. 23), a walking foot with a stepper finger (see Fig. 45) and a cutting cutter of the cutting mechanism (Fig. 24).

Guide bars, a fixed mandrel, a coiling pin and a cutting cutter ensure reliable operation of the spring-coiling machine and experience heavy loads when feeding and cutting wire.

For questions regarding placing orders for the production of springs, please contact:

How to make a spring with your own hands from wire and in production: we describe it in detail

Steel springs can be of different configurations and it is not always possible to purchase the desired type - the product is quite rare on the market. For this reason, I make them myself for my needs.

Requirements for wire and its diameter

Steel wire for the manufacture of a spring, which will subsequently be hardened, must meet the requirements specified in GOST 14963-78. According to the document, it is classified according to the following criteria:

- winding method (cold and hot);

- method of surface finishing (without finishing and with finishing);

- manufacturing accuracy (normal and increased);

- class of mechanical properties (general and critical use);

- diameter (from 0.5 to 14 mm);

- type of delivery (in rods or coils).

At industrial enterprises, springs are made from wire with a diameter of no more than 16 mm using the cold winding method, and up to 80 mm using the hot method. In production, they are wound using a rotating mandrel, feed rollers and one or two stop pins.

Products are made from wire grades 51ХВА, 70С3А, 65С2ВА, 60С2А, 65Г, 60ХВА with a ground, polished surface or without grinding and polishing. Based on this characteristic and the manufacturing method, the wire is produced in rods or coils of the following groups:

- A, B, C, D, E – with special finishing;

- N - without finishing.

The wire symbol in the technical documentation and on accompanying tags consists of numbers and letters:

ХХХХХ (1) – Х (2) – Х (3) – Х (4) – ХХ (5) – ХХ (6) GOST 14963-78 (7)

Where:

- 1 – steel grade;

- 2 – surface finishing method;

- 3 – manufacturing accuracy;

- 4 — class of mechanical accuracy;

- 5 - winding method;

- 6 - diameter in mm;

- 7 - designation of the standard.

For example, a wire with a polished surface made of high-precision class I steel 60C2A for hot coil springs with a diameter of 2.0 mm will have the following designation:

60S2A – A – P – I – GN – 2.0 GOST 14963-78

The state standard specifies permissible maximum deviations, out-of-roundness and the inadmissibility of certain types of defects, as well as methods of packaging and transportation.

Spring calculation

To do this, you need to use the table in the spring section to correctly select the diameter of the steel wire, the number of turns and pitch. In this case, how the new spring should work - compression or tension - plays a huge role.

The last type of springs can have a rather complex design, but you can also make it yourself.

Having performed preliminary calculations and found out the thickness of the wire for a steel spring, the pitch and number of turns, as well as having determined the design features and created a drawing of the future spring, you can proceed to practical actions.

There is also special software for calculating all parameters:

Common mistakes

We clamp the mandrel in the chuck of the lathe. We insert the end of the steel wire into the hole in the mandrel, start the rotation and wind the steel string tightly.

After checking the thickness of the spring with a caliper, we cut the wire with wire cutters and watch how our spring increases in diameter.

In addition, removing it from the mandrel will be quite problematic - to do this you will have to cut the string at the very beginning of the turn.

Doing it right

We clamp the wire on the mandrel using a screw.

Now we need to create tension on the steel string before winding.

Using a regular piece of thick plastic to clamp the wire into the cutter holder will not be enough. We will need a special device with a guide, in which the tension of the wire can be adjusted by a pressure plate made of soft metal (copper or bronze).

It is also necessary to adjust the rotation speed of the lathe chuck and the movement of the work platform to obtain the desired spring pitch.

How to make a mandrel template for winding a speaker coil?

You can make a template for rewinding speakers from any suitable metal: steel, duralumin, brass or bronze.

But it is not necessary to use more expensive non-ferrous metals instead of cheap steel. Even if the steel template is stored in a damp place, it can be wiped with machine oil or petroleum jelly to protect it from corrosion.

I also do not advise you to waste time and money on making a template of a more complex design, as some printed publications recommend. It is especially expensive to make a composite template when you only need to rewind one loudspeaker head.

It is much easier to make a template in the form of a simple cylinder with a slight taper. The winding technology, which I will tell you about below, does not require high precision when making a template, so a turner of the least qualifications can turn such a mandrel. And in some cases, you can even pick up something ready-made. Thus, some craftsmen use bodies of electrolytic capacitors of a suitable size as a mandrel.

But, as for the outer surface of the mandrel, it should be treated to a mirror shine. This will be the only price to pay for the simplicity of the design. If the turner is too lazy to do this, then you can polish the surface of the template yourself by clamping the mandrel into the chuck of a drilling machine or hand-held electric drill. The required taper in the region of 0.05 by 50 mm can also be obtained by final grinding and polishing of the mandrel.

It is also quite simple to draw a sketch of such a template for a turner. The diameter is chosen equal to the diameter of the core.

The length of the mandrel is chosen with a margin, one and a half to two times longer than the size of the intended sleeve.

The diameter of the shank can be set to 9mm so that it fits into the chuck of any hand drill.

But what to do if there are no lathes in the visible space?

To make a template of small diameter, you can use electrolytic capacitors of a suitable size.

True, we need to clarify here. The housings of electrolytic capacitors are produced by drawing from sheet aluminum. Therefore, the shape of the outer surface of the case may differ from the shape that we need. If the deviation is small, then it can be compensated for during grinding, but if it is large, then it is better to choose another capacitor.

The capacitor can be secured using an ordinary screw, pos. 1.

If, when screwing a screw into the capacitor, the foil from which the plates are made begins to rotate inside the housing along with the screw, then you can screw one or several smaller screws from the edge, position 2.

The screw position 2 must have a countersunk head so that the latter does not later cause the template to run out.

To secure the capacitor in the drill chuck, we need several parts. The dimensions and shape of the parts can be arbitrary. The only requirement for the “Shaft” is that it fits in the drill chuck.

- Screw.

- Sleeve.

- Plank.

- Shaft.

The diameter of the holes in the strip, position 3, should be slightly larger than the diameter of the screws, position 1, so that the runout of the cylindrical surface of the capacitor relative to the axis of symmetry can be eliminated.

This is what the device for mounting a capacitor in a drill chuck looks like.

The surface of the capacitor can be fine-tuned using sandpaper and an electric drill clamped in a vice.

The arrow indicates sandpaper.

You can polish the surface using a piece of felt and GOI paste.

This is what happened.

You can measure the diameter of the core using a caliper, unless, of course, the speaker housing interferes with this, which sometimes happens.

The picture shows just such a case. The Columbia rests against the upper part of the hull.

If this does happen, then the measurement can be made using a meter from the kitchen.

Help for those who studied in the computer era. A drawing room is a set of drawing tools.

Return to top to "Navigation".

Equipment and fixtures used

To make an elastic element, specialized equipment is required. These are winding machines. You can make a part on a regular lathe, but it will require additional equipment with special equipment. Medium and large series are produced on semi-automatic machines that operate with minimal operator intervention. You can also make a spring from wire by hand. This will also require special equipment.

At the next stage of machining, the ends are ground on face grinding machines. For single production or small series, this can be done with a grinding wheel.

Heat treatment is carried out using mandrels that prevent product deformation in specialized furnaces for hardening and tempering. Both operations can be done in a universal oven.

Equipment and fixtures used

For quality control, load installations and measuring systems are used. In case of single production, measurements can be made with a universal tool.