High-quality fittings are an important condition for long-term and stable operation of the door system. You just need to purchase loops of the appropriate size. If they are not available, homemade hinges will come to the rescue, which are made independently, taking into account the parameters and weight of the sash. To do this, prepare tools and materials.

Self-made loop

Why choose homemade ones?

Many people refuse industrially manufactured fittings in favor of homemade ones for several reasons. Such products:

- Withstands significant loads. What is relevant for garage doors and solid doors;

- They have the required size. If the parameters of those manufactured in industrial conditions are standardized, then when producing in-house, the size that is required is chosen;

- They have a high level of reliability, since the fittings produced for themselves have a high level of strength compared to those produced in the factory. You can always choose a material with high mechanical properties and greater thickness.

Will need

We will make the hinges from a steel plate 1 mm thick and a steel rod with a diameter of 4 mm. To turn them into a finished product, we need:

- bench vice;

- chisel with a blunt tip;

- hammer and core;

- hacksaw for metal;

- pliers;

- drill;

- metal scissors;

- file and sanding paper.

We make loops with our own hands

The process of making loops is simple. In order for the fittings to turn out to be of high quality, you must be able to perform various types of work on your own.

Preparing tools and materials

To make high-quality accessories at home, prepare the appropriate tools, materials and equipment. You must have the following tools and equipment:

- Tape measure or other measuring tool. Sometimes you can get by with a regular ruler, but in this case it must fully meet regulatory requirements;

- A marker that writes on metal. Instead of a marker, you can use chalk;

- A hacksaw with a blade for metal. Those who know how to use a grinder can use this equipment if it is available;

- File;

- Hammer;

- A welding machine with suitable technical characteristics, as well as personal protective equipment necessary for welding work.

Preparing the tool

- Metal plate 2-3 mm thick;

- Pipe section;

- Steel rod. Its diameter is consistent with the internal diameter of the pipe section. Select a rod so that it fits inside the pipe with a slight interference fit. It is better to discard a rod whose size is smaller than the internal dimensions of the pipe.

When choosing a material, pay attention to its characteristics. The plate, pipes and rod must withstand the applied operating load.

Manufacturing sequence

Initially, two sections of pipe are sawed off. The total length depends on the size of the door leaf. So if it is 11 cm, you need to prepare the first piece of pipe 5 cm long. Before cutting the pipe of the required size, carefully apply markings. You will also need a piece of pipe whose length is 1 cm longer, i.e. – 6 cm. As a result, the total length is 11 cm.

After sawing, burrs often form on the metal surface, which can cause injury during installation work. To prevent this from happening, remove defects with a file. Wear gloves to avoid damaging your hands. Perform processing on both sides.

Once the tubes are ready, the rod is prepared. Its length is equal to the total length of the pipes, that is, 11 cm. To do this, markings are applied to the surface of the rod and a saw is made. The cutting line must be perpendicular to the nominal axis of the rod.

After cutting the rod and pipes to size, they are connected together. To do this, a rod is pressed into the sleeve. Once the sleeves are in place, the plates are prepared. Their size is consistent with the dimensions of the door and the dimensions of the manufactured hinges. There should be two such plates, and they have the same length. This concludes the preparatory stage. Moving on to welding work.

After making sure that the rod has taken the desired position inside the sleeve, the ends of both tubes are welded. This prevents the rod from moving inside the pipe during operation.

The plates are then welded to the sleeves. They are positioned perpendicular to the conventional axis of the sleeves. To do this, the plates are first grabbed, and then, after making sure of their correct spatial arrangement, they are finally welded.

Decoration

To make the manufactured hinges look beautiful, they are painted or galvanized. Both of these options allow you to give the surface a beautiful appearance, as well as protect it from external negative influences. To do this, the thickness of the applied coating must be sufficient for specific operating conditions.

After decoration, the fittings look almost the same as those sold by official manufacturers. In this case, you can always choose the color of the product that you require. So, if you can find fittings on sale, as a rule, black, then hinges made in-house can be painted in any suitable color.

Ready-made accessories

Installation of hinges

After the fittings are completely ready, they are installed. To do this, one plate is screwed to the sash, the second to the door leaf. The fastening is done so that the plate with the upper sleeve is screwed to the door, and the second part to the vertical post of the box. During the installation process, the manufactured loop is assembled into a complete product.

Tools for work

Welding tools

It should be noted that even specialists, let alone inexperienced welders, cannot always perform this work correctly. They may encounter many difficulties. A beginner will read these lines and may give up. Well, is it possible to do it yourself? It turns out that it’s quite possible, even for people who have no experience. All you need to do is know how to cook at least a little and be attentive. Worth a try. To work you will need the following tools:

- hammer;

- tape measure or other measuring tool;

- level for leveling the door leaf;

- selected loops;

- mounting plates;

- electrodes;

- Bulgarian;

- welding machine;

- protective mask and gloves.

Other options

Not everyone can boast of having a welding machine at home. For others, such products turn out to be an expensive option, which is a pity to install on a light door. In this case, the necessary fittings are made from scrap materials. Which option is suitable depends on the size of the door leaf and the material of the door leaf.

To do this, prepare a conveyor belt and metal plates. Their thickness can be relatively small. You can take metal whose thickness is not much greater than the thickness of the sheets that are used in the manufacture of cans. To fasten the fittings, prepare nails 4–5 cm long.

Installation of hinges is carried out by placing the panel in the doorway. Leave one centimeter between the vertical post and the door leaf on the side where the hinges will be located. Having fixed the position of the door, nail the hinges. To do this, first place a conveyor belt and metal plates on top. In this case, the conveyor belt acts as a flexible element that ensures the opening and closing of the sash.

Such fittings are suitable for lightweight doors that are installed at the entrance to a chicken coop or a place where rabbits are kept. Their distinctive feature is the absence of creaking during operation, as well as the ability to operate without lubrication.

Thus, anyone can make loops on their own. Such fittings are suitable for garage doors and entrance doors. If you approach the manufacturing process responsibly, you can make your home a real fortress. High-quality and durable fittings can withstand external loads and at the same time have an aesthetically attractive appearance.

Pendulum loops have several other names: bar, western, metro. The origin of the names is quite justified, because doors on pendulum hinges can be found in American bars in the Western style and in Hollywood films about the wild west. These hinges are classified as double-sided; thanks to them, the door can open in both directions. The scope of application of hinges is in places with high traffic: bars, restaurants, shops, industrial and production premises.

Pendulum loops are usually installed in bars and restaurants

How to cook loops

Welding process

When working with a welding machine, it is extremely important to observe safety precautions. That’s why you need rubber gloves, as well as a mask to protect your eyes from damage. It is better to start cooking by laying the gate cloth on the surface of the ground. Welding steps include:

- The very first step is to take a lining 2-5 mm thick, then slip it under the bottom of the canopy.

- The upper part of the canopy can be lightly secured by welding at the end.

- Further, the technology differs depending on the shape of the pillar.

Operating procedure

- Install the door leaf vertically.

- Check using a plumb line.

- Place the hinges on the gate and check whether they are on the same line or not, even or not.

- The awnings are first welded towards the canvas, and then towards the pillars. It is necessary that the seam is even.

- At the end of welding, the seams are cleaned using a grinder.

Plates for welding parts

The importance of editing records

Quite often, to simplify the welder’s work and at the same time redistribute the load, metal plates are first attached to the hinges by welding.

Such plates depend on the mass and thickness of the metal gate leaf. The plates can also play a decorative role.

Hidden internal hinges

If there is a need to weld internal hinges to the sashes, it is easier to ask a professional to do it. Welding such hinges yourself is quite a labor-intensive task and requires an experienced welder. Therefore, it will not be possible to weld them with inexperienced hands.

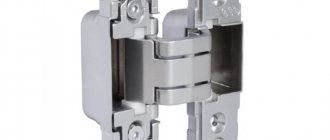

Features of bar loops

Classic door hinges, card (overhead) hinges, consist of two leaves on a common hinge. Such hinges are installed most easily - by screwing them to the door leaf and door frame.

A door pendulum hinge has fundamental differences from a regular card hinge and consists of two cards mounted on pins, allowing the door to rotate in both directions. The opening angle in one direction is 90º; accordingly, the door can swing open in both directions within a range of 180º.

Products have their own characteristics, advantages and disadvantages.

Advantages

Thanks to bar hinges, doors can be opened in both directions, which is very useful in hospitals, subways, bars and shopping centers. This design is sometimes used in ordinary residential premises to create an unusual design, most often in country-style interiors.

In addition, hinges for swing doors have the following advantages:

- comfort of opening doors when your hands (body) are busy;

- maintaining heat in the room (the doors do not remain open, as they close automatically);

- unhindered passage through the doors of a large number of people;

- automatic return of hinges to the closed position;

- Thanks to installation by insertion, the product looks aesthetically pleasing and unnoticeable in the interior and can be easily combined with other fittings.

It is worth noting that insertion can be made into a door leaf made of almost any material - plastic, metal (including aluminum), wood, glass.

Flaws

Pendulum hinges for wooden doors, if they are well made and installed, have only one drawback - the price. Their cost is several times higher than the cost of ordinary card loops.

Although the high price is partially offset by the good reliability of the products, achieved due to the spring design. Thanks to it, the hinges will last a long time, which means you will no longer need to incur the cost of replacing them, and also waste time on it.

Construction of houses

0 votes

+

Vote for!

—

Vote against!

Hinges are accessories that just a few years ago were an unremarkable unit of one option. Now the situation has changed and this fittings may be different. Hinges are necessary to open and close doorways. There are several options for mounting door hardware, the methods directly depend on the type of door. To carry out this work, you need some skills, a suitable tool and an understanding of a certain sequence of actions. Most often, hidden loops are chosen, since they are almost invisible and thanks to this everything looks more attractive. The insertion of closed loops is available to any craftsman.

Table of contents:

- Hinge options for interior doors

- DIY hidden door hinges

- Installing hidden hinges on doors

- How to install concealed awnings

- How to decide on the choice of invisible loops

- Door frame: how to install hidden hinges correctly

- Hidden hinges for doors with your own hands, adjustment

- How to hide door hinges, requirements for the mechanism

Hinge options for interior doors

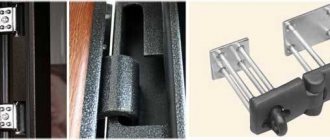

There are currently five options for door awnings. Each option has its own specificity and strengths. You can find and purchase the following types of canopies:

- straight or card - simple classic, with special side plates;

- corner - similar to the first, classic canopy with a slight difference in the shape of the plates, most often installed on pendulum structures;

- “invisible” - special mechanisms that are recessed into the door leaf, most often used on expensive doorways;

- eversible - there are no plates, but only pins on a special eversible axis;

- Italian - equipped with a special hinge, installed on European doors.

All interior hanging structures are divided into universal ones and those that have a specific direction: right-handed and left-handed.

As for the loop options, they are:

- mortise;

- invoices;

- screw-in

DIY hidden door hinges

Most often, the invisible version of the loops is a priority, as it allows you to make the object aesthetically attractive. Installation of this fittings is a little more complicated than overhead fittings and also requires more time, but if you wish and have some skill, you can install the hinges quickly and correctly with your own hands.

The advantages of this option are as follows:

- Reliability and safety - thieves will not be able to enter the premises due to the fact that they cut off the hinges, as happens with overhead options; hidden hinges are hidden from outsiders.

- High strength - the product can easily withstand the weight of the structure itself, made of metal or wood material.

- Practicality - products can last for decades with proper care.

- Visual appeal - when the doors are closed, the hinge is not visible, this allows you to maintain the aesthetics of the appearance.

- Wide variety - you can choose canopies that can withstand heavy loads or small designs for closet doors.

The disadvantage of this method is the fact that installation is not easy and requires some effort. In addition, there are a number of weaknesses of this product:

- A hidden canopy is expensive compared to other options. But even among the category of hidden interior structures, you can find those that stand higher or lower. It should be understood that the quality of the hinge directly affects the price of the product.

- Unfortunately, there are a large number of fakes on the market; as a result, you can purchase a low-quality product and lose money

- A noticeable disadvantage is the fact that not every canopy can be disassembled if necessary.

- Due to the large recessing depth, it is not always possible to install this type of canopy.

Installing hidden hinges on doors

If you do not delve into the specifics of installing the door structure, then installing the hinges of the hidden version is simple and straightforward: you need to cut a niche and insert the mechanism, then securely fasten it and start using it. But in reality, everything is a little more complicated.

Installing hidden hinges yourself is not entirely easy. It is necessary to stock up on the tools needed to carry out the work. In addition, there is an instruction that describes all the stages; following the recommendations of specialists allows you to install the mechanism efficiently and quickly. The following tools and items are required for installation:

- "invisible loops";

- fastening elements for installation;

- a simple pencil;

- yardstick;

- sharp knife;

- chisel;

- screwdriver;

- screwdriver;

- hammer.

First of all, you need to make a hidden basting. It is important to think about which direction the door will open and at what level the hidden door hinges will be located. This is not at all blindly following the requirements for show; in fact, this will affect the ease of use, durability of the canvas and consumables. To slow down the swinging of doors, experts advise installing special stoppers. In this case, the door will not hit adjacent furniture or the wall.

The number of hinges depends on the characteristics of the door: material, weight, purpose. A classic door requires the installation of two hinges, this is enough. A door made of heavy wood has a different weight, so a couple of hinges will not be enough; three elements need to be installed. Two are installed near the floor and top of the doorway. The third loop is located in the center of the side panel. All attachment points are marked with a pencil. It is necessary to calculate the depth of the excavation in advance.

How to install concealed awnings

As already mentioned, depending on the weight and size of the door, the number of hidden hinges is planned. The markup has specific stages, and they can be displayed in the following order:

- at a distance of twenty to twenty-five centimeters from the top and bottom, a mark is placed for future loops; for convenience, you need to mark with a simple pencil;

- to the future location of the canopies, it is necessary to attach loops and outline their contours;

- when installing the third loop, it is placed strictly in the center, at an equal distance between the first and second;

- two contours are immediately marked, internal for the canopy and external for the lining.

Marking a door, namely a door frame, is considered a difficult task. Like any other process, door marking has its own order and looks like this:

- the accuracy of the door leaf is measured using a building level and secured with wooden wedges;

- now you need to mark the places where the loops will be inserted;

- The loops are outlined with a pencil to indicate their attachment location.

To avoid mistakes, you need to carefully carry out the insertion process. Holes must be made after several checks of the correctness of the future location of the hinged hinges of the hidden version.

How to decide on the choice of invisible loops

The hidden mechanism is a kind of invisible mechanism, equipped with a hinge, equipped with two elements connected by a screw. To make the right choice when purchasing hidden mechanisms, you should listen to the recommendations of experts:

- before purchasing a mechanism, you should study their features; if they are not universal, then you need to decide on the sides of the attachment - right or left;

- if the hinges are inexpensive, then most likely the manufacturer saved on the control mechanism;

- When installing heavy doors, you should not prioritize the issue of savings;

- when installing a door in a new building, it is necessary to purchase a copy with adjustment so that when the house shrinks, it is possible to correct the misalignment of the door, which will happen in any case;

- when installing awnings with adjusting screws, there will be no problems with large objects drifting in - the swing angle of the sash can reach 180 degrees;

- It is necessary to select hinges based on the characteristics of the door.

Door frame: how to install hidden hinges correctly

The first step to install the mechanism is milling. This is the creation of shallow recesses for recessing hinge elements. It is possible to make such connectors yourself using a hammer and chisel. The main requirement for the notch is accuracy and correct size. The depth of the notch depends on the thickness of the loop, and if a shallow one can be widened, it will be very difficult to correct an excessively deep one.

Using a drill, make a recess along the contour outlined with a simple pencil. There is no need to rush; the result depends on the measured actions. It is necessary to make recesses in the sash and in the frame. This work takes no more than forty minutes. The hinges are installed in the cleaned recesses. This involves the following actions:

- the canopy is immersed in a specially made hole, you need to ensure that the part fits tightly and takes its place;

- Recesses are made for the screws with a special tool - a screwdriver;

- You need to insert loops into the resulting recesses and tighten them, you need to make sure that the loop does not skew.

If necessary, it is important to adjust the “invisible” hinges. In this case, you can check the functioning of the door and make sure that the “invisible” hinges are located correctly.

Hidden hinges for doors with your own hands, adjustment

The adjustment features depend on the type and version of the loop. And although there is a wide range of hidden-mount hinges on the market, they all have identical adjustment options and design. To adjust the hinges, you must follow the following steps:

- the cover is removed from the loop, this allows you to expose the adjustment mechanism;

- to change the vertical skew of the door, you should turn the bolt; this manipulation can be done using a special hex key;

- Under the mechanism panel there is a screw with which the surface of the blade is adjusted.

Expensive and complex structures have a complex adjustment mechanism in three directions at once, and this makes it possible to create ideal conditions for operation and quality of service.

It is necessary to avoid the situation when hinges are purchased immediately before installing the product. Such purchases can be made in a hurry and without taking into account many features, which will negatively affect the durability of the door. It is recommended to purchase hinges in parallel with the purchase of the door, in order to take into account its dimensions and weight, and select the color of the hinges. And although they are called hidden and are partially recessed, they are visible when the doors are open, so it is advisable to select a shade.

Also, you should not purchase a mechanism of unknown origin or go for cheapness: hinges ensure reliable opening and closing of the door.

You can make installation easier and faster using a special template. This will help avoid mistakes when basting.

How to hide door hinges, requirements for the mechanism

There are certain requirements for fittings. The main thing is that they must withstand mechanical loads. Since the door material can be different, awnings are divided into three main categories:

- for doors up to sixty kilograms of weight;

- for a one hundred and twenty kilogram door;

- for massive structures weighing up to two hundred and fifty kilograms.

If the door has even more weight, individual structures for fastening are made. There are a number of requirements for hinges:

- they must be durable, reliable, and easy to install;

- the form must be made in such a way that the fastening is as reliable as possible;

- it must be taken into account that during its service life the door can open half a million times, so the material must be appropriate;

- priority is given to the use of hinges made of aluminum, hard plastic or metal - depending on each specific situation;

- parts must be coated with anti-corrosion agents.

If you still have questions about how to make a choice and install hidden hinges with your own hands, watch the video. There you will find answers to all questions. It is possible to install hidden hinges on your own if you follow the recommendations and prepare the necessary tools. The use of such mechanisms will allow you to enjoy the quality and aesthetics of the product.

Selection of pendulum loops

Choosing pendulum hinges is no more difficult than usual, the main thing is to know what you should pay special attention to. The most important selection criteria are determined not by aesthetic qualities, but by the quality of the products themselves. Let's look at them in more detail:

- The first thing you should pay attention to when purchasing is the manufacturer. It is best to give preference to brands from Germany or Italy.

- The second important criterion is the width of the product. Pendulum hinges are available in different widths, so they should be selected to suit the thickness of the door.

- The third selection criterion is load weight. On average, one loop can support a weight of 25 to 60 kg. In some cases, three or more pieces may be needed (the heavier the door, the greater the number of hinges required).

- The fourth criterion is the aesthetics of the product. Bar pendulum hinges can vary in length and color. The most common sizes are 75 mm, 100 mm, 125 mm; popular colors are matte brass and polished brass, matte chrome and polished chrome, and bronze.

How to properly weld hinges on a gate made of corrugated sheets. Hinge installation sequence

- How to weld hinges on gates so that the metal does not move and the gate opens easily. For straight hinges, it is recommended to weld them onto the gate first while it is on a flat surface, on the ground or on a mounting table.

- The procedure for both loops is identical. After the loops have already been tacked, you need to use a rectangular block (30x30) to set the loops, placing it along the loops.

- Next, two tacks are made on each side of the loops. Cook the loops using short potholders, alternately on each side of the loop.

- Then the loops are welded to the posts. The gates are set with the required gap of one to one and a half centimeters in the middle, the gap near the pillars can be two to two and a half millimeters. The bottom of the loops is tacked to the posts; if necessary, you can use inserts between the posts and loops made of a round or rectangular section of a suitable size.

- Now you can carefully open the gate, carefully holding it, and if the gate opens easily, then several tacks are made from the outside.

- After closing the gate, it is necessary to make a stand in the middle so that they do not sag during cooking. The welding seam is laid from bottom to top. After welding, it is necessary to allow the hinges to cool, and only then can the gate be opened. To weld the hinges on the other side, a stand is also made under the gate leaf.

For half the length of the loop, a backing of two to four millimeters is made under the lower half of the loop, and the upper part is grabbed from the end. If the gate is installed on round supports, then the hinges extend 5mm outside the gate, and if the supports are rectangular, then they must be welded flush.

Installation of pendulum hinges

The installation of pendulum hinges is almost no different from the installation of overhead and mortise hinges. The sequence of actions is as follows:

- Marks are placed on the door leaf and door frame to determine the location of the hinges.

- Stoppers are removed from both loops (pendulum loops are usually spring-loaded).

- Then a mandrel is inserted into the hole on the hinge and turned clockwise.

- The cards are applied to the surface of the door and secured with self-tapping screws in accordance with the diagram proposed below.

If the pendulum loop is spring-loaded, then before starting work it is relaxed, and at the end it is clamped again

- The springs are then compressed. To compress the spring, you need to turn the mandrel clockwise and then insert the stopper into place.

- After this, you should screw the hinges to the door leaf and to the door frame.

- At the final stage, the door is checked for smooth movement. If you find that the door closes unevenly, the spring will need to be adjusted.

Having installed the element on the door leaf, you can begin attaching the mating parts to the door frame

- This completes the installation of the pendulum hinges.

To clearly understand what pendulum hinges are, what the principle of their installation and adjustment is, we recommend that you familiarize yourself with this video instruction.

In everyday life there are often situations when the most convenient would be a door that swings open in any direction. But ordinary canopies do not allow this. But there are special double-sided door hinges designed just for such structures. They are often called pendulum or bar.

The features of such loops, their scope of application, design and installation will be discussed in this article.

Types of loops and their properties

The gate lasts for more than one year. At the same time, it must provide reliability and a good level of protection, and the hinges that hold it must:

- turn without effort;

- do not make sounds;

- don't hang out;

- be strong.

The quality of the product, the reliability of the manufacturer and the permissible load are important.

If you hang heavy sashes on weak elements, they will quickly fail. Sometimes the number of loops increases to six instead of the standard four.

In the context

Types of loops:

- Cylinder-shaped (drop-shaped) - the design has a support bearing, is not used for light gates, load - up to 400 kg.

- In the form of a cylinder with an amplifier - the design includes a support bearing, and for reinforcement there are plates that are designed for better load distribution. For such loops the maximum load will be 600 kg. They are fastened by welding or screws and are suitable for swing gates.

- Through - this type of hinge is used when it is not possible to weld them or use screws. To fix such a hinge, you need to drill through the post, and it will be attached to the sash using nuts. Can withstand a maximum of 200 kg.

- Three-section - for very heavy large sashes. They are highly resistant to burglary. They are secured by welding.

- Forged (zhikovina) - the installation of hinges of this type has been used since ancient times. In addition to the fact that they perform their function well, these loops are very decorative. It is best to use them for wooden gates.

- Arrow hinge – made of steel, with hinges, suitable for heavy gates made of thick metal. They can be made curly. They are most widespread when used on garage doors.

- Adjustable - provide for changing the position of the sashes in height. They are usually used when the support posts can change their position. The maximum load of these loops is 200 kg.

Balls for easy and smooth opening

Scope of application

The easiest way to illustrate the operation of swing doors is using the example of cowboy salons. They say that cowboys used to ride into a bar directly on a horse, but, as you understand, the horse, as you understand, cannot open the door for itself. That's why they came up with structures that move freely around an axis in any direction.

Now the scope of application of pendulum loops has become mainly places with high traffic volumes of people - retail premises, train stations, subways. They are also convenient in cases where it is difficult for a person to open the door towards themselves. For example, if his hands are full, or he is a wheelchair user.

Therefore, double-sided door hinges are often used in medical institutions, catering establishments, warehouses, as well as in apartments where elderly or disabled people live.

But such structures do not always perform only a utilitarian function. They fit very organically into some interior styles. For example, the last picture shows a decorative wooden gate, stylized as the entrance to a cowboy saloon.

Pros of hidden awnings

Hidden hinges for doors are now in quite high demand and the reason for this is a number of undeniable advantages of these mechanisms.

- Hidden canopies are anti-vandal fittings; these mechanisms are not visible, which means they cannot be affected in any way, for example, by cutting them off;

- The range of hidden awnings is impressive in its diversity; there are awnings in furniture design, for light cabinets, and at the same time, powerful metal hinges for doors and a quarter are produced;

- Door canopies for hidden installation are especially valued in furniture production; such fittings do not spoil the appearance of the products;

- The amplitude or opening angle of a hidden canopy is often greater than that of its traditional counterpart;

- Hidden hinges are made of either stainless steel or high-strength alloys and can withstand quite heavy loads.

Hidden hinges are made of high-strength alloys, especially for canopies for steel doors

Selection options

To choose reliable and suitable double-sided door hinges, you need to pay attention not only to their appearance and color. This, of course, is also important for aesthetic perception. But it’s even more important that the door works properly and lasts a long time.

Therefore, we consistently evaluate the following parameters:

- Opening direction. This has already been mentioned above.

- Dimensions. First of all, the width of the cards, which should not be greater than the thickness of the door leaf.

- Permissible load. It is unlikely that every canopy comes with an instruction manual, but the seller should have information about the maximum load on it.

Advice. Please note that the load is per loop. Knowing the mass of the door leaf, you can calculate the required number of canopies.

- Appearance. This is also a shape that may differ from the standard rectangular one. And a color that matches the door or other interior details. The choice is quite large: gold, chrome, brass, bronze in matte and polished versions. There are also canopies coated with powder paint in different colors.

Some products come with additional features. For example, bearings for smooth and silent movement and elements for regulating the speed of spontaneous closing of the door.

Homemade gate hinges: save 1000 rubles

Good hinges for metal gates are expensive. the price for one loop can reach about 1000 rubles. Of course, you want to save such an impressive amount for an ordinary piece of metal. Is it possible to do this? It turns out that it is possible!

This article will talk about how to make homemade gate hinges with your own hands . Go!

And it is proposed to make our miracle loops from ordinary scraps of metal pipes. It is necessary to take pipes of such a diameter that a smaller pipe fits inside the large pipe.

It is also necessary to weld the bottom of the outer pipe. To protect the internal mechanism from external influences. As a result, we have a high-quality analogue of the factory hinge. You can even weld the bottom of the inner tube to fit the bearing inside.

A high-quality hinge will last a particularly long time if it is well lubricated. Our homemade loop also requires timely lubrication . For this we used graphite lubricant. You can take any similar lubricant.

The final step in our work will be attaching metal plates to our pipe scraps so that we can comfortably attach our loops to the elements of the enclosing structure.

The final version of homemade loops is shown in the photo below. As you can see, these loops are not at all different from their store-bought counterparts, but cost mere pennies.

We hope that this article will be useful to you, dear readers! We wish you smart savings and efficient use of resources!

Installation

The installation of such loops is slightly different from the installation of ordinary card loops. To better understand the description below, first look at the completeness of the products and their diagram.

So, double-sided spring door hinges can be adjusted by changing the compression force. Before installation, they must be loosened, and after installation, tightened to ensure that the base returns to its original position on its own.

- 1 – spring;

- 2 – bushing with holes for the stopper;

- 3 – stopper;

- 4 – locking screw;

- 5 – end nut.

And the mandrel is a metal pin with which adjustments are made.

Now you can see how to install a door on double-sided spring hinges with your own hands:

| Image | Description |

Advice. The adjustment must be carried out carefully, without applying much effort. Otherwise you can break the spring.

Often, over long periods of use, the springs themselves weaken. In such cases they are pulled up again. The main thing is not to lose the mandrel.

Installation Guide

The hinges are installed on the side in which the opening will occur. Work is carried out in a horizontal position; surfaces involved in welding are degreased and treated with a brush, having previously removed the layer of paint coating in the area.

The location of future hinges is outlined - they are placed 15-20 cm from the upper and lower edges of the gate. To do this, the door is placed inside the opening on mounting pads that provide a gap between the bottom edge of the gate and the ground. Level by changing the height of the linings. It is recommended that at least two people perform this operation. Having leveled and fixed the canvas, apply the awnings, mark their location on the gate and on the door frame.

After applying the markings, the swing element is removed from the stands, removed from the opening, and returned to the horizontal plane. The hinges are welded in disassembled form: the upper half is allocated for the door leaf, the part with the pin is for supporting structures. The part is laid along the marks and secured by preliminary spot welding. Check the level to see if there is any misalignment. If the axis of the canopy is parallel to the plane of the swing element, major welding is performed along the entire contact line. The finished continuous seam is cleaned with a grinding machine.

The lower part of the loop is welded to the loot. If it is not possible to lay the support horizontally, then they work in a vertical position. Tack spot welding is performed according to the following algorithm:

- Above.

- From below.

- In the center.

- In the center of the upper half of the future seam.

- In the center of the lower half of the future seam.

This is followed by leveling and checking installation of the sash. If there are no defects in the connection, it can withstand the load, the door opens smoothly and fits tightly to the frame, then weld it with a permanent continuous seam. When welding, the oil used to lubricate the hinges may burn out or leak, causing the door to creak and jam. To prevent this from happening, the sash is lifted and the insides of the canopies are generously lubricated again.

The door is returned to its operational position, and the weld seams are cleaned with a grinder. Surfaces are degreased and painted, and attachments (locks, bolts, mailboxes) are installed. A small hole is made in the hinges, through which the mechanism will be lubricated during operation.

Varieties

Hinges allow you to smoothly open and close the gate without making a single sound. Of course, it is important to remember that the product needs regular lubrication to prolong the effect. Particular attention is paid to durability, so the structure that will open and close metal gates must be strong and reliable.

All types of loops can be divided into three groups:

The first ones have a normal appearance, because the consumer encounters them quite often, since they are installed on entrance and interior doors. Even though we are talking about gate hinges, they are not particularly different. In this case, there is one aspect that plays an important role, this is the special treatment of the material, thanks to which the hinges will withstand any weather conditions.

Increased reliability is one of the most important characteristics during hinge production. This element must withstand heavy loads, because the gate is heavy and is also used regularly. Therefore, additional bearings are often installed to improve the data. You can often find hinges without ears on sale, since the consumer can independently weld them to the product, depending on the structure of the system.

Articulated

Hinges are in great demand and this can be reasonably explained. They allow you to easily and smoothly guide the gate and are resistant to breakage, which is an important indicator. Some of the hinges of this device are designed for installation on large gates, as they can withstand heavy loads. Spontaneous opening and closing is excluded if the structure itself is installed correctly and this fitting option is selected.

For the manufacture of hinges, durable and reliable metal is used, which has excellent performance. Heavy gate leaf doors will last a long time and faithfully with this installation.

Hidden

They resemble classic ones, but the main advantage is their increased burglary resistance, and for many this is the main indicator. Removing such gates will be problematic and will also take a lot of time.

Decorative

According to the principle of operation, they do not differ from the classic ones, but they look more aesthetically pleasing and can emphasize the design of the gate installation. Hinges can be antique, forged, or in a certain style. Welded structures are strong, reliable and provide safety.

teardrop-shaped

They take their name from the shape of the bearings, which are an integral part of the structure. Such hinges are in demand during the installation of garage and entrance gates, steel doors and even safes. Thanks to the teardrop shape, the problem of uneven movement is solved, so if you have heavy swing gates, this option will be one of the best. When opening, you will not hear creaking or noise, the structure will move smoothly.

To increase reliability, qualified specialists capture more of the contact surface of the product to the canvas.

Cylindrical

They are suitable for a massive frame where strength and resistance to heavy loads are required. They have support bearings that do their job for a long time. In such hinges the crown will be hidden in the body.

Read also: Welding seam on the GOST drawing

Adjustable

This type of hinge is distinguished by its ability to be adjusted, which is an indispensable advantage in certain situations. Thanks to them, you don’t have to worry about the sashes jamming. As for the cost, it all depends on the variety you have chosen, as well as the manufacturer, because everyone sets their own prices.