12/02/2019 Author: VT-METALL

Issues discussed in the material:

- What is semi-automatic welding

- What are the types of semi-automatic welding?

- What are the main advantages and disadvantages of semi-automatic welding

- What are the pros and cons of semi-automatic welding in a carbon dioxide environment?

- What are the advantages of semi-automatic welding without gas

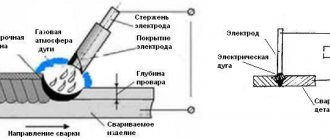

Semi-automatic arc welding is perhaps the most convenient type of connection, especially for beginners. It occurs due to the melting of the electrode, which is moved automatically. Let's look at the advantages of semi-automatic welding for specialists with experience and those just entering the profession.

Semi-automatic welding technology

In semi-automatic welding, three main devices are involved: a semi-automatic welding machine, an arc power source, and a device for moving the parts or equipment being connected. The latter consists of rollers, a gear shift unit and an electric motor. Its undoubted advantage is the mechanization of the process and its acceleration.

In addition, a welding wire feeder is used. It can be pulling, pushing or universal pulling-pushing. The wire is fed through a special hose, consisting of a wire spiral in a special braid and rubber insulation.

In addition to the wire, shielding gas, current and coolant are supplied separately through a flexible hose - each has its own wires in the control circuit.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

The length of a hose of this design depends on the type of feeder, but, as a rule, should not exceed 3.5 m. As it increases, uneven wire feeding occurs.

When carrying out semi-automatic welding, an important device is the torch - it is used to control the process. The torch handle for semi-automatic operation has a device for starting the supply of wire, shielding gases and fluxes. The opening of the gas valve most often also occurs from it.

Gas burner complete with tips

One of the most important components of the design of semi-automatic machines is a holder with a channel that provides direct supply of gas and filler wire to the place where the weld pool is formed.

The handle of this part must be made of high-quality insulating material and equipped with a special start button with a protective visor.

The main components of the burner are a specially designed nozzle for supplying gas and a tip for connecting current wires.

To avoid the effect of sticking of molten drops, the surface of the nozzle is either polished or coated with a protective material.

At operating currents exceeding 325 Amperes, the burner (more precisely, the nozzle) requires additional cooling to prevent overheating. Since the warranty period of the nozzle usually does not exceed 6 months, it is recommended to change it after this time (every six months).

For the manufacture of tips, materials that conduct electricity well (bronze and copper alloys with graphite or tungsten) are used. Their service life is ultimately determined by the quality of the components.

Direct connection of the holder to the semi-automatic welding machine is carried out using permanent connectors or using Euro Mig-Mag connectors. It is these connectors that connect burners to well-known models of branded semi-automatic machines “ПШ-112”, “А-1197” and a number of other units.

Types of semi-automatic welding

The type of material being processed, as well as the method of movement of the semi-automatic machine along the surface of the part, influence the type of semi-automatic welding. It differs by:

- Type of electrode - it can be aluminum, steel or a combination.

- Mobility – devices can be stationary, portable or mobile. Small portable units are suitable for use at home or for small repair work. Their main advantage is lightness. Large stationary devices are used in factories and workshops where a large amount of work is required. Their significant advantage is high productivity.

- Seam protection, which can be done using flux, gas or cored wire. The latter melts, forming a layer that protects the seam from an aggressive environment.

The semi-automatic connection process occurs in the following way. Electrical energy is converted into heat using an arc, which, acting on the metal being processed, melts it and solders it. Simultaneously with the metal, the filler wire is melted and automatically supplied to the working area from a copper coil. This wire is the main conductor of energy.

Types of construction

The basis of the semi-automatic design is the welding current source or power supply. This node can be built according to one of two principles. The classic version is represented by devices based on a conventional step-down transformer.

But devices based on inverter converters predominate on the market. Welding equipment built on the basis of this innovative technology has been confidently pushing aside the classics for several years now, and there are good reasons for this.

The advantages of inverter semi-automatic machines are obvious and confirmed by repeated testing. Among the important advantages of inverters, the following should be highlighted:

- high stability of the electric arc, ensured even at low supply voltages;

- higher efficiency compared to transformer devices;

- relatively light weight and small dimensions of the devices.

The only positive features of transformer semi-automatic devices include the simplicity of the design, and the fact that in the event of a malfunction, an electrician who is not very highly qualified can repair it.

The designs of semi-automatic devices differ in the supply voltage used. Devices aimed at household consumers are powered by a single-phase 220 Volt network.

Devices intended for industrial use are often produced in a three-phase version. Such semi-automatic machines are capable of welding with higher currents, using thicker wire and in a more loaded mode.

The main advantages and disadvantages of semi-automatic welding

There are many types of semi-automatic welding machines on the market. They differ in their functionality. High-quality equipment capable of joining most types of metals, all alloys and aluminum is popular. But its use for minor repairs is unprofitable. Most often, this type of semi-automatic machine is used for production with a flow system and large volumes of work. Its advantage is high performance.

Semi-automatic equipment has a number of the following advantages:

- the ability to work with almost all types of metals and alloys, even those that have undergone corrosion;

- low final cost taking into account high productivity;

- the thickness of the parts to be connected should not exceed 5 mm, and most works are suitable for this parameter;

- Possibility of welding with copper wire.

The disadvantage is the large spread of metal splashes from the weld pool when working without a protective gas jet. The presence of a significant electric arc is also negative.

At the moment, semi-automatic welding units have found worthy use in production for carrying out various types of repairs. The work is carried out on ferrous metal, aluminum or stainless steel. For safety, protective gas is used - helium, argon or carbon dioxide.

Semi-automatic selection criteria

You should choose an inverter semi-automatic welding machine according to its technical characteristics, comparing them with the tasks that are supposed to be solved with its help. Let's consider the main parameters that influence the choice of device.

Maximum welding current. This is one of the main characteristics. The welding current, as well as the associated wire diameter, together determine the thickness of the metal penetration. Knowing the thickness of the metal that is supposed to be welded, using the data in Table 1, you can determine the required value of the welding current.

When choosing a machine based on welding current, it is advisable to provide a margin for this parameter. It is good if the maximum current value of the selected device exceeds that required by technology by at least 30%.

Acceptable operating mode. Manufacturers may designate this parameter differently. It is often called on-duration (ON) and is indicated as a percentage. The meaning of this characteristic is as follows. The work of the welding unit is usually divided into 10-minute cycles. The cycle duration is taken as 100%. For example, if a duty cycle of 60% is indicated, this means that during a cycle of 10 minutes the device should operate in welding mode for no more than 6 minutes.

Sometimes the operating mode is indicated for several values of welding current. For example: at a current of 150 Amperes, duty cycle 100%, at a current of 250 Amps, duty cycle 50%. This record means that with a welding current of 150 Amps, the machine can work for a long time without stopping, and at 250 Amps, only 5 minutes out of 10.

Based on this feature, as well as on the value of the welding current, machine models are conventionally classified into:

- Professional;

- Semi-professional;

- Amateur or household.

Pros and cons of semi-automatic gas shielded welding

Welding is the process of creating permanent joints of two metals by melting, applicable in production conditions and in everyday life. There are many types of welding, but most often they use a connection with shielding gases.

Maintenance and repair of semi-automatic welding equipment must be entrusted to experienced certified specialists. This guarantees safety during work, quality of the seam and a decent service life of the expensive device.

VT-metall offers services:

The environment in which welding occurs has a great influence on the final result. The characteristics of the welding seam, as well as the properties of the arc, differ from the same indicators in electric welding. They vary depending on the gas used.

Methods for processing welds

Unlike the TIG method, semi-automatic welding of stainless steel results in black seams. These are oxides from the melting of metal, gases, and the combustion of protective sprays. To keep the seam white, cleaning with a metal brush is required. Then the scales will be visible and the connection will become more beautiful.

If necessary, the seams can be sanded if this is the front side of the product. A mirror effect, like TIG welding, cannot be achieved without additional processing. To do this, the seam is cleaned with flap wheels, gradually reducing the grain size of the abrasive in order to remove all risks on the surface. Then the metal is polished with felt pads and paste.

Pros and cons of semi-automatic welding in a carbon dioxide environment

Carbon dioxide welding is one of the most popular types of joining parts made of various metals. Its main advantages are considered to be durable, high-quality seams and low cost of the process. Working with carbon dioxide is quite simple, even beginners can do it.

1. How does semi-automatic welding occur in a CO2 environment?

Carbon dioxide is supplied to the weld pool formed by heating the metal, protecting the melt from exposure to atmospheric air.

2. What are the features and advantages of this type of welding, its modes?

One of the main advantages was the lack of contact of parts with the environment, displaced by CO2. This makes it possible to create an extremely strong seam. However, to avoid the oxidation of iron and carbon in the material, filler wire with a high content of silicon and manganese should be used.

The next feature is the use of direct and reverse polarities. Young specialists can also use direct current polarity, since it makes it easy to hold the arc. It is used more often for welding metal.

The semi-automatic welding mode is selected in accordance with the thickness of the workpiece and the diameter of the wire. Since as the current increases, the depth of penetration also increases, the current strength increases with increasing thickness of the product. This must be reflected in the equipment settings.

3. Advantages and disadvantages.

Working with CO2 has the following advantages:

- connection of thin parts;

- welding of products with different characteristics;

- high-quality and even seam;

- convenience of the arc, which is especially important for beginners;

- lack of oxidation due to gas protection, this makes the connection especially strong;

- relatively high process safety;

- inexpensive equipment available to anyone.

The disadvantage is that the equipment used is more complex than when working with other gases.

Conclusion: semi-automatic welding with carbon dioxide is an economical way of working that gives a simple and high-quality result.

Manufacturer value

An important factor when deciding which semi-automatic welding machine to choose is the choice of manufacturer. It is difficult to give recommendations here, because there are situations when products from unknown manufacturers work flawlessly for years, and products from world brands do not fulfill their warranty period.

Despite this, it is still better to give preference to famous manufacturers. Mainly because, when selling a product, they usually create a network of service centers that provide maintenance and, if necessary, warranty repair of the device.

It is especially important to pay attention to this if you purchase an inverter semiautomatic welding machine, the repair of which requires specially trained, highly qualified personnel.

Advantages of semi-automatic welding without gas

Let's try to understand what is the difference between semi-automatic devices with gas and equipment operating without the use of gas.

In the first case, the connection is protected by an inert medium (CO2 or a mixture of argon and carbon dioxide). Due to the absence of combustion, which is impossible in the presence of carbon dioxide, the metal does not burn through.

In semi-automatic devices where there is no gas, filler wire coated with flux is used. When it burns, CO2 is released, which prevents the metal from burning out.

What are the advantages and disadvantages of working with and without CO2?

When welding without gas, the working area is protected by the environment created by the combustion of a flux that is lighter than the metal.

When connected to a gas (for example, CO2), the working conditions are considered more favorable; in addition, the metal in the working area is cooled. The gas welding method is more popular, also due to lower financial costs.

However, there is a significant advantage of welding without the use of gas - a smoother and neater seam.

It is worth paying attention to the fact that you cannot use simple wire for this work. With its use, the quality of the seam will decrease - it will become uneven, the amount of wire used will increase significantly, because most of it will evaporate. The weld pool will be filled with oxygen, therefore, cavities and oxides will begin to appear in the metal.

The pros and cons of both methods are described in sufficient detail. The choice is yours. The equipment necessary for such methods is sold in specialized stores.

The appearance on sale of simple, high-quality and inexpensive devices has led to the spread of semi-automatic welding without gas, and its ability to be used even by non-professionals.

The popularity of the equipment has brought ease of handling, which is an undeniable advantage while maintaining extremely high quality of work. Even a beginner can get a beautiful and even seam using this equipment.

Working with gas requires carrying heavy cylinders and charging them, which is an additional expense. If welding is required only occasionally, it is much easier to use semi-automatic machines without gas.

For such work, flux-cored or flux-cored welding wire is used. It consists of a steel tube used for welding, with a standard diameter (0.8 mm). The center of the tube is filled with a powder (flux) similar to the coating of a simple electrode. During operation, the flux burns, resulting in the weld pool being filled with shielding gas.

The advantage of this method is that there is no need to use heavy gas equipment, and the ability to visually monitor the work, of course, through a protective mask.

Different fillings of the welding wire allow you to change the chemical composition of the formed seam and the characteristics of the arc.

It is not recommended to suddenly change the direction of operation of the semi-automatic welding machine or turn it due to the rather thin walls of the welding wire. For the same reason, it is necessary to feed the wire with slight compression through a special mechanism.

The use of flux-cored wire requires compliance with polarity: the product is connected to the positive, and the burner to the negative. This is a direct connection. The opposite applies when working with gas. The explanation for this is quite simple - when working with flux, a higher temperature is required for its combustion and the formation of protective gas.

Safety precautions when working

When working with welding equipment, the following safety precautions must be observed.

- The welder must protect all areas of the body from splashes of hot metal. For this purpose, special clothing is used that tightly covers exposed areas of the body, as well as protective gloves. Clothing should be made of dense material that can withstand hot splashes. Under no circumstances should clothing be made from synthetic fibers, which begin to melt when exposed to high temperatures. Such material burns through instantly, which can cause burns to the welder.

- Since welding produces hard ultraviolet radiation, it is necessary to protect your eyes from it using a mask with tinted glass. Not long ago, masks with chameleon glass, which darkens when exposed to bright light, appeared on sale. Other areas of the body should also be protected from ultraviolet radiation.

- Shoes must be closed to prevent hot splashes from getting into them.

- The room where welding work is carried out must have forced or natural ventilation (the presence of windows that can be opened). Inhalation of vapors and smoke generated during the welding process has a detrimental effect on human health.

How to determine the standard sizes of kitchen cabinets and the overall dimensions of a kitchen set

Those readers who have taken on the interesting but difficult task of independently designing their own kitchen ask, among other questions: what is the optimal height of the kitchen unit from the floor and the dimensions of the kitchen cabinets. Undoubtedly, the layout of a kitchen set is largely determined not only by considerations of ergonomics and design, but also by the presence of dimensional standards. After all, making completely individual furniture is quite labor-intensive and not always cheap. In most cases, standard elements (modules) are used, from which, like Lego bricks, a kitchen set is built according to the size of the kitchen.

Influence of speed on weld configuration

As the welding speed increases, the weld width decreases. The depth of penetration first tends to increase, and then it begins to decrease.

Compensation is carried out by increasing the current value. At a high welding speed, undercutting of the welded seam may occur, on both sides. This is due to heating that is insufficient to obtain a high-quality seam.

If the metal is thick, it makes sense to weld it with narrow seams, while ensuring high speed. Slow welding can lead to the appearance of defects in the metal in the form of pores.

The best way to weld body metal

Semi-automatic welding is most often used for welding car bodies. MMA welding (manual arc) is not suitable for this work. Read more about types of welding on the website mmasvarka.ru.

Firstly, when welding with an electrode, careful preparation of the surface is necessary. Sometimes doing this in a hard-to-reach place on the body is problematic, and the risks of burning through thin metal are very high.

Therefore, semi-automatic MIG/MAG welding is used to repair thin body metal. By professionally using a semi-automatic welding machine, you can weld very thin metal (0.5-0.8 mm), which is most often used in various car body elements.