[Artistic metal engraving] can add special value to an item.

Firstly, most often, such work is performed individually, you become the owner of an exclusive item.

Secondly, the artistic engraving looks very beautiful.

Thirdly, you can do it yourself, at home. Engraving is the application (transfer) of a design onto a metal object.

How to make engraving on metal at home, what tool or machine is needed? What is the price of engraving tools? You will learn about this in our article.

Photo:

Engraving in production

Metal engraving in production is not much different from the procedure carried out at home. Initially, the working surface is cleaned and degreased. After this, it is tinted with a solution of sulfuric acid. Next, the contour is outlined with a metal needle. The engraver does the bulk of the work. When the main work is completed, the surface is covered with colorless varnish.

Engraving on metal is done in various ways. A variety of equipment and tools are used for this. There is no need to buy expensive equipment to decorate a metal surface.

Design Features

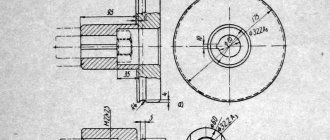

When deciding how to choose a drill or how to make it yourself (which is quite possible), you should understand the design and operating principles of this equipment. The main elements of any drill are:

- a tip on which working attachments are installed;

- electric motor, which can be brushed or brushless;

- a device that provides power to the drill motor.

Design of a corded drill

It is clear that a pneumatic drill, powered by compressed air energy, does not have an electric motor in its design. If a brushless electric motor is installed on the drill, it additionally contains a special control unit that ensures the creation of an alternating magnetic field between the stator and the rotor of the drive electric motor. A commutator drill, unlike a brushless one, can be connected directly to a DC source.

Power supply for simultaneous operation of two low-voltage drills

When comparing commutator and brushless type drills, you need to pay attention to the following points:

- Collector drills are easier to manufacture and, accordingly, cheaper. To ensure their operation, no expensive control unit is required.

- Brushless drills are more powerful and are capable of providing a rotation speed of the tool used in the range of 50–60 thousand rpm, while collector ones develop a speed not exceeding 45 thousand rpm.

- The presence in the design of commutator devices of an intensively rubbing unit (brushes and commutator surface) leads to their significant heating during operation, which requires ensuring effective ventilation of the electric motor of the drill.

- The presence of a rubbing unit in the design is also the reason for a significant loss of power in collector-type drills. Because of this, the efficiency of collector devices is only 60–70%, while for brushless devices this parameter is at the level of 90%.

- To increase the power and torque generated by brushed electric motors, it is necessary to increase the size of the device.

- The brush-commutator assembly itself is the reason for the large size of commutator devices when compared with brushless ones.

- Collector drills are also characterized by a higher noise level during operation.

- The service life of commutator drills is slightly shorter than that of brushless ones.

MicroNX brushless drill with reverse and continuously adjustable rotation speed up to 60,000 rpm

In general, to summarize all of the above, we can say that in terms of the ratio of the most significant parameters, collector drills are the most preferable option in most cases, which is confirmed by the high popularity of devices of this particular type. Brushless drills are more expensive and difficult to operate and maintain when you often have to process very hard materials.

Engraving methods at home

If you know the features of the technology and have practice, you can make engraving on metal with your own hands. To apply a design to a metal surface, you only need to use several tools.

Performing engraving on a machine

Using a special device for applying drawings and inscriptions

To obtain a high quality drawing, you must use an engraver. A large number of accessories are included with the equipment. Principle of operation:

- A sketch of the future pattern is applied to the working surface. You can use a thin marker for this.

- The part is secured in a vice. Processing should be done in one direction.

- When the work is completed, the product must be coated with colorless varnish.

In order not to damage the workpiece and tool, you need to choose the right equipment. Engraving on metal using an engraver requires perseverance and accuracy.

Drawing a drawing using a handy set of materials

Engraving can be done using manual tools. Metal surface processing process:

- Prepare a container that is larger in size than the workpiece being processed.

- A design is scratched onto the part with a needle. The top is coated with colorless varnish.

- A positive wire is attached to the product. At the same time, the minus should be placed in a separate glass of water.

The etching process takes place. After this you need to remove the remaining varnish from the part.

Engraving on a metal object with a drill

Experts know how to engrave metal using a drill. However, this power tool is expensive and it is not advisable to buy it for one-time processing.

When working with a drill, the working part of the power tool removes a layer of metal using special attachments. The equipment comes complete with the machine. Before you start working with this power tool, you need to test it on unnecessary workpieces.

Metal engraving using various equipment

During the development of technologies, equipment and engraving skills, many techniques for decorative metal processing have appeared:

- To make a beautiful inscription or drawing, laser systems are used.

- A tetrahedral recess can be made with a diamond cutter.

- It is more convenient to process voluminous parts with a conventional milling machine.

A small engraver is suitable for a home workshop.

Engraving on wedding rings

Engraving of wedding rings has some features:

- To apply an inscription to the surface of the ring, it must be of a certain width.

- The softer the metal, the easier it is for the master to work with it.

You can process the side edges of the ring if their width allows it.

Areas of use

The drill, the main working part of which is a shaft rotating at high frequency with the function of a spindle that transmits rotation to the tool, is today actively used by both professionals and home craftsmen, who also appreciate the versatility and efficiency of such a device. In addition to the already mentioned dentistry, where pneumatic drills are mainly used, such devices are necessary for:

- instrument making, where drills are used as mini-drills and compact polishing devices;

- manufacturing products for decorative and applied purposes (carving wood, stone and bone, applying inscriptions and patterns to the surface of products made from various materials (engraving));

- jewelry making, where with the help of such equipment beautiful jewelry is created from various materials.

Wood carving with a drill

In order to turn a drill, which is essentially a driving device, into a multifunctional equipment, it is equipped with special working attachments. Each of them is designed to solve specific technological problems. Thus, the most popular types of working attachments used in conjunction with drills are:

- drills that turn the drill into a mini drill;

- cutters, with the help of which a drill is used to process both flat and shaped surfaces, as well as holes of various configurations;

- mini-disk tool designed for cutting the material being processed;

- an engraving tool used to apply inscriptions and patterns to the surface of the workpiece;

- tools that are used to clean the surface being treated from traces of corrosion and various contaminants, as well as grind and polish it.

Read also: How to pour oil into a rotator

If stationary use is necessary, the drill can be secured in a special device

Modern models of drills differ from conventional dental devices not only in that they are electric rather than pneumatic, but also in the presence of additional options (in particular, the ability to adjust the spindle speed). The most reputable manufacturers of such devices are Dremel, Omax, Proxxon and PowerMax.

If we talk about the degree of autonomy of electric drills (engravers), then depending on this parameter, such devices are divided into the following types:

- stationary equipment;

- manual engraving devices;

- compact cordless drills;

- models operating from a central power supply network.

The convenience of battery models lies in the absence of connection to the electrical network

General technology

The technique can be manual or mechanical (various equipment is used).

It is also divided into line and armor:

- The line engraving technique is performed by applying contour lines and strokes to an object. Metal carvings are not deep, affecting only the surface of the object;

- Defensive, otherwise called three-dimensional, mechanical deep technique allows you to achieve a three-dimensional pattern. See photo.

Incisive engraving is performed with a special tool – a graver.

If you ask yourself how to make it yourself and where to buy these tools, then the answer is simple: this tool is sold in the same stores where you can find various art supplies.

The finest lines are made with a Messer-Stichel. If you need to make parallel lines, they are made with a rap pen.

Photo:

To perform high-quality work, this tool must be sharpened; for this, a fine-grained whetstone is used, which is pre-moistened with water or oil.

The graver is brought “to readiness” with a leather product (you can take an old belt) coated with chromium oxide.

Manual processing of small items at home requires the presence of a special pillow; you can easily make it yourself: take two pieces of fabric of the same size (round or square), sew them together along the edge, stepping back from it a little, but you need to leave a small gap in order to so you can pour sand inside.

The prepared form is turned inside out, dried sand is poured in, and the remaining hole is sewn up.

The cushion engraving tool is ready.

How to properly hold the instrument in your hand?

This should be done as if you were holding a regular ballpoint pen: the index finger should be on top of the blade (that’s what the metal part of the cutter is called), and the thumb should hold it on the side.

Work must be done on your own.

In the case when you need to change the direction of the pattern, unfold the pillow with the object on which the element is being applied, but do not change the direction of movement of the hand.

What else is useful to know about incisors?

To do your own engraving at home, it is advisable to first practice so that the carving turns out beautiful in the end.

IMPORTANT TO KNOW: Composition and application of alloy steel

It is better to purchase a set of tools: it is better to apply rounded lines with a square section of cutters, and it is better to make straight lines with a round section.

During work, burrs very often appear, which cannot be avoided, but they can be removed with the help of a scraper.

You can make the scraper yourself. To do this, you will need a file, from the edges of which you need to grind off the notch.

Before application, the surface must be cleaned with fine sandpaper and polished. A special polishing paste is used for polishing.

The paste can be easily replaced with chromium oxide (oil paint). The surface of the object must be thoroughly and vigorously rubbed. The paste is ground with a thick piece of leather.

How to choose the right drill

Regardless of what you are purchasing the device for - for small jobs in the home workshop or for professional use - it is very important to choose this mini-equipment correctly. The parameters of such a device that you should pay special attention to are:

- rotation speed that the drill spindle is capable of developing;

- device power;

- force, or torque created by the drill.

A set with two drills: a full-fledged mains one for basic work and a miniature low-voltage one for “small things”

Many of those who purchase a drill to perform simple work in the home workshop opt for high-speed models, which is not entirely correct. For most of such work (and for solving most professional problems associated with drills), models capable of spindle rotation speeds of up to 35–40 thousand rpm are quite suitable. In particular, the tool used to process ceramics must rotate at this speed, but for work on softer wood, more modest parameters are sufficient. It should also be borne in mind that a drill capable of operating at very high speeds is significantly more expensive than its slower-speed counterparts. Therefore, you need to think carefully about whether you will need options on an expensive device that you will use very rarely or not at all.

A more important practically important characteristic of any drill is the torque that such a device is capable of developing.

There is a direct relationship between torque and power of the drill, so special attention should be paid to this parameter. Compact drills, which are often called micromotors, have the lowest power of the models on the market today. Such mini-devices, the working attachment of which is combined in one housing with a drive electric motor, cope quite well with the finishing of products made of various materials. Working attachments for this equipment (both straight and angular) are small-diameter drills, mini-mills, grinding and polishing heads. It should be borne in mind that micromotors, like pneumatic engraving tools, are not intended for use in conjunction with massive working attachments and for performing rough work.

A jaw or collet chuck can be used to secure attachments in drills.

Technical drills have higher torque and, accordingly, power. Such devices, the straight or angular working nozzle of which is driven by a flexible shaft, are equipped with a powerful electric motor that can successfully cope even with fairly high loads. The working attachments themselves, which are equipped with such drills, also have a reinforced design, which allows them to be used in conjunction with large and heavy tools and with their help to perform rough processing of products made from various materials.

Technical drills, which have high power and operate mainly at medium speeds, are not very suitable for performing delicate work. This is also explained as follows. The working attachment (straight or angular) installed on such equipment is driven by a flexible shaft, which puts a lot of strain on the hand, and this can cause defects when performing delicate work.

Even taking into account the high saturation of the modern market with drills of various models and types, it is difficult to find a device that would combine high power and the ability to operate at high speeds. That is why specialists who constantly work with such equipment immediately purchase high-speed hand tools and more powerful technical drills.

Much attention should also be paid to the selection of working attachments for completing the drill. This can be either a straight or an angular nozzle, which is equipped with clamping mechanisms of various types and sizes. The straight nozzle is more universal, while the angular nozzle is used mainly in cases where it is necessary to process hard-to-reach areas.

You can save on purchasing a branded drill if you make a similar device yourself. As a drive motor for such a device, for which you will still have to purchase a flexible shaft and working attachments, you can use an electric motor from an old washing machine or other household appliance that can develop a sufficient number of revolutions.

It is recommended to make a drill yourself if you plan to use it to perform simple work in your home workshop. Such a device may not be able to cope with professional tasks.