The goal of the gate is to lock securely, withstand force loads, and be functional. Another good gate is that it opens and closes comfortably. You not only need to know how to weld hinges on a gate or wicket, but also be able to use electric arc welding, then everything will be done efficiently and correctly. When the elements are welded correctly, the gate will open well. At the same time, there will be no gaps in the closed gate.

Variety of options

Features of the teardrop model

A drop-shaped hinge with a bearing is a combination of classic convenience of fittings and its practicality in installation. This version of awnings is considered modern and practical. The invention itself has the shape of a cylinder, but for ease of use during production it is given a drop-shaped shape.

They are made of metal, and their special shape allows for convenient installation using a welding machine. The seam is as smooth and durable as possible. Thanks to this, the canvas holds securely, even if the load on its frame is high. The presence of a ball bearing, which is located between the welded hinges, ensures smooth and soft movement of the valves.

Hinge model equipped with roller bearing

Main types of garage hinges

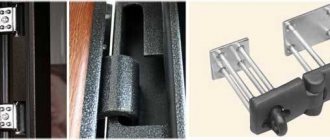

The building materials market offers a wide variety of hinges for swing doors. Each variety has individual parameters and advantages of use. The first thing you need to do when choosing is to select an installation option. The following installation methods are available:

- welding - the hinges are fixed on the door leaf and frame;

- installation using bolts - used when working with wood material;

- fastening with self-tapping screws - suitable for structures made from profiled sheets.

Based on placement, clamps are divided into hidden and internal. Their main differences lie in the installation method and decorative characteristics. When choosing garage hinges, the weight of the door is of great importance. Incorrect calculation of the expected load provokes skew of the canvas and difficulties with opening. For dense sheet steel with a large mass, it is recommended to purchase reinforced clamps.

With support bearing

Hinges equipped with a support bearing are the basic type of cylindrical type fasteners. The support bearing and swivel joint are reliably protected from external influences by the main body made of metal alloys.

Models with support bearings are intended for lightweight swing structures. The maximum permissible load is 100 kg. The clamps with support bearings are attached to the sashes and frame using a welding machine.

Cylindrical with additional reinforcement

Reinforced clamps are equipped with additional plates, which helps distribute the load over a large surface of the sashes or pillar. It is recommended to use cylindrical hinges with improved plates for thin profile structures. The parts are fixed to the swing gate leaves and frame by welding or screw connection.

Depending on the side of location, cylindrical reinforced hinges are divided into right and left. The diameter of the element is 50 mm. The maximum total load reaches 600 kg.

End-to-end

If it is not possible to secure the hinges by welding or screwing to the frame, a through type is used. For installation in the gate frame, mounting columns are drilled along the entire length, into which part of the retainer is threaded. For final fastening, nuts of the appropriate size are used. Thanks to a special fastening scheme, through-type fasteners can withstand loads of up to 200 kg.

Three-section invoices

For massive swing gates, it is necessary to increase the number of latches and choose a type with increased wear resistance. The best option is three-section models that can withstand the load of a heavy structure. The main advantages of overhead three-section hinges are:

- smooth sliding when opening and closing the gate;

- no creaking;

- reliable protection against burglary;

- preventing the sash from warping and sagging.

Boom loops

Garage boom hinges are suitable for attaching large swing doors, gates and thin-profile structures. The main distinguishing feature is the increased area of the clamp, due to which it provides additional strength and prevents distortions.

At the connection points, the arrow loops are able to withstand increased stress. This is facilitated by uniform distribution along the entire length of the sash. The range of dimensions of the clamps varies up to 700 mm, which makes it possible to find the optimal option for any gate design. The fastening parts are made from durable sheet steel, which ensures a long service life.

Invoices

Despite the ease of installation, overhead types of hinges are highly reliable. The fasteners are made from durable materials, including steel alloys, brass and stainless steel, which significantly increases the variability of their use. Inside the housing there are 2-4 ball bearings necessary for smooth opening of the gate.

To fix the overhead hinges on the frame, you need to mark their exact location and secure it with self-tapping screws. The clamps are included in the universal category and are not divided into left- and right-handed ones. If after installation it becomes necessary to remove the canvas from the hinges, you will need to unscrew the screws.

Why do you need a roller bearing?

A ball bearing is used between the running joint parts. Such a mechanism is always metal and is of high quality, since it bears the main weight. In addition, thanks to the stop, the friction force of the running parts is reduced. Bearings are used in ball or washer form. They are treated with oil lubrication for better performance. Usually they are lubricated when the doors are hung, but after some time the lubricant dries out and is periodically renewed.

Drop-shaped garage hinges

Selection and preparation of loops

It is important to calculate the hinges based on the weight of the gate

Steel gates are a heavy and large structure. In addition, the gate is constantly exposed to snow, rain, cold and sun. Accessories for them need to be chosen very carefully:

- The most important parameter is the weight that the hinges can support. The marking indicates the recommended weight of the sash, taking into account movement, so it is prohibited to exceed this figure.

- Opening angle - if trees grow next to the gate and the gate cannot open completely, there is no point in choosing hinges with a 180-degree rotation. If the sashes must completely clear the opening, it is better to buy the latter.

- Fastening method - this parameter is determined by the design of the canvas and support posts.

- Service life - changing the fittings on the gate is difficult and difficult. Preference is given to the most reliable products and companies.

Often, decorativeness is also a decisive factor in the choice. For wooden carved gates, it is better to choose beautiful overhead “arrows”.

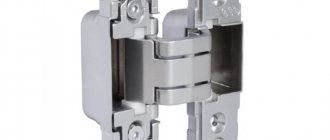

Improved teardrop-shaped hinges on support bearing

Today, such teardrop-shaped fittings have received another significant feature. Now the sashes are also adjustable for mounting height. The hinge acquired this feature thanks to the use of the following adjustments in production:

- the lower half of the fittings, like the upper, is now hollow, but has a through hole;

- applying a thread in the hole of the lower part from below;

- the loop rod in the cavity of the lower part tightly rests against a screw screwed into the thread from below;

- An intermediate flange is used between the roller bearing and the hinge element.

Thanks to the latter feature, the panel is welded and adjusted in height or compensation is performed for shrinkage during operating time.

Varieties

Hinges allow you to smoothly open and close the gate without making a single sound

All types of loops can be divided into three groups:

- classic;

- decorative;

- hidden.

The first ones have a normal appearance, because the consumer encounters them quite often, since they are installed on entrance and interior doors. Even though we are talking about gate hinges, they are not particularly different. In this case, there is one aspect that plays an important role, this is the special treatment of the material, thanks to which the hinges will withstand any weather conditions.

Increased reliability is one of the most important characteristics during hinge production. This element must withstand heavy loads, because the gate is heavy and is also used regularly. Therefore, additional bearings are often installed to improve the data. You can often find hinges without ears on sale, since the consumer can independently weld them to the product, depending on the structure of the system.

Articulated

Hinges are in great demand and this can be reasonably explained. They allow you to easily and smoothly guide the gate and are resistant to breakage, which is an important indicator. Some of the hinges of this device are designed for installation on large gates, as they can withstand heavy loads. Spontaneous opening and closing is excluded if the structure itself is installed correctly and this fitting option is selected.

For the manufacture of hinges, durable and reliable metal is used, which has excellent performance. Heavy gates will last a long time with this installation.

Hidden

They resemble classic ones, but the main advantage is their increased burglary resistance, and for many this is the main indicator. Removing such gates will be problematic and will also take a lot of time.

Decorative

According to the principle of operation, they do not differ from the classic ones, but they look more aesthetically pleasing and can emphasize the design of the gate installation. Hinges can be antique, forged, or in a certain style. Welded structures are strong, reliable and provide safety.

teardrop-shaped

They take their name from the shape of the bearings, which are an integral part of the structure. Such hinges are in demand during the installation of garage and entrance gates, steel doors and even safes. Thanks to the teardrop shape, the problem of uneven movement is solved, so if you have heavy swing gates, this option will be one of the best. When opening, you will not hear creaking or noise, the structure will move smoothly.

Cylindrical

They are suitable for a massive frame where strength and resistance to heavy loads are required. They have support bearings that do their job for a long time. In such hinges the crown will be hidden in the body.

Adjustable

This type of hinge is distinguished by its ability to be adjusted, which is an indispensable advantage in certain situations. Thanks to them, you don’t have to worry about the sashes jamming. As for the cost, it all depends on the variety you have chosen, as well as the manufacturer, because everyone sets their own prices.

Lifetime

The teardrop canopy distributes the weight of the door equally across the entire ball bearing surface. Unlike the commonly used ball to set the door in motion, a washer bearing allows the door hinge mechanism to last longer. Thanks to experiments conducted on the strength of a modern drop-shaped canopy, it was concluded that the minimum service life is 53 years.

Model size and characteristics

Manufacturing sequence

In practice, there are 3 main ways to properly weld garage doors:

- Before the garage is built, the door frame is prepared separately as a single piece. After this, they are transported to the construction site and installed in the opening. The metal frame is then covered with building material.

- In the finished garage, the doors are made according to the dimensions of the opening, the frame is installed and the panels are secured.

- Using the already made opening, all parts of the structure are welded in stages right on the spot.

Before processing

In this case, high accuracy of preliminary calculations and measurements is not required, there is no need to maintain the diagonals of the structure down to the millimeter, and there is no need to transport massive metal products.

If the work is done correctly, the welded product will stand securely and work without breakdowns for a long time.

It is necessary to weld the frame correctly

Aesthetic characteristics of the model

When attaching teardrop-shaped fittings, the weld seam is neat. This improves the overall aesthetic appearance of the mechanism. The added bonus to this is strength and durability. It is worth saying that this kind of hinged structure has a smoothly polished surface. This means that the powder paint will adhere to the door and onto it firmly. The paint will protect the surface of the door mechanism from chips and unwanted physical impacts during operation, and the externally painted hinge element to match the door looks beautiful and organic.

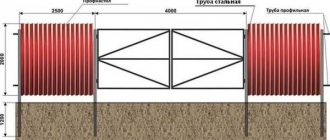

Planning the design

Metal fences and gates begin to be made by determining the location of structural elements and taking measurements based on which the frame and posts will be made. This stage is quite important, since the necessary materials are purchased based on the measurements taken. You can opt for metal poles or give priority to brick supports.

Also, at the planning stage, a gate scheme is developed, which can be sliding or swing. The choice of design determines the manufacturing features (for example, for sliding gates, in addition to supports, it is necessary to create an additional platform on which the rollers that displace the gate will move).

The minimum width (or diameter for round posts) must be 10 cm, otherwise the structure may sag. This figure is justified if the cladding material is relatively light in weight. When choosing heavy materials, you need to increase this indicator. For the correct installation of gates and wickets, all collected data is transferred to drawings of metal structures (it is much easier to make adjustments on paper than during the installation process).

How to install teardrop-shaped canopies?

It is easier to mount mechanical awnings in a horizontal position with the frame and canvas. When vertical welding, even a specialist will have difficulties in working. The fastening seams for the hinges are made continuous. It is believed that this welding method is reliable in strength. Before starting installation work, you will need to take preliminary measurements and determine the future location of the canopies. After the calculation stage, they proceed directly to their installation.

Drop-shaped model

The fittings are fastened according to the following scheme:

- the profiled cover is disassembled into two parts, each of which is drop-shaped, one of which with a bearing is welded to the box, and the second to the running surface;

- the bottom element is installed first;

- then they try it on, so first the parts of the mechanism are not welded with a continuous seam, but are only tacked in several places;

- if the parts are located correctly, then the final strong attachment is made using a welding machine.

Such drop-shaped loops are always designed for a large mass of fabric. The main condition for installation is to make a strong seam, then the loop will easily withstand any weight. To have an accurate idea of what a teardrop-shaped hinge mechanism looks like and what its features are, we suggest watching a short video review of one of these models.

Voted over 277 times, average rating 4.2

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Hinges, Fittings Features of hinges for interior folding accordion doors In small apartments, the issue of saving free space ...

Hinges, Fittings Varieties, features of hinges for aluminum doors Aluminum doors are becoming more popular every year - the design ...

Hinges, Fittings Types and materials of hinges for installing glass doors When installing doors and furniture facades made of glass, they use ...

Hinges, Fittings Types of decorative door hinges and features of each type Any door fittings can be installed with your own hands, but to what extent...

Installation recommendations

For square-section posts, it is recommended to always use plates, maintaining a gap of 3–5 mm between the edge of the gate and the support. There are several ways to weld hinges to round posts:

- without the use of mounting plates;

- with a plate only on the sash;

- with a narrow spacer on the side of the post and a full plate on the gate.

When using spacers, it is possible to increase the gap between the hinge and the support, and the spacer can be placed at an angle. This design is more forgiving of welding flaws, but it looks sloppy.

Method of fastening to the gate

The hinges are welded onto the finished sash. They must be fixed to a support frame; installation on metal sheathing sheets is prohibited. The optimal assembly option is with installed support pillars. It may be difficult to lock the gate in the working position. To do this, you can use additional substructures.

Recommendations for installing a loop group:

- the gap between the support post and the sash frame is up to 5 mm;

- Markings are made in advance, taking into account that the loops must be on the same axis;

- part of the loop group with the pin is located at the bottom, its direction is at the top;

- first, test welding is done at a maximum of three points, it is recommended to start from the bottom loop;

- after this, the correct operation of the gate is checked - it must open and close freely, the gap is controlled, there is no spontaneous movement of the leaf, regardless of its position;

- final welding of the plates around the perimeter, after cooling - removal of scale and cleaning of the surface.

Over time, the sash may sag or change its position. If the gap does not compensate for this, it is necessary to redo the mounting units. To solve this problem, it is recommended to use hinges with an adjustment function.

Materials

The pillars are made from profile pipes with shelf sizes of 80 or 100 mm. Taking into account its lowering into the ground by 800 mm, the length of the pillars should be 3 m. Plugs are welded to the upper ends to prevent water from entering.

For greater rigidity and securing the rack, you can weld small pieces of reinforcement or other rolled steel, 1 m long, on the section extending into the ground.

For standing ones, take a 40/40 or 40/60 profile, cut off two parts with a length of 2100 mm using a grinder. The edges of the pipes are cut at an angle of 450 for a larger welding area and reliable fastening.

The upper and lower lintels are prepared from the main profile, with a gate width of 1000 mm. parts are cut to size 980 mm. This will provide a gap of 10 mm between the loot and the gate on each side. Cut the edges at an angle of 450.

For the middle lintel you can take a 25/40 profile, its length should be 900 mm, it will be inserted inside the frame, so the width of 2 profile shelves is subtracted from the total length of the workpiece, in this case it is 80 mm.

You will need 2 hinges with an outer diameter of 30 mm and 4 steel plates with a thickness of 5 mm and a width of 40 mm. It should be disassembled and the internal surfaces well lubricated with grease or other thick lubricant, then reassembled . It is better to purchase loops with balls.

The plates are laid out on a flat surface and loops are attached to each part from different sides. That is, if a plate is attached to the part of the loop with a hole from the outside, then on the mating part the plate is placed towards the inside.

Welding is mandatory on both sides to ensure welding of the root of the seam. After the first pass, you need to beat off the slag and weld the second pass. At the root, welding is performed in one pass.

Marking

The next step is to lift the gate leaves to a vertical position and install them “idle” to where they should be located.

Don't forget that the doors should open outwards. If they open only inward, then in winter with heavy snowfall this will result in serious problems.

Then you should mark the locations for future installation of hinges on the gate - they should be located at a distance of approximately 20 centimeters from the lower or upper border of the door leaf.

Sometimes, if the structure weighs too much (more than 200 kilograms), another additional fitting is placed at the top of the support.

All hinges must be installed strictly vertically; even a tiny misalignment during welding will lead to difficult closing or opening, and therefore to rapid destruction of the support bearings. The evenness of their position can be checked with a plumb line or laser level.

Sheathing

If you are sewing up the gate with mesh or rods, they should be secured before installing them on the posts. When laying a sheet of corrugated sheets, it should be fastened after welding. The corrugated sheeting is secured with self-tapping screws, the heads of which are covered with decorative overlays.

Without high-quality welding, the gate will not last long. For reliability, be sure to check the filling of the seam with molten metal.

Before welding, double-check that the part or the structure as a whole is installed correctly. Take your time.

Before sheathing with corrugated sheets, be sure to degrease all surfaces and first apply a primer and then paint that matches the color of the decorative coating of the gate and fence.

Having completed all the work on welding and installing the gate correctly and efficiently, you gain invaluable experience in the manufacture of frame structures.

Wicket made of corrugated sheets

For gates and wickets made of corrugated sheets, it is important to select hinges that are suitable in type and size. Properly selected products will improve the aesthetics of the entire structure and significantly extend the years of its service. Profiled metal sheets, as a building material, are very popular in every region of the country. It has low cost, good technical characteristics, and resistance to the vagaries of nature.

He is easy to work with. Corrugated sheeting has different markings, levels of rigidity, wave shapes and their height.

Attaching hinges to a gate frame made of corrugated sheets

The metal fabric is presented in a wide range of colors, which simplifies the buyer’s choice.

To carry out structures in a vertical direction, such as gates, it is preferable to choose canvases marked “C8” - “C20”, where “C” indicates the wall purpose of the product, and the number following the letter is the height of its waves in millimeters.

In addition, corrugated sheeting is beautiful and has a wide range of additional advantages. This building material can be either simply galvanized or painted with paint with polymer components. It is painted corrugated sheeting that is recommended for the manufacture of wickets, fences and gates.

This metal sheet has 2 layers of protection:

- anodic;

- dye.

The average weight of a profiled sheet is about 5 kg per m2. This allows you to use not the most massive and complex, and therefore not the most expensive, hinges for fastening the gate.

Scheme for installing a gate made of corrugated sheets

It is easy to make a gate from this material yourself according to a pre-prepared drawing.

Rolled metal, for example, square pipes, is often used as a frame for the canvas. Support posts are also made from pipes (100 mm). The height of the pillars is determined by the height of the gate, to which is added at least 130 cm, which will be buried in the ground.

Tools for work

When all the main parts of the gate are ready, you should decide on the lock and handles. If necessary, you will need to weld brackets to attach the handle from the inside.

Next, tools and additional materials are prepared for welding. You will definitely need:

- welding machine;

- electrodes for welding steel grades MP-3 or ANO-21;

- hammer, sledgehammer;

- protective clothing and welding mask;

- building level or simple plumb line;

- trowel or spatula;

- several sections of pipe, 1000 mm long, for lintels when concreting pillars;

- concrete solution;

- For installation and welding of hinges, embedded parts are prepared to provide gaps between the gate, hatch and floor.

Having prepared all the materials and tools, we begin to manufacture and install the gate.