Laser engraving and cutting along with 3D printing provide great benefits for your production or hobby. This technology can be used from markings, logos and numbers on parts, marketing and advertising applications, to use in complex production facilities. But to start benefiting from it, you must understand how laser engraving works and what design guidelines you need to follow to successfully start using it.

What is laser engraving

Laser engraving is based on the action of a laser beam directed at the surface being processed. First you need to prepare a raster (vector) image file in gcode format, which is sent from the computer to the CNC controller of the laser engraver. The controller positions the laser beam so that the surface being burned is in the shape of the outline of the image.

There are two types of laser engraving: line engraving and surface engraving. The first uses vector images to follow the lines, outlines of the image's boundaries. Surface engraving works with a raster image created from photographs.

Benefits of using a CNC laser machine for business

CNC laser machines are preferable for organizing your own business than devices with metal cutting tools (if you are just starting out, it is better to have both as you develop).

Key advantages of laser machines:

- Fast engraving, which ensures the execution of more orders per unit of time;

- Exceptional accuracy of the finished product (possible deviations from the established parameters - 0.01 mm);

- Almost eternal life of engraving on objects;

- Use of any materials: from fabric to metals;

- Automation through computer control;

- Simple fixation of the material thanks to the non-contact processing method;

- The edges and walls of the material remain in perfect condition after processing;

- Low level of dust and noise;

- The minimum number of additional tools required.

What is laser cutting

Laser cutting is a high-precision CNC process that uses a powerful laser beam to cut. Ideal for a variety of materials (including metals, wood and polymers), it allows you to produce complex parts without the need for special tools.

Unlike an engraver, which burns only part of the sheet thickness, a cutter does this completely, cutting out the part along a given contour.

Due to its high repeatability, the process is suitable for both one-off jobs and small to medium volume production. Laser cutting is especially useful for making sheet metal parts (steel, brass, aluminum or nickel). It has become a firm favorite in the medical device industry due to its high precision and reliability.

Unlike CNC machines, laser cutting works with sheet material, in most cases creating objects up to 50 mm thick (depending on the type of material).

conclusions

A CNC laser machine allows you to set up large-scale production with relatively small investments. Installation of the machine does not require much space, and prices for machines start at approximately 100,000 rubles. The entire process, from developing a sketch or digital model to receiving the finished product, can be completed by one worker. Thanks to the high precision of the machine, the result is predictably excellent.

To get a consultation

Find out more about the possibilities to improve your production by integrating new equipment:

What are the advantages of laser engraving and cutting?

This technology is especially useful for forming parts directly from sheet metal or applying markings and logos to parts or finished goods. The process is very fast and quite reliable. This is especially effective where production time is of the essence. This technology significantly speeds up the production process.

Laser engraving can work on a wide range of materials, from wood to cardboard and plastic, where traditional methods may not be effective. In this way, laser engraving can complement your production with new materials and give you new design freedom.

Laser cutting produces highly precise cut parts suitable for anything from bottle openers to circuit boards. It is both faster and more efficient than manual manufacturing methods.

Types of machines

Before buying a laser engraving machine, you need to understand the possible types of this equipment. According to the processing method, the following types of machines are distinguished:

- Solid - used for drawing pictures, making holes, cutting hard materials (plastic, metal).

- Gas - installations with which you can work with any non-metallic surfaces.

Gas emitters are more popular due to their price. They are separated by the type of tube through which the focused beam exits. Cheap models have glass attachments. Expensive units are equipped with ceramic devices.

Equipment can be divided by power. There are three groups:

- Low power - up to 60 W. They are used for processing workpieces made of wood, plastic, and plexiglass.

- Average power - up to 100 W. Using such installations, metal workpieces are processed.

- High power - up to 160 W. Industrial equipment designed for cutting metal.

If we talk about the purpose of laser units, they can be divided into models for working on wood, plastic, and metal.

Solid State Engraving Machine

Types of Laser Engravers and Cutters

Laser Cutter Type No.1: CO2 Laser

Of the three types of laser cutters, CO2 is the most commonly used. Low power consumption, relatively low price and high efficiency make this laser cutting technology the most suitable for consumers and manufacturers. The laser source is created from a gas mixture, which mainly consists of carbon dioxide. In addition, CO2 lasers are compatible with the widest range of materials.

- Wavelength 10.6 nm

- Efficiency 10%

- Laser spot diameter 0.15 mm

- Energy density 84.9 MW/cm2

Laser Cutter Type No.2: Crystal

This laser, created using crystals doped with neodymium or yttrium, has a much shorter wavelength and higher intensity compared to CO2 lasers. The laser can cut through thicker, stronger materials, including metals and some ceramics. The downside to this type of laser is that machine parts wear out very quickly, requiring more extensive and expensive maintenance. In addition, they consume significantly more energy during operation. A diode or lamp is used as a light source.

- Wavelength 1.06 nm

- Efficiency 2% tube, 6% diode

- Laser spot diameter 0.3 mm

- Energy density 8.5 MW/cm2

Laser Cutter Type No.3: Fiber Optic Laser

Created on the basis of the so-called “seed laser” and reinforced with special optical fibers. This laser source has a high intensity that is on par with neodymium, but is easier to maintain due to its design. Fiber laser cutting machines are mainly used for laser marking processes. A diode is used as a light source.

They are up to 3 times more energy efficient than gas cutters. Fiberglass cutters have no moving parts (such as fans to circulate gas or mirrors in the light source), making the tool easier to maintain. Unlike carbon dioxide lasers, fiberglass alternatives can cut thin sheets faster at the same power and can also cut reflective materials without damage.

The price is somewhere between a CO2 laser and a crystal-based one.

- Wavelength 1.07 nm

- Efficiency about 30%

- Laser spot diameter 0.15 mm

- Energy density 113.2 MW/cm2

Scope of application of engravers

In terms of their functionality, engravers are used wherever it is necessary to finely apply patterns, barcodes, stamps, drawings or inscriptions on various surfaces, including complex shaped ones.

This:

- applying artistic patterns to wooden products;

- production of packaging, incl. decorative;

- outdoor advertising;

- production of souvenir products from metal, wood, glass, plastic, stone;

- drawing patterns on leather materials, in the textile industry - cutting complex materials.

The engraving machine is also successfully used in funeral services for engraving inscriptions on monuments.

Materials used in laser cutting and engraving

There are many materials to choose from with different colors and thicknesses. Choosing the right material is an important step, so we will now give you an overview of the materials.

Acrylic

Acrylic is a flexible material that is durable and quite scratch resistant. It is also quite stable in terms of shrinkage. It copes well with laser operations, which means that your design will be of good quality.

In addition, this material can be exposed to other design methods such as bonding and painting, it is waterproof and can be used in damp environments such as kitchens or bathrooms. Great applications of acrylic lie in various industries such as medicine, lightning or electronics.

For available thicknesses and colors, check the acrylic page.

Plywood

This material is made from several sheets of wood glued together. Due to this, plywood is widely used by builders, cabin manufacturers or industrial designers. The main characteristics of this material are mechanical resistance, flexibility, water resistance, lightness and aesthetic appearance.

Plywood is an excellent material for finished products. Made from wood, it will give your design a unique, natural look. This material can also be worked with like natural wood; it can be glued, screwed, sawed and nailed.

MDF

MDF, Medium Density Fiberboard, is an engineered wood. This material is made from the remains of hardwood or softwood, decomposed into wood fibers. The fibers are joined with wax and resin. Using high temperature and pressure, MDF panels are formed.

MDF has a fine texture and natural light beige color. The main advantage of this material is the amount of adjustment it can withstand, unlike solid wood. MDF can be painted, stained, stained, fire resistant, water resistant, molded and even curved. It will also perform well when sanded and planed as it contains no knots or rings.

Cardboard

Cardboard is made by laminating flat, corrugated or embossed paper of varying thicknesses. Cardboard can be very useful for your products as it is lightweight and competitively priced.

Like other laser engraving materials, it can be modified by cutting, gluing or folding. Among other things, cardboard is also recyclable and biodegradable. It is widely believed that cardboard is only used in packaging, but in fact, it can also be great for prototyping or production of presentation models in the field of architecture.

P.O.M.

Polyoxymethylene, POM, is an engineered thermoplastic, also known as acetal or delrin. This material is especially popular due to its excellent mechanical properties, strong resistance and great dimensional stability. It has a smooth, glass-like surface.

This material has been designed with internal technical details in mind. It is lightweight, strong and durable, but also weatherproof, waterproof and solvent resistant. It resists cracking well, making it an excellent candidate for industrial tools, spare parts, gears, hinges or locks.

Metal

Laser cutting or engraving on metal has long been widely used in many large factories and industries.

In principle, the technology is almost no different from laser processing of wood and other materials, except that the laser is much more powerful (usually either CO2 or diode fiber-optic lasers are used) and a cooling system is included.

Metals Used for Laser Cutting Laser cutting is a versatile manufacturing method that can be used to cut a variety of materials, including metals, plastics, wood, paper, and textiles. When it comes to metals, steel cuts better than aluminum and copper. This is because steel, unlike aluminum and copper, reflects light and heat energy, which can otherwise lead to warping. Below you can find a summary of the most common metals used for laser cutting.

Metals used for laser cutting:

Aluminum 5052:

- +Exceptional finishing qualities (easy to anodize)

- + Moderate to high strength

- – Low hardness

Aluminum 5754

- + Stronger than 5052

- + Corrosion resistance

- + Good machinability

Copper C110

- + Excellent thermal and electrical properties

- + High ductility

- — High thermal conductivity

304 stainless steel

- + Excellent mechanical properties

- + Excellent corrosion and acid resistance

- - Relatively complex processing

316L stainless steel

- + Excellent mechanical properties

- + Excellent corrosion and acid resistance

- - Relatively complex processing

Mild steel 1018

- + Semi-magnetic

- + Relatively easy to process

- — Low corrosion resistance

Main settings

In order to make seals and stamps and decorate small-sized products, it is not at all necessary to purchase large engraving equipment from professional series - it is enough to buy a desktop laser engraver. Such equipment will not only take up little space in the workshop, but will also cost much less than industrial installations.

As for the prices for desktop laser engravers, they vary greatly and depend on a number of parameters. Such parameters, in particular, include:

- type of device according to the working element used in it (fiber laser engraver, discrete fiber, diode, etc.);

- laser engraver power;

- dimensions of the working platform;

- functionality;

- company manufacturer.

Approximate prices for laser engravers

In order to make stamps, as well as perform engraving work on the surface of small-sized products made of various materials, you can order an inexpensive laser engraver from China, which does an excellent job of such functions. A Chinese laser engraver is capable of successfully coping with many tasks. In particular, with the help of such a device, engraving can be performed not only on metal, but also on glass, wood, leather, plastic, cardboard and a number of other materials.

Guide to preparing files for laser engravers and cutters

There are particularly important rules that you must follow when it comes to laser engraving. A very popular aspect of laser engraving is text engraving. When text is sent to the controller, the machine automatically adds a border around the letters, so it's important to remember:

- Make sure letters are spacing correctly

- Minimum text size 2 mm

- Narrow fonts are preferred

Laser cutting programs

How to choose the right device

How to choose a laser engraver? First of all, you should get an idea of the types of such devices and understand the operating parameters that characterize them. You should not choose a device for specific tasks, since in the future you may not have enough of its functionality. So, having bought a laser engraver for seals, that is, for working with rubber and polymer materials, you will not be able to use it in the future to design products made of metal and other hard materials. That is why it is better to immediately choose universal engraving devices.

Depending on what type of element is used in a laser engraver to form the working beam, all such devices are divided into two categories:

- gas laser engravers;

- solid state devices.

Neje mini laser engraver is a popular home model focused on miniature engraving

Gas-type laser engravers are inexpensive and versatile. Using such devices, which are most often purchased to equip home and small production workshops, you can engrave on the surface of products made of metal, leather, plastic, wood, etc. Engravers that use a solid-state element to generate a laser beam are distinguished by the fact that They create radiation that has special properties. Devices of this type are used primarily for engraving on metal and some types of plastics. The most significant advantage of using engravers with solid-state laser elements is that such processing can be performed with very high precision.

Choosing a laser engraver for making prints and processing products from various materials should be based on its power. So, for working with small objects made of not too hard materials, you can choose devices whose power is within 40 W. Using such devices, in particular, it is possible to make prints with fairly good detail. To engrave on harder materials (such as stone), you should choose engravers with a power of at least 60 W. Such devices, in addition to engraving, also allow cutting of the material being processed.

Laser engraver for seals and stamps Raytronic S7 with air-water cooling system

The power of a laser engraver affects not only what material can be processed using such a device, but also the thickness of the processed layer, as well as the range of operations performed. Thus, to process a metal sheet more than 10 mm thick, you will need a laser engraver with a power of at least 100 W. To process thinner items made from softer and more pliable materials, you can choose less powerful engraving units.

On the modern market, laser engravers are presented in a fairly wide power range. So, depending on your needs, you can choose similar devices whose power is in the range of 20–120 W.

The compact tabletop engraving machine TST-3040 is great for making signs and souvenirs

When choosing a laser engraver, you should pay attention to the additional characteristics of such devices. One of these characteristics, which ensures the duration of the continuous processing process performed on a laser engraver, as well as a longer service life, is the presence of a cooling system in its equipment.

Another important option to look for when choosing a laser engraver is auto focusing. On laser engravers with this function, processing can be performed not only with greater productivity, but also with higher accuracy.

Manual carriage function allows you to quickly start a job from the desired location

The configuration in which laser engravers are supplied from the manufacturer is another important parameter. No one will argue that it is much more convenient to purchase a device that includes everything necessary for its operation. The standard set of modern laser engraver models usually includes:

- the device itself;

- safety glasses, which must be used when working with such a device;

- debug key;

- software installed on the control computer.

- cable for connecting to the control computer.

The best laser engravers and cutters

OMTech 40W Laser Engraver and Cutter

- CO2 laser type

- Working area 300 x 200 mm

- Laser power 40 W

- Price $389

OMTech is a Chinese manufacturer of laser engravers and cutters. OMTech imports equipment to the USA, where it carries out enhanced quality control.

This 40W laser engraver and cutter is a compact machine with a cutting area of 300 x 200mm, 4500dpi resolution and a maximum cutting speed of 80mm/s. In fact, this is a great model for beginners, it costs less than $400 and offers excellent value for money. Some components can be upgraded, such as an exhaust fan, a water pump, or even a laser.

Depending on the material, this laser should cut to a depth of 2–3 mm, leather and wood, as well as rubber, and engrave metal.

Laser engraver cutter Flux Beamo 30 W

- CO2 laser type

- Working area 300 x 210 mm

- Laser power 30 W

- Market price $1499

The Beamo 30W is Flux's entry-level laser engraving and cutting machine that hits the sweet spot between affordability, ease of use, looks and functionality.

There are some disadvantages. Etching and shading could be better, the app didn't always work, and the camera preview mode doesn't capture the entire work area.

OMTech 80W Laser Engraver and Cutter

- CO2 laser type

- Working area 710 x 500 mm

- Laser power 80 W

- Price: $2,799

This OMTech 80 W is a powerful semi-industrial laser cutter capable of handling a wide variety of cutting jobs. It offers a working area of 500 x 710 mm and can work with a variety of materials such as wood, leather, rubber and plexiglass. This particular model can handle long jobs that extend beyond the cutting area.

Overall, this company offers high-quality equipment suitable for small businesses and industries. The laser is also relatively easy to set up, but keep in mind that this is a large machine - 119 x 86 x 91cm - and you'll also need plenty of space for exhaust fans.

The CO2 laser is particularly powerful, but OMTech offers an even more powerful unit with a power rating of 100W.

Full Spectrum Muse Core Laser Cutter

- CO2 laser type

- Working area 508 x 305 mm

- Laser power 40 W

- Price $3500

The Muse Core from Full Spectrum Laser is a 40W (45W optional) CO2 laser cutting machine with a 508 x 305mm workspace and several useful features.

At around $3,500, the Muse Core isn't the cheapest cutter on this list, but it is slightly cheaper than the Glowforge (its main competitor) and also has a slightly larger build area. Full Spectrum Laser also has some pedigree: the Las Vegas-based firm is a well-known manufacturer of much more sophisticated industrial cutters.

Particularly for manufacturers and small businesses, Muse Core can be a worthy alternative to the likes of Glowforge. This cutter is not capable of cutting glass or metal, but wood, fabric, leather, paper, acrylic and rubber should not cause problems.

It also comes with browser-based software that doesn't require an internet connection to operate, an optional rotary tool for cylindrical work, and support. Additional attachments and accessories are also available for those looking for something more suited to their needs.

Glowforge Plus Laser Cutter

- CO2 laser type

- Working area 500 x 280 mm

- Laser power 40 W

- Price: $3,995

Equipped with a 40W CO2 laser tube that delivers high cutting power and precision down to 0.025mm, the Glowforge Plus is a cross between the much-loved Glowforge Basic and Glowforge Pro. Optimized for home and office use, this device is equipped with packaging features such as water cooling, a HEPA filter and an air compressor to blow stray particles out of the laser and prevent fires.

It is compatible with a wide range of materials including leather, wood, acrylic, glass, fabric, cardboard and can cut up to 12mm deep depending on the material. This laser cutting machine is often used by small businesses looking for a versatile and reliable laser cutting machine.

Design and principle of operation

To understand how equipment works, you need to know its design. Engravers can be industrial (large-sized designs) or desktop (small-sized models). Regardless of the size of the machine, the design has a number of key elements:

- The base is a frame with legs to hold the equipment at the same level without vibration.

- A structure with guides attached to it. Frame made of plastic or metal.

- Desktop. The possible dimensions of the processed workpieces depend on its size.

- The portal on which the working part of the unit is fixed.

- Stepper motors that move the movable portal along guides.

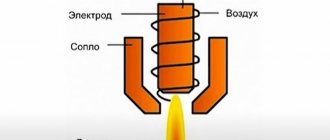

- Laser head. A working piece of equipment that consists of a drive and a lens system for focusing the beam.

- Frame with protective inserts.

- Control system. A set of wires, sensors, screen, fasteners.

- Cooling system. Necessary for long-term active operation of the equipment. It can be air or water.

When choosing laser engravers, you need to consider various parameters. The operating principle of these units is that a focused beam burns out the material being processed. The small beam divergence angle allows you to make thin cuts, burning out a minimum of metal.

Best lists

Let us separately consider the leading devices in the selected categories, namely:

- universal;

- mini engraver;

- high accuracy.

We'll tell you about each one personally.

Universal

An excellent universal hobby engraver would be the Feungsake 4050 . The device is large, which allowed the developers to create a large working area - 100x100 cm. The model has a laser with a power of 5500 mW. Suitable for processing most surfaces.

The cost of the device is about 11,000 rubles.

laser engraver Feungsake 4050

Mini engraver

The Meterk DK-BL mini engraver deservedly bears the title of customer choice in this category. The device is equipped with Bluetooth function. The connection is made via USB. It is convenient to control - you can do this through your smartphone. The machine works on wood, plastic, rubber, leather, bamboo.

The cost of the device is 7,500 rubles.

laser engraver Meterk DK-BL

High accuracy

One of the best devices in this category is the Annoytools S1 engraver. With its help you can process workpieces measuring 395x285 mm. It requires an electrical outlet to operate, so it is mainly used at home. The laser power is 5500 mW. A toothed belt is responsible for high precision. If I monitor its condition and change it on time, the images will not lose quality.

The cost of the product is 9000 rubles.

Annoytools S1 laser engraver.

What to look for when choosing

When choosing a device, first of all, you need to decide on the purpose of the machine and what materials will be processed. Even if you don’t intend to process metal or plastic at first, you should give preference to models with advanced functionality in order to be able to be widely used in the future. It would be useful to have a cooling system - this way the device can work longer without the risk of damage due to overheating. Also, do not chase power - it makes practical sense to choose a device with lower laser power but greater accuracy.

Comparison table of characteristics

In order to better understand which of the presented engravers is better, let’s resort to a table where we compare the characteristics of all models:

| Power, W | Working surface, cm | Dimensions, cm | Weight, kg | |

| KKMOON Engraving Machine | 3000 | 80x80 | 155x166x143 | 0,56 |

| Moski-MSQ Laser AS-5 | 1500 | 140x200 | 320x300x210 | 3,5 |

| Wolike Mini 3000mW | 3000 | 500x650 | 790x70x110 | 4,9 |

| Neje DK-8-KZ | 1000 | 90x90 | 198x160x146 | 1,7 |

| Moski-MSQ CNC-2418 | 500, 2500, 5500 | 240x300 | 400x310x210 | 6,0 |

| Vassal 5065 | 1000 | 500x650 | 670x410x110 | 4,5 |

| Feungsake PD271 | 1500 | 1000x1000 | 2800x3200x 230 | 3,6 |

Advantages and disadvantages

A laser engraver compares favorably with mechanical and electrical engravers in several ways.

Among the advantages:

- Wide range of hard materials processed;

- Accuracy of the created image;

- Very thin recesses, through holes that cannot be created mechanically;

- A large number of customizable parameters, the ability to create very complex images;

- Full automation of the workflow, no workarounds.

Users note the following disadvantages:

- Low productivity; the laser sequentially burns through each point of the pattern, one complex image takes a lot of time;

- Changing settings after starting the engraving process is not available;

- Strong local heating at the burning site, deformation is possible.