The frame of a truck is a loaded structural element that takes on dynamic and shock loads. Despite the fact that such units are usually made of high-strength steel, they are susceptible to deformation and breakage. In addition, you should not discount the physical wear and tear of the metal, which tends to rust and deteriorate under the influence of weather conditions and road reagents.

Taking these features into account, GAZelle frame repair is something that any car owner will have to face sooner or later. Of course, you can weld a broken structure with your own hands. However, this is only a temporary measure. Welding for repairing frame structures of trucks is considered the most unreliable method, and such a weld can burst at any time. Therefore, it is better not to take risks and immediately seek help from professionals.

Types of frame damage

All defects in such metal structures are natural or artificial. In the first case, we are usually talking about metal “fatigue” or violations of operating conditions when the load on the chassis exceeds permissible standards. In the second, the breakdown is caused by an extreme situation, for example, an accident.

If we talk about specifics, the following damage is typical for truck frames:

- Twisting of axial beams;

- Diagonal displacement of side members;

- Transverse tears;

- Bends in a vertical or horizontal plane;

- Cracks.

As mentioned above, almost any defect in the frame structure can be eliminated, but only if it is beneficial to the client. In other situations, the frame is usually replaced.

Arc welding with electric rivets

When welding with electric rivets, in most cases an arc process is used without moving the arc and without feeding the electrode wire into the arc zone. Welding with electric rivets is carried out using portable or stationary electric rivets. As a rule, electric rivets are used to overlap the welded parts. The essence of the process is as follows.

An electrode wire or a rod of electrode wire with a diameter of 3...6 mm is fixed in a special holder-electric riveter with a contact tip and short-circuited on the product at the place where the rivet is placed. Then the entire area around the electrode is covered with welding flux or protected by carbon dioxide supplied to the contact zone. Voltage from a DC or AC power source is supplied to the part being welded and to the electrode through the current-carrying tip of the riveter. An arc is excited, which melts the end of the electrode and melts the surface of the product. The arc burns, melting the electrode, and thus lengthens until it naturally breaks. The resulting molten electrode metal together with the metal of the product forms a rivet during crystallization. The connection with electric rivets is quite strong and looks neater in appearance than fastening with self-tapping screws or bolts.

What to do if a GAZelle frame bursts?

Professional advice is not to try to fix the defect yourself. The fact is that in makeshift conditions it is impossible to restore the frame to the factory level, therefore, after such repairs, the operation of the vehicle will be unsafe.

If the defect is invisible to the naked eye, it is recommended to diagnose the frame. This will help identify linear deviations and detect internal damage. In situations where damage is obvious, a decision is made to repair or replace. Let's consider several typical situations.

Frame crack

In such situations, repair of the GAZelle frame cross member is carried out by welding. However, it was said above that this method is not reliable. Therefore, the seam section is reinforced with additional inserts, which will help reduce loads.

Alternatively, the frame can be cut through the area of the broken metal and the beams connected with extensions. Such elements are pushed onto the ends of the frame and fixed with a riveted connection through the mounting holes. The length of the wheelbase does not increase.

The frame is rotten

Repairs here are usually impractical. Of course, proper strengthening of the GAZelle frame will help reduce the load on weak areas, but this is the so-called “patching holes.”

Restoring rotten frames is expensive, so it is better to change the design.

The frame was twisted

Linear deformation can be eliminated. To do this, the metal is heated and stretched, restoring the damaged geometry. If the bend is strong and there is a risk of damaging the metal when pulling, control marks are made, the deformed part between them is cut out and replaced with a new channel.

When is frame repair necessary?

All the main parts and assemblies of the car are attached to one large frame, which is called a car frame. Here, even the slightest chip or crack on it can subsequently lead to irreversible damage not only to the frame itself, but to the entire car.

For this reason, frame repairs should be done in a timely manner before minor damage can cause major damage. The greater the damage, the less efficient the cooking.

It is important to monitor the condition of the car frame, otherwise it can lead to fatal consequences.

Cold riveting repair

This is the best option for restoring frame structures of trucks. Unlike hot-riveted and bolted joints, this method provides maximum strength by reducing the friction force at the joints. As a result, cold rivets are more resistant to shearing.

The technology for such repairs is quite simple. At the fastening areas, mounting holes are cut into which the rivets are actually pressed. There is no thermal expansion here, which ensures maximum joint density.

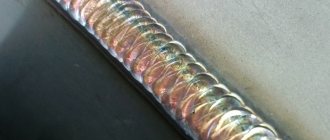

Seam treatment after welding

All seams must be properly processed after completion of welding work. Metal must be protected from the negative effects of the environment. The connection area must be washed, then sandblasted, degreased, primed and painted.

In conclusion, it is worth noting that welding a truck frame is a process that requires concentration and care. In order for the weld to be as strong and high-quality as possible, the welder must have some experience. Because the frame is an important part on which the safety of driving a car depends. Do not forget about safety and when welding, be sure to wear special protective clothing. If you follow all the rules and requirements, then in the end you will get the highest quality connection.

The car frame is the main supporting structure to which other components are attached.

p, blockquote 1,0,0,0,0 —>

The frame body structure was used on almost all cars in the world until the early 1960s. The first frames were made of wood (most often ash). In the 1930s, wooden frames were replaced by steel frames. Over time, almost all passenger cars changed their design to a “unibody” (see article “Design of a monocoque car body”). These days, frame bodies are mainly used for SUVs, trucks and buses. The longitudinal beams of the frame bear the main loads. Cross members provide resistance to lateral loads and increase torsional rigidity.

p, blockquote 2,0,0,0,0 —>

Content:

A frame with one layer of metal is used on most small and medium-sized vehicles. Some frames consist of two layers of metal and have an additional beam inside the main beam. This design provides increased strength without loss of flexibility. This design can be used on large trucks. Often double metal is used only on certain sections of the frame. Different manufacturers have their own design and development concepts to achieve the desired frame performance.

Preparing the frame for welding

The following sequence of actions is performed here:

- The visible ends of the crack are determined. For maximum accuracy, it is better to use a magnifying glass.

- Drilling in progress. Holes are created at a distance of 5-10 mm from the edge of the crack.

- The edges are processed at an angle of 90 degrees. This is done using a grinder.

- The edges are cleaned with a grinder or steel brush.

Here it is necessary to clarify that welding is advisable only if the crack can be welded “to the root.” In other situations, such a connection is not used due to low mechanical strength. However, even with root welding, the surface is still reinforced with steel plates.

Welding is carried out in several passes with a constant increase in voltage. The exact number of stitches is always determined individually, depending on the depth of the damage.

Stages of restoration of car body parts by welding and surfacing

Wear of mechanical elements occurs unevenly. In this case, due to damage that is small compared to the size of the part, its performance is lost. Accordingly, the functioning of the unit or even the entire mechanism deteriorates or stops.

Among the methods of metal restoration, restoration of parts by welding and surfacing is in first place in terms of prevalence. There are two main reasons:

- Restoring the original properties of the element.

- Relatively cheap.

In the article we will focus on the practical application of restoration techniques in relation to body welding work on cars and trucks.

What does the repair involve?

The processes of welding and surfacing are fundamentally different . In the first case, the melt is used to join the parts. In the second, it acts as a working layer, which is applied to the surface of the part in order to restore its original dimensions.

There are situations when these functions coincide. An example is the restoration of the underbody of a car damaged by corrosion. At the same time, severely damaged areas are replaced with sheets of metal, cracks and holes are restored by surfacing.

In other cases, the wear on the axle or frame of the body part is completely restored by surfacing . At the same time, welding can be used to repair (for example) a crack on the same element.

Another example: welding a truck frame. Here, the elements of the supporting frame where cracks have arisen are welded, and the excavations in the eyes and grooves for fastening units, rods, axles, etc. are welded.

As for iron wear, choosing repair by surfacing is not always advisable . If an automobile plant produces the necessary components, repairs may come down to cutting out the worn part and then welding a new one.

As a rule, welding of a car body is used more often than surfacing on its parts. The reason is the nature of wear caused by the similarity of causes of damage during operation.

Equipment used

With all the variety of work methods and tooling, the classification of welding during car repairs comes down to only two types:

Electric is divided into manual, semi-automatic in an inert gas environment, submerged, etc.

There are other methods, such as laser, friction, and diffusion welding. However, they are practically not used for car repairs.

In some cases, a type of welding is used, such as soldering . It is used to repair damage to pipes made of non-ferrous metals, radiator blocks, and parts of refrigerator equipment made of thin copper.

Which welding is best for welding a car body depends on the nature of the damage, as well as the characteristics of the place or part that needs to be restored.

Today, the majority of work is carried out using electricity. Gas welding, which was once almost the only method of repair, is today used to connect parts made of thin metal.

In addition, oxy-acetylene welding is still popular where various rods that create dynamic loads are attached to the body .

Electrical appliances for small repairs include car welding using an inverter or a conventional manual welding machine. For delicate work that requires high quality, as well as surfacing, semi-automatic machines with carbon dioxide or inert gas are used.

With the spread of aluminum and titanium alloys, the arsenal of repair mechanics was replenished with arc welding devices using a non-consumable electrode in an inert gas environment. With feeding of the melting filler rod by hand or automatically.

Part preparation requirements

The quality of restoration largely depends on how correctly we prepare the part . This applies to welding, and especially surfacing.

The metal is thoroughly cleaned of rust using an angle grinder (angle grinder), better known as an “grinder.” Or with a hand brush. If necessary, chamfer or level.

In critical cases, during surfacing and soldering, the surface is degreased.

Sandblasting or waterjet treatment gives a good effect..

The cracks are cut with angle grinder grinding discs to the full depth to obtain V-shaped grooves in their place. Thick metal is processed on both sides. At their ends, to eliminate stress and prevent further development, through holes with a diameter of 4-6 mm are drilled.

Before fusing the holes, their edges are countersunk on one or both sides; if there is a thread, it is drilled out.

Considering that welding a car with an electrode or gas flame creates a high temperature, care should be taken to ensure the safety of adjacent finishing elements, electrical components. equipment, plastic parts.

To do this, remove the element being repaired or parts that may be damaged. If this is impossible for some reason, measures are taken to protect them (close them, cover them with wet rags).

Electrodes used

The selection of electrodes or welding wire is carried out based on three parameters:

- Type of metal.

- The required thickness of the part or surfacing layer.

- The level of responsibility of the part being restored.

When performing body repairs semi-automatically with carbon dioxide, flux-cored welding wire, copper-plated or plain, is used.

Surfacing of a layer with high hardness characteristics is carried out using electrodes of the T-620 type, with a thick coating including graphite, boron carbide, etc.

The required diameter of the electrode is selected based on the thickness of the metal being welded, according to special tables.

Aluminum parts are connected by gas (oxyacetylene) or arc welding. In the latter case, OZA-2 type electrodes are used. When using technology with a non-consumable tungsten electrode, a rod of the corresponding aluminum alloy is used as an additive.

When surfacing worn engine parts to obtain alloyed coatings, wire of the Np-65 type with a high carbon content is used. Work is carried out under submerged arc, in an environment of inert gases.

Methods for welded repair of car and truck bodies

A variety of technologies are used to weld the body of both passenger cars and trucks. Fundamentally, they all boil down to an electric arc or a hot gas stream, but at the same time they often have significant technological differences.

Manual arc

Both AC and DC devices are used for work . The first include welding transformers of various types. The latter are represented by welding machines and generators.

The transformer produces an unstable arc and requires significant current across the diameter of the electrode (this characteristic is called current density). At the same time, the temperature of the arc increases, which is fraught with burnout and overheating.

This danger was relevant for old welding transformers, and even now the question: is it possible to weld a car with electric welding does not always give a positive answer. At a minimum, if we are talking about homemade devices or ordinary welding transformers.

The situation has changed with the advent of inverter devices, but this type of connection is used to a limited extent for connecting elements made of thin metal.

As a rule, this method is used to repair massive parts, such as frames or assemblies made of thick metal, for example, mufflers.

Automatic submerged surfacing

It is used quite widely for repairing industrial equipment, especially unique ones. For automotive repairs, the distribution is usually small, for restoration by surfacing of rotating parts (for example, a camshaft) .

The meaning of the method is that the welding arc does not burn openly, but under a layer of special powder - flux. It protects the metal from oxidation and combination with air nitrogen. The quality of the weld or surfacing layer is not inferior to the original metal, and when using special electrodes it can exceed it in hardness and wear resistance.

Vibro-arc method

Like submerged arc surfacing, it is used exclusively in factory conditions, since it requires bulky installations that ensure accurate positioning of the part.

The meaning lies in the oscillatory movements of the melting electrode with a frequency of 100-120 Hz, at a voltage of 12-18 Volts. In this case, surfacing is performed with tiny particles of metal with simultaneous cooling.

In gas protective environments

A method that gives the highest quality results in service stations and repair shops.

Welding or surfacing is carried out in an inert gas environment using a non-consumable electrode (TIG), or with a fusible electrode surrounded by an inert or active gas (MIG/MAG welding, respectively).

Allows you to obtain a connection that is not inferior to that made in the factory . But most importantly, with the help of this method, for the first time, current repairs of parts made of titanium and aluminum alloys and high-strength alloy steels became available to motorists.

Semi-automatic methods

One of the most popular methods used today by small workshops and private craftsmen.

The process is carried out in air or under carbon dioxide. Welding wire of the required composition is used as a consumable electrode. It is served by unwinding from the reel as needed.

Moreover, even household-level devices are capable of automatically adjusting the wire feed speed depending on the arc strength.

Alternative Pressure Recovery Technology

To restore parts under pressure, surfacing or welding is not required. The part is only preheated to plasticity.

The meaning of the method is to change the geometric dimensions of parts during their deformation. There are three main methods:

- draft;

- compression;

- casing.

In the first case, when cylindrical parts such as bushings are compressed, the internal diameter decreases with decreasing height. By crimping, I reduce the lateral deformations of the part, and when casing, on the contrary, they increase it (see picture photo

In some cases, such operations are supplemented or preceded by surfacing.

Features of truck frame welding

Welding parts of a truck and a passenger car is fundamentally the same. Minor differences are caused by different body metal thicknesses.

It’s a different matter when it comes to how to properly weld a broken frame on a truck that can take the load of the cargo being transported, sometimes weighing no less than the vehicle itself.

In case of significant damage caused by accidents or improper operation, it is advisable to cut out the deformed area, replacing it with a whole one.

In this case, only methods that do not overheat the metal should be used.

When surfacing cracks, they are pre-treated as described in the preparation section. Then the seam is cleaned, and the area is additionally reinforced with a metal plate.

Frame reinforcement

This helps eliminate deficiencies in structural rigidity, prevent cracks from appearing and twisting of beams during subsequent operation of vehicles. Strengthening frame structures is allowed by technical regulations, but only in certain cases.

Gain Options

Based on the context of the current regulations, only two methods are allowed to increase the reliability of the frame:

- Redistribution of loads on support points. It is performed at the body mounting area, and the desired effect is achieved by installing a subframe. This structure is welded from a metal profile and helps reduce dynamic loads on the load-bearing base.

- Segmental enhancement. This increases the strength of individual, potentially weak areas. Such reinforcement is usually performed with U-shaped inserts, which are placed inside the longitudinal side members. This option is great for strengthening areas with welded or riveted elements.

It should be noted that strengthening the frame does not refer to changes in the design of the vehicle, because the linear dimensions and characteristics of the chassis remain unchanged. Therefore, there is no need to separately register such modifications with the traffic police.

How to weld a car frame

In any car, the body is an important integral component that protects all internal components. A truck, like any other, requires constant maintenance, and in case of breakdown, repair. Very often you have to weld the frame on a truck. It is this process that will be discussed in this article.

You can read about welding a car body here.

Welding an SUV frame

I'll contribute my 5 kopecks. WHEN WELDING THE FRAME, MINIMIZE THE TRANSVERSE SEAMS. I inserted the patch, welded it in a circle, and the overlay on top along the length, so that it overlaps with a good margin and weld only longitudinal seams, and not continuous ones - in a run-up, do not cook across. Do not cook everything with smoke breaks overheating the frame - there are different sequences depending on the situation. The bullet machine, of course, rules. If you’re an MMA pro, you can do the same.

AMP Posted 17 February 2010 — 23:34

I'll contribute my 5 kopecks. WHEN WELDING THE FRAME, MINIMIZE THE TRANSVERSE SEAMS. I inserted the patch, welded it in a circle, and the overlay on top along the length, so that it overlaps with a good margin and weld only longitudinal seams, and not continuous ones - in a run-up, do not cook across. Do not cook everything with smoke breaks overheating the frame - there are different sequences depending on the situation. The bullet machine, of course, rules. If you’re an MMA pro, you can do the same.

I completely agree. You have to deal with this at work - either repairs or strengthening. I’ll add on my own behalf: I consider patches a half-measure, overlays are much more reliable. Welding, preferably semi-automatic.

It is necessary to thoroughly clean the metal until it shines and not try to stick the reinforcement to the half-living rot. The easiest way: a strip that is adjusted to the location.

So far, there are no complaints about this method, but I think there are options that are simpler and with a greater margin of safety. And the main thing is not to rush #33;

Natey-Golenko Posted 18 February 2010 — 10:44

The bullet machine, of course, rules.

Welding, preferably semi-automatic.

From what point of view is PA better?

hihkook Posted 18 February 2010 — 11:44

From what point of view is PA better?

Less heating of the frame, hence less deformation. I’m not comparing it with TIG, only with MMA. But if you take the frame of something more serious (a truck, where the thickness is 8-10 mm or more), then MMA welding is quite acceptable.

Natey-Golenko Posted 18 February 2010 — 11:49

Less heating of the frame, therefore reducing deformation.

What about impact strength? If we compare Sv08G2S wires and UONII 13/55 electrodes?

But if you take the frame of something more serious (a truck, where the thickness is 8-10 mm or more.)

You can take PA more seriously.

hihkook Posted 18 February 2010 — 12:16

You can take PA more seriously.

Undoubtedly, but if not, it’s more serious, and if the ceiling is cooked with cutting. I only approach serious frames with UONI or LB-52; I can’t lift my hand to take other electrodes.

Natey-Golenko Posted 18 February 2010 — 18:39

Those. PA rules only for frivolous frames.

Features of MAZ frame repair

A serviceable MAZ frame is a guarantee of the safety of the driver and passengers of a heavy-duty vehicle.

However, bad roads and increased loads lead to part failures.

Over time, the frame of your truck can crack or burst. Then there is the question of how to straighten the truck frame.

AvtoResurs Group of Companies LLC will help solve problems with truck frame repair.

We will tell you about the structure of the “skeleton” of a heavy-duty vehicle, the most common breakdowns and how to fix them.

Repair cost

In all auto repair shops, prices for frame restoration are calculated individually.

When determining the final price, the following parameters are usually taken into account:

- Nature of damage;

- The need to dismantle existing superstructures;

- Material cost;

- Difficulty performing the work.

However, by paying for the services of professionals, the car owner receives a guarantee of quality. Before performing work, the frame must undergo diagnostics, which allows us to identify any hidden defects and damage that the car owner is not even aware of.

General information

The frame in a car is the power frame that serves as the basis for attaching all body parts, engine, gearbox, drives, etc. You should usually resort to a technology such as frame welding when there is minor deformation of this part. For example, if cracks, chips, or folds have formed, then in this case, it would be advisable to weld the frame. However, you should strictly follow the welding technology, because not only the quality of the frame, but also the future safety of using the car will depend on this.