An electric or regular jigsaw is useful for a creative craftsman, since the equipment allows you to cut shaped or straight cuts from a wide variety of materials, from soft wood to glass or even steel. The versatility of the tool lies in the files, each of which serves a specific task. Therefore, it is very important to understand their classification and know how the file is secured in the jigsaw clamps.

Jigsaw

Classification of jigsaw files by type of material being processed

Initially, when jigsaws were not yet electric, this equipment was used only for wood processing. But modern devices allow you to cut metal, plastic and any type of wood surface. Therefore, before purchasing a jigsaw (Bosch, Makita or similar models), you need to decide on the material to be processed. After all, depending on the purpose, you will have to look for a specific cutting blade.

For wood and wood materials

Files for wood processing are divided into several groups:

- Quick cut Sometimes the quality of processing of wood material is not as important as the speed of the process itself. For such work, a long blade (from 60 mm) with large teeth (up to 6 mm) is suitable. If the master is going to make a longitudinal cut, then it is advisable to buy files with oblique teeth. And for a cross cut, a straight “tooth” is used.

- Clean cut (average tooth size not exceeding 3 mm, as well as a slight gap). Such files are usually used in furniture assembly plants.

- Figured cut. It is difficult to make a curved cut with a small radius, so special shaped files are used that have a very narrow blade, not exceeding 4 mm. The canvas is also characterized by small teeth (up to 2 mm) and short length (40 mm).

Important! If you choose the wrong file, there is a risk of overheating the motor of the jigsaw (models Dexter, Whirlwind and others).

For metal

Cutting metal is not the most obvious solution when working with a jigsaw, but this is possible thanks to a special blade. But, it should be borne in mind that the process will be very slow, and you will have to change a lot of files, as they become dull.

Experts recommend keeping three types of metal cutters with you at once if the master often works with this material:

- for aluminum;

- for non-ferrous metals;

- for steel.

If these blades are rarely used, you don’t have to spend money on buying additional ones, but choose only one - for processing steel. It will cope with non-ferrous metals and aluminum, but will become dull very quickly.

Attention! Metal files are made of durable steel; they have very small teeth (up to 1 mm), which are arranged in a wave-like manner.

Types of jigsaw blades

For polymer materials

To process PVC pipes or other similar materials, it is necessary to use blades with large teeth. Small ones will also work, but you will have to use the maximum speed of the jigsaw, otherwise the melted plastic will begin to clog the cutter.

If you have to work with thin sheets of plastic or plexiglass, experts advise using blades for metal processing. To cut thick plastic, you can take wood saws, but work at low speeds.

For specific tasks

There are special blades for processing ceramics and glass. They are coated with diamond coating or tungsten carbide.

It is advisable to use an electric jigsaw (Dexter, Diold and other models) for processing ceramic tiles or glass only if it is necessary to make very complex shaped elements. For straight cuts, it is advisable to use tools designed specifically for this purpose.

When sawing cement or plaster with a jigsaw, you will have to buy special files with carbide tips on the cutting edge.

In stores you can also find files that are suitable for processing rubber, cardboard and other soft materials. There are practically no teeth on them, and the cutting edge is a polished wave.

Universal

These types of blades are made from high-speed steel. They are suitable for processing different materials: plastic, wood, metal.

You shouldn’t expect high-quality cuts from such tools precisely because of their versatility - a specific material requires the use of a special blade (this is the key to a high-quality cut).

Tips for choosing saws

When replacing a file, it is important to know what you are going to change and for what. Even if you work only with wood, you may need to replace the saw blade due to wear of the old one or a change in the thickness of the timber.

All saws have their own designations. Those used for woodwork are marked with the abbreviation HCS, and those for metal have the HSS marker.

- When choosing a saw for using a jigsaw, it is worth knowing what material will be processed with it. For soft materials, high carbon steel tools are suitable.

- If you need to get a straight cut, you should choose a straight saw with wide teeth.

- For shaped cuts, thin models are used.

- It is recommended to cut laminate with special devices that have a reverse slope.

- But metal tools, as a rule, are not straight; their teeth have different sizes.

- For steel, it is recommended to use a wave-shaped tool.

- For ceramics, files that have no teeth at all (with carbide coating) are suitable, but for plastic, medium teeth are required.

- Don't choose short models. According to the rules, the saw must come out of the cutting material.

- Do not use a tool with teeth that are too large, as this may damage the material.

Saws made from bimetallic material are the highest quality and most durable. They need replacement less often than other models.

Jigsaw file made of bimetallic material

What can a saw holder be like?

The saw holder is the most vulnerable part in the unit under consideration. It is he who is subjected to the heaviest loads during work, and accordingly fails.

The material for the saw holder is usually of the highest quality, but not all manufacturers take care of this, so the percentage of replacement units on jigsaws is high.

There are three types of holder, and each has its own characteristics, how to install a file in a jigsaw.

Saw holder

Bolt-on clamp (shoe) mount

This is the first option that began to be used on electric jigsaws. Almost all modern manufacturers have already abandoned block fastening, since replacing the cutting part in this case is a labor-intensive process: unscrew two bolts, install a file, and then fasten them back. For this operation you need to have a hex wrench with you.

Quick release mount

Used on many modern jigsaws. The process of replacing the blade takes no more than a minute, since you only need to press a special button to loosen the clamp and insert a new file there.

Radial clamp

The simplest type of fastening. Used on new models of jigsaws. To simplify operation, it is equipped with a spring that returns the cams to their initial position.

Important! When replacing the cutting part, it is important to pay attention to the fastening units, since they most often fail. Over time, play appears there, causing the file to beat, which affects the evenness of the cut.

Safety precautions

A jigsaw is one of the tools that is fairly easy to use. But still, the presence of a sufficiently sharp cutting element requires compliance with certain safety rules:

- Cutting any materials should be done on a flat, stable surface with the blade first secured. In this case, cutting parts in midair is completely eliminated.

- The workpieces should be cut at a distance of at least 40 centimeters from the eyes. For protection, it is recommended to use special glasses.

- Before work, you should make sure that the file and other parts adjacent to it are firmly fixed.

- Before connecting the jigsaw to the network, you must check the integrity of the electrical cable.

- The handle of the cutting device must be securely fastened. Otherwise, the tool may slip and cause injury.

When cutting workpieces from various materials, you should always take into account the technical capabilities of the tool. Proper use of a jigsaw and compliance with all safety rules during its operation will allow you to cut any part according to the intended sketch without any problems.

How to insert a file into a jigsaw

Shoe mount - how to insert a file into a jigsaw:

- Loosen the block by turning the two bolts counterclockwise.

- The canvas is placed with the teeth forward.

- The bolts are tightened evenly to their original position.

It is important to ensure that there is no skew, otherwise the cut will be uneven.

If only a bolt is installed on the block, then it needs to be loosened and tightened. There is no need to tighten the screw all the way, as unnecessary vibration will be created during operation. This data is enough to understand how to insert a file into a jigsaw with a block mount.

Quick-release technology - procedure:

- Press and hold a special key.

- Insert the shank of the file into the corresponding slot.

- The key can be released.

If you hear a click, it means the operation was successful.

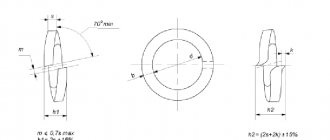

The easiest replacement option is with radial mounting, but you need to choose the correct shank shape (there are U-shaped and T-shaped). The second option is the most common; the u-shaped model has special holes for additional fixation.

Jigsaw with file

How to change a file on a jigsaw:

- Rotate the device head 90 degrees.

- Insert the fabric into the special slot.

- Release the jigsaw.

The clamp will return to its original position under the action of the spring.

How to change and install the canvas correctly?

The saw blade must be changed periodically. This can be caused by its failure, the need to change the type of file, and other considerations. The replacement procedure is not difficult at all, but for novice craftsmen it will be useful to once again clarify the procedure:

- Loosen the clamping screw using the supplied hex key.

- Remove the file.

- Insert/pull the new blade into the socket, teeth first.

- Secure the blade with a clamping key.

To install a file using an automatic clamp, you simply loosen the grip by pressing the lever in the appropriate direction, remove the file, insert another one and turn the lever again. There is no fundamental difference in the procedure.

Most craftsmen prefer to use tools with a hand clamp. To store the key, there is a plastic socket on the wire, allowing you to always have the key at hand. If the clamping screw fails, installing a new one will be without problems, and if the thread wears out, you can cut another one and continue to use the tool.

With automatic clamping, as a rule, there are continuous problems - the workshops do not have replacement parts, and there is nowhere to order a ready-made unit or it is out of production. Therefore, it is recommended to choose a jigsaw with a manual clamp - it will allow you to work with the tool for a long time (for example, Bison or Makita).

Attention! When changing the blade, you must disconnect the tool from the power supply to avoid accidental starting of the engine and serious injury.

Installation in jigsaw machine

A jigsaw machine is a comfortable device, since both hands of the master will remain free when working, which allows for more manipulations.

Attention! To use the device, it is advisable to use special blades with a pin for reliable fastening. If you buy a sample without a pin, you need to tighten it more carefully.

How to properly secure a file in jigsaw clamps:

- Secure the canvas in special grooves (first in the lower part, and then in the upper).

- The teeth should point down and away from the person standing behind the machine.

- The fabric is tightened using a special lever.

If the file is tightened correctly, then after a slight blow it should ring. If the canvas does not have a font, then it must be secured very carefully, since it often jumps out of the device.

Jigsaw machine

What is an electric jigsaw?

Figure 1 – Electric jigsaw.

A jigsaw is a hand-held power tool designed for cutting sheet materials or boards along the intended contour.

A special feature of the tool is its focus on curved cuts - it does not require the installation of guides, and control over the direction and accuracy of cutting is carried out exclusively visually.

The use of guides or templates is not excluded, but the main purpose of the tool is precisely cutting curved shapes of complex configurations along both an external and internal closed contour.

The quality and result of the work largely depends on the level of skill and skills of the user.

The design of the jigsaw consists of an electric motor and a crank mechanism installed in a housing with a handle equipped with a start button. Unlike a conventional tool, a jigsaw has a file that is attached at only one end and is held in a given position only due to its own rigidity and elasticity. Outwardly, it resembles an iron, from the working surface of which a file protrudes in a perpendicular direction. The tool is convenient for performing openwork cutting, as it does not require permanent fastening of the second end of the file, which is typical for a regular jigsaw.

Possible problems

When working with jigsaws, certain problems may arise that need to be resolved in time:

- The blade latches fail. They should not be overtightened so as not to break the thread.

- Fastening bolts, which gradually wear off during intensive work, are also subject to timely replacement.

- You should always pay attention to the condition of the file, as it can deteriorate and cause the engine to overheat. And also, if the master works with a dull file, the quality of the work decreases.

- The blades may become distorted, which will affect the processing of the material.

- When working with a dull saw, the wood will char (this is the wrong working technology).

- If you do not lubricate the roller in an electric jigsaw in time (for example, in a Bosch or Zubr model), the motor will overload.

- When working with an electric jigsaw, do not use excessive force, as the blade clamp may be damaged.

- Electrical devices need to be given time to cool down.

This information is enough to understand how to secure a file in a manual jigsaw, as well as maintain the device (for example, Interskol models) in working condition.

Fastening

The saw blade is fixed, as mentioned above, by three types of locking mechanisms:

Quick-clamping. The main advantage is clear from the name - quick change of cutting tools. But there are some disadvantages:

- The mechanism works only with “native” types of shanks specially developed for it. Other types will not work.

- There are restrictions on the geometric parameters of the files - width and thickness.

Mounting order:

- mechanism, a plastic handle-block (lever), is pulled inside the jigsaw, the rod is released;

- the file is inserted all the way, with the shank into the slot;

- The block is released - the saw blade is fixed.

ADVICE. From practical experience: saw blade jams occur due to abnormal cutting conditions (excessive force, curved cut with a wide blade). Pounding, using pliers and other “brutal” techniques is extra work and risks damaging the instrument. It’s easier to carefully disassemble the jigsaw itself and unlock the exposed locking mechanism.

2. Block screw fastening. By the way, it should be noted that all types of shanks are suitable for this system. The procedure for installing the file:

- the fixing screws must be loosened, - the protective casing is moved and the threaded elements are unscrewed with a wrench (two or three turns);

- a file is installed in the groove (slot), with the cutting part from the jigsaw, in the direction of the cut;

- the screws (located frontally, at the bottom of the tool) are tightened with a hex wrench (must be included in the kit);

- the casing returns to its place.

The main disadvantage, which appears immediately or over time, is inaccurate fixation in the cutting direction. The canvas leads to the side. Another disadvantage is the thread breaking due to excessive tightening efforts. The third negative factor is the failure of the support block. It is almost always impossible to find a replacement; you have to grind it yourself.

3. Side screw fastening (with locks). Occupies an intermediate position in terms of ease of changing the file between the shoe-type fixation and the quick-clamping mechanism. Stages of work:

- the side screw unscrews;

- the shank is installed in the opened groove;

- the canvas is exposed visually and to the touch;

- the screw is screwed back in.

Accuracy of installation depends on initial factory assembly. Over time, individual elements wear out, play appears, and the file begins to wander.

Recommendations for selection

In addition to the main tactical and technical characteristics, the attachment point in a jigsaw is a mechanism that affects the accuracy of cutting the workpiece. Hence, when visually inspecting the selected tool, you need to take a closer look at the operation of the fastening elements:

- Check for play - insert the file and move it; there should be no free yaw motion.

- Turn on the tool and try to determine whether there is any beating in the blade. Minimal displacements are difficult to notice, but visible to the eye, indicate poor quality assembly.

- Perform a test cut (if the seller allows it). The cut must coincide with the markings - the file follows exactly the cutting path.

- Evidence of reliable fastening - during the test test, the cutting tool remained in place and did not fall out of the fixation mechanism.

Mastering the method of installing a saw blade into a power tool will not be difficult; just carefully study the instructions included with the product. During further operation of the jigsaw, carefully monitor the condition of the file attachment unit.