Sandpaper, also known as sandpaper, is the name for sandpaper, a carpentry abrasive that has no analogues today. The material is used in various sectors of industry and life, from a construction site to an art workshop. Emery cloth is intended for manual and machine processing of wooden, plastic, ceramic and metal surfaces in the production of various products to improve the adhesion of elements when gluing or to prepare the surface for painting.

What is sandpaper

Sanding paper is a combined material that consists of:

- The basis of sandpaper is most often paper or fabric.

- Abrasive is a grain that is applied to a substrate using glue or resin.

Manufacturing

Sandpaper production was first started in China in the 13th century. Craftsmen glued river sand of various sizes, crushed shell rock, and plant seeds to parchment using agar-agar or starch glue. Later they came up with the idea of using crushed glass as an abrasive, hence the appearance of “glass paper.”

Serial production of sandpaper began in London in 1833, then began to spread throughout the world, technology improved, and today we see a variety of types of this product.

Production stages:

- The paper base or fabric is impregnated with polymers, most often rubber latex.

- Glue heated to 30...500C is applied to the prepared base.

- The abrasive of the required fraction is applied using the bulk method.

- The semi-finished product is sent to the oven for drying. The temperature depends on the type of glue, grain fraction and other factors.

In this way, you can make low-quality sandpaper at home using thick cardboard, crumbs from an abrasive wheel or crushed glass, sand.

Release form

Finished products are stored by stacking sheets or rolling them into rolls. Sheet fabrics have sufficient rigidity, so they are difficult to bend. Sandpaper in rolls is more compact to store, its fraction and grain size are smaller than that of sheet sandpaper.

Other release forms:

- The abrasive mesh is a sparse sheet with fixed grain. When sanding, even the smallest dust particles pass through the material and do not become clogged in the pores. This working method is called “dust-free sanding”.

- Abrasive wheels are fine-grained sandpaper cut to the shape of attachments for mechanical devices. Its purpose is to clean the metal surface from rust and remove old coating.

- Sandpaper of different grits, cut to the shape of the attachment for power tools with Velcro fastening or to the holes made.

- Sanding belts intended for threading into sanding machines and machines.

Marking

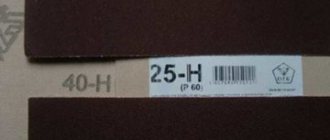

Sandpaper markings indicate the fraction and concentration of the abrasive. Domestic GOST 3647-80 determines the number of grains of different sizes per 1 square unit, but this classification is considered outdated. Today, sanding paper complies with international ISO standards; this designation can be found on the back of the product . It should be noted that the data of the old GOST and the values of international standards overlap with each other. Their correspondence can be seen in the table.

The main difference between the old and new standards is the different movement of numbers in the markings:

- In GOST 3647-80, the values of grain size and density are reduced, which is quite logical;

- In the new ISO 6344 standard (GOST 52318-2005), the product number increases with decreasing value in the marking.

Decoding grain size

The letter "P" in the designation indicates the grain size. The larger the value behind the letter, the finer the skin fraction. P400 is a known zero. P600...P2500 have small fractions and an almost smooth surface; their grain size is not so noticeable to the touch. This type of sandpaper is used for final polishing in industry.

In the old GOST, things were different. Using 10-N as an example: the first number means that an abrasive of a size corresponding to a sieve with a mesh of 100 microns is applied to the surface of the product. The lower the indicator, the smaller the screening size.

Other designations

Types of sandpaper differ in the composition of the base and the properties of the grains. This information is also reflected in the product labeling.

- The letter “L” indicates the sheet form of the product. Rolled is not indicated in any way.

- The letter "M" stands for waterproof sandpaper.

- The product marked “P” is intended for grinding dry products without contact with moisture.

- “1” is an abrasive for soft surfaces, “2” is for hard surfaces.

To select emery for a certain type of work, you should take into account not only the main classification, but also the information provided, which is contained on the back of the sheet.

Manufacturing

The production of such a seemingly simple thing as a strip of paper with abrasive coating is a rather complex technological process and requires appropriate equipment and training of workers. At the first stage, the characteristics of the future sandpaper are printed on the base tape in such a way that they are repeated at a distance equal to the width of the tape.

Next, the tape is impregnated with components to make it waterproof. On the next unit, glue is applied to the surface of the base. Next, pre-sifted and calibrated abrasive chips are applied to the layer of binder material. The next stage is drying in an oven, where the adhesive mass, reacting to the temperature, is baked and firmly attaches the abrasive to the base. Next comes the application of the fixing layer and final drying.

Machine for cutting paper into rectangular sheets

The last operation is cutting the finished tape into rectangular sheets or sheets of other shapes for the manufacture of abrasive belts, gluing them, drying and packaging.

The basis

Abrasive paper can be made on different materials:

- The bulk of products with abrasive are produced on a paper basis. To increase the strength of the paper web to tearing, abrasion, and bending, it is impregnated with polymers and resins. Thanks to these compositions, the product also acquires moisture-resistant properties. But still, paper is a fragile object and is not suitable for intensive long-term work. Fine grain is applied to it.

- Fabric-based sandpaper is more resistant to abrasion and wear. The grain holds just as well, the canvas additionally has elasticity and resistance to moisture, intensive work with various materials, even with a sander, for which they produce velcro attachments.

- Combined fabric-paper fabric (two-layer) combines the best properties of previous materials. The product is elastic, resistant to abrasion, bending, and moisture. Coarse-grained sandpaper is produced on a combined basis.

On sale you can find paper with a sponge base. This one allows dust to pass through well, is not afraid of moisture, and is suitable for manual and mechanical work for a long time.

Types of grain size by material

Abrasive is made on different bases:

- Silicon carbide (carborundum) is suitable for working with hard surfaces made of metal and plastic.

- Pomegranate grains are hard and soft at the same time: such abrasive paper is able to remove unevenness from the surface of the wood and seal the fibers, so that the paint or varnish coating applies evenly.

- Ceramics are used to make coarse sandpapers used for smoothing wood.

- Aluminum oxide is a material of considerable price, but it also has an impressive service life for its “compatriots”: soft crystals break during grinding, smoothing the surface, but in their place smaller particles with the same sharp edges are formed.

- Diamond sandpaper is the most durable and expensive. It hardly wears out and is used mainly for machine processing of products in industry.

In what form is it produced?

The first sandpaper was made, consisting of paper and fabric. After production, the product was wound into rolls and transported to its destination. Another product parameter is width. In addition to paper and fabric backing, the following types of abrasive devices are produced:

- Mesh - looks like a canvas with holes. Abrasive particles are attached to the outside of the blade. The mesh structure of the product is designed to allow dust particles to pass through during the processing process, which are removed from the surface being treated. When using such materials, dust clogging between the grains is eliminated. The method of grinding with a mesh abrasive is called dust-free

- Circles - Look like sandpaper cut into a circle shape. This form of the product is needed in order to use it on power tools to quickly wipe a metal surface from corrosion or remove paintwork.

- Tapes - sandpaper is used for installation and work in tandem with sanding machines and machines

For each type of surface being treated, the appropriate types of sandpaper are used. They differ in the types of abrasives used. Let us consider in more detail what types of abrasives are found on sandpapers used for processing different surfaces.

Application

- Sandpaper for wood in carpentry is necessary when preparing the surface for painting or varnishing.

- In construction, sandpaper is used to clean out sagging on plaster and putty, and wood fibers before use. The sandpaper also helps get rid of paint smudges.

- Car repair: stripping old paint, preparing the surface for puttying, matting the gloss.

- In the production and repair of furniture and in many other industries.

How to choose?

When choosing, you should pay attention not only to the cost, but also to the characteristics of the product.

- Grain size of the material. The choice of fraction is made based on the purpose of the purchase: P22...P60 sandpaper is suitable for the primary preparation of wood. To prepare a wood or metal surface for painting, choose P240 or finer.

- Material is the basis. For long-term work, it is worth buying an abrasive on a fabric or combined basis. If manual leveling of surfaces is expected, paper will do.

- For manual labor, you can take a product of any format. For grinding machines and machines, it is more convenient to choose special wheels or strips that do not need to be cut and glued.

Grit index

The main indicator that is taken into account when choosing is the number of paper corresponding to its abrasiveness. The number indicates the number of abrasive particles per square inch of material. The greater the number of abrasive grains placed per unit area, the smaller they are and are suitable for finer operations. Based on the number of particles per square inch, sandpaper is divided into three main categories:

- Large. Marked with numbers from 12 to 80. Mainly used for rough processing of wood, metal and other materials, as well as for removing varnish, paint and rust. When processed, it leaves deep furrows and requires further processing with smaller sandpaper.

- Average. The abrasiveness index ranges from 80 to 160. Mainly used for processing wooden parts, finishing surfaces after rough processing.

- Small. The number of abrasive particles is from 160 to 1400 per square inch. Used for surface finishing, grinding and polishing.

The sandpaper grit table below allows you to more accurately select the paper in accordance with the planned work.