Gas welding is a process in which the edges of the elements being joined are heated by the combustion of flammable gases mixed with oxygen. Do-it-yourself gas welding is used for the manufacture and repair of products from sheet steel 1-5 mm thick, cast iron, brass, copper, aluminum, correction of casting defects, surfacing of hard alloys. Welding materials for gas welding include: flammable gas (acetylene, propane, hydrogen), technically pure oxygen, filler wire, fluxes, if required when working with a specific metal or alloy.

Peculiarities

Often, when cooking tin bronze, a phenomenon such as the formation of frozen drops is observed. This happens for the reason that fusible fractions float to the surface. Components such as lead and zinc are subject to waste. Their boiling point is lower than that of copper, so natural evaporation occurs.

The type of flame should be controlled. It must be strictly normal. An oxidizing flame burns out the tin, and a carburizing flame causes pores to appear. Acetylene consumption during gas welding should be 70-120 liters per hour per 1 mm of metal sheet thickness. The surface must be in the reduction flame zone, which is 7-10 mm. This is the only way to reduce the degree of tin burnout.

It is recommended to preheat cast bronze parts to a temperature of 450°C degrees. The filler material is BrOTs4-3 or BrOF6.5-0.15 wire. Difficulties in welding aluminum bronze are associated with the formation of an oxide film, which has a high melting point. It can only be dealt with with a special flux. The latter is a substance containing sodium fluoride, sodium chloride, barium chloride and potassium chloride. Silicon bronze, unlike other types of alloys, is weldable well due to the presence of elements such as silicon and manganese.

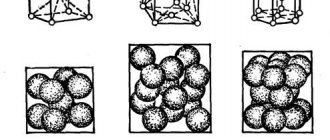

There are features characteristic of any alloy containing copper. The welder must be aware of these features, because he will certainly encounter certain difficulties. The presence of copper in an alloy determines its physical properties. The thermal conductivity of bronze, like brass, is quite high, as a result of which intensive heat transfer must be taken into account. Rapid crystallization is accompanied by the formation of cracks. Another factor influences here - a high coefficient of thermal expansion. When a metal crystallizes, it “contracts”, resulting in internal stresses.

Bronze is widely used by artists and sculptors in the manufacture of busts or monuments. It is used to make fittings and decorative elements. Welding work must provide not only a reliable connection, but also an aesthetic appearance. The presence of elements such as zinc, tin or lead in alloys largely determines the characteristics of welding work.

The burnout of the listed elements is due to a significant difference in boiling points. After the metal melts in the weld pool, atmospheric oxygen is absorbed. Alloying elements react with it. A film forms on the surface of the bath. At the same time, hydrogen enters the metal, and during crystallization, pores remain. They significantly reduce the quality of the weld.

Expert opinion

Bagrov Viktor Sergeevich

Welder of the highest 6th category. He is considered a master of his craft, knows the intricacies and nuances of the profession.

Welding technology must be strictly followed. Failure to comply with the parameters leads to the appearance of cracks and other defects.

Some problems can be solved by protecting the bath with inert gas. Argon is most often used. All of the above indicates that bronze welding is a rather complex process, so the welder must have certain knowledge and experience.

Properties of aluminum

Before you start welding aluminum with argon, step-by-step instructions for beginners will be discussed below, you should familiarize yourself with the properties of this material.

Aluminum without impurities conducts current 4 times better than steel. This material conducts heat with an index of 2.2 W/(cm∙K). For steel, for example, it is 0.6 W/(cm∙K). This must be taken into account by the master when welding aluminum with argon. For beginners, step-by-step instructions should be followed down to the smallest detail.

Frequently used alloys are AlMg5, AlMg4, 5Mn. Their thermal conductivity is also higher than that of steel and is about 1.3 W/(cm∙K).

Due to these features, the technology of welding aluminum with argon does not allow an increase in the speed of the process. Otherwise, the penetration depth will decrease. Rapid crystallization of the weld pool leads to incomplete gas evolution. This feature of argon welding of aluminum can cause the formation of pores in the weld. Therefore, more current is required than for steel.

Preparing for work

Today, welding of bronze, like other alloys containing copper, is carried out in three ways: manual arc welding, argon arc welding and gas welding. Preparatory work is defined for each type of work and does not depend on the choice of welding method. The need to prepare metal surfaces is dictated by the requirements for the weld.

First of all, by mechanical processing it is necessary to form edges that will adjoin each other with the maximum area. Then, using sandpaper or any abrasive tool, you will have to polish the ends until a characteristic golden shine appears. This procedure must be performed in any case, since bronze is quickly covered with a layer of oxide, which can prevent the formation of a high-quality seam.

If it is not possible to carry out mechanical treatment, and the edges are in normal condition, then you can get rid of the oxide using a solution of nitric or hydrochloric acid.

Manual arc welding

Bronze welding is most often necessary when carrying out repair work, correcting defects or when surfacing. You can use preheating of the part to 350-450°C degrees, but it should be remembered that at high temperatures the strength of bronze decreases. Manual arc welding is carried out in the lower position. Metal or carbon electrodes are used as consumables.

- When using a metal electrode, a constant welding current of reverse polarity is set.

- Carbon electrodes require straight polarity.

Welding with alternating current is also possible, but for a stable arc the current strength must be significantly higher. If with direct current it is selected based on the calculation of 40 A per 1 mm (electrode diameter), then for alternating current the figure increases to 80 A. The seam is applied continuously, without transverse movements of the electrode.

After welding, cast bronze parts should be annealed at a temperature of 500°C degrees. The rolled product is forged without heating. Phosphor bronze can be arc welded, but it is recommended to use electrodes containing tin, phosphorus and copper. Tin bronze electrodes contain zinc, tin, lead, phosphorus, nickel, iron and copper. Aluminum bronze is welded with copper rods that contain aluminum, manganese and iron. Surfacing of bronze is carried out using bronze electrodes OSTS-5-3-20 or AZH-9-4.

Process Rules

Welding aluminum with argon for beginners, whose step-by-step instructions will allow you to do the work at home, uses electrodes made of refractory tungsten.

They often contain additional impurities that increase the strength and quality of the final result.

The main rule that should be followed in work is the location of the wire. It should always be in front of the electrode. It can only be moved along the seam.

The welding itself can be performed in different positions in space.

However, the best quality is achieved when the process is carried out horizontally. For welding on ceilings or walls, a mixture of argon and helium is used.

To control the process and be able to perform work of increased complexity, the device is regulated by alternating current frequency and balance.

Argon-arc

This type of welding is fundamentally similar to manual arc welding. The only difference is that the process occurs in a protective gas environment. Argon is heavier than air, so it forms a protective zone through which atmospheric oxygen does not enter the weld pool. Argon arc welding can be carried out with non-consumable tungsten electrodes or consumable electrodes, the role of which is played by rods.

It is argon arc welding that is most often used when working with bronze and brass. This preference is especially given when the metal thickness exceeds 5 mm. Welding productivity is quite high, but the process itself requires the welder to have certain qualifications. An electric arc formed between the metal surface and the electrode partially melts the edges, after which a connection occurs to form a seam. As mentioned above, preliminary preparation of the edges is required.

There are a number of recommendations that allow you to obtain high-quality connections between parts made of copper alloys.

- It is advisable to form the seam in small sections.

- When the process is finalized, the voltage gradually decreases, and then the arc is moved to the side.

- To prevent evaporation of alloying elements, special additives containing silicon, aluminum or boron are used.

Welding bronze and brass is accompanied by the release of toxic substances, so it is carried out in compliance with all possible safety measures. Argon welding has a number of advantages over other types of joints.

- Obtaining an aesthetic seam.

- Economical process.

- There is no need to clean the part from slag.

- For bronze, argon welding is the most preferable.

- Argon welding can be used to fuse parts, restoring their previous shape (for example, when worn).

- It is possible to work with thin sheet metal.

Which filler wire to choose

For AC TIG welding, the industry produces standard rods designed only for aluminum. Their appearance is shown in the photo below:

They are produced in various diameters and are selected depending on the thickness of the metal and the current welding mode. The indicative table will help in choosing the right solder.

Table 1

Universal ER 4043 - for welding aluminum and its alloys AD31, AD33, AD35 with magnesium, silicon and other elements. Types of industrial solders for TIG aluminum welding are determined by GOST 7871-75. The most common:

- AL ER5356 - for AlMg4, AlMg3, AlMg5, AlMg6 alloys.

Both the quality and speed of welding depend on the choice of solder, which is important - the TIG welding process is several times slower than MMA or MIG, so the possibility of speeding it up is very relevant.

Gas

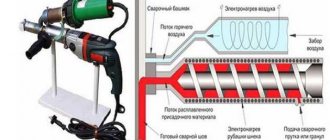

Gas welding of copper alloys is used primarily in order to minimize the waste of alloying elements. The welding flame is adjusted so that three zones are clearly distinguished. The metal surface should be on the border of the second and third zones. Working with silicon bronze requires an oxidizing flame. It is obtained by burning a mixture of oxygen and acetylene, if the ratio of the first gas to the second is 1.2. Bronze containing aluminum causes many problems during welding, since a film of aluminum oxide is formed, thickening the contents of the weld pool.

In the absence of preliminary and subsequent heat treatment of the seam, the quality and strength of the joint obtained using gas welding is 85% of the strength of the base metal. A good result can only be obtained after forging the seam. Gas welding requires a lot of experience from the master. At low burner speeds, pores may form in the metal. It is necessary to correctly select the burner power, gas composition, based on the type of bronze and the thickness of the workpiece.