There are many different types of welding filler materials, each type is endowed with some unique properties that the other does not have.

Any welder will sooner or later have to do work with some kind of alloy, and not pure metal. They are much more often used in industry. This is due to the fact that the alloy can have the properties of several metals at once. However, improving properties and characteristics directly affects the level of complexity of repair work. In many ways, this becomes noticeable when exposed to high temperatures; most of the important chemical components evaporate before the base material reaches the melting point.

Naturally, the disappeared elements “take away” with them some important properties that the alloy previously possessed. This problem can only be dealt with using one method - the use of filler material with a large number of different chemical elements in the composition. Many types of fusion welding use a special welding wire that differs in size, diameter and properties.

An example is the welding of stainless steel products. When exposed to high temperatures, the anti-corrosion material becomes ordinary and loses its protection against corrosion. This can be avoided by using additional alloying, which can be achieved using an alloyed filler material.

The same principle occurs with all other alloys: when exposed to high temperatures, they lose their properties, but the appropriate type of alloy welding wire makes it possible to replenish the lost elements in the composition.

Using various versions of high-alloy consumables, you can increase the level of ductility, strength, reduce the chance of crystalline cracks in the structure, etc. Selecting the right type of filler wire is a rather difficult task, but if you cope with this task, you can restore all the properties of the alloy after repair work and even improve them.

High alloy filler wire models are widely used for welding copper, aluminum, stainless steel, cast iron, nickel, etc. A small fraction of any additional element in the composition of the filler material, which sometimes even amounts to hundredths of one percent, can be capable of completely changing the physical properties of the wire.

Due to this feature, high-alloy filler material is manufactured with the highest precision, strictly following state standards. The same model of welding wire can be produced in different versions, which differ in cross-sectional diameter.

Symbols and markings

The designation and marking of alloyed welding wire is based on GOST 2246-70. Consider, for example, 1.2Sv-06X19N9TA – VI – E – O.

- St – means that the wire is welding, the number 1.2 indicates the diameter of the wire in mm.

- 06 – shows the percentage of carbon (0.06%).

- X19 – chromium content 19%.

- H9 – nickel content 9%.

- T – titanium content less than 0.5%.

- A – indicates a reduced content of phosphorus and sulfur (determines the purity of the metal). If the designation is AA, then the content of harmful phosphorus and sulfur is half as much.

- VI – made of steel smelted in a vacuum induction furnace. If the designation is VD, then the steel was produced by vacuum-arc remelting, if Ш - by electroslag remelting.

- E - talks about the purpose of the wire for making electrodes.

- O - copper-plated, if there is no sign - not copper-plated.

Fubag copper-plated welding wire. Photo 220Volt

There are a very large number of alloyed welding wires based on their chemical composition. Therefore, there are quite a lot of elements with percentage content in the wire designation, for example M (molybdenum), F (vanadium), C (silicon) and others.

Surfacing wire

Surfacing is the technological process of applying a layer of metal to the surface of a product by fusion welding. It is used to restore the original dimensions of parts and to give the surface layers of the part special properties required for its successful operation.

When surfacing by fusion welding, a pool of liquid metal is formed, which includes part of the molten metal of the product and the deposited electrode metal. Thus, the metal of the electrode turns out to be diluted with the metal of the product. When restoring worn parts, unless it is necessary to increase their wear resistance or other properties, electrodes and filler wire of a composition are used that ensures the production of deposited metal that is similar or close to the composition of the metal of the product. If, according to operational requirements, it is necessary to increase wear resistance, heat resistance and other properties, a variety of alloyed electrodes and wires are used, which, taking into account the partial dilution of the deposited metal, ensure the formation of a surface layer of the required quality. In addition to increased alloying, technological methods are used to reduce the proportion of the base metal in the surfacing, in particular, they reduce the welding energy (surfacing at low currents), increase the transverse vibrations of the electrode, etc.

The main raw material for arc surfacing of metal on worn parts is steel surfacing wire. They produce 19 grades of surfacing wire, including: 8 grades - from carbon steel Np-25, Np-30, Np-35, Np-40, Np-45, Yp-50, Np-65, Np- 80); 8 grades—alloy steel (Np-40G, Np-50G, Np-65G, Np-ZOGSA, Np-30Kh5, Np-40Kh2G2M, Np-5KhNM, Np-50KhFA); 3 grades - made of high-alloy steel (Np-30X13, Np-40X13, Np-PZA).

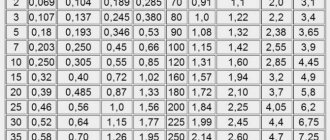

Steel surfacing wire is produced in the following diameters, mm: 0.3; 0.5, 0.8; 1; 1.2; 1.4; 1.6; 1.8; 2; 2.5; 3; 4; 5, 6; 6.5; 8. The hardness and purpose of the surfacing wire are shown in the table below.

Hardness and purpose of surfacing wire

| Wire grade | Approximate hardness of deposited metal | Welded products |

| Np-25 | NV 160…220 | Axes, spindles, shafts |

| Np-30 | ||

| Np-35 | ||

| Np-40 | NV 170…230 | |

| Np-45 | ||

| Np-50 | NV 180…240 | Tension wheels, trolley ramps, support |

| Np-65 | NV 220…300 | Support rollers, axles |

| Np-80 | NV 260…340 | Crankshafts, cardan shaft crosspieces |

| Np-40G | NV 180…240 | Axes, spindles, rollers, shafts |

| Np-50G | NV 200…270 | Tension wheels, support rollers for tracked vehicles |

| Np-65G | NV 230…310 | Crane wheels, support roller axles |

| NP-ZOHGSA | NV 220…300 | Crimping rolls, crane wheels |

| N l-30X5 | HRC3 37.. 42 | Rolling rolls of section rolling mills |

| NP-40ХЗГ2МФ | HRC3 38…44 | Parts exposed to impact and abrasive HOCV |

| Np-40Х2Г2М | HRC3 54…56 (after hardening) | Machine parts working with dynamic loads (crankshafts, steering knuckles: axles of road wheels) |

| Np-55ХНМ 60 | HRC3 40…50 | Forging and punching dies, forging machine rolls |

| NP-50HFA | HRC3 43…50 | Splined shafts, crankshafts of internal combustion engines |

| NP-30Х13 | HRC3 38…45 | Hydraulic press plungers, crankshaft journals, dies |

| NP-40X13 | HRC, 45…52 | Support rollers for tractors and excavators, conveyor parts |

| Np-GIZA | NV 220…280 | Railway crosspieces, crusher jaws, bucket teeth |

Kinds

All steel welding wires are divided according to their application into the following groups:

- for welding low-carbon steels;

- for low and medium alloy steels;

- for joining high alloy steels.

In order to improve technological properties, the surface is coated with copper . This copper-plated wire, or commonly called copper (!but this is not entirely true, since these are two different types of materials), has excellent corrosion resistance and reduces wear on the tips leading to the welding zone. In addition, it has improved conductivity, which allows you to maintain a stable arc and reduce metal spatter.

ESAB OK Autrod 12.64 is a solid copper-plated wire alloyed with 1.7% Mn, used for semi-automatic welding of carbon and low-alloy steels. Photo Welding Technologies

The properties that copper coating gives to the wire make it effective for use in semi-automatic welding machines . Approaches the characteristics of polished copper wire. It also guarantees the smooth operation of semi-automatic machines. For molybdenum-containing consumables, which are used in welding technology of high-strength and heat-resistant steels, polished is the best option, since they are difficult to copper plating.

Alloyed welding wires contain many different chemical elements. do not interact with the environment during the welding process . Such a medium is the inert gas argon. It is heavier than air and can reliably protect the welding area. Argon arc welding is most preferable when welding alloy steels, so wire for this technology is a popular category of consumables.

Stainless steel wire DEKA ER308LSi 1.6 mm. 15 kg each. Photo by DEKA

Stainless steel products are widely used in everyday life. Many of them went through welding technology. Therefore, consumable welding material such as stainless wire is indispensable in the operation of most structures made of such steel. The properties of the material protect the welding seam from corrosion and belong to the group of alloyed welding wires.

Video

Physical and chemical properties

Absolutely all physical properties of welding wire depend on its chemical composition. It is impossible to fit all the unique abilities that filler materials have in one article, but their general trends can be considered.

One of the most important properties inherent in any model of high-alloy welding wire is an increased level of resistance to the influence of the corrosion process. One can also note a high level of plasticity and resistance to various metamorphoses. Thanks to this property, the quality of the created seam is at a fairly high level, so it can easily withstand loads no worse than the base metal.

Some modifications of the filler wire can increase or, conversely, decrease the thermal conductivity of the metal. Which has a very strong effect when working with metals that are highly sensitive to high temperatures.

Almost every wire model has a melting point equal to the melting point of the base metal for which this consumable is intended. When creating wire, the coefficient of relative expansion of the material is also taken into account, which makes it possible to reduce or completely eliminate metal warping during the welding process.

Popular brands

Sv08G2S welding wire has good consumer properties (according to the American Welding Society AWS standard, it is designated as ER70S-6). Used in many types of welding technologies. Compatible with many types of welded materials.

PANCH-11 is used for welding cracks and connecting various cast iron elements . In this case, welding is performed without additional heating and protection of the weld area with gas or flux.

Sv-01Х19Н9 is used for welding the most common stainless steels 08-12Х18Н10Т. Has increased resistance to intercrystalline corrosion.

Corrosion-resistant wire Sv-10Х16Н25М6AF (another name ZI112) is used for welding alloy steels that have been hardened. Post-weld heat treatment is not required with this filler wire.

Sv-06Х19Н9Т is used in argon arc welding of high-alloy stainless steels. The low carbon content allows it to provide good ductility.

Alloyed welding wire SV-08G2S Monolith. Photo 220Volt

Sv-06Х15Н60М15 belongs to the category of heat-resistant consumables . It is used to weld structures based on nickel alloys. The seam has increased requirements for heat resistance.

Low carbon wire L-56 has a high content of manganese and silicon. The presence of such elements allows you to obtain a weld without slag scale. It is used when welding root seams of parts contaminated with corrosion.

The joints of main and field gas pipelines are welded using American equipment using K 600 wire. Welding is carried out in a shielding gas environment.

Chemical engineering equipment is manufactured and repaired using welding technologies using Sv-01X19N18G10AM4 (or EP 690). The welding seam must be resistant to aggressive environments.

Stainless steel welding wire Sv-12X25N16G7AR is used for welding seams operating in conditions of high humidity and high temperatures. Has excellent corrosion properties.

How to choose the right model?

First of all, when purchasing high-alloy welding wire, you need to pay attention to its composition. Most models are intended for a specific metal; accordingly, this is indicated on the packaging of the consumables. However, if you have to work with some complex or rare alloy, then before purchasing it is imperative to take into account the composition of both the object being welded and the filler wire.

After you decide on the composition of the filler material, you need to pay attention to its nomenclature. The point is that the cross-sectional diameter of the wire should be slightly less than the thickness of the product being welded. Using the correct size consumable will prevent you from burning through the metal. In addition, the same model of high-alloy filler wire of different sizes may have different temperature marks at which it begins to undergo the melting process. This also needs to be taken into account when purchasing.

If you have to work with metal whose thickness exceeds four millimeters, then it is imperative that you carry out preliminary cleaning and alignment of the working edges before performing welding operations. The wire itself most often does not require any additional preliminary procedures before starting work. Also, especially when working with metals or alloys that are sensitive to high temperatures, it is necessary to preheat both the product and the filler material. It is required to achieve approximately the same values.

Characteristics

Welding wire is selected depending on the brand of materials being welded . The choice is based on the technical characteristics of the wire. For example, the chemical composition must correspond as closely as possible to the amount of alloying elements in the parts being joined.

BlueWeld copper-plated welding wire. Photo Welding Technologies

When working on semi-automatic welding machines, the tensile strength limit should ensure that the wire operates without breaks. Knowing the value of the deposition coefficient (the amount of deposited material per unit time at a given current value) is necessary to calculate the effective consumption rate and speed of the technological process of deposition of welding wire onto a given surface.

An individual approach to working with welding wire requires familiarization with the technical parameters of each individual brand.

Copper-plated wire for metal welding

Unlike ordinary steel wire, copper-plated wire has a special coating of copper alloy. Its thickness is several micrometers, and its main task is to guarantee reliable contact with the part being welded. Copper-clad wire simplifies the work process and also gives the seam additional strength characteristics. The finished connection is capable of withstanding mechanical loads, shocks, sudden temperature changes, tearing forces, and high-temperature influences. Another advantage is the low amount of spatter, which reduces the cost of consumables. It also provides a higher speed of the welding process.

Certification, GOST

Welding wire is not on the list of goods that are subject to mandatory certification. However, in order to promote their product on the market, many manufacturers voluntarily confirm the quality of their products by obtaining a certificate of compliance with regulatory documents. These may be GOSTs, industry specifications. Welding standards have been in effect, maintaining their relevance since Soviet times.

Alloy welding wire DECA ER70S-6 0.8 mm. Euro-cassette, 5 kg. Photo Welding Technologies

Distinctive features, advantages and disadvantages

The main advantage of alloy steel wire is the ability to mechanize welding work using semi-automatic and automatic machines. It is quite easy to use it for welding materials of various sizes by changing only the diameter of the rod.

Mandatory protection of the weld area with gases increases the cost of welding work. For flux-cored wire, for example, a gaseous environment is not required.

Release form, packaging, packaging

packaged in coils, coils, coils or cassettes in accordance with GOST 2246-70 Skeins from one batch are tied into coils. The skein is tied with soft wire in at least three places. The weight of the coil (skein) should not exceed 80 kg. Greater weight is possible only by agreement with the customer.

Flux-cored alloyed welding wire Bars in a cassette. Photo Welding Technologies

The label attached to the coil indicates the manufacturer, the designation of the wire batch, its name and the quality control department acceptance stamp. Coils (skeins) are placed in special packaging materials, as specified in GOST 2246-70.

Manufacturers

ESAB is a Swedish industrial company. It is a leader in the development of equipment and consumables for welding technologies. Wire ER70S-6 (Sv08G2S) is produced at this enterprise.

Prima is a Chinese manufacturer of copper-plated wire for semi-automatic machines ER70S-6. This results in significant savings compared to European ones when purchasing.

OLIVER is the largest manufacturer in Belarus. Stainless steel welding wire Sv-01Х19Н9 can be purchased from employees of this company.

Copper-plated welding wire (5 kg; 0.6 mm.) QUATTRO ELEMENTI 770-346. Photo VseInstruments.ru

LINCOLN ELECTRIC - the website representing this American company in Russia offers corrosion-resistant wire Sv-10Х16Н25М6AF.

Hyundai Welding is a universal copper-plated wire Sv08G2S-O in the product range of this South Korean company.

Reference. The production of titanium consumables: VT6sv, VT1-00Sv, VT20-1sv and others is mainly carried out by Russian enterprises.

GOLDEN BRIDGE - Chinese manufacturer offers a wide selection of stainless wire.

DEKA, a company from China, offers ER70S-6 wire at an affordable price. Attractive prices and good quality products make other types of wire, such as aluminum, in demand.