According to technical terminology, artistic forging is a method of metal processing in which the required shapes and sizes are achieved through deformation. This definition hides one of the most ancient technologies, which allowed man to take a huge step in history and has not lost its significance today. Forging is actively used in metallurgy and mechanical engineering.

Handmade rose

History of appearance

The history of practical application and processing of metal goes back several thousand years. The history of the manufacture of artistic elements dates back just as many millennia, as evidenced by ancient archaeological finds. Primitive tips for spears and hoes show signs of creative processing. Previously, forging had a mainly practical orientation, but among the blacksmiths there were always craftsmen who knew how to combine practicality with artistry. Examples include samples of weapons and armor, horse harness, and household utensils.

The beginning of the formation of this art as an independent craft can be considered the Renaissance and the associated flowering of arts and science. Medieval palaces and temples in the Renaissance or Baroque style contain forged elements in their decoration, reflecting the spiritual, heraldic or simply aesthetic needs of the owners.

Notes

- ↑ 1 2 3 4 5 6 G. Semerak, K. Bogman

: Artistic forging and metalworking art, M: Mechanical Engineering, 1982, 232 p. - [dic.academic.ru/dic.nsf/bse/91374/Art Art and art industry - slovari.yandex.ru]

- [slovari.yandex.ru/art%20forging/Dictionary%20on social%20sciences/Art%20forging./Art Encyclopedia - slovari.yandex.ru](inaccessible link since 06/14/2016 (2087 days))

- Hephaestus // Real Dictionary of Classical Antiquities = Reallexikon des klassischen Altertums: Leipzig: BG Teubner Verlag, 1855: [trans. with German] / auto-comp. F. Lubker.

Tools

For many centuries, the standard set of blacksmith equipment and tools has not changed. A forge with coals, bellows for fanning them, a hammer and anvil, tongs and a barrel of water were the main tools of the blacksmith. The development of medieval production introduced elements of mechanization into this set, and the industrial revolution turned blacksmithing into an industry aimed at mass production of products.

Hammer and anvil

This direction received at its disposal a whole range of special equipment for artistic forging - machines and devices that made the blacksmith’s work easier and made it possible to produce complex products.

The classic coal forge still remains in the blacksmith's arsenal, but muffle furnaces and induction heaters have also come to its aid. Many forging machines retained their historical names, corresponding to their purpose - benders, snails, waves, twisters and torsion bars - but received a powerful electric drive or turned into universal multifunctional machines.

Advantages and disadvantages of artistic forging

Advantages of artistic forging elements

Making forged products allows craftsmen to embody their wildest creative ideas in metal. Using his own sketches or reproducing copies of generally recognized masterpieces, the blacksmith-artist creates works of applied art that are unique in their beauty. Even elements of artistic forging repeated many times by a master will, upon close examination, turn out to be different from each other.

Household items, interior and landscape design elements are not only beautiful and utilitarian in their purpose, but also quite durable and can serve their owners for decades.

Architects have long noted the ability of artistic forging elements to be combined with any building materials, be it brick, concrete, natural stone, wood and others. Order forged products for your garden, country house or city apartment and see for yourself their versatility. A large architectural form or small designer items will decorate the interior and exterior of your home and give it a respectable look.

Disadvantages of artistic forging elements

Artistic forging has almost no disadvantages, but we still note what you need to be prepared for when ordering a forged product:

- high cost of finished goods;

- long production cycle;

- difficulty in producing a large batch of identical products.

Types of blacksmithing

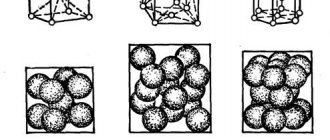

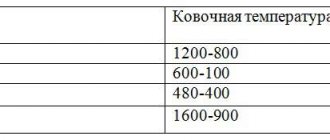

Forging technology includes several types of operations that differ in the tool used, execution modes and purpose. These operations are fully used in the technique of artistic forging, and the manufacture of any product can include any set and sequence of them. The main feature for classification is the processing temperature - hot and cold forging. Other criteria can also classify the operation into different types and subtypes.

Hot forging

During hot forging, the product is subjected to preliminary and, if necessary, accompanying heating to increase softness and ductility. There are two types of hot forging of metal:

- Free or hand forging, in which the workpiece is freely placed on an anvil, and the required shape and size are achieved by blows of a hand or mechanical hammer. This type also includes forge welding - the connection of parts heated to the melting temperature using a forging tool.

- Stamping, in which the workpiece is placed in a die with an internal cavity, the shape and size corresponding to the finished product. During the forging process, the workpiece is deformed and fills the empty die area.

Hot forging (Photo: pixabay.com)

Cold forging

In cold forging, the product is processed without preheating. It takes a lot of force to deform cold metal, so this method is used for processing small-section workpieces. Cold forging uses a variety of machines, including cold stamping.

Interesting Facts

The peak of development of artistic forging as a separate art occurred in the 6th-8th centuries AD. To become a master, future blacksmiths began training in early childhood. At first, the apprentice only observed and helped the blacksmith: he handed over tools, looked after the stove, brought water and firewood. Gradually, the student was allowed to do simple work: preparing metal and forging small, simple elements. After 5-6 years of training, the young blacksmith was already able to independently produce various types of products: from door handles to forged swing gates.

The entire forging process was done by hand. An experienced craftsman could determine the type of metal by examining the breakdown of the product and the type of spark produced. The temperature was also determined by its appearance: focusing on the color of the red-hot part, the master accurately determined at what moment it warmed up to the required temperature.

Forged products made to order were especially popular. During the period from the 13th to the 15th century AD. e. Rich nobles loved to decorate their estates with forged fences, gates, window bars and various interior items. Many products have survived to this day and are a cultural achievement of the nation.

Hephaestus - ancient Greek god of fire and blacksmithing

Basic Techniques

Each type of forging of metals and alloys has its own technologies and processing methods. Forging decorative elements uses in its arsenal almost all the basic techniques of blacksmithing, with the help of which any creative idea can be expressed in metal.

Disembarkation

The purpose of the operation is to reduce the length of the workpiece while simultaneously increasing the cross-section. In hot hand forging, the heated part is placed vertically on an anvil and hammered at the upper end. By heating individual places and holding the part with tongs, thickened nodes, bends, volumetric or flat elements of the intended decoration can be made on it.

Broach

Broaching is the opposite operation to upsetting and is used to lengthen the workpiece. The direction of impact when broaching is across the axis of the part with its rotation or advancement along its length.

Depending on the shape of the workpiece (flat, round, hollow, ring) and the equipment used, the broaching technique includes many techniques. Individual broaching techniques can be called by their own terms - spreading, flattening or rolling.

Blacksmith working

Rounding

The operation is used in hot forging methods and consists of rounding the edges of profile blanks. Initially, the corners of the workpiece are forged, bringing it to an octagonal cross-section. The final rounding is performed using special crimps or cutout hammers.

Threading

Threading is carried out in two ways - by assembling according to the principle of chain links or by flashing a hole in one of the elements. In this case, chisels of the required shape and size are used for the operation.

Decoration of ledges

Ledges of various shapes are made for both decorative and technological purposes in order to secure parts together. The ledges are made using sharp anvil ribs or special backing equipment.

Bending

Bending is a common technology actively used in artistic forging. Special machines and devices have been developed for bending, allowing craftsmen to work according to their own templates.

DIY forged elements and parts

Today there are shops or workshops offering art products of their own production. The demand for these products is stable, despite the inflated cost of forged products.

If you wish and have some experience working with metal, you can do much of what professionals can do with your own hands. It is not at all necessary to arm yourself with a forge and a sledgehammer or purchase a special machine. Even for the manufacture of complex elements or products, a workbench, a vice, a welding machine and a hammer are sufficient. The material for amateur creativity will be a round rod, a profile pipe with a small cross-section, a narrow strip of steel or sheet metal.

Metal bending (Photo: pixabay.com)

Furniture

As furniture for self-production, you can consider garden or country tables and chairs, decorative shelves for walls. Forged elements can decorate the interior of a kitchen, bedroom, hallway or garden gazebo, and an old stool or floor lamp intended for scrapping can be reinforced with forged strips and presented as an antique.

Alcove

A gazebo is the cherished dream of summer residents and owners of their own plots; it does not have to be made of wood or brick. You can also make a metal structure from a profile. It is easy to turn it into a light and elegant composition with the help of hand-made forged parts - an openwork arch twisted from a steel circle at the entrance, curlicues around the perimeter of the gazebo or an intricate pendant for a lamp.

Gates

Forged gates and entrance gates are perhaps the most popular products from the range of artistic forging today, in which practicality is combined with artistic taste. Meanwhile, many owners of private houses, for economic reasons, make do with an entrance unit purchased or independently made from standard rolled metal and metal profiles.

Any metal structure can be classified as non-standard or made initially using the simplest self-made forged elements. The already mentioned steel rods, profiles or strips are used as a workpiece. From them you can make various twisted patterns and monograms, leaves and buds, strict or arbitrary geometric shapes.

What are the elements of artistic forging?

Artistic forging is a metal processing method through which elegant products for household and decorative purposes are made. As a rule, elements of artistic forging are made according to an individual drawing (project), embodying exclusive design ideas, so the finished product acquires artistic value.

The heyday of the craft dates back to the 14th-15th centuries, especially the Renaissance period, when the fashion for creating landscape gardening ensembles arose and began to actively develop in Western European countries. Elements of artistic forging, used in the construction of figured fences, gave the building monumentality, respectability, and indicated the wealth of the owners. One of the main customers of medieval blacksmiths was the church.

Elements of artistic forging of the Baroque period were distinguished by their particularly splendid details and pretentiousness of patterns. Rococo radically changes the appearance of forged products; symmetry and strict geometric shapes disappear, but plant motifs appear and filigree techniques are used.

In Ancient Rus', elements of artistic forging were widely used in the manufacture and decoration of warriors’ armor, horse harness, and weapons. Blacksmiths have always been held in high esteem; blacksmithing was especially respected. Gradually, communities of craftsmen were formed who moved from rural areas to large Russian cities and organized entire blacksmith productions there.

VT-metall offers services:

The production of forged products received a new impetus during the time of Peter I, a supporter of everything European. Elements of artistic forging became very popular in architecture; they were used to decorate the palaces of the nobility and secular institutions.

The first quarter of the twentieth century - the time of industrialization - brought rolling and stamping production to the forefront, pushing artistic forging into the background.

Nowadays, the art of artistic forging is experiencing a new birth. Interest in the ancient craft is completely predictable and justified. Forged products combine practicality and beauty, monumentality and grace, and serve as interior decoration for apartments, summer cottages, and country houses.

Forged furniture items are in good demand: beds and sofas, benches and chairs, tables and decorative consoles, hangers and flower stands, fireplace accessories and grates, railings and stair steps, chandeliers, sconces, floor lamps and much more. All these products are able to emphasize the individuality of the interior. Landscape design widely includes forged benches and bridges, all kinds of fences, swings, gazebos, arches, figured groups, flower stands, gates, door hinges and handles.

A variety of forged products allows you to choose any according to your desire. You can rely on your taste or take advice from experienced designers.