01/12/2022 Author: VT-METALL

From this material you will learn

:

- 3 signs of metal corrosion

- Main types of metal corrosion depending on the type of aggressive environment

- Types of metal corrosion according to the nature of destruction

- Protective properties of metal oxide films

- 5 ways to protect metals from corrosion

There are different types of metal corrosion. They are classified according to the type of exposure to an aggressive environment: atmospheric, underground, electric; and by the nature of the destruction: continuous, selective, local. Each metal and alloy resists the corrosion process differently.

If we talk about natural protection, then this is an oxide film. Various technologies are also used to prevent and prevent corrosion. The simplest and most widespread is coloring. You will learn about the types of metal corrosion and methods of protection from our material.

Types of corrosion

A variety of metals are used everywhere. Almost all of them succumb to corrosion over time. This is the name given to the process of material destruction due to oxidation. That is why the issue of corrosion protection is so relevant. Timely processing extends the service life of metal products and protects them from harmful environmental influences.

To properly protect a structure from destruction, it is necessary to understand the classification of corrosion processes. This will help you choose the right product and processing method.

There are three types of metal corrosion:

- atmospheric;

- liquid;

- soil

Atmospheric corrosion is caused by the influence of the squat layer of the atmosphere. With this type of destruction, metal products come into contact with oxygen and water vapor in the air. Chemically active substances as impurities accelerate the process of metal destruction.

Relative air humidity is the main criterion for dividing into subspecies. There are dry, wet and wet atmospheric corrosion. At its core, the first is a chemical process, while wet and wet are electrochemical.

This is the most common type of destruction, since all metal structures that are located in the open air are subject to it. In particular, we are talking about:

- pipelines;

- metal parts of buildings;

- supports;

- bridges;

- vehicles.

Liquid corrosion affects structures located in a liquid environment. Conditions of interaction with water allow us to distinguish the following subspecies:

- corrosion during incomplete immersion - only part of the structure is in a corrosive environment;

- along the waterline;

- with complete immersion - the metal is completely immersed in the liquid;

- underwater;

- corrosion during variable immersion - the structure is immersed in a liquid medium periodically, completely or partially.

The service life of above-ground and underground metal structures is affected by the composition of the soil and groundwater. The chemical processes occurring due to these features cause soil corrosion. As a result of this process, rust may appear on:

- pipelines;

- underground sealed tanks;

- supports of various metal structures.

Types of corrosion processes

The type of steel corrosion can be chemical or electrical. In the first case, the metal and oxidizing atoms react and form strong bonds. The resulting structure does not conduct electricity, unlike the original composition of the product. Electrical corrosion is characterized by complete decomposition of the metal, which becomes unsuitable for further use.

In addition to chemical and electrical, other types of corrosion can be distinguished:

- The most common type of corrosion is gas corrosion, which occurs at high temperatures and minimal moisture content in the working environment;

- atmospheric corrosion develops when a metal product is in a gas environment of high humidity;

- biological microorganisms can also have a negative impact on the strength and integrity of steel structures, causing oxidation of the material;

- when different metals interact, the composition and stationary potential of which are different, rust spots may appear at the points of contact of the products;

- exposure to radioactive radiation leads to the destruction of the steel structure and the development of corrosion processes.

In most cases, it is difficult to identify any one type of corrosion that negatively affects the condition of metal structures. The destruction and degradation of steel is caused by the influence of several factors, such as high humidity, unfavorable atmospheric composition, biological activity of microorganisms, and background radiation. The only way to eliminate or reduce the rate of corrosion spread is to protect the material with special compounds and means.

Characteristic types of damage to metals by rust

In most cases, rust occurs on the surface of the metal. However, in some cases, the lesion can penetrate deeper. Depending on how the corrosion spreads, it can be:

- uniform - when the structure is destroyed over the entire surface, which is typical for alloys with a single-phase structure;

- local (spots, ulcers, pinpoints) - affects mainly multiphase alloys with a coarse structure, less often pure metals or single-phase alloys after the destruction of the protective film;

- intergranular - the most dangerous due to the fact that the destruction is invisible externally; aluminum alloys and chromium-nickel steels are susceptible to it;

- cracking;

- subsurface;

- combined.

Another criterion for categorization is the mechanism of the corrosion process. According to him, corrosion can be chemical or electrochemical.

Chemical destruction is caused by oxidation of the surface of the product in a liquid medium. Of all the metals, steel is most susceptible to the effects of moisture, with the exception of stainless steel. The iron contained in it forms three types of oxides. In most cases, reliable protection of a steel structure from destruction is impossible. Also, under the influence of the liquid, cobalt, nickel and lead are quickly destroyed.

Electrochemical corrosion is accompanied by the generation of electric current. It can occur in various environments and is always associated with serious destructive processes. For example, if power lines and electrical circuit elements corrode, then in addition to the corrosion itself, energy consumption increases significantly.

Corrosion of metals and alloys

Lecture questions:

1. Classification of corrosive environments, destruction and processes. Corrosion rate indicators.

2. Chemical corrosion: types and varieties.

3. Electrochemical corrosion: causes and mechanism of occurrence.

4. Thermodynamics and kinetics of gas and electrochemical corrosion.

1. Classification of corrosive environments, destruction and processes. Corrosion rate indicators.

One of the very tangible manifestations of redox processes is corrosion - the process of oxidation of metals under the influence of the external environment.

There are no absolutely corrosion-resistant metals. Gold, stable under normal conditions, dissolves in solutions of potassium or sodium cyanide due to the formation of stable complex ions. As a result of corrosion, metal products lose their valuable technical properties, so anti-corrosion protection of metals and alloys is important.

Corrosion (from the Latin corrodo) is the destruction of structures and products made of metallic materials (metals and alloys), which occurs as a result of their physicochemical interaction with the environment, which is called corrosive (or aggressive) , and the resulting chemical compounds are corrosion products.

Corrosion is accompanied by the release of energy (corrosion processes occur spontaneously and are accompanied by a decrease in Gibbs energy (? G < 0) and dissipate corrosion products in the environment. The corrosion process of iron and its alloys is called rusting.

Corrosive media are liquid and gaseous, conductive and non-electrolyte, natural and artificially created.

Gaseous gases include the natural atmosphere and gases formed during the combustion of fuel or released in various chemical industries.

Liquids are electrolyte liquids (aqueous solutions of salts, acids, alkalis, sea water) and non-electrolyte liquids (sulphurous oil, gasoline, kerosene, etc.).

Natural substances, in addition to the atmosphere, are water and soil; artificial substances are many chemical substances.

Corrosion is classified according to the nature of surface destruction:

a) continuous (general), in which the entire surface of the product is affected. It can be uniform and uneven;

b) local (local), in which only certain areas of the surface are affected. It manifests itself in the form of spots, ulcers and pitting (point destruction to great depths).

There are other types of destruction:

1. erosion - mechanical abrasion, wear (i.e. destruction that occurs only due to physical reasons);

2. cavitation corrosion - destruction due to simultaneous impact (mechanical impact) and corrosive effects of the environment (corrosion of propeller blades),

3. corrosion erosion (destruction under the simultaneous influence of friction forces and a corrosive environment - corrosion of pumps, engines, turbines), etc.

Corrosion of metals is always an oxidation process:

Me – ne? Men+

Based on the mechanism of the process, corrosion is divided into chemical and electrochemical. The reason for corrosion of metals and alloys is their thermodynamic instability, therefore corrosion processes occur spontaneously and are accompanied by a decrease in Gibbs energy ((? G < 0). The smaller (more negative) the value of ? G of the corrosion process, the higher the thermodynamic possibility (probability) of its occurrence. For chemical corrosion, the change in the standard Gibbs energy ΔG is related to the equilibrium constant by the relation ΔG0 = – RT ln Kp. In the case of electrochemical corrosion, ΔG0 is related to the standard emf (E0) by the equation ΔG0 = nF E0.

At this link you will find a complete course of lectures on mathematics:

| Solving problems in mathematics |

Chemical and electrochemical corrosion refer to heterogeneous redox processes occurring on the surface of metals and alloys (at the interface between the material and the corrosive environment).

The heterogeneous process consists of sequential stages:

— diffusion of oxidizing particles to the metal surface,

- their adsorption on it,

— surface chemical reaction (resulting in metal oxidation),

— desorption of products from the surface, their transfer into the volume of the corrosive environment.

The rate of corrosion is determined by the rate of the slowest (limiting) stage under given conditions, which can be of both a chemical (metal oxidation) and physical (diffusion of electrolyte or gas) nature.

Most often, the mass loss indicator and the depth indicator are used to characterize the corrosion rate.

Mass loss indicator rmass. indicates mass loss per unit time? per unit surface S of the test sample:

rmass. = ?m / ?·S

Depth indicator r depth. is determined by the ratio of the average depth h of metal destruction per unit time ?:

r depth =h/?

In the reference literature r depth. usually given in mm/year.

2. Chemical corrosion: types and varieties.

Chemical corrosion is typical for environments that predominantly do not conduct electric current (exception: experiment No. 1 from laboratory work - where chemical corrosion occurs in an HCl solution). Depending on the type of these environments, they are distinguished:

1. Chemical corrosion in non-electrolyte liquids - non-electrically conductive liquid media, usually of organic origin (sulphurous petroleum, kerosene, benzene);

2. Chemical gas corrosion (hereinafter gas corrosion), usually occurring at high temperatures.

These two types of chemical corrosion are not accompanied by the generation of electric current, i.e. represent the usual redox (chemical) interaction of a metal with the environment.

Gas corrosion is the most common type of chemical corrosion and usually occurs at high temperatures in gases and vapors of aggressive substances, when the possibility of their condensation on the metal surface is excluded, therefore it is called high-temperature corrosion. This is corrosion of rocket engine nozzles, gas turbine blades, electric heater elements, etc. Gas corrosive agents include O2, CO2, SO2, H2O, H2S, Cl2. Their aggressiveness towards different metals is not the same, therefore, the corrosion rate varies.

Let's consider an example of the most common gas corrosion in practice: corrosion of iron, cast iron and steel in an atmosphere of O2, CO2, and H2O:

When these materials are heated, they oxidize:

Fe + H2O ? FeO + H2

Fe + CO2 ? FeO + CO

2Fe + O2 ? 2FeO

The composition of oxidation products is determined mainly by the temperature of the gaseous corrosive environment.

Along with oxidation, the process of decarbonization occurs in steels and cast iron—depletion of the surface layer in carbon due to the interaction of the iron carbide contained in them with oxygen and oxygen-containing reagents:

Fe3C + O2 ? 3Fe + CO2

Fe3C + CO2 ? 3Fe + 2CO

Fe3C + H2O ? 3Fe + CO + H2

At the same time, their mechanical and anti-corrosion properties deteriorate.

Decarbonization can also occur in a hydrogen atmosphere:

Fe3C + 2H2 ? 3Fe + CH4 ?

This type of gas corrosion is called hydrogen corrosion. Along with decarbonization, hydrogenation is also carried out simultaneously - the penetration of atomic hydrogen into the material and its subsequent dissolution in it, which leads to a sharp decrease in the ductility of the metal.

3. Electrochemical corrosion: causes and mechanism of occurrence.

In practice, we most often have to deal with electrochemical corrosion. It, unlike the chemical one, is accompanied by the appearance of an electric current and, as a rule, occurs in media with good ionic conductivity.

According to the conditions of implementation, there are:

— corrosion in electrolytes;

— atmospheric corrosion;

— electrocorrosion;

— stress corrosion, etc.

The causes of electrochemical corrosion are various types of inhomogeneities of both the surface of the metal or alloy and the corrosive environment. As a result, the entire surface in contact with the conductive corrosive medium is divided into cathode and anodic sections, which are very small in size and alternate with each other. In such an environment, they represent a collection of a huge number of short-circuited corrosive galvanic elements, as a result of which electrochemical corrosion is often called galvanic corrosion.

IN SYSTEMS, THE APPEARANCE OF CORROSIVE NOT ONLY MICRO-, BUT ALSO MACROELEMENTS IS POSSIBLE, FOR EXAMPLE, IN CONTACT WITH AN ELECTROLYTE OF TWO CONTACTING PARTS MADE FROM METALS OF DIFFERENT ACTIVITY (SO-CALLED CONTACT CORROSION).

The mechanism of electrochemical corrosion comes down to the emergence and functioning of corrosive galvanic macro- and micro-elements, therefore its processes are similar to those occurring in chemical power sources: galvanic and fuel cells, batteries. The main difference between corrosion processes is the absence of an external circuit. During the corrosion process, electrons do not leave the corroding metal, but move inside it from the anodic to the cathodic areas.

The process of electrochemical corrosion is a combination of two interrelated half-reactions simultaneously occurring on the metal surface:

a) anodic, accompanied by oxidation of metal atoms on the anodic areas of the surface:

(–) A: Me – ne? Men+

b) cathodic, accompanied by the reduction of the oxidizing agent (oxidized form of the O component) of the corrosive medium (electrolyte) on the cathodic areas of the surface:

(+) K: Of + ne? Vf

Electrochemical corrosion oxidizers are called depolarizers. The most common depolarizers include O2, H2O molecules and hydrogen ions H+. The main cathodic reactions with their participation during electrochemical corrosion are:

1) in aerated (oxygen-saturated) corrosive environments:

neutral and alkaline (pH ≥ 7)

(+) K: O2 + 2H2O + 4e? 4OH– (?0 = 0.401 V);

in acidic (pH < 7)

(+) K: O2 + 4H+ + 4e? 2H2O (?0 = 1.229 V);

2) in dearified (not containing dissolved oxygen) corrosive environments:

neutral and alkaline (pH ≥ 7)

(+) K: 2H2O + 2e? H2? + 2OH– (?0 = –0.828 V);

in acidic (pH < 7)

(+) K: 2H+ + 2e? H2 (?0 = 0 V);

Corrosion accompanied by the reduction of oxygen molecules (in aerated environments) is called corrosion with oxygen absorption or corrosion with oxygen depolarization.

The following types of electrochemical corrosion occur with oxygen depolarization: atmospheric, underground, in water (fresh and sea), and salt solutions. Corrosion accompanied by the reduction of water molecules and hydrogen ions is called corrosion with hydrogen evolution, or corrosion with hydrogen depolarization. Under some conditions, electrochemical corrosion can occur simultaneously with both hydrogen and oxygen depolarization - the so-called mixed type of depolarization.

The processes described by the equations written above are called primary processes, and their products are called primary corrosion products. In addition to the primary ones, during electrochemical corrosion, secondary processes also occur - chemical interactions of the primary products with each other, with the components of the electrolyte corrosive medium, with gases dissolved in it, etc. In this case, films of poorly soluble secondary products are formed, for example, hydroxides, metal phosphates, which make it difficult to access of the electrolyte to the metal surface. As a result, the rate of electrochemical corrosion decreases, and sometimes corrosion stops completely.

Let us consider the most typical and frequently encountered cases of electrochemical corrosion in practice.

— Corrosive destruction of an alloy is due to its heterogeneity in chemical composition (an example from laboratory work or from a test).

— Contact corrosion is associated with the design features of products and machines and occurs during their operation in real conditions. Often parts made of different metals come into contact in one assembly. In a corrosive galvanic macrogalvanic cell that occurs in an electrolyte environment, the cathode is a part whose metal has a higher potential, and the anode is a part made of a metal with a lower potential. Figure 1 shows a diagram of contact corrosion of two iron sheets connected with copper rivets. The corrosive galvanic macrocell is functioning.

You might find these pages useful:

| Finding the original from an image |

| Theory of armature windings of DC machines |

| Permissible stress strength condition |

| One-sided limits, right-sided limit, left-sided |

The rate of this type of electrochemical corrosion in general is greater, the further the metals from which the parts forming the macrogalvanic cell are separated from each other in the voltage series.

— Stress corrosion is the destruction of parts located in an electrolytic environment in a mechanically stressed state. Mechanical stresses change the potential of the metal: the potential of the metal on a stretched surface will be less than the potential of a metal without stress, and the potential of a compressed metal, on the contrary, will be greater than the potential of a metal without stress. In this regard, the stretched surface will be anodic, and the compressed surface will be cathodic. Therefore, if a plate made of steel, duralumin or titanium alloy is bent and placed in this state, for example, in a corrosive environment with pH < 7, then the stretched surface will begin to corrode and cracks will appear on it after a short time, while the compressed surface will remain unchanged (Fig. 2).

Fig.2 Corrosion destruction of a part in a mechanically stressed state:

1– steel plate; 2– Teflon stand; 3 – acidic corrosive environment.

— Corrosion under the influence of stray currents (electrocorrosion). Stray currents are those that branch off from their main path. These are leakage currents from electrical circuits or any currents entering the ground from external sources (electric train tracks, grounding of current lines, electrical cables, etc.).

Stray currents cause corrosion of gas and oil pipelines, electrical cables, and various metal underground structures. Their range of action is tens of kilometers. Typically, corrosion damage is of a local type and is located where currents exit into the ground or water. For underground pipelines and electric train tracks, these are, as a rule, places of isolated joints and poor contact of rails at the joints, respectively, as well as places with insufficient insulation from the ground. They are anodic zones and are subject to increased corrosion (Fig. 3).

The cases considered do not exhaust the entire variety of electrochemical corrosion processes, but give an idea of the main types of inhomogeneities, the nature of the interaction of products with a corrosive environment and the reasons for the emergence of potentials in corrosive environments.

Rice. 3. Scheme of the occurrence of stray currents from the tram line and the mechanism of corrosion destruction of rails and pipelines by them.

3. Thermodynamics and kinetics of gas and electrochemical corrosion

Thermodynamics and kinetics of gas corrosion.

In practice, gas corrosion most often manifests itself as corrosion of metal materials at high temperatures in an atmosphere of oxygen-containing gases, therefore, in addition to high-temperature corrosion, it is often called high-temperature oxidation.

On the surface of products made of metals and alloys, as a result of their interaction with such a corrosive environment, a film of products representing various metal oxides is formed. The process can be described by the following equation:

x Me (t) + y O2 (g) ? MechOu(t)

The oxidation reaction is reversible and its equilibrium constant is:

Kr = 1/ Ru/2equal O2 (PequalO2 – equilibrium partial pressure of O2)

The thermodynamic possibility of the oxidation process occurring under specific conditions can be assessed using the equation:

?GT = ?G0T + RT ln 1/ Ru/2equal O2

If the oxide film formed on the surface of the metal prevents further penetration of the corrosive environment to the metal surface, then it is called protective. A metal with a protective film on the surface becomes chemically inactive, i.e. passive. The initial stage of formation of a protective oxide film is a purely chemical process. The further course of the process is determined by the rate of counter diffusion of metal and oxygen ions inside the oxide film.

In oxide films of a certain thickness and perfect structure (without cracks, pores), the processes of counter diffusion stop. Such films are protective. In order to have protective properties, the oxide film must meet the following requirements: be continuous, non-porous, chemically inert to aggressive environments, have high hardness, wear resistance, adhesion (adhesion to metal) and a thermal expansion coefficient close to that of the metal. The main requirement is the Pilling-Bedwords continuity condition, according to which the volume of the formed oxide must be greater than the volume of metal consumed for oxidation -

VMechOu > VMe

The ratio of these volumes is called the Pilling–Bedwords continuity factor ?, which is calculated using the molar mass of Mme atoms and the density ?me of the metal, as well as the molar mass MMexOy and the density ?MechOy of its oxide:

а = VМехОу / VMe = ММехОу · ?ме / ?МехОу · m Мме

where m is the number of metal atoms in the oxide molecule. Magnitude ? for many metals and their oxides can also be found in reference literature. If a > 1, then the formation and growth of film thickness during oxidation occurs under compression conditions, so it is continuous. If a < 1, then the film during its formation and growth experiences tension, which contributes to its destruction and the appearance of cracks and various defects, as a result of which oxygen freely penetrates to the metal surface.

The Pilling–Bedwards continuity factor can only approximately estimate the protective properties of oxide films. Under real conditions, continuous films ( a > 1) may not have protective properties, such as FeO, MoO3, WO3. Therefore, it is very roughly believed that if 1.0 < a < 2.5, then the film is continuous and may have protective properties. The reasons for the poor protective properties of films with a > 2.5 may be the volatility of the oxide, stresses that destroy the oxide film, its insufficient ductility, etc.

Fulfillment of the continuity condition is always a necessary but insufficient requirement.

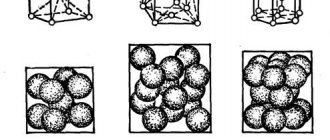

During the formation and growth of a protective oxide film, the condition of its orientational correspondence to the metal is also important, i.e. maximum similarity of the crystal lattices of the metal and the resulting oxide.

Laws of growth of oxide film thickness

Typically the rate of gas corrosion, i.e. oxidation process, expressed through the rate of thickness growth ? oxide film over time?:

r = d? /d?

Increase in thickness, i.e. oxidation of the metal surface can occur in accordance with various kinetic dependencies, or laws: linear, parabolic, logarithmic (Fig. 4.)

According to the linear law, the rate of the oxidation process is constant over time. This law is satisfied both in the complete absence of an oxide film on the surface, and in the presence of a thin or non-protective (porous, non-continuous) oxide film, for which a < 1. In all these cases, access to the surface is free. According to a linear law, oxidation of alkali and alkaline earth metals, as well as vanadium, tungsten and molybdenum, occurs at high temperatures. For the former, it is due to their heating due to poor heat removal caused by the formation of loose oxide films on the surface, preventing its outflow; for the latter, it is due to the volatility of their oxides at high temperatures.

In accordance with the parabolic law, the rate of the oxidation process is inversely proportional to the thickness of the oxide film. This law is observed when a film with protective properties is formed on the surface of the metal during its oxidation, i.e. continuous and non-porous, for which a > 1 According to the parabolic law, tungsten, cobalt, nickel (with the exception of the initial sections), as well as copper in the temperature range 300...1000°C and iron - 500...1000°C are oxidized.

The logarithmic law occurs when either the protective oxide film thickens or defects appear in it in the form of bubbles or delaminations, inhibiting the processes of counter-diffusion of oxygen and metal ions.

In this case, a strong attenuation of the oxidation process is observed, and the growth of the thickness of the oxide film occurs more slowly than according to the parabolic law.

In accordance with the logarithmic law, copper is oxidized at temperatures below 100°C, tantalum - below 400°C, as well as aluminum, zinc and nickel - below 3000°C. The rate of the oxidation process in this case is inversely proportional to the time it occurs.

The oxidation process of most metals with changes in conditions (temperature, composition of the gas corrosion medium, contact time) proceeds according to different laws. For example, for titanium:

Temperature, °C < 350 630–830 > 850

Law of thickness growth

oxide film...logarithmic parabolic linear

In addition to internal factors (the state of the oxide film), the rate of gas corrosion is much more influenced by external factors, such as: composition, pressure, temperature and speed of movement of the gaseous medium, time of its contact, heating mode. With increasing temperature, on the one hand, the thermodynamic possibility of gas corrosion decreases, on the other, the rate constant of the chemical reaction and the diffusion coefficient increase, and the protective properties of the oxide film also change. In general, with increasing temperature, the corrosion rate increases in accordance with a dependence close to exponential. Temperature fluctuations, especially alternating heating and cooling, cause rapid destruction of the protective film due to the occurrence of large internal stresses.

Thermodynamics and kinetics of electrochemical corrosion.

The possibility of electrochemical corrosion, like any chemical process, is determined by the change in the Gibbs energy. Since corrosion is a spontaneous process, it is accompanied by its decrease, i.e. ?Gt < 0. Since electrochemical corrosion is associated with the functioning of a corrosive GE, the possibility of its occurrence can also be assessed by the sign of the EMF. The latter is related to the Gibbs energy by the relation:

nFE0 = – ?G0

A negative value of ?Gt corresponds to a positive EMF value.

| Overall electrochemical corrosion rate |

determined by the rate of the limiting reaction (either cathodic or anodic). But since the cathodic and anodic reactions occur interconnectedly, the slowdown of one inhibits the other.

Temperature changes can speed up or slow down the galvanic corrosion process. For example, with increasing temperature, the concentration of gaseous dissolved substances (O2, Cl2) involved in electrode processes decreases, but the protective properties of films from secondary products (slightly soluble salts, hydroxides) decrease, and the polarity (cathode or anodic) of metal protective coatings may also change.

Based on the effect of solution acidity (medium pH) on the rate of electrochemical corrosion, all metals are divided into five groups, each of which has its own type of dependence (Fig. 5):

1) metals with high corrosion resistance in acidic, neutral and alkaline solutions, such as Ag, Au, Pt, etc. The rate of their corrosion does not depend on the pH of the solution (Fig. 5, a);

2) metals that are stable in acidic solutions, but unstable in alkaline solutions - Mo, Ta, W, etc. (Fig. 5, b);

3) metals that are low-resistant in acidic solutions, but stable in alkaline solutions - Ni, Cd, etc. (Fig. 5, c);

4) metals that are stable in solutions close to neutral, but are destroyed in alkaline and acidic ones due to amphotericity - Zn, Al, Sn, Pb (Fig. 5, d). Each of them has its own specific pH value, at which the corrosion rate is minimal: 7(Al). 5(Pb). 9 (Sn), 10(Zn), 14(Fe);

5) metals that are poorly resistant in acidic solutions have a constant corrosion rate in the pH range of 4...8.5, which at pH > 10 sharply decreases due to the formation of poorly soluble hydroxides on their surface - Fe, Mg, Cu, Mn, etc.

Coagulation is caused by ions that have a charge sign opposite to that of the granules. Coagulation of positively charged ions is caused by anions, negatively charged by cations.

2. The higher the charge of the coagulant ion, the stronger the coagulating effect of ions ( Schulze-Hardy rule )

РAl3+ > PCa2+ > PK+;

PPO > PSO > PCl-.

3. For ions of the same charge, the coagulating ability depends on the radius of the solvated ion: the larger the radius, the greater the coagulating ability

PCs+ > PRb+ > PK+ > PNa+ > PLi+;

PCNS->PI->PBr->PCl-.

QUESTION 6. Phenomena occurring at the interfaces, as well as those associated with changes in the concentrations of the third component at these boundaries, are called surface phenomena .

The most important property of the surface layer is that the molecules in it have excess Gibbs energy compared to the molecules in the interior of the same phase.

Using the example of a liquid, this can be explained as follows: for internal molecules, the resultant of all intermolecular interactions is equal to 0, and for

surface molecules it is directed

Rice. 1. Formation of excess perpendicular to the surface inward

surface energy. phases (Fig. 1). Those. per molecule "B"

located on the border with steam, liquid molecules act only on one side; on the side of the vapor, the interaction forces are small, as a result of which a resultant appears, directed into the liquid. Therefore, the “B” molecules tend to be drawn into the liquid, as a result of which the liquid interface tends to decrease.

In a free drop of liquid, the tendency to reduce the surface leads to its spherical (spherical) shape. To bring molecules to the surface, it is necessary to overcome this force, that is, to do work and impart a certain energy to the molecules, and if the surface area increases by some amount, then the surface energy also increases by some amount.

The amount of work that needs to be spent on increasing the surface by 1 cm2 is numerically equal to the free surface energy per 1 cm2 of surface and is called surface tension? (sigma). Units of measurement are J/m2 and N/m.

The free energy of any interface (surface energy) can be calculated using the equation

Gs=?.S,

Where ? – surface tension at the interface; S – surface area.

From a thermodynamic (energy) point of view, colloidal disperse systems, having high surface energy, are unstable systems. Processes that reduce the surface energy GS should spontaneously occur in them, for example, by enlarging the particles of the dispersed phase (decrease in entropy).

For pure liquids? constant at a given temperature. Substances that lower the surface tension of a solvent are called surface-active agents (surfactants). Surfactant molecules consist of polar groups –OH, -NH2, -COOH, etc. (“head”) and a nonpolar part (“tail”).

polar nonpolar

"head" "tail"

This structure gives the surfactant diphilic (duality) properties. The polar group is hydrated, which determines the surfactant’s affinity for water—hydrophilicity; the nonpolar radical determines the solubility of these substances in water and makes the surfactant hydrophobic. Surfactants are used as stabilizers - special substances that do not impart stability to colloidal solutions against the enlargement of dispersed phase particles.

The change in the concentration of a solute in the surface layer of a solution (or at the interface) is called adsorption. If a substance is absorbed by the entire volume of the solvent, then this process is called absorption.

Surface phenomena determine processes such as impregnation, extraction, flotation, lubrication, etc.

Flotation is a mineral beneficiation method based on the different water wettability of valuable minerals and waste rock.

Industrial protection methods

Methods for protecting metal from corrosion for industrial purposes include:

- heat treatment;

- paintwork;

- passivation or alloying;

- protective metal coating;

- electrical protection;

- use of inhibitors.

Heat treatment is reduced mainly to increasing the heat resistance of metals. This can be achieved in various ways. This method of protection is aimed at combating selective, point and intercrystalline destruction. As a result of heat treatment, structural heterogeneity is eliminated and the alloy is deprived of internal stress.

Corrosion protection using paint coating is very popular due to its reliability. This is an affordable method with simple technology, which also allows you to change the color and appearance of the structure. As a result of using this protection technology, a continuous film is formed on the surface of the product. It prevents the destruction of the metal structure and protects against aggressive environmental influences. Anti-corrosion paints and varnishes usually consist of film-forming substances, solvents, plasticizers, pigments, fillers, and catalysts. The effectiveness of this method largely depends on the correct application technology and surface preparation. An important factor is the thickness of the coating.

Passivation involves adding alloying components when melting metals. Such impurities include chromium, nickel, and molybdenum. This really effective method slows down the anodic process. The metal alloy enters a state of increased resistance to destruction—passivation occurs. An oxide film with a perfect structure is formed on the surface. Iron, aluminum, copper, magnesium, zinc, and alloys based on them are processed in this way. As a result of passivation, metals acquire not only corrosion resistance, but also heat resistance.

Metal coating has become widespread as a protective agent. It can be cathodic or anodic. The integrity of the protective layer guarantees effective protection of the metal from unwanted influences. However, damage or the formation of pores on the outer layer can provoke oxidation of the inner one. Therefore, this method is controversial. The formation of a protective metal coating can occur in different ways:

- electrochemically;

- immersion in molten metal;

- applying a molten coating to the surface to be treated with a jet of compressed air;

- chemical

Electrical protection is used when it is necessary to protect boilers, steel parts, underwater parts of marine transport, parts of drilling platforms. The product is connected to the negative pole of the current source. Due to this, the current in the electrolyte passes through the anode plates, and not through the protected part.

Inhibitors are substances that slow down or stop chemical reactions that cause rust. When introduced into an aggressive environment, inhibitors create an adsorption film on the surface of the product. Thanks to it, the electrochemical parameters of metals change and electrode processes slow down. This is an effective and technologically simple protective measure.

Let's sum it up

In this article, we looked at the types of chemical corrosion and how it differs from electrochemical corrosion. Provided that a number of requirements are met, the risk of metal destruction can be significantly reduced. These include:

- Control of the formation of a protective oxide film.

- Excluding contact of certain materials with aggressive environments.

- Use of additional protective coatings.

- Monitoring the composition of a gas mixture or electrolyte.

- The use of metals with alloy components that slow down the reaction.

Compliance with these requirements will significantly increase the duration of use of your metal product.

Return to articles Share article

Household methods of protection

Methods of corrosion protection that are used in everyday life are simple and accessible. All activities come down to applying paint and varnish coatings. Metal protection involves the use of various means. Components may include:

- silicone based resins;

- polymer materials;

- inhibitors;

- metal filings.

If rust has already damaged the metal surface, you can prevent the spread of corrosion by:

- Primers. They provide good adhesion, so applying them to the surface before painting saves the consumption of the finishing coat. The composition contains inhibitory substances, which is why primers are so effective in protecting metal from corrosion.

- Stabilizers - with their help, iron oxides are converted into other substances. Such chemical compounds are not subject to rust.

- Substances that convert iron oxides into salts. Slow down the re-formation of rust.

- Resins and oils. Their action is to neutralize rust. Oils and resins bind its particles, compacting them.

If several products are used to treat the surface to prevent corrosion, it is better that they come from the same manufacturer. They must match each other in chemical composition.

You can do the work of applying paints and varnishes at home yourself. In most cases, this does not require the involvement of specialists.

In everyday life, the following metal structures most often require such treatment:

- roofs;

- gates;

- various fences;

- sports equipment;

- pipes;

- radiators;

- doors and handles.

Both new products can be treated to prevent their destruction, as well as those that have been in use for many years, but their service life needs to be extended.

Chemical corrosion in non-electrolyte liquids

Although gas corrosion is considered the most common, metal damage upon contact with various electrolyte liquids should also not be discounted. The greatest danger comes from contact of the material with substances that can conduct electricity.

They are divided into two large groups - organic and inorganic. There are many electrolytes that pose a great danger to metal - from molten sulfur and benzene to liquid bromine, alcohol, kerosene, oil and others.

The purity of the electrolyte is of great importance during the course of a chemical reaction. When it is completely clean, there is no interaction. But as soon as a small amount of impurities gets into the composition, the reaction begins to develop especially rapidly.

Another additional risk factor is the presence of moisture. Then the threat of electrochemical corrosion is also added to the danger of chemical corrosion.

How to process metal with your own hands?

Carrying out anti-corrosion work independently requires compliance with a certain sequence of actions:

- The surface that needs to be protected from corrosion must be prepared. It is thoroughly cleaned from oil stains, rust and other contaminants. This can be done using metal brushes or special attachments for an angle grinder.

- When the surface is properly prepared for the application of primer or rust converter, apply a coat of the product. It should be completely absorbed and dry.

- After this, protective paint is applied to the metal surface. It is necessary to apply two layers, allowing each to dry thoroughly. It is worth taking care of protective equipment for performing work: gloves, goggles, respirator.

This is a standard scheme for treating a metal surface to protect it from destruction.

Factors of the rate of gaseous chemical corrosion

As they studied the characteristics of the chemical corrosion process, scientists were able to identify important factors that affect its speed and other features. These include:

- The temperature of the medium in which the metal is immersed.

- Alloy composition and other features of the metal.

- Features of the gas environment, its composition, predominant elements.

- Duration of contact of the material with a corrosive environment.

- Emerging corrosion product.

As with other types of corrosion damage, the type and characteristics of the oxide film created on the surface are of great importance.

Protective paints for metal

Applying special protective paints to a metal surface is one of the most effective means against corrosion. When dry, they form a hard film containing pigments. The thickness of this film may vary depending on the purpose of the metal product. The thickness and nature of the interaction of the paint with the surface determine the protective properties of the coating.

Anti-corrosion agents for metal can be divided into three groups:

- primers;

- paints;

- products for applying directly over rust.

When choosing a protective paint, it is important to consider the properties of the metal surface on which it will be applied. For example, for ferrous metals such as steel, it is better to choose a primer that contains zinc. The fact is that a galvanized surface can withstand destruction for a long time. As a rule, the instructions contain information about what type of surface the product is intended for.

Rust paint becomes a good solution in a situation where the surface cannot be properly cleaned of rust. It is simple and easy to use, lays down in an even dense layer. The coating created by this paint is durable and resistant to corrosion. Despite the fact that there are already pockets of corrosion on the metal surface, rust paint will not allow them to grow and spread.

Most products are suitable for manual application at home. Some paints apply better if you spray them. The composition of the paints takes into account the fact that they will be used, among other things, to protect structures located on the street. The products can be applied outdoors. As a rule, anti-corrosion paints are applied in a fairly thick layer for best effect.

The painted surface looks aesthetically pleasing. At the same time, it is reliably protected from corrosion. The film formed as a result of dyeing prevents the negative effects of light, moisture, and impurities in the atmosphere. Surface protection against oxidation is provided for up to 8 years.

Factors in the formation of a protective film

The oxide film can have a pronounced protective effect on the material. But this requires that it meet several important requirements:

- Continuity. On the surface, the film is distributed in an even layer, without pores and areas that are not affected by it.

- Good adhesion to the surface of the material. This is required to keep such a protective barrier in place and prevent deterioration of its properties.

- Chemical inertness. The film will protect the metal only if it enters into chemical reactions with the environment. Otherwise, there is a great danger that the entire protective effect will be reduced to zero.

Since the material will be used for a long time and it is difficult to predict what will affect it, wear resistance and an increased level of hardness are of great importance.

No less important is the fact that the film is not porous and loose. When it is in poor contact with the surface, the risk of destructive processes becomes much higher.

When studying the various properties of oxide films, scientists take a particularly close look at continuity. It is noted that it is influenced by molecular volume. Its indicators must be higher than the atomic volume of the metal.

Continuity is not put in first place when determining the protective properties of the oxide film only for a small group of metals. These include alkaline earth and alkaline.

When carrying out work on protection against chemical corrosion, much attention is paid to the method of measuring thickness. Analysis of characteristics occurs at different stages of formation. Of great importance are the obtained indicators of the rate of metal oxidation and the nature of such a process.

When oxides are formed, experts recommend checking what kind of film they have created on the surface and whether it has the necessary protective properties.

SNiP norms and rules

Protecting metal structures from destruction at enterprises is a technological process in which it is necessary to comply with established standards. The official document that regulates the rules and regulations for anti-corrosion work is SNiP 2.03.11-85.

This document specifies acceptable methods for treating metal surfaces to prevent corrosion. These include:

- coating with paints and varnishes;

- impregnation with anti-corrosion compound;

- pasting with special protective films.

When performing protective work, the document prescribes taking into account the characteristics of the environment: the degree of aggressiveness, physical condition and nature of the action. For different environments, the use of materials is provided that can provide effective protection against destruction.

If the treatment of metal structures against destruction is carried out independently, the recommendations and rules from SNiP must be taken into account.

At the Cherepovets Metal Structures Plant, all work to prevent corrosion, from appropriate design to post-installation maintenance, is carried out taking into account state standards and rules. Confidence in the high quality of metal structures allows us to give our customers a guarantee of up to 24 months on all products.