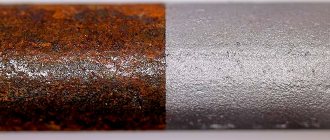

When working with metal, it is often necessary to clean its surface from paint, rust, or remove welds. The easiest and fastest way to do this is with a grinder. This device can significantly reduce the process of stripping metal without compromising the quality of the treated surface. However, you need to take into account some nuances in the work in order to properly clean the iron using a grinder.

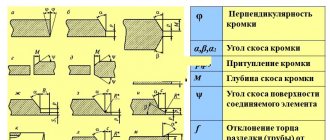

Clean the weld seams with a grinder

Cleaning welds is a job that requires a responsible approach.

In order not to damage the seam, and to keep the surface looking smooth and neat, you need to grind it off with a grinder. During the stripping process, remember that after the processing process, as much metal as possible should remain on the weld. Proper cleaning of weld seams is possible with a disk no less than 3 mm thick. Otherwise, the disc may burst and cause harm to surrounding objects and the health of the operator of the angle grinder.

After welding two metal elements, scale and slag remain within 2-3 cm of the seam, which must be ground. This must be done immediately, because when the surface is covered with paint it should be smooth. And if you don’t clean these places, bulges will remain and the appearance will be ruined.

Where it is difficult or impossible to reach with a grinder, use a flat chisel.

Safety precautions when working

Using accessories for an angle grinder requires compliance with safety measures.

- It is prohibited to use accessories for angle grinders with inappropriate technical parameters.

- When processing any surface, small solid particles fly off. They can damage the eyes, skin, and respiratory system. At high speeds, the brush itself may fly apart. To avoid a traumatic situation, it is recommended to wear personal protective equipment before connecting the power tool. These are: glasses, a respirator, gloves, workwear made of thick fabric.

- Contact of the brush with metal at high speed is accompanied by a loud sound. Construction headphones or earplugs will help to avoid irritability and strain on the hearing organs.

- Before installing the attachment on the grinder, you need to inspect it for damage and defects. If they are present, they must be replaced.

The importance of safety lies in taking care not only of your health, but also of those around you.

How to remove rust from a gate using a grinder

There is a garage that has a gate that is naturally rusty. We need to paint them, but first get rid of the rust. I don’t want to play around with acid - it’s harmful to health and needs to be washed off before painting. I have a Makita 9558 angle grinder. On sale I saw flap wheels (many strips of sandpaper glued on) and brushes for an angle grinder.

le wrote: petal circles remain.

Will they be able to clean it up? It will be expensive, IMHO. And they can withstand such a speed of 11500.

2le][a It depends on how you press. Buy one petal and one stripper - compare which is more convenient.

le wrote:

which has a gate that is naturally rusty. We need to paint them, but first get rid of the rust

Are you absolutely sure that getting rid of rust is really necessary?

Maybe it would be easier to buy a bottle of car rust converter and turn this very rust into soil? Or even just a can of Tikkurilov paint, which is applied directly to the rust?

I used it on large surfaces, nothing flew off it except rust. The very corners are similar, but for a drill and a drill, of course. I cleaned it, washed it with water, let it dry and two coats of primer. It has lasted for 12 years. Fine.

There are paints that can be applied directly to rust. I recommend and use them. Using a grinder to clean it is ideal for applying regular paint will not work 100%; as a result, the gate will bloom under the paint.

READ MORE: Spinal surgeries under the compulsory medical insurance policy in Moscow - 46 clinics

I painted it with something expensive, like Tikkurila, for my grandmother’s cross - 2 years have passed and the paint still hasn’t come off. And the cross was terribly rusty.

I would do this: Clean off everything loose, loose and generally cleanable with a wire brush (those who have not worked with brushes are afraid of flying wires, well, yes, they fly off, but other than sticking into clothes at the end there are no troubles, and in thick clothes stuck; it is advisable to always wear gloves and glasses when working with an angle grinder), then treat the surface with a rust converter, then paint.

le wrote: I don’t want to play around with acid - it’s harmful to health and needs to be washed off before painting.

The B-52 still holds its mark. Don't underestimate her. Minimum work, acceptable result. But if anything happens, using a brush is also an option.

It’s easier to do it by hand - wrap a simple piece of sandpaper around a block and rub it. and there will be less dust.

It’s easier to buy Hammerite and not fuck your brain with any stripping

Vo.VA wrote: It's easier to do it by hand - wrap a simple piece of sandpaper around a block and rub it. and there will be less dust.

If you have an angle grinder and a brush, it’s easier to combine them. Dust. It depends on what and where the garage is, and what is in it))) Yes, a brush for a small grinder should be taken with a small diameter (60-70mm) and when buying, make sure that the nut is secured evenly so that there is no beating when rotating.

Swarovski wrote: it’s easier to buy Hammerite and not fuck your brain with any stripping

If you don't care about the budget, definitely.

Homemaster wrote: but other than sticking into clothes at the end there are no troubles

Not counting the pulling out of the hands and stomach of the wires that entered almost a centimeter

But it was my own fault that I cleaned it with the wrong brush in just a shirt because of the heat. But wearing a mask. By the way, it was a garage door.

Eddy21 wrote: Maybe it would be easier to buy a bottle of car rust converter and turn this very rust into soil? Or even just a can of Tikkurilov paint, which is applied directly to the rust?

These products require preliminary cleaning of layered and loose rye. Otherwise, you will trap it under the upper crust that the converter will create, and after some time it will still swell and come out. Tested repeatedly on car bodies and rims.

Why isn't the red lead already giving up? As far as they know, they can even paint over rust.

DJGlukBH wrote: Cleaning with a grinder is ideal for applying regular paint will not work 100%, as a result the gate will bloom under the paint.

I will apply primer

The process is also complicated by the fact that in some places the old paint remains - it looks like it will also have to be cleaned off. Moreover, apparently it is better to do all the gates manually.

READ MORE: The best inexpensive tablets: TOP for 2020

munya wrote: Why isn't the red lead already talking?

That's right, I got it wrong in post 8. I didn't apply primer, but red lead. Please excuse me.

go wrote: Apart from pulling out the wires that had entered almost a centimeter from my hands and stomach, but it was my own fault that I cleaned them with the wrong brush in one shirt because of the heat. But wearing a mask. By the way, it was a garage door.

Well, you still have to be able to do this

In principle, of course, there are many things people do, including swallowing swords and eating glass.

The maximum volume that I have done with brushes is a two-story wooden house, all walls and ceilings. The last time I used brushes was about a week and a half ago, I stripped the battery - two cup brushes to zero, one to a third, I worked with 125 and 230 grinders, without adjusting the speed.

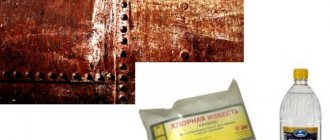

About rust converters and paint removers

To remove rust and clean old paintwork down to metal, Western paintwork manufacturers recommend using exclusively mechanical means - sanders, sandblasting, brushes.

And none of the leading Western manufacturers of paints and varnishes produces or recommends the use of rust converters or neutralizers. This is partly due to the fact that it is generally not customary to repair rotten parts there, but the main reason is that the residues of the acid that is part of such products can provoke corrosion later, after painting. So using a rust converter is tempting (especially if rust is everywhere), but risky.

But some manufacturers have a remover for old paint - it softens and undermines the paint, after which it is cleaned off with a spatula or sander. But the use of such washes is also quite controversial. The aggressive chemical composition of these products does not give us complete confidence that we will be able to completely get rid of their residues after use. This means there is no guarantee that our new paintwork will not receive completely unexpected defects in this way. And even if you use a wash, then you need to apply it only to the entire surface of the part (otherwise the paint will still swell at the borders), which is irrational when removing small defects, for example, a small dent.

Thus, the most effective way to clean paintwork defects to metal today is mechanical processing, that is, grinding. Modern grinding materials make it possible to do this work in no less time than chemical methods, and with absolutely no risk.

The defects awaiting us at this stage can be divided into the following types:

- minor defects (scratches, chips, small dents),

- major damage (parts after straightening, thick layers of old repair coatings, putties, primers),

- pockets of corrosion,

- welds,

- anti-gravel coating,

- sticky tapes.

Let's figure out which tools and materials will be most effective in each specific case.

If the part is new and covered with low-quality shipping primer, then it also needs to be removed. Read more about this here.

READ MORE: Which stove radiator to choose, copper or aluminum. Expert advice

From metal surfaces

For roughing work on metal, be it removing a layer of old paint or removing rust, craftsmen use wire brushes. They look like a brush made of twisted or untwisted metal wire inserted into a metal glass, or a disk made of the same wire.

You can hear complaints from craftsmen who have used wire brushes for scraping metal that small pieces of wire fly off the nozzle and get stuck into clothing.

Depending on the quality of roughing work you want to carry out, the thickness and hardness of the brushes is selected. You should take into account the fact that the metal wire used in brushes leaves scratches on the surface being treated. Therefore, it is better not to use them to remove paint, for example, from a car body. They can only be useful for removing rust and paintwork from hard-to-reach places.

For gentle metal stripping, it is better to use special wheels made of silicone carbide fibers (XCS) - they are usually black. Clean and Strip discs, which are more wear-resistant, are also used for these purposes. They come in blue color, have a similar structure, but consist of nylon threads.

This grinding wheel is available in 2 versions: for a drill and for an angle grinder. Its distinctive feature from other types of nozzles for removing paint from metal is that it does not clog and does not cause damage to the metal in the form of scratches. It also successfully removes welding spatter, rust, various sealants and anti-corrosion coatings.

Clean and Strip wheels have good wear resistance and can be used until completely worn out.

Often, petal attachments for an angle grinder are used to remove paint from metal. They are a disk with sandpaper in the form of petals glued to its surface.

For rough surface treatment, nozzles with a large grain size are used. For finishing work, it is necessary to select a grinding wheel with fine sandpaper. Although this sanding disc wears out quickly and becomes clogged with remnants of removed paint, it can be restored quite simply. You can understand how this is done from this video.

What is it used for?

Various devices are used to remove rust or old paint from a metal surface. You can get the job done quickly and efficiently using a grinder and a special brush attachment.

The design is a round base with wire or nylon bristles. The working elements are located evenly around the entire circumference of the cup. The length of the bristles is uniform.

Disc brush for angle grinders, nylon wire with abrasive coating BISON “PROFESSIONAL”

If the wheel is unevenly covered with wire bristles, involuntary vibration of the attachment is observed during grinding. Because of this, the quality of cleaning decreases.

Equipment is selected for an angle grinder taking into account technical indicators. One of the main ones is the number of revolutions per minute. It is unacceptable to use a metal brush with a low speed on an angle grinder with a high rotation speed. The effect of such processing will be minimal. The equipment will quickly fail.

For what purposes are cord brushes used:

- stripping the old protective coating (LCM);

- grinding of metal blanks;

- deburring;

- brushing, roughening of wood blanks;

- cleaning parts before welding;

- removing unnecessary part of the deposited metal from the seams;

- grinding off sharp corners, etc.

Sometimes metal brushes are used as substitutes for abrasive wheels.

Rust removal

To quickly and effectively combat pockets of corrosion, you should also use a stripping machine.

The best materials are the fiber and petal discs described above - with their help you can quickly and effectively remove rust on large surfaces. If, after working with these circles, rust pores remain on the metal, additionally use SCM disks, which will remove rust from small depressions and pores.

However, we often have to deal with rust, which is located in hard-to-reach places that are difficult to process (on thresholds, edges, in recesses). In such cases, an axial grinder such as the Rodcraft 7040 or the small Rodcraft 7100 angle grinder will be most convenient.

Rodcraft 7040 axial grinder

In tandem with these machines, special grinding rollers (spiraband) and small grinding wheels (siafix) are used. Working speed with rollers - up to 23,000 rpm, with siafix circles - from 15,000 to 30,000 rpm. for 50 mm discs, and 13000-27000 rpm. for discs with a diameter of 75 mm.

Sanding rollers

As a result, the small size of the machine and grinding wheels provide good access to repair areas, and the high speed of work ensures fast and effective rust removal.

In the case of processing the edges of doors, the edges of the hood or trunk lid, various recesses and “narrow” places on the body, a regular cutting disc can help out. It is clear that its main task is cutting metal, but with careful handling using a cutting wheel you can very quickly and effectively remove rust, especially in hard-to-reach places.

Removing thick layers of paintwork

An indispensable tool when working on surfaces with large damage (for example, after straightening), as well as on surfaces that have previously been repaired and have thick layers of old repair materials on them, is an angle grinder, popularly called a “grinder”.

For example, a Rodcraft 7150 pneumatic grinder or an electric rotary sander Festool RAS 115.04 E.

Cleaning with Festool RAS 115.04 E

The most commonly used materials for this task are fiber discs: regular or with Velcro fastening. For Sia, these are siamet and siatop circles, respectively. These are very aggressive materials, so they can easily cope with the removal of thick layers of paintwork. However, these materials should be used carefully so as not to leave too rough marks on the metal surface.

siamet fiber cleaning wheel

The recommended speed for working with siamet wheels is 10,000 rpm. For siatop discs, the speed should be limited to 8000 rpm, as at higher speeds the Velcro on the edges of the discs may burn.

Wiping wheel based on synthetic fibers SCM

Special cleaning wheels based on synthetic SCM fibers also do an excellent job of removing thick layers of paintwork materials. Due to their structure, these wheels are almost not clogged with paint particles and leave virtually no marks on the metal, which makes it possible to avoid regrinding the surface with finer abrasives to avoid subsidence. As mentioned above, these circles are also great for eliminating small defects.

The grain size of these materials is indicated by the letter “K”. They have three gradations: K060 (coarse), K100 (medium) and K150 (fine). To attach these circles, the same plate is suitable as for fiber circles with Velcro. Operating speed - no more than 85000 rpm.

Very good for removing old paintwork and stripping flap discs. Sia has siaflap wheels. Due to the fan-shaped arrangement of the abrasive blades, such discs wear evenly and do not clog. They last 6 or more times longer than regular circles! Operating speed with 115 mm discs is up to 13,000 rpm.

siaflap cleaning flap disc

Grinding Rules

• Cleaning is carried out with confident reciprocating movements with moderate pressure to the surface. There is a direct relationship between the pressure on the wheel and the processing speed: the stronger the pressure, the higher the processing speed. However, the circle itself will wear out faster. Therefore, do not press the machine too hard.

• For effective sanding, hold the sander at a slight angle (15-20˚ ).

• Smooth out the boundaries of the transition of metal into the old paintwork until it is as smooth as possible.

• Remember that the tool must be turned on and off over the workpiece. First place the machine on the surface, then turn it on.

• Do not use the end face as this may cause premature wear or damage to the wheel.

• Observe the recommended speed for a particular circle. If the recommended rotation speed is exceeded, the wheel will quickly wear out and lose its abrasive properties.

• To process paintwork before subsequent puttying, use P80 gradation wheels in the main defect area and P150 in the peripheral area.

• When sanding surfaces that have previously been repaired and have thick layers of putty on them, the main task will be to get to a reliable layer of coating. Indeed, as a result of damage and deformation of the element, the elastic metal could lose its adhesion to the inelastic putty. Sometimes there may not be visible signs of this, but after you start sanding, all this ins and outs (cracks, peeling of putty) are revealed.

Our surface already shines with a metallic sheen and has been sanded for better adhesion of subsequent layers. It's time to start filling up the damage. More about this next time.