Dear customers, in this review we will help you with choosing a Svarog welding machine with the markings ARC 205 and ARC 200. ARC 205 - there are four devices in the model range. This is Svarog ARC 205 (J96), ARC 205 (Z122), ARC 205 B (Z203), ARC 205 B (Z203S) . There are only two devices labeled ARC 200 (except for the EASY series, we previously published a separate article). These are Svarog ARC 200 ll (R50) and Svarog ARC 200 B (R05) .

Svarog ARC 205 (J96)

Perhaps the most popular device. This device is very light, its weight is only 5.8 kg. The letter “J” indicates that the device is multifunctional (the ability to weld metals in the MMA mode - manual arc welding with a stick electrode and TIG - argon-arc welding). The device is small in size and has a convenient adjustable strap. Most often it is bought for the dacha and for installation work. The maximum current is 185 A. You can read more about the device in the product card.

Svarog ARC 205 (Z122)

This device has a higher duty cycle than stated, the manufacturer indicates underestimated characteristics (60% duty cycle), but tests have shown that the duty cycle is much higher - 75%. The device is economical, low energy consumption at idle and during operation. The device cools very well and quickly during the welding process. The device is intended only for welding in MMA mode (manual arc welding with a coated electrode)

Svarog ARC 205 B (Z203) and Svarog ARC 205 B (Z203S)

The main difference between these devices is that if the code contains the letter “S”, it means the device does not have a digital display. These devices are equipped with the latest technology, they contain all the basic functions, such as HOT START, ANTISTICK and Arc Force, reducing energy consumption both during operation and at idle. The devices have high performance.

Now a few words about the Svarog ARC 200 || R50 and Svarog ARC 200 (R05)

Svarog ARC 200 ll R50

Maximum current - 180 A. Convenient and lightweight. The device has a durable plastic case. Welds metals with an electrode with a diameter of 4 mm. Installation crews and summer residents really liked this device, and it is also often used when welding fences and small metal structures.

Svarog ARC 200 B (R05)

The maximum current is 200A. This device is in demand at construction sites. A device of increased reliability and increased strength. Has proven itself well on construction sites. Not picky about weather conditions. Works stably even in severe frosts.

0 ₽

Manufacturer: Svarog

Technical characteristics of the inverter Svarog ARC 205 (J96)

One of the most modern technical components of the inverter allows you to create high-quality welded joints. The welding current adjustment range is 10–180A, and information about the parameter value is displayed. When welding, direct current electrodes UONII-13/55, UONI-13/55 and their modifications are used. Universal electrodes ANO-4S, MR-3, OZS-12 are applicable. The best welding quality was observed when using electrodes with a diameter of 1.5–4.0 mm.

Photo of inverter Svarog ARC 205 (J96)

The welding machine is equipped with all cables, electrode holders and terminals necessary for operation, and is equipped with a welding helmet. It is quite compact, its dimensions are 336x120x198 mm, and its weight does not exceed 7.8 kg.

Rules for using equipment

Like most inverters, Svarog ARC 205 (J96) is not recommended for use in conditions of precipitation, as evidenced by its protection class - IP 21S. Select a flat area for the installation location of this device. The inverter housing should not be cluttered with foreign objects. If you do not provide natural ventilation to the device, it will quickly fail. It is necessary to ensure that sparks, particles of molten metal and dirt do not fall on the equipment body.

When connecting the inverter to the electrical network (a socket with an automatic fuse is used for this), it is necessary to ensure the tightness and reliability of the contacts in order to avoid their sparking and intense heating during the welding process. To avoid problems when operating the welding inverter, it is best to use the original power cable to connect it.

Typical inverter malfunctions and methods for eliminating them

The cables through which electric current is supplied to the welding holder and ground are connected to the corresponding connectors on the front of the device. The contact tips of the electrical cables are inserted into such connectors and turned clockwise until they stop. In this case, it is necessary to ensure that the contact is tight and reliable. Then during welding there will be no sparking, heating in the links of the electrical circuit and voltage losses.

As is known, welding, depending on its characteristics and the type of electrode used, can be performed with direct or reverse polarity. In the first case, a cable going to ground is connected to the positive connector on the inverter, and a cable with a welding holder is connected to the negative connector. To perform welding with reverse polarity, respectively, the cable of the welding holder is connected to the positive connector, and the ground wire is connected to the negative connector.

To avoid significant voltage losses in welding wires, inverter manufacturers make them quite short, about 2.5 meters. If there is a need to use longer wires, you will need a cable with a larger cross-section. Then the voltage losses will not be too critical.

Packaging and appearance of the welding machine

As mentioned above, the Svarog ARC 205 welding inverter is also used for welding in a shielding gas environment (TIG). To practically implement this technology, it is necessary to additionally purchase a valve-type burner and a special connecting set for the inverter apparatus. Using a connecting set, the burner is connected to the negative connector of the inverter, and a ground cable is connected to the positive connector, the reverse end of which is fixed to the parts being welded using a clamp. Before starting welding work, the housing of the inverter device must be grounded. This will ensure welding safety and eliminate the risk of static electricity.

When performing TIG welding, shielding gas must be constantly supplied to the work area, which is provided through a gas supply system that includes:

- gas cylinder;

- a hose through which gas is supplied to the welding zone;

- a reducer with which the pressure of the supplied gas is regulated.

Welding set for argon welding

The design of the inverter of the model under consideration does not have an oscillator that provides non-contact ignition of the welding arc, therefore, when performing TIG welding, the arc must be ignited by touching the surface of the parts being joined with the electrode.

Technical characteristics of the welding machine Svarog TECH ARC 205 B (Z203)

Also check out these articles

- Profitable purchase of real estate in Vyshgorod

- Advantages of being a locksmith

- What to look for when choosing a bouquet as a gift

- Advantages of making a custom kitchen

Photo of welding inverter TECH ARC 205 B (Z203)

| Supply voltage | 220 V ±15% |

| Mains frequency | 50 Hz |

| Current consumption | 41 A |

| MMA power consumption | 9 kVA |

| Power consumption TIG | 5 kVA |

| Welding current MMA | 10–200 A |

| Welding current TIG | 10–200 A |

| Operating voltage MMA | 20.4–28.0 V |

| Operating voltage TIG | 10.4–18.0 V |

| Open circuit voltage MMA | 63 V |

| Open Circuit Voltage MMA (VRD) | 9 V |

| Open circuit voltage TIG | 12 V |

| Mon (40°C) | 80% |

| Welding current MMA (PN 100%) | 170 A |

| Welding current TIG (PN 100%) | 170 A |

| Power factor | 0.93 |

| Efficiency | 85% |

| MMA electrode diameter | 1.5–5.0 mm |

| TIG electrode diameter | 1.0–3.0 mm |

| Insulation class | B |

| Protection class | IP 21S |

| Dimensions | 410x160x260mm |

| Weight | 8 kg |

| Antistick | There is |

| Hot Start | There is |

| Lift-Tig | There is |

| VRD | There is |

| Adjustable arc force | There is |

Advantages

- The welding machine Svarog Arc 205 is a powerful model suitable for beginners and professionals;

- It has easy arc ignition;

- The cost of the equipment is significantly lower than that of other models with such characteristics;

- Availability of additional modes to facilitate the process;

- The model can be plugged into a regular outlet or connected to a current generator;

- Makes minimal noise during operation;

- Two main operating modes, for ordinary arc welding and argon-arc welding;

- High PV level, which ensures long-term operation without overheating;

- Well-chosen cooling system;

- High quality of the resulting compounds.

Flaws

- The welding inverter Svarog Arc 205 does not work well with UONI electrodes, in particular, difficult ignition of the arc is noticed;

- The supplied power cables are too weak;

- When working with thick workpieces, sometimes lack of penetration occurs;

- The length of the supplied wires is not enough for professional use;

- If a breakdown occurs, both welding options will not work, so combining the two modes is not always an advantage.

Characteristics of the welding inverter Svarog Arc 205

The welding inverter Svarog Arc 205b has become popular among users due to its characteristics. It can operate in almost all required ranges that are needed in the private sector and repair shops. When choosing, people first pay attention to the characteristics. You need to know what maximum current the device can produce, what thickness of electrodes it can work with, what time of continuous operation it can provide, and so on. For each application, the most important parameters come to the fore. Here you can find out what characteristics this model has and decide how suitable it is for your purposes.

| Options | Parameter meaning |

| Type of processes carried out | manual welding (MMA), semi-automatic argon arc (TIG) |

| Current adjustment range at (MMA), A | 10-200 |

| Current adjustment range at (TIG), A | 10-200 |

| Input voltage range, V | 185-260 |

| Voltage x.x. | 76 V |

| Output current | constant |

| Power | 5.7 kVA |

| PV at maximum parameters | 80 % |

| Consumable Diameter | 1.5 – 5 mm |

| Efficiency | 70 % |

| Insulation | class F |

| Hot start | present |

| Arc Fast and Furious | Present |

| Protection | IP21 |

| Dimensions | 336 x 120 x 198 mm |

| Weight | 5.8 kg |

The set includes a holder for a welding machine, a cable, a tip, a grounding terminal, and a power cable for connecting to the network.

Operating instructions for welding inverter Svarog Pro Arc 205 J96

The first priority is to prepare the workplace, as you need to ensure good ventilation so that nothing interferes with the penetration of air into the cooler. It is best if there is additional natural ventilation, as when working in an open area. If the ventilation is weak, the PV level may decrease significantly, which will lead to overheating and possible breakdowns.

Particular attention should be paid to input parameters from the network, since jumps or large discrepancies with the nominal value are often observed. You should measure everything before turning it on, so as not to expose the equipment to unnecessary risks. You also need to check the reliability of the wire connections, since loose terminals can lead to breakdowns, overheating and other negative phenomena.

Modes

For each metal thickness, you need to select your own diameter of the consumable. This is required so that the seam can be welded to the proper depth. To ensure welding, a certain temperature is required. It is set by the current value, but it must be selected quite accurately, since if you exceed the optimal value too much, the workpiece will burn out, and if you make it lower, the electrode will stick. Here are the main modes for a certain type of part thickness:

| Setting modes | |||||||

| Workpiece thickness, mm | 0,5 | 1-2 | 3 | 4-5 | 6-8 | 9-12 | 12-15 |

| Diameter of consumables, mm | 1 | 1,5-2 | 3 | 3-4 | 4 | 4 | 5 |

| Current value, A | 15 | 40 | 79 | 130 | 160 | 180 | 200 |

Application area of the inverter

The device is packed in a stylish case, allowing you to carry both the device itself and all the necessary accessories, as well as protective equipment. A set of additional functions ensures comfortable work for the welder on site. The outer shell with protection level IP 21 protects the device from foreign objects and drops of water falling vertically onto the housing.

The inverter is suitable for welding in private households, garages or small car repair shops. It is indispensable when carrying out construction and installation work of any volume associated with visiting the site, and is applicable in the housing and communal services sector. The device is convenient to use as part of the equipment of mobile emergency services complexes, in small-scale production. Low weight and dimensions allow welding in hard-to-reach places when repairing metal structures.

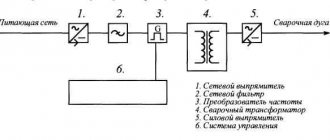

Operating principle of a welding inverter

We recommend reading our other articles

- Sprayed polyurethane foam (PPU)

- Reasons for the popularity of women's leather jackets with fur

- Features of choosing office desks for staff

- STALEX pipe benders

Welding with the Svarog ARC 205 inverter is carried out with direct current (DC) using inverter technology. The device is powered from a conventional single-phase network 220 V, 50 Hz. In the absence of a stationary power source, it is possible to connect to a gasoline or diesel generator that provides voltage in the range of 185 V–260 V.

The AC supply voltage is converted into DC by the mains rectifier and inductor. The resulting direct current is supplied to the IGBT block of power bipolar transistors. It inverts direct current into RF alternating current with a frequency of 20–50 kHz. The step-down transformer reduces the voltage to the operating level, after which it is rectified again and supplied to the operating connectors located on the front panel of the case.

Such preliminary conversion to high-frequency current allows the use of a transformer with very small dimensions. Compared to “classic” welding machines, the inverter weighs several times less, has better technical characteristics and efficiency.

The high quality of the welding process is ensured by a control unit with digital signal conversion (DSP).

Frequent malfunctions and their elimination

The welding inverter “Svarog ARC 205” is characterized by problems inherent in all similar models.

- Protection shutdown due to overheating. The reason may be dust on the device. The inverter should be cleaned periodically or selectively by blowing with compressed air. Dust accumulates with constant use on open construction sites. If the thermal relay fails, it triggers falsely, although the device does not overheat. The part should be replaced by a service center. There may be bad contacts at the connection points that need to be tightened.

- Constant sticking of the electrode and poor quality of the arc with a working device occur when the voltage in the network drops below normal or when weak power wires are used.

- The burnout of the device with the smell of burning insulation occurs as a result of a short circuit. Repairs are carried out in specialized workshops. Burnt out wires can be replaced yourself.

Annual maintenance of the device at the service center allows you to operate it significantly longer than the warranty period of 5 years. It may differ from one manufacturer to another and may not exceed 2 years, although this is not too short.

Key features of the device

- the presence of the Hot Start function (hot start) when igniting the electric arc;

- equipped with Antistick anti-stick option;

- adjusting the arc force (increasing power) guarantees deep penetration and a flat, even seam even at low current;

- 80% load duration when operating at a maximum current of 180 A;

- the ability to connect to a container with argon with subsequent welding of “non-ferrous metal” with non-consumable electrodes using the TIG method;

- equipped with a fan, protection against overheating and overvoltage of a single-phase 220 V network;

- the presence of a switchable idle voltage reduction system VRD.

Description of the device

High reliability of welding inverters is ensured through the use of IGBT modules manufactured by the German concern Siemens and designed to operate in adverse conditions.

In terms of functionality, the device does not particularly stand out among others. The following functions are used here.

- Hot start - a sharp increase in current when the electrode touches metal. It does not stick here, which is typical for conventional welding transformers. This is especially noticeable during welding of products with layers of rust or at low supply voltage.

- ArcForce is a convenient feature for accidental arc extinguishing. A surge of current also occurs here.

- Antistick – when the electrode sticks, the voltage drops to zero, which prevents a short circuit. The electrode can be torn off the part and the welding process can be continued again.

Advantages and disadvantages of the ARC 205 model

The inverter has the following advantages:

- the weld seam, subject to the minimum rules, is laid evenly and is always deeply welded;

- Electrodes with any type of coating can be used as consumables;

- possibility of connecting a TIG torch for welding in argon;

- presence of forced cooling with a built-in fan.

The disadvantages of this model include:

- lack of push-button activation/disabling of the “hot start” and “anti-stick” functions (automatic only);

- activation of the overheating protection system, which turns off the device for a few minutes during continuous hours of operation;

- The inverter shell does not protect against dust, dirt particles and side drops of rain from entering the device, in this it is inferior to models from other manufacturers presented on the Russian market.

Photo of the display of the welding inverter ARC 205

Advantages and disadvantages

Like many inverters, the Svarog line has the following advantages:

- due to the ease of ignition and a stable arc that self-regulates, even a beginner can easily master the welding process;

- little splashes are formed and the metal is well boiled;

- high efficiency – 85%;

- a small open-circuit voltage when the inverter is not working is only 9-15 V with recovery to 65 V when the electrode touches the surface;

- The device is protected from overheating, and the circuit also compensates for differences in mains voltage.

Among the disadvantages, susceptibility to moisture should be noted. It is better not to weld in the rain, or the machine should be reliably protected from splashes. The presence of dust inside inverters adversely affects their performance. Contamination from cutting or grinding metal has a particularly negative impact. The devices should be periodically cleaned by blowing with compressed air to prevent the accumulation of dust inside.

Customer Reviews

According to customer reviews, the ARC 205 welding inverter model can be considered one of the best in its class. With its help, you can perform work of varying complexity and volume. However, for confident welding with “five” electrodes, the maximum current of 180 A is not enough.

The model is equipped with a handle (and not just a strap) for carrying, which creates additional convenience for users. The display quite accurately reflects the actual current of the inverter; the spread of the parameter is ±3–4 Amperes. According to users, the peculiarity of this device is that it does not overheat and operates stably at ambient temperatures up to +40ºС. The use of toggle switches on the front panel in real operating conditions is more justified than “pressable” pseudo-sensors.

Applications and device design

The technical characteristics, weight and dimensions of the Svarog ARC 205 inverter determine the most popular areas of its application. This equipment, which can be connected to gasoline and diesel electric generators, is convenient to use as part of mobile installation complexes. This inverter is very popular among home craftsmen, workers in housing and communal services and emergency services, builders and installers of various metal structures. In addition, this model of welding inverter can often be found in the equipment of car repair shops.

The manufacturer recommends operating this inverter not only in rooms with a free flow of fresh air, but also in open areas (if they are located in a temperate climate zone: ambient temperature no more than 40 degrees, relative humidity no higher than 80%). If the welding machine will be connected to autonomous sources of electric current, you should check that their characteristics are compatible.

Advanced patented technologies were used in the development and creation of the Svarog ARC 205 inverter. The quality of the welding process, which is carried out using such equipment, is monitored by a control unit operating using digital signal processing (DSP) technology. The basis of such a unit is a special chipset produced by the famous company Atmel.

The inverter unit, which is responsible for generating high-frequency current pulses, is assembled on the basis of power transistors manufactured by Toshiba (MOSFET) and Siemens (IGBT).

The electrode holder included in the package is very convenient and of good quality.

Reviews of inverters of a similar category from other manufacturers indicate that the Svarog brand device is not the best in its class. However, if you take into account the cost, dimensions, weight and decent technical characteristics of the inverter of this model, it deserves the attention of specialists.

conclusions

The Svarog ARC 205 inverter is suitable for welders with any experience, including novice welders. The product item is popular with buyers and has been a trending product in the domestic welding equipment market since its introduction. The selling price of the installation in most cases is lower than the cost of many foreign models with similar characteristics. The Svarog ARC 205 will meet the expectations of those users who need a welding machine with a reputation as a trouble-free “workhorse” at an affordable price.

How to work with the Svarog inverter device?

The durability and reliability of the inverter depends on its proper operation. The device is installed in such a way that it is provided with sufficient air flow for ventilation, and is not exposed to dust, dirt, metal sparks, or exposed to an aggressive environment.

When connecting the Svarog ARC 205 inverter to the network, you should check its compliance with the characteristics given on the plate attached to the case. The circuit breaker and socket must match the power of the standard plug of the device. When working at contact points there should be no sparking or overheating. The device can be used for argon welding.

When manual arc welding, MMA mode is selected using a switch on the panel.

The forward and return cables are tightly inserted into the panel connectors “+” and “-”. Then the tips are turned clockwise all the way. When welding with straight polarity, the electric holder is connected to the “-” connector, and the return line is connected to “+”.

Excessively long welding cables should be avoided. To prevent a large voltage drop across them, long wires should be taken with an increased cross-section.

The welding current is set by the control knob of the same name. It must match the diameter of the electrode.

Under normal operating conditions, special maintenance of the welding inverter is not required. Particular attention is paid to the reliability of connector fastening and the absence of damage to power cables, housing and controls.