Roofing screws

Self-tapping screws with a hexagonal head have a wide range of applications, but most of all they are used for fastening roofing coverings such as metal tiles and corrugated sheets, as well as components for them, for which they received the general name “roofing”.

- The length of self-tapping screws with a hexagonal head varies from 19 to 100 mm.

- Rod diameter 4.8 and 6.3 mm.

They are equipped with a washer with a rubber gasket, which is responsible for the tightness of the connection, which is important for installing a roof (to prevent leaks).

In terms of color diversity, caps can be of very different colors: red, brown, green, white and others. The color of the cap is matched to the color of the material being fixed and is marked according to the Ral and RR color standards.

There are also self-tapping screws without painting - just with a galvanized head and washer.

To fasten (tighten) these screws, bits with an internal hexagon are used.

Bit size:

- for self-tapping screws with a core diameter of 4.8 mm - 8 mm bit

- with a rod diameter of 6.3 mm - 10 mm bit

Confirmat - furniture screw

.

Confirmats are used when assembling furniture.

The most used ones are 50 mm long with a hex head.

This type of fastener requires mandatory pre-drilling. There is a special confirmation drill for this.

To tighten the confirmations, use hexagons or bits for HEX 4 brand screwdrivers.

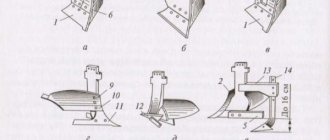

Construction wood grouse

A capercaillie is a thick-rod self-tapping screw with a hex head.

Capercaillie are widely used in fastening various units of heavy structures, where special strength and reliability of the connection is required.

When constructing pitched roofs, wood grouse are used for wooden rafter systems and interfloor ceilings.

- The thickness of the wood grouse's rod is from 6 to 10 mm.

- The size of the hexagonal head of wood grouse varies from 10 to 19 mm.

They are tightened manually with wrenches of the appropriate size, or with attachments using ratchets or power tools. Pre-drilling may be necessary.

For fastening to bases made of concrete, brick, foam block, etc., they are used together with a plastic dowel.

What are they?

There are few types of self-tapping seed screws. First of all, they differ in design features.

- Tip shape. “Bugs” can have either a sharp end or a drill-shaped end. Self-tapping screws with a drill are intended for fastening metal with a thickness of 2 mm, and sharp ones - for sheets no more than 1 mm.

- Head shape. All self-tapping screws for gypsum boards have a semi-cylindrical head with a fairly wide base. This allows you to increase the clamping area of the two parts being connected, as well as close the fastening point.

Self-tapping screws are made of low-carbon, durable steel. However, in order to give these hardware increased anti-corrosion properties and thereby increase their service life, the products are coated with a special protective layer. It comes in 2 types.

- Phosphate layer. Self-tapping screws with this top layer are black. Due to this protective layer, the adhesion of the lacquer coating to the hardware is improved, which means that for painting work, “seeds” with a phosphate layer are the best choice. Very often, after installation, such self-tapping screws are coated with a layer of bitumen varnish, which enhances the characteristics of the protective layer in conditions of high humidity.

- Galvanized layer. “Bedbugs” with this type of protective coating have a silver color, an attractive appearance and can even be used on decorative surfaces as a unique design element.

Also, self-tapping seed screws have different sizes and come in several types:

- 3.5x11 – galvanized with a sharp end;

- 3.5x11 – galvanized with drill end;

- 3.5x9 – galvanized sharp;

- 3.5x9 – galvanized with drill;

- 3.5x11 – phosphated with a sharp end;

- 3.5x11 – phosphated with drill;

- 3.5x9 – phosphated sharp;

- 3.5x9 – phosphated with drill.

The dimensions and external coating of the screw are selected based on the operating conditions of the structure, its dimensions, and the materials used.

Galvanized metal-to-metal 4.2 mm. with press washer

The most common self-tapping screws for metal. As the name implies, they are used for screwing metal to metal. To be more precise, for screwing thin (no more than 0.9 mm) sheet material to an equally thin metal base. This is if without preliminary drilling, during drilling the thickness of the sheets being pulled together can increase significantly.

These self-tapping screws are available with or without a drill. Length from 13 mm. ( "bugs"

) up to 51 mm. Fine-pitch threads promote good fixation in sheet metal, and also hold well in not too loose wood and plastic. As a standard, products without a drill are designed for fastening into metal up to 0.9 mm, equipped with a drill on the tip - up to 2 mm.

Despite the fact that products with a drill according to German DIN standards are designed for screwing into metal up to 2 mm. without pre-drilling - in fact, they often break when screwed. Perhaps it all depends on the quality of the screws and on the specific manufacturer, but for metals thicker than 1.5 mm. I highly recommend pre-drilling the hole with a drill bit, more on that below.

I would also like to note that for fastening in metals thinner than 1 mm. It is better not to use self-tapping screws with a drill tip. This self-tapping screw holds weakly in thin metal. As an example, we can consider attaching a suspension to a profile when facing with plasterboard - the self-tapping screw spins and dangles. By the way, hardware with sharp tips, without a drill, should also be carefully screwed into thin profiles, being careful not to overtighten.

If there is a question of choosing between a sharp tip and a drill for universal tasks, then it is better to choose the option without a drill. All the same, with thick metal you need to pre-drill holes, and both a sharp tip and a drill fit equally well into the drilled holes. Self-tapping screws with a drill will be good, for example, for multiple screwing into 1.5 mm sheets.

Another argument in favor of the versatility of the sharp tip is that the screws are perfectly screwed into plastic dowels. But the tip with the drill goes very poorly with the dowels.

All products of this type are equipped with a slot for a PH2

(Philips).

Since the hardware is coated with a layer of zinc, they are very resistant to humid environments and do not require additional painting. In addition, galvanizing looks quite good and in many cases there is no need to cover the caps of these screws. Table of sizes and weights of galvanized 4.2mm self-tapping screws with a press washer

| Size | L length, mm | Weight 1000 pcs, kg without drill | Weight 1000 pcs, kg with drill |

| 4,2×13 | 13,0 | 1,66 | 1,85 |

| 4,2×14 | 14,0 | 1,73 | 1,87 |

| 4,2×16 | 16,0 | 1,89 | 2,05 |

| 4,2×19 | 19,0 | 2,04 | 2,26 |

| 4,2×25 | 25,0 | 2,45 | 2,61 |

| 4,2×32 | 32,0 | 2,87 | 3,05 |

| 4,2×41 | 41,0 | 3,60 | 3,71 |

| 4,2×48 | 48,0 | 3,78 | No |

| 4,2×51 | 51,0 | 3,87 | 4,10 |

In fact, in stores you may find products with different lengths. The table only shows common values. There are even screws 75 mm long, but this is rather an exception.

Description and purpose

Self-tapping screws are so-called self-tapping screws. The main feature of such products is that there is no need to make a hole for their installation in advance. These hardware themselves, in the process of screwing in, thanks to their special shape and grooves, create grooves of the required size.

The thread of any self-tapping screw has a triangular shape with sharp edges. Structurally, this hardware is a close relative of the screw, but the latter has less pronounced and sharp thread edges. Self-tapping screws are used for mounting and fixing a wide variety of materials: wood, metal and even plastic. This variety allows you to simplify your work and achieve high installation speed. Drywall also has its own fastening elements - “seeds”.

Self-tapping seed screws differ from all their “brothers” primarily in their small size. But they also have their own design features. The head of the screw-bug has a wide and flat shape, on the edge of which there is a special roller that presses the part it fixes. Most often, this type of fastener is made of galvanized steel or ordinary steel using phosphating.

A type of self-tapping seed screws also includes products with a press. The diameter of such hardware is 4.2 mm, and the length can be very varied. For plasterboard structures, a length of up to 11 mm is used. Self-tapping screws with a press washer are a reinforced type of fastening. This means that thanks to the higher trapezoidal head, the slot is deeper, and therefore the fastener is more reliable.

Depending on what material will be placed on the plasterboard structures - wood, plastic or metal, you can select the most suitable hardware.

Conclusion

Of course, there are other types of metal screws. However, whatever type of screws you choose, buy them only from trusted manufacturers to avoid unpleasant surprises. If you buy hardware from a store, ask for quality certificates. Well, the best option is to purchase fasteners from TsKI, since we carry products only from reliable suppliers and test each item in the laboratory.

Write to us and share your practical experience on using self-tapping screws for metal!

Did you like the material?

comments powered by HyperComments

Tips for use

In order to work correctly with self-tapping seed screws, you should adhere to the following practical recommendations.

It is very convenient to tighten screws in gypsum boards using a reverse screwdriver. Installation of hardware is carried out using a special bit (Ph2), which controls the drilling depth. Thus, the head of the self-tapping screw, screwed all the way, is flush with the surface of the drywall. A good screwdriver and a suitable attachment are the key to quick and high-quality installation.

Butterfly fasteners are used when working with gypsum boards in cases where it is necessary to attach something quite heavy to the drywall. The device looks like a special plastic dowel with a self-tapping screw. To install it, you must first drill a hole in the sheet. When screwing the hardware, the internal mechanism folds and is pressed very tightly against the back wall of the drywall. There are several fundamental technical points:

- the hole for the “butterfly” is drilled with a diameter equal to the diameter of the dowel, and its depth should be 5 mm greater than the size of the screw;

- Next, the hole is cleaned of dust (using a construction vacuum cleaner), and the fastening can be installed.

The “butterfly” can withstand a load of 25 kilograms.

In order for the fastening of the gypsum board to the profile to be reliable and of high quality, the required number of “seeds” should be taken into account. So, if the frame is made of wood, then the step for installing hardware is 35 centimeters, and if it is made of metal, then from 30 to 60 centimeters.

A variety of fasteners allows you to select high-quality hardware for any type of work. When working with drywall, reliability and speed of installation are important, which is why self-tapping seed screws are so in demand. With their help, all work with gypsum boards goes much faster, and the result is always pleasing.

To see what the “Bedbugs” self-tapping screws look like, see the following video.

How to choose the “right” self-tapping screw

It is not enough to decide on the type of self-tapping screw that is needed for a certain type of work; it is also necessary, among the many options, to choose really high-quality, durable fasteners that will not fail at the most crucial moment. Just carefully inspect the screw. It must meet these simple criteria:

- Same color scheme. All self-tapping screws of one batch must be the same color and shade, if we are talking about black or yellow self-tapping screws. If all products are in the same color, this may indicate that the entire batch has undergone the same type of processing under the same conditions and has the same strength and corrosion resistance.

- The sizes of self-tapping screws from one batch should not be visually different from each other.

- The pitch between threads must be the same.

- If these are self-tapping screws with a drill at the end, then it should not have burrs on the edges, the sharp end of the screw should be without burrs and not broken off.

- The hole in which the slot is made must be clear, symmetrical and deep enough.

- High-quality self-tapping screws are usually marked in the form of a capital Latin letter. This indicates factory production, and it’s also a small hint for you in case you have to buy missing fasteners.

If you see that the screws you have chosen meet the above criteria, then you can be sure that you are holding in your hands really high-quality fasteners that will not break during the installation process.

How to choose wood screws

You should not use metal or universal screws to fasten wood. Universal ones are good when you need to twist wood and metal. And when twisting two pieces of wood, they work worse. In the sense that specialized fasteners will hold the wood better. That is, we consider only wood screws. Believe me, there will be plenty to choose from.

Self-tapping screws for wood are better yellow (yes, expensive) or white (a little cheaper)

As already said, wood screws have a rarer thread with a higher profile (the grooves between the turns are deeper). They are used not only for wood, but also for all types of sheet materials: gypsum fiber board, plywood, OSB (OSB), fiberboard and chipboard. Now about when which ones work better.

Carving and other bells and whistles

First you need to choose the type of hat. Countersunk or with a press washer, cylindrical, hemispherical - choose based on what kind of connection you need to make. It is also recommended to choose a TORX type slot, as it best transmits torque from the power tool. Next in order.

- You need to decide whether the thread should be applied to the entire rod or not. If you need to fasten two pieces of wood and pull them tightly together, use a self-tapping screw with an incomplete thread. This means that there should be an area without threads under the cap. The length is equal to the thickness of the attached part or slightly more. Due to this zone, “attraction” of one part to another occurs.

- To make screwing into hardwood or sheet material easier, there are wood screws with a router or mill. The cutter is only available on self-tapping screws with incomplete threads. It looks like several screw-type notches that are applied before starting the carving. The notches soften the wood, after which the self-tapping screw fits better.

- In general, wood screws have a thinner point and this prevents cracking of the wood. But there are also special “lotions” against cracking. These could be: grooves;

- cutting edges in the form of notches on the body of the screw;

- notches on several lower threads.

Are these bells and whistles necessary or is it a waste of money? As for the incomplete carving, this is not news. One part “fits” onto another much more tightly. And try the rest. Only from your own experience will you understand whether it works or not, and what exactly suits you best.

And practical advice on choosing wood screws

It is important that the thread goes straight from the very tip. If the first turn is too far or the tip is blunt, don’t take it

It will be pure torment, not work.

What is a metal self-tapping screw?

This is the name given to screws that are commonly used to join metal sheets and other similar materials. The other two types of screws that exist are the "wood screw" and the "metric thread" screw, which has no point and is secured with a nut. A threaded screw, also called a self-tapping screw, does not require a nut.

There is also a so-called self-drilling screw, which penetrates into sheets thanks to its tip, which resembles the tip of a drill. The self-tapping screw is widely used in roofs, PVC or aluminum windows and in general for metal structures. The parameters of the self-tapping screws comply with the European standard DIN 267 regarding the resistance of materials.

When choosing hardware, we must always consider what material we will use it on.

Main areas of application:

- Support and anchoring systems;

- Connection of metal profiles;

- Connecting metal sheets with wooden parts;

- Metal doors;

- Garage Doors;

- Roofing and facade cladding.

The self-tapping screw is characterized by several technical characteristics that determine its type:

- Head shape - three types of heads are possible;

- Type of step - carving, mainly on metal and wood;

- Diameter - expressed in mm;

- Length - expressed in mm, from under the head for round and flat heads and from above the head for flared ones;

- Optionally, graft and material.

How to screw a self-tapping screw into thick metal?

It is quite possible to screw any roofing screw or galvanized one with a press washer into thick metal, even if the hardware is not equipped with a drill. To do this, you just need to pre-drill the base. Using this method, you can tighten screws even into metal thicker than 5 mm.

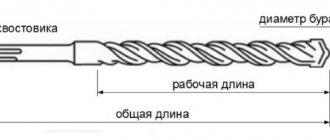

The main principle for such operations is that the diameter of the drill should differ from the diameter of the screw by only a few tenths of a millimeter. The thicker the base and the harder the metal, the smaller the difference. For example: for tightening galvanized products 4.2 mm. in metal 2 mm. You will need a drill of 3.5 - 3.8 mm, and for screwing into metal 5 mm. You will need a 4.0mm drill. To achieve this goal, it is worth purchasing several drills, in increments of 0.1 mm, up to the stated diameter of the self-tapping screw.

Before screwing it into a critical place, it is better to drill a test hole and try to tighten the screw. After all, if the diameter is poorly chosen, the cap will easily break off and it will be difficult to remove the stuck tip.

Rate this publication:

- Currently 4.67

Rating: 4.7 (9 votes)

Self-tapping screws for polished soft metal and agglomerate

Such self-tapping screws have the property of being screwed in without preparing a hole. Pointed and threaded along the entire length, they do not damage the material when screwing.

They have a countersunk coated head and are made of bichromate (yellow screw), stainless steel or galvanized (silver).

Drilling holes for screws

There are often cases when, before fastening to a self-tapping screw, it is necessary to drill the materials being fastened (pass the fastening point with a drill). This must be done for dense and thin materials. For example, if you try to screw a self-tapping screw into dense oak wood without pre-drilling, the self-tapping screw will simply break off, bend, or significantly under-tighten to the end, and there will be no tightness of the connection (a gap will appear between the connected elements).

When fastening thin parts, pre-drilling is necessary in order to avoid cracks and splits in the thin material being attached.

You can select the diameter of the required drill for drilling for a particular self-tapping screw using this table:

| Self-tapping diameter | Drill diameter |

| 4.0 mm | 2.5-3.0 mm |

| 4.5 mm | 3.0-3.5 mm |

| 5.0 mm | 3.5-4.0 mm |

| 6.0 mm | 4.5 mm |

If the diameters of the drill and the screw are equal, the adhesion density will be very low or there will be none at all.

Tighten the black screws using a screwdriver with a PH2 connector or a similar bit. For golden screws - PZ bit No. 1, No. 2 or No. 3, depending on the diameter of the screw.

Metal screws

This is the type of hardware that combines the largest number of shapes, lengths, diameters, head types and different pitches. As a rule, the characteristics of metal screws are calculated by the manufacturer depending on the device or machine on which they are installed.

The material is very important from a mechanical use point of view as it determines the resistance to deformation, tearing, torsion, temperature and any form of pressure to which the screw may be subjected. If you need to replace one or two self-tapping screws, choose a completely identical type - the values are written on the head.

Depending on corrosion resistance, there are:

- Bichromate screws: they resist corrosion quite well if they are of high quality. Inexpensive ones, as a rule, lose their surface layer during operation (therefore they are easily susceptible to corrosion) and break when tightened too much. They are yellow in color and lose protection when damaged;

- Galvanized: Same concept as bichromates, the difference lies in the quality of the finish and the various signs of wear that appear after use. Its corrosion resistance is medium and its color is silver;

- Phosphated screws: black. They are quite durable and have good corrosion protection;

- Chrome plated looks the same as galvanized plated and has the same level of durability. Corrosion resistance depends on processing and signs of wear after use;

- Brass Screws: Brass is intended for interior use in structures and often in joinery where wood and metal are joined. Brass has low corrosion resistance, turns green and is very expensive;

Stainless steel screws - ideal for outdoor use. Stainless steel is resistant to corrosion. There are two main options: A2, which is more common and cheaper, and A4, which is a molybdenum alloy, which provides acid protection and therefore greater stability.

The principle of fastening siding panels

Installation of siding panels is carried out on a frame fixed to the wall. The lathing for installing siding can be made of a wooden block or a metal profile. It is better to install metal siding on metal profiles, given its greater weight than vinyl. To install the panels, oval-shaped holes are made along the edge of the upper side of the panel. They are located quite often, so aligning the mounting hole and the sheathing post is not difficult.

Below the perforation there is a side bent downwards. The next panel is hooked onto this protrusion using a special groove, the size of which corresponds to the protrusion. Which is also attached to the top through perforations. The panels are installed from bottom to top. All additional elements also have similar perforations for fastening. The photo shows a schematic representation of the principle of siding installation.

Self-tapping hex head screw (“hex self-tapping screw”)

In appearance it resembles an ordinary bolt, but differs in the following features:

- infrequent screw thread;

- slightly pointed end.

The main application is the fixation of massive parts and large objects. The “hexagonal self-tapping screw” can be screwed into wood, and if you use a dowel, then into concrete.

Attention! Dowels for hex head screws must be two sizes larger in diameter than the self-tapping screw!

All work with such fasteners is carried out with 17, 13 and 10 mm wrenches. It is clear that the head of the long and thick screw will be 17.0 mm in size, and the shortest one will be 10.0 mm.

Self-tapping screws for metal with a pointed end

The appearance of pointed self-tapping screws for metal strongly resembles the classic screws of the USSR era. They are made of good (high-quality) metal and have frequent threaded turns - the inter-ridge distance is small. This is done specifically to improve the adhesion of the screw to hard material.

Most often, the diameter of metal screws varies in the size range of 3.50-5.00 mm, and its value increases as the screw lengthens.

Manufacturers produce such fasteners with the following parameters:

— length from 10.0 to 50.0 mm with a thread pitch of 5.0 mm;

- from 60.0 to 100.0 mm in increments of 10.0 millimeters;

- from 110.0 to 120.0 mm with a 15 mm thread - a rather rare variety;

Benefits of siding

There are many reasons for the popularity of siding. The price of siding panels competes well with the cost of other materials for finishing facades: lining made of natural wood, plank - wooden or composite materials, blockhouse, porcelain stoneware, alucobond panels, natural stone. The second reason is ease of installation. Anyone who has held a tool in their hands can decorate the facade of their own house. All work consists of mechanical fastening of standardized parts to the frame.

Choosing screws

A rich assortment of additional parts - window frames, internal and external corners, joining strips - allows for the installation of panels with the installation of decorative architectural decorations of the facade without any production of additional elements. The absence of parts requiring gluing and painting means the siding can be installed in any weather conditions. Unified, well-thought-out facade finishing elements allow for complete installation in a short time.

The mechanical fastening method involves the use of fasteners. Below we will look at how to install the panels so that the facade decoration will last for many years and delight the owner with its appearance.