The working part of a step drill for metal (also called a cone drill) is formed by a spiral groove and a number of stepped annular transitions of different diameters. Thanks to this unique design, step drills allow you to determine at any time during processing what diameter the hole has been formed.

One step drill can replace a set for metal processing, including crowns

At first glance, it may seem that using such drills (which, by the way, are quite expensive) does not make much sense, because you can always select a tool of a certain diameter and use it to create the required hole. Meanwhile, conical tools for drilling holes have a number of unique advantages that make their use justified in many cases.

Which step drills for metal are best to choose?

To make a high-quality hole in metal, you need to select a drill that will cope with this task. If you need to perform high-precision work in sheet material up to 4 mm thick, then a step drill for metal will be most suitable for this. Such cutting products not only have increased accuracy, but also require the correct approach to the drilling operation.

To process the material correctly, you need to know some of the nuances of selecting and using such a tool. All the intricacies of metal processing using cone drills will be discussed in detail below.

What are the advantages of cone drills?

Like all types of cutting tools, cone drills have their own characteristic advantages. The advantages of using the devices in question include:

- Possibility of drilling holes of different diameters using just one nozzle

- Wear resistance - unlike cylindrical elements, conical elements have a long service life. The cutting edges of the nozzles have high strength values, so the device wears out very slowly

- Speed - the nozzle allows you to quickly drill holes, which has a positive effect on its service life. The cutting edges do not have time to heat up, so their quality does not decrease

- There is no need to pre-punch the material, since the tip of the cone drill easily cuts into any metal, even with a dense structure

- At the same time, it plays the role not only of a tool for drilling holes, but also as a grinding material

- Improves the quality and efficiency of drilling thin sheet material

- Eliminates the possibility of deformation of the drilled sheet, which is associated with a smooth transition with increasing diameter

- Possibility of using the attachment not only on stationary drilling equipment, but also on drills

- The presence of abrasive coating increases the strength and efficiency of the equipment. Cone drills can be coated with titanium or diamond

- Does not require frequent sharpening

Cone drills make it possible to drill large-diameter holes, thereby eliminating the need to use metal crowns. This type of cutting attachment is suitable not only for drilling holes in sheet materials, but also corners, pipes, profiles, etc. The main condition is that the thickness of the steel should not be more than 7 mm, and ideally no more than 4 mm.

This is interesting!

The main disadvantage of cone drills is their high price.

However, one such expensive attachment can completely replace a full set of cylindrical drills. Stepped types of nozzles are classified according to the type of edge into spiral and straight. The straight edge design has the advantage of being easier to sharpen than the spiral edge design. Spiral types of edges are characterized by softness and smooth movement of the drilling device.

How to sharpen a step drill with your own hands

Long-term use of a gimlet causes it to become dull. This makes it necessary to have information on how to sharpen it correctly. Although this is not an easy procedure, if you have reliable information and skills, everything will work out.

The procedure for sharpening a cone drill requires the following sequence of actions:

- secure the gimlet with a vice;

- install a grinding wheel on the grinder;

- Being careful, sharpen the cutting edges that have been damaged.

There are several options for sharpening a step drill. For example:

- Single-plane. This type of sharpening is used to sharpen tools whose thickness does not exceed 3 mm. During the sharpening process, it is recommended to attach the tool to the sharpening wheel, moving the gimlet along the wheel. It is worth noting that using this type of sharpening may cause slight damage to the cutting edge of the drill.

- Conical. Recommended for sharpening gimlets with a length of 3 mm or more. While working, it is recommended to lightly press the drill onto the circle and carefully move it along the work surface.

- Finishing. Used to correct small errors and inaccuracies that have arisen after sharpening. For work you should take a soft sharpening stone.

Sharpening step drills yourself requires excellent lighting, vision and accuracy.

Design and characteristics of a cone-step drill

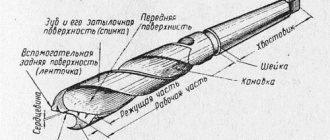

These instruments have a rather complex design. Their configuration may differ depending on the variety. Let us consider in more detail what parts such products consist of. The top of the drill is represented by a pointed tip, which makes it possible to cut into metal of any density without much difficulty.

Other tools are also used for processing metal sheets, for example, crown tools. A metal drill of this type does not require the use of auxiliary centering devices, but it is not suitable for working with thin metal. Spiral analogues also do not allow such work to be performed accurately.

Step products are very effective when working with aluminum, steel, copper and other sheets and pipes. Tools of this type are shaped like a cone, which includes 2 grooves. They promote drilling of materials. During operation, when moving to the next level, a chamfer is formed for the hole that is created by the previous step.

Due to their design, step drills are suitable for working with copper, steel and aluminum sheets

A 4-32 mm step drill for metal also has an opposite end, which is mounted in the tool chuck. The opposite end, or tail, has the most suitable design for this and consists of six edges. The advantages of such tools are undeniable, which is why many craftsmen recommend them for working with metal parts.

Appearance. Dimensions. Weight.

The drill was wrapped in a very simple translucent bag, stapled, nothing special. Although for those who order from other places, drills come in more civilized and reliable packaging - plastic cases.

The consumable was covered with oil, which was almost dry, apparently from long storage in the warehouse. The yellow coating is most likely titanium nitride, which is supposed to protect against corrosion. The drill consists of ten steps of different diameters in the range of 4-22 mm

, together forming a kind of herringbone, which is why this consumable got its nickname among the people. You can also find other sizes on sale with a larger range of diameters or with a greater height of the steps themselves.

The shank is hexagonal for a triangular chuck, which will prevent it from turning:

Instead of a spiral-type groove, the drill has a straight line in the form of two L-shaped grooves symmetrical relative to each other:

The column with the diameters of the steps is written only on one side, but not on the other side:

The steps themselves are also located at a certain angle relative to the horizontal:

The tip of the drill through the lens of a pocket microscope:

The height of all steps, except the outer ones, is about 5 mm, which means you can drill no thicker than this value. The height of the extreme steps is a little larger - about 6 mm:

I decided to measure the diameters of the steps, which in the end turned out to be not entirely accurate:

The length of the drill including the shank was 77mm:

Weight 55g.

Advantages of cone drills

Stepped products have the following positive properties:

- allow you to make a hole with smoother edges compared to spiral and feather counterparts;

- For holes of different diameters, one step drill is used;

- perfectly centers the hole;

- used for processing very thin sheet metal;

- ideal for processing non-ferrous metals;

- for large volumes of work, it saves time due to the absence of the need to frequently replace drills of different diameters.

A step drill allows you not only to perform high-quality drilling of metals, but also to correct hole defects that were made with other types of products. For example, if the center of the hole is displaced when using spiral analogues, a conical one can completely correct the defect.

It is also possible to expand the holes if necessary to a fixed diameter. Despite the higher cost of cone drills, significant savings can be achieved with frequent use. Due to the absence of the need to purchase a large number of tools of different diameters.

A cone drill allows you to chamfer during drilling and therefore does not require additional time, which saves time during large volumes of work.

Advantages and disadvantages

Step drills could be called ideal if not for a couple of negative aspects.

We recommend: How and with what can you quickly wash off Finalgon from the skin and mucous membranes?

Let's start with something pleasant. Step drill:

- gives perfectly clean holes with a small material thickness;

- performs several operations at once: drills, chamfers, cuts, grinds;

- has several drill diameters in one;

- the sharp tip easily penetrates the material, regardless of its density and structure;

- can be used in drilling tools with automated and manual drive;

- As a rule, it is characterized by increased strength and does not dull for a long time.

Step drills have few disadvantages, but all are quite significant:

- High price. A high-quality nozzle costs 2000 rubles. and higher. The cost is determined by the quality of the steel, the presence of spraying, the brand, as well as the operating range. The more diameters, the higher the price. The cheapest Chinese nozzles cost from 400 rubles.

- The device is ineffective in situations where you need to drill holes in materials thicker than 6–10 mm.

- Requires careful handling. Great force, misalignment, or a fall from a height can lead to deformation. Then all higher diameters will become unavailable.

Checking the sharpness of the drill

After a visual inspection shows that the cutting edges are smooth and sharp, check whether the correct sharpening angle of the metal drill is maintained and whether the length of the working edges meets the standards. To evaluate, you will need a special template, a protractor or protractor, and a caliper.

Checking the length of the cutting edges with a caliper

What parameters need to be checked?

- Is the angle of the cutting edge tilted forward? The presence of such an error makes the cutting edge not the highest point of the tooth and forms a hill on the back surface. This causes the drill bit to rub against the back surface of the material and not drill. The error is corrected by sharpening the drill again.

- Are the lengths of the cutting edges consistent from the center point on the web to the side apexes of the cutting edges? This distance must be the same on both sides, otherwise the diameter of the final hole will be larger than the nominal value.

- Check that the apex angle is 120°. You can determine the sharpening angle of a metal drill using a purchased or homemade template. It is important to ensure that the apex angles match for both teeth, otherwise only one side will work.

Correct and incorrect sharpening of a drill

After checking the basic parameters, drill into any metal workpiece. If the sharpening is done correctly, the drill will smoothly enter the metal, and the chips will evenly exit the grooves on both sides. And the finished hole will exceed the nominal diameter by no more than 0.05–0.1 cm.

After drilling the workpiece, sharpen the jumper to reduce the force applied during operation and reduce tool wear.

How to make a template for checking drill sharpness?

A template for checking the sharpening of a metal drill can be made independently from sheet steel or tin. You can take a template from the store as a guide. The simplest template can be made from two or three nuts. Nuts are ideal for these purposes, as they are regular hexagons with internal angles of 120°. If the nuts are connected, the angle between their faces will also be 120°. The nuts can be welded or glued to each other using hot glue.

Manufacturers of step drills

Products made in China are of low quality (there are exceptions). To buy a good cone drill, you should pay attention to tools made in Europe and Russia.

1. “Zubr” - stepped drills from a domestic manufacturer are of reasonable cost. The quality is at a fairly high level.

Cone drills can be made from ordinary tool steel or coated with more wear-resistant alloys. In the latter case, the price will be significantly higher, but the quality of the cutting surface will remain sharp longer even when performing a large volume of work.

2. “Attack” - Russian-made conical drills, which in quality and cost are not inferior to the best products from foreign companies.

Reviews about the products of this company are only positive, so you don’t have to worry about the quality, and in order not to overpay, you should select a tool taking into account the maximum diameter that will be needed in the work.

3. “Bosch” - the products of this German company are excellent for professionals and for working with metal at home.

The diameters on the tool are marked using a laser system, so in case of long-term use, the inscriptions are not erased. To increase the drilling speed, the top of the Bosch step drill is sharpened crosswise, and the workpiece is ground in both the transverse and radial directions.

Such processing of the tool allows, when using it, to obtain a high-quality hole, the diameter of which will fully correspond to the stage of the product.

4. “Falon-Tech” - drills from a German company have an additional titanium coating, which allows you to increase the tool life by more than 2 times.

The product has a laser marked diameter and a standard shank that is ideal for use with a screwdriver or hand drill.

Despite the increased quality of the product, its cost remains low. If you need to purchase a cone drill for home use, then the choice of products from this company is the most optimal.

All of these cutting tools do an excellent job of drilling metal up to 4 mm thick. If you need to work with thicker metal, it is recommended to use core drills.

Kinds

Step drills differ in type of material, shape, size (working range). For the manufacture of tools, high-speed steel HSS is used. It can be further processed or sprayed.

The strength of the product can be judged by its color:

- gray – steel without reinforcement;

- black – hardened steel;

- yellow – addition of cobalt;

- bright gold – titanium nitride coating (ensures maximum service life).

According to the shape of the stepped type nozzles there are:

- ordinary;

- without guide point;

- of two conical parts with different angles of inclination to the surface;

- with 1–3 grooves;

- with straight grooves and spiral grooves.

The spiral shape of the grooves increases the efficiency of the tool. Moreover, the more there are, the higher the speed can be used.

The sizes of the nozzles are very different. They differ in the number and height of steps, and the size of the starting diameter. The minimum first size is 4 mm. One drill can consist of 5–15 steps and start with different diameters. The standard step height is 5 mm (from 3 to 6 mm).

We recommend: 10 tests that will help distinguish silver from cupronickel

The step range of 6–38 mm covers almost all domestic drilling needs.

How to drill correctly

If you have a sharp tool, you can drill a hole in a metal workpiece no more than 4 mm thick. For proper operation, it is recommended to follow the following sequence of actions:

- Mark the location where the hole needs to be drilled using a core.

- During drilling, the tool must be held perpendicular to the working surface of the metal workpiece.

- The grinder (screwdriver) should operate at low speeds. Their value depends on the diameter: with increasing diameter, the rotation speed of the tool decreases.

- As a result of drilling, the operating temperature of the working surface increases. To reduce it, it is recommended to use a thin layer of oil to lubricate the tool.

Violation of the operating procedure can lead to its rapid dulling.

It is important not only to adhere to the recommendations for using the tool, but also to choose it correctly. The quality of a drill largely depends on the color of the metal from which it is made. For example:

- Steel with a hint of grey. This indicates that the finished tool has not been subjected to heat treatment. Such a gimlet will not last long.

- Black. After manufacturing, the drill was processed using hot steam. Thanks to this, the strength of the metal also increases.

- Golden. This color of the gimlet means that the metal is free from tension. This increases its quality and strength.

- Bright golden. This color indicates a high level of wear resistance. When creating such a tool, a metal containing titanium nitride impurities is used. They are characterized by high cost and long service life.

With proper use and selection of a stepped gimlet, the tool will serve correctly and for a long time.

Types of Step Drills Available for Sale

For the manufacture of cone tools, high-speed steel HSS (High Speed Steel) is used. The types of additional processing of the material and surface can be judged by the color of the metal :

- a regular gray color indicates the absence of additional reinforcement and that you should not count on a long working life;

- black color indicates heat treatment with superheated steam followed by hardening, which increases strength;

- a yellow tint to the surface means the presence of cobalt in the additive, and the ability to work with high-alloy and stainless steels;

- the bright golden surface of the most expensive and durable products with the addition of titanium nitride is classified as a professional tool to achieve maximum service life.

A thin layer of abrasive material made from artificial diamonds or titanium alloys can be applied to the surface of the drill. Such processing does not contradict the requirements of the standards and significantly increases wear resistance.

Characteristics of brands

You should purchase products from trusted stores, giving preference to well-known brands. The quality of steel in cheap no-name drills may not correspond to reality, and dubious stores often sell banal counterfeits at an inflated price. Recommended brands for purchase:

- German: Falon Tech, Karnasch, Ruko, Topcraft;

- Polish: Geko;

- Russian: Attack, Globus;

- Ukrainian: Lezo, Zubr.

Thanks to careful quality control in European factories, Polish and German tools are more efficient and durable, although they are more expensive. Drills from the countries of the former USSR are a compromise between price and quality, but when choosing them you need to make sure that the quality of the metal complies with GOST. It is recommended to refrain from purchasing suspiciously cheap Chinese products.

How to extend the life of a drill

To ensure less wear on the drill, you must follow some operating rules.

- Do not overheat the drill. To do this, work at intervals and use coolant.

- Set the correct rotation speed. It is set taking into account the type and diameter of the drill, as well as the material.

- Remove the chips. Periodically remove the drill from the hole and remove the chips so that it does not get stuck in the workpiece.

- Drill holes in several approaches. If you need to make a hole with a diameter of more than 6 mm, use drills of different sizes (from larger to smaller), this will guarantee higher accuracy.

Differences between a smooth conical and a stepped drill

Before we find out the scope and advantages of cone devices, let’s look at their varieties. Smoothing elements in the form of a cone drill thin sheet steel, gradually increasing the size of the hole. To drill a hole of the required diameter with such a drill, you need to periodically stop and take measurements. Some manufacturers of smooth-bore cone drills eliminate this drawback by applying digital markings.

Stepped elements allow you to drill a hole with greater accuracy due to the presence of degrees. When drilling, there is a smooth transition through the steps, and as a result, the operator can easily track what diameter the hole has. It should be noted that cone drills are quite expensive. Their price ranges from 2 thousand rubles or more. It all depends on the material of manufacture, as well as the size of the holes being drilled. Many people may think that cone devices are completely useless equipment from China until they test the cutting tool in action. Craftsmen openly declare that if frequent drilling of thin-sheet materials is necessary, it is recommended to use conical cutting attachments.

Which step drills for metal are best to choose?

To make a high-quality hole in metal, you need to select a drill that will cope with this task. If you need to perform high-precision work in sheet material up to 4 mm thick, then a step drill for metal will be most suitable for this. Such cutting products not only have increased accuracy, but also require the correct approach to the drilling operation.

To process the material correctly, you need to know some of the nuances of selecting and using such a tool. All the intricacies of metal processing using cone drills will be discussed in detail below.

Self-sharpening

Only the cutting edge (groove) is sharpened.

It is prohibited to sharpen the transitions of step drills, as this leads to a change in the geometry of the working surface and the formation of burrs during operation. Improper sharpening leads to a decrease in the quality of the tool, often to complete disrepair. The long service life of conical drills requires periodic re-sharpening. At home, drills with a straight translational groove are the easiest to use. This is done manually using abrasive rods, diamond stones for knives or sandpaper.

Any home craftsman needs to know how to sharpen a step drill for metal with a spiral flute. The process requires the use of sharpening machines, on which the drill is directed so that the abrasive wheel passes exclusively in a spiral. For simultaneous smooth rotation, special devices are used; feeding the drill manually is highly not recommended.

Sources

- https://pressadv.ru/metally/kak-zatochit-stupenchatoe-sverlo.html

- https://TehnoPanorama.ru/instrumenty/stupenchatoe-sverlo-kak-zatochit-i-pravilno-sverlit.html

- https://gazsnabstroy.ru/prochee/kak-zatochit-stupenchatoe-sverlo-po-metallu

- https://steelfactoryrus.com/kak-zatochit-konusnoe-stupenchatoe-sverlo/

- https://ooo-asteko.ru/kak-zatochit-stupenchatoe-sverlo-po-metallu/

- https://remoskop.ru/stupenchatyie-i-konusnyie-svyorla-po-metallu-ekspluatatsiya-i-zatochka.html

- https://SdelaySam-SvoimiRukami.ru/7469-3-sposoba-zatochit-stupenchatoe-sverlo-v-domashnih-uslovijah.html

- https://master-pmg.ru/raboty-po-metallu/kak-zatochit-stupenchatoe-sverlo.html

- https://generator98.ru/metally/kak-zatochit-konusnoe-stupenchatoe-sverlo.html