It is better to drill steel before the heating process, since this will not cause any difficulties. If you come across a hardened workpiece (of great thickness), release it, drill holes with a standard drill and re-harden if the situation requires it. However, this option is not always possible. There are often situations when you need to make a hole in a steel workpiece, but it is already heavily hardened. In production and by folk craftsmen, many options and technologies for drilling hardened steel have been created. You need to proceed from the situation, the materials that are at hand. An obligatory factor is the goals for which this work is required.

At home

Sometimes, to get a hole, it is enough to make a slot with a grinder. Pass a screw through it, then secure the workpiece. To make the hole smaller, it needs to be made from 2 sides. In this case, the disk of the smallest diameter is used. A practically erased disk would be better.

Before work, the steel must be examined for hardness. Based on this, choose a method. If the workpiece bends well, a drill with pobedit tips will do, i.e. on concrete. A prerequisite is that it must be spicy. You can sharpen it with a diamond wheel. Otherwise, the use of special tools is required.

During work, the workpiece is pressed tightly with a drill, and high speeds are set. The drilling site is pre-lubricated. It would be better to initially use a drill of a smaller diameter, and then replace it with a larger one. This reduces the resistance area and increases efficiency.

If a special drill made of carbon steel is used, you need to work taking into account the following subtleties:

- Do not press the drill too hard against the workpiece;

- Do not turn on high speeds.

The following method will take from 2 hours. First, the metal is etched with sulfuric or nitric acid. A side is made from paraffin, and acid is placed there. The diameter of the “eye” turns out to be slightly wider than the side itself, so when making it, this nuance is taken into account. To speed up the process, the workpiece is heated to 50 degrees.

The hole is also made with a conventional welding machine. The place itself is burned or “released”, and then simply drilled. Melted edges must be sanded.

What is the problem

Understanding how to drill a hole in hardened metal requires a little explanation.

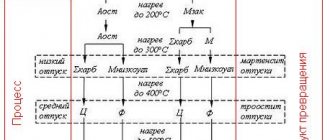

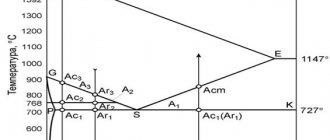

Hardening is a special type of metal processing in which it heats up greatly and then cools sharply. After the procedure, hardened steel becomes harder and stronger, resistance to fracture decreases, and resistance to abrasion increases. At the same time, the material becomes more brittle, less flexible and ductile.

Drilling into plain steel is not difficult. To do this, use standard drills made of high-speed material. Tempered steel is much stronger; a regular drill will not take it - it will quickly become dull and become unusable.

If possible, it is better to drill the necessary holes before hardening the steel. If this is not possible, you need to prepare a suitable tool. Commercial drill bits for drilling hardened steel are usually suitable, but in rare cases special equipment may be required.

In production

To drill thicker hardened workpieces, special machines are used. In them, the drill is mounted in a special drill chuck, which is secured with a conical tail in the tailstock quill. Drilling work is carried out thanks to the linear feed of the drill and the quill feed wheel. At the same time, both the workpiece and the drill rotate. The maximum usable drill diameter is 1.5 centimeters. Large drills are secured with a tail with adapter sleeves. They come in standard sizes. They are called Morse cones.

Drills are:

- Spiral with cylindrical and conical shanks. They can drill not only hardened steel, but also cast iron, as well as other “strong” materials;

- With inserts made of carbide materials. Also suitable for thick, hardened steel;

- Deep drill bits. They are used in cases where a hole is made with a depth of 5 times the diameter of the drill.

Before work, the surface of the workpiece is processed. A recess is also made with a centering drill. Otherwise, the drill begins to “walk” in front of the steel sheet, and the hole moves away from the central axis of rotation.

The depth of the hole is controlled by notches with markings on the quill. If there is a dial on it, then the drilling depth will be accurate to 0.01 millimeters. Drilling must be done in several stages. Having made a hole 2 mm deep, the drill is removed from the steel and chips are removed (from the hole and drill outlet channels). After which the process continues. If you do not follow this technology, the drill may jam and break. Don't forget to use lubricant.

Before you start drilling, you must remember that the diameter of the hole is larger than the diameter of the drill. This value is called breakdown. For a drill with a diameter of 1 centimeter, the breakdown will be 0.15 millimeters. Splitting occurs due to insufficient precision during drill sharpening.

To obtain a high-quality hole, the first step is to use a drill whose size is 70% of the diameter of the required hole. At the second stage, it is changed and the required size is used. More precise processing is obtained using countersinking and reaming.

Drilling process

Before you start drilling in hardened steel, there are a few things to consider. They are related to the hardness of the material.

Source grandmetal.pro

Before drilling hot metal at home, it is worth considering the following features:

- During operation, a large amount of heat is generated. It is advisable to supply cooling liquid to the work site.

- A drill, especially an unprofessional one, can quickly become dull. It must be sharpened using a diamond wheel.

Before starting work, you need to check the strength of the fastening on the tool itself, as well as whether the part is firmly fixed. If the part is made of polished or chrome-plated steel, put fabric or leather gaskets on the vice to prevent scratching. It is recommended to wear safety glasses and durable clothing.

You should also follow the following rules:

- First you need to turn on the drill at low speeds, then bring it to the workpiece, otherwise it will quickly become dull.

- You also need to withdraw the drill gradually, reducing the speed, but not stopping it completely.

- You need to drill at low speeds, no more than 1000 rpm. This is easy to check: when rotating, the grooves should be visible. If they merge into one whole, it is better to slow down.

Source behance.net

- Before you drill a hole in hardened metal, you need to check the strength of the metal, especially if the drill does not go deep. For this, files of different strengths are used. If there are no marks left on the surface, you should choose a harder drill or one with a diamond tip, and work at low speeds.

- When drilling deep holes, it is worth placing a small piece of compressed foam on the drill. This will allow you to deepen the drill to the desired level and ensure that the chips are blown away.

- When working with a polished surface, you should put a felt washer on the base of the nozzle to avoid contact between the cartridge and the surface.

- If the drill is too thin and does not fit well in the chuck, its tail must be wrapped with brass wire, adding volume.

The power of the drill is calculated based on the technical characteristics of the device.

Additional preparation

To make the drilling process faster and easier, it is worth preparing the surface if possible. To do this, it needs to be softened.

Source mkada.ru

Before drilling into hardened steel, it can be prepared by:

- Welding machine. It is necessary to heat the drilling site to make the metal softer.

- Punch. It allows you to make a small recess, which will simplify drilling.

- Acid (sulfuric, perchloric or any other). It is necessary to make a border around the drilling site so that the acid does not spoil the entire surface, pour liquid there and leave for several hours.

During operation, strong friction occurs, the nozzles begin to heat up and become deformed. This can be dealt with using a special lubricant, but machine oil will also work. It is used in various moments:

- Before starting work, apply a few drops to the drilling point.

- A little oil is applied to the cutting edge of the drill; it is added during operation as the oil is consumed.

- While working, it is worth taking a break from time to time to allow the tool to cool down.

These precautions will help increase tool life and keep drill bits intact.

You can see in more detail how hardened steel is drilled in the video

Size control

After obtaining the holes, size control is carried out. A caliper is used for measurements. If the hole made has ledges, or the length of the measuring jaws of the caliper is not enough to measure the size of the hole, gauges (measuring plugs) are used. These are two measuring cylinders. One of them is equal to the diameter of the hole, the second is 0.3 mm larger. During measurement, a cylinder “to size” is immersed in the “eye”, but the second one should not enter there. In case of piece production, such calibers can be made yourself. In production, instruments with high measurement accuracy are used.

Drilling a hole in hardened steel

The widespread question of how to drill through hardened steel can be associated with the fact that when using conventional technology, the tool quickly becomes dull and becomes unusable. That is why you need to pay attention to the features of drilling hardened alloy. Among the features of the technology, we note the following points:

- It is necessary to properly prepare the hardened workpiece.

- In some cases, a special tool is required.

- Coolant is being used.

If necessary, you can make a drill for hardened steel with your own hands, which requires certain equipment and skills. However, in most cases, a purchased version is used, since it will cope better with the task when cutting hardened steel.

Hardened steel drilling process

Drill selection

Twist drills, which are represented by a vertical rod with two grooves, have become quite widespread. Due to the specific arrangement of the grooves, a cutting edge is formed. Among the features of the choice, we note the following points:

- The pobedite drill bit has become quite widespread. It can be used to work with various hardened alloys. However, a surface with too high hardness cannot be processed with such a tool.

- The choice is also made based on diameter. It is worth considering that it is quite difficult to obtain a large diameter hole. The larger diameter version is much more expensive due to the use of a large amount of material in its manufacture.

- Attention is also paid to the sharpening angle, the purpose of the product and the type of material used in manufacturing. For example, cobalt versions are characterized by higher resistance to high temperatures.

- It is recommended to pay attention to products exclusively from well-known manufacturers. This is due to the fact that Chinese versions are manufactured using low-quality materials. However, such an offer is much cheaper and can be used for short-term or one-time work.

- When choosing a drill, you can be guided by the markings. It can be used to determine which materials were used in production. The diameter of the hole that can be obtained when using the tool is also indicated.

Drill for hardened steel

In a specialized store you can find almost everything you need to carry out the work. However, the fairly high cost of the product and some other factors determine that some decide to make a drill themselves from scrap materials. Similar work can be done if you have the required tools.

Use of lubricants

When drilling through hardened steel, serious friction occurs. That is why it is recommended to purchase and use various lubricants. Among the features of this processing method, we note the following points:

- First, the drilling area is processed. A small amount of lubricant is applied to the surface where the hole will be located.

- Oil is added to the cutting edge. To process hardened steel, a small amount of the substance is required, but it must be added from time to time, since it scatters when the tool rotates.

- During work, it is recommended to take breaks to cool the cutting surface and the surface being processed.

Lubricating steel with special oil

Special oil not only simplifies drilling, but also increases the service life of the tool used.

This is because oil can reduce the temperature of the cutting edge.

Drilling rolled steel

Drilling holes in metal is one of the types of mechanical processing to produce through and blind holes of the required diameter. The essence of the process is to secure the workpiece, marking and processing with manual or automated tools.

Drilling equipment

The type of equipment is chosen depending on the tasks assigned. Drilling machines can be radial drilling, vertical drilling, coordinate drilling. With their help they perform:

- through and blind holes with cylindrical walls;

- multifaceted, oval and other holes;

- internal thread;

- finishing;

- drilling an existing hole.

Application of lubricants

- The drilling area on hardened metal is marked with a core. Apply a small amount of lubricant to this point. If it is liquid, then squeeze out a drop of oil so that it does not spread.

- The cutting area of the tool is dipped into the lubricant and placed at the previously marked point.

- When drilling hardened metal, monitor the amount of lubricant and add it as it is used up.

- Monitor the heating status of the instrument, preventing it from overheating. Intensive smoke emission from burning lubricant indicates the need to stop work and cool the equipment and metal.