GOSTs and specifications for steel

GOST 1133-71 “Forged steel round and square. Assortment"; GOST 12766.4-77 “Rolled long products from precision alloys with high electrical resistance. Technical conditions.”; GOST 18143-72 “Wire made of high-alloy corrosion-resistant and heat-resistant steel. Technical conditions.”; GOST 18907-73 “Work-worked, heat-treated, ground rods made of high-alloy and corrosion-resistant steel. Technical conditions.”; GOST 25054-81 “Forgings made of corrosion-resistant steels and alloys. General technical conditions.”; GOST 4986-79 “Cold-rolled strip made of corrosion-resistant and heat-resistant steel. Technical conditions"; GOST 5582-75 “Corrosion-resistant, heat-resistant and heat-resistant thin-sheet rolled products. Technical conditions"; GOST 5632-72 “High-alloy steels and corrosion-resistant, heat-resistant and heat-resistant alloys. Marks"; GOST 5949-75 “Sorted and calibrated steel, corrosion-resistant, heat-resistant and heat-resistant. Technical conditions"; GOST 7350-77 “Corrosion-resistant, heat-resistant and heat-resistant thick sheet steel. Technical conditions"; GOST 9940-81 “Hot-deformed seamless pipes made of corrosion-resistant steel. Technical conditions"; GOST 9941-81 “Cold- and heat-deformed seamless pipes made of corrosion-resistant steel. Technical conditions"; TU 14-1-2186-77; TU 14-1-1024-81; TU 14-1-1081-74; TU 14-1-1141-74; TU 14-1-1154-74; TU 14-1-1160-74; TU 14-1-1180-74; TU 14-1-1183-74; TU 14-1-1190-75; TU 14-1-1197-75; TU 14-1-1214-82; TU 14-1-1215-75; TU 14-1-1303-75; TU 14-1-1494-75; TU 14-1-1497-75; TU 14-1-1531-75; TU 14-1-1541-75; TU 14-1-1554-75; TU 14-1-1644-76; TU 14-1-1655-75; TU 14-1-1671-76; TU 14-1-170-72; TU 14-1-1731-76; TU 14-1-1747-76; TU 14-1-1754-76; TU 14-1-1785-76; TU 14-1-1846-76; TU 14-1-1848-75; TU 14-1-1905-76; TU 14-1-1964-77; TU 14-1-2070-77; TU 14-1-2071-77; TU 14-1-2075-77; TU 14-1-2075-87; TU 14-1-2111-77; TU 14-1-2121-77; TU 14-1-2131-77; TU 14-1-2132-77; TU 14-1-2134-77; TU 14-1-2144-77; TU 14-1-2149-77; TU 14-1-2176-77; TU 14-1-2227-77; TU 14-1-2230-77; TU 14-1-2240-77; TU 14-1-225-72; TU 14-1-2260-77; TU 14-1-2261-77; TU 14-1-230-72; TU 14-123-134-95; TU 14-1-2396-78; TU 14-1-240-72; TU 14-1-2421-78; TU 14-1-2450-78; TU 14-1-2452-79; TU 14-1-2455-78; TU 14-1-2475-78; TU 14-1-2476-78; TU 14-1-2478-78; TU 14-1-2606-79; TU 14-1-2674-79; TU 14-1-2692-79; TU 14-1-2702-79; TU 14-1-2715-79; TU 14-1-284-72; TU 14-1-286-72; TU 14-1-2879-80; TU 14-1-2922-80; TU 14-1-2973-80; TU 14-130-280-96; TU 14-1-3039-80; TU 14-1-3041-80; TU 14-1-3049-80; TU 14-130-60-73; TU 14-1-3071-80; TU 14-1-3109-81; TU 14-131-195-77; TU 14-131-224-75; TU 14-131-404-78; TU 14-1-3140-81; TU 14-1-3148-81; TU 14-1-3164-81; TU 14-131-685-86; TU 14-131-755-85; TU 14-131-756-88; TU 14-131-764-88; TU 14-131-844-91; TU 14-1-3190-81; TU 14-1-3191-81; TU 14-1-3230-81; TU 14-1-3233-81; TU 14-1-3239-81; TU 14-1-3262-81; TU 14-1-3281-81; TU 14-1-3291-81; TU 14-134-277-91; TU 14-1-3490-82; TU 14-1-3528-83; TU 14-1-3546-83; TU 14-1-3547-83; TU 14-1-3587-83; TU 14-1-3622-83; TU 14-1-3639-83; TU 14-1-3652-83; TU 14-1-3660-83; TU 14-1-3686-83; TU 14-1-3760-84; TU 14-1-3768-84; TU 14-1-377-72; TU 14-1-3801-85; TU 14-1-3812-84; TU 14-1-3856-84; TU 14-1-3880-84; TU 14-1-3909-85; TU 14-1-3918-85; TU 14-1-3996-85; TU 14-1-4009-85; TU 14-1-4017-85; TU 14-1-4035-85; TU 14-1-4042-85; TU 14-1-4056-85; TU 14-1-4082-86; TU 14-1-4105-86; TU 14-1-416-72; TU 14-1-4202-87; TU 14-1-4289-87; TU 14-1-4296-87; TU 14-1-4319-87; TU 14-1-4362-87; TU 14-1-4363-87; TU 14-1-4372-87; TU 14-1-4479-88; TU 14-1-4628-89; TU 14-1-4645-89; TU 14-1-4646-89; TU 14-1-4673-89; TU 14-1-4684-89; TU 14-1-4719-89; TU 14-1-4723-89; TU 14-1-4724-89; TU 14-1-4730-89; TU 14-1-4734-89; TU 14-1-4745-89; TU 14-1-4795-90; TU 14-1-4800-90; TU 14-1-4870-90; TU 14-1-4881-90; TU 14-1-4896-90; TU 14-1-489-76; TU 14-1-490-72; TU 14-1-4913-90; TU 14-1-493-72; TU 14-1-4978-91; TU 14-1-4998-91; TU 14-1-5014-91; TU 14-1-5015-91; TU 14-1-5021-91; TU 14-1-5072-91; TU 14-1-5076-91; TU 14-1-5155-92; TU 14-1-5156-92; TU 14-1-5191-92; TU 14-1-5201-93; TU 14-1-5203-93; TU 14-1-5258-94; TU 14-1-52-71; TU 14-1-5350-97; TU 14-1-5361-98; TU 14-1-5366-98; TU 14-1-565-84; TU 14-159-252-95; TU 14-159-93-77; TU 14-1-625-73; TU 14-1-692-73; TU 14-1-756-73; TU 14-1-810-73; TU 14-1-833-74; TU 14-1-894-74; TU 14-1-895-74; TU 14-1-911-74; TU 14-1-927-74; TU 14-1-941-74; TU 14-1-952-74; TU 14-1-975-74; TU 14-226-130-92; TU 14-226-141-98; TU 14-3-1129-82; TU 14-3-1227-83; TU 14-3-1275-83; TU 14-3-1320-85; TU 14-3-1478-87; TU 14-3-1591-88; TU 14-3-1711-90; TU 14-3-1854-92; TU 14-3-396-75; TU 14-3-415-75; TU 14-3-59-72; TU 14-3-694-78; TU 14-3-696-78; TU 14-3-751-78; TU 14-3-763-78; TU 14-3-822-79; TU 14-4-3071-80; TU 302.02.095-90; TU 48-0814-11/0-83; TU 48-0815-80-92; TU 48-0815-84-92; GOST 10160-75 “Precision soft magnetic alloys. Technical conditions.”; GOST 2590-88 “Hot-rolled round steel. Assortment."; GOST 4543-71 “Rolled products from alloy structural steel. Technical conditions.”; GOST 4405-75 “Hot-rolled and forged strips made of tool steel. Assortment."; GOST 14119-85 “Rods made of precision alloys for elastic elements. Technical conditions.”; GOST 5950-2000 “Rods, strips and coils of alloy tool steel. General technical conditions.”; GOST 19265-73 “Rods and strips made of high-speed steel. Technical conditions.”; GOST 28393-89 “Rods and strips made of high-speed steel produced by powder metallurgy. General technical conditions.”; GOST 8479-70 “Forgings from structural carbon and alloy steel. General technical conditions.”; GOST 14955-77 “High-quality round steel with special surface finishing. Technical conditions.”; GOST 2590-2006 “High-rolled hot-rolled round steel products. Assortment."; GOST 2591-2006 “High-rolled square steel products. Assortment."; GOST 7417-75 “Calibrated round steel. Assortment."; GOST 4405-75 “Hot-rolled and forged strips made of tool steel. Assortment."; GOST 8559-75 “Square calibrated steel. Assortment."; GOST 8560-78 “Calibrated hexagonal rolled products. Assortment."; GOST 1133-71 “Forged steel round and square. Assortment."; GOST 5632-72 “High-alloy steels and corrosion-resistant, heat-resistant and heat-resistant alloys. Marks."; GOST 103-2006 “High-rolled hot-rolled steel strip. Assortment."; GOST 5949-75 “Sorted and calibrated steel, corrosion-resistant, heat-resistant and heat-resistant. Technical conditions.”; GOST 2879-2006 “Hot-rolled hexagonal long steel products. Assortment."; TU 14-11-245-88 “High precision shaped steel profiles. Technical conditions.”; OST 3-1686-90 “Blanks made of structural steel for mechanical engineering. General technical conditions.”; GOST 10994-74; GOST 1414-75; TU 14-1-3283-81; TU 14-1-4492-88 “Blums and hot-rolled square billets made of high-quality and high-quality carbon steel, alloyed and high-alloyed and alloys”; TU 14-1-3904-84 “Forged square and rectangular blanks made of precision alloys. Technical specifications""; TU 14-1-5277-94; TU 14-1-2252-2007; GOST 14117-85 “Tape made of precision alloys for elastic elements. Technical specifications""; TU 14-1-4693-89 “Hot-rolled and hot-rolled turned rods from structural micro-alloyed calcium-containing steels for controlled forging”; GOST 14080-78 “Tape made of precision alloys with a given temperature coefficient of linear expansion. Technical specifications""; OST 95 10441-2002 “Equipment for working with radioactive media. Welding. Basic provisions""; GOST 14081-78 “Wire made of precision alloys with a specified temperature coefficient of linear expansion. Technical specifications""; TU 14-136-344-98 “Calibrated carbon and alloyed bismuth-containing steel with high cutting machinability””; GOST 14118-85 “Wire made of precision alloys for elastic elements. Technical specifications""; GOST 801-78 “Bearing steel. Technical specifications""; TU 14-1-1213-75 “Hot-rolled and forged, square and rectangular billets made of high-quality carbon and alloy steel. Technical specifications""; TU 14-1-4487-88 “Rods made of alloyed hard magnetic steel. Technical specifications""; GOST 12766.1-90 “Wire made of precision alloys with high electrical resistance. Technical specifications""; TU 14-1-5022-91 “Rods and coils from alloys of grades 25Kh15KYUBF (EK33, 25Kh15K1) and 22Kh15KTF (EK159, 22Kh15KA). Technical specifications""; GOST 14118-85 “Wire made of precision alloys for elastic elements. Specifications" "; ST TsKBA 016-2005 “Pipeline fittings. Heat treatment of parts, workpieces and welded assemblies made of high-alloy steels, corrosion-resistant and heat-resistant steels""; GOST 12766.2-90 “Tape made of precision alloys with high electrical resistance. Technical specifications (with Amendment No. 1)""; TU 1-83-77-90; TU 14-1-3182-81 “Hot-rolled and forged rods from alloy 58NHVKTBYU-VI (EP877-VI)”; GOST 800-78 “Bearing pipes. Technical specifications""; TU 14-1-2830-79 “Rods from alloys 79NM-P, 16Kh-IP, melted by plasma-arc remelting. Technical specifications""; TU 14-1-3680-83 “Pipe billet from evacuated chromium steel grades ShKh15-V and ShKh15SG-V. Technical specifications""; TU 14-1-3911-85 “Pipe blank made of bearing steel. Technical specifications""; TU 14-1-1875-76; TU 14-1-3397-82 “Hot-rolled and forged rods made of maraging corrosion-resistant steel with increased machinability by cutting grade 04Х13Н8МТУЕ””; TU 14-1-4495-88 “High-precision round bars made of high-strength steel ATs28KhGN2AFB. Technical specifications""; TU 14-1-1054-74 “Hot-rolled sheets of hard magnetic steel grades EX3 and EX5K5. Technical specifications""; TU 14-1-2244-2005; TU 14-1-3045-80 “Rods made of corrosion-resistant steel. Brand 11Х18М-ШД double remelting (electroslag + vacuum arc). Technical specifications""; TU 14-1-3367-82 “Hot-rolled sheets from alloy grades KHN85MYU-VI (EP797-VI), KHN85MYU-ID (EP797-ID). Technical specifications""; TU 14-134-295-91 “Hot-rolled rods with subsequent grinding from corrosion-resistant steel grade A10Х16Н15Т (ChS117) with high cutting machinability””; TU 14-1-3578-83 “Cold-rolled sheets from alloy grades KHN85MYU-VI (EP797-VI), KHN86MYU-ID (EP797-ID). Technical specifications""; TU 14-1-3823-84; TU 14-1-4398-88; TU 14-1-4963-91 “Welding wire made of alloy grade Sv-KhN85MYU-VI (EP797-VI). Technical specifications""; TU 14-19-24-87; GOST 10533-86 “Cold-rolled strip made of thermobimetals. Technical specifications""; GOST 8803-89 “The thinnest round wire made of precision alloys with high electrical resistance for resistive elements. Technical specifications""; TU 14-1-1373-75 “Cold-rolled strip made of alloy 36НХТУ8М. Technical specifications""; TU 14-1-1968-77; TU 14-1-2244-2005; TU 14-123-92-2011; TU 14-1-2554-78 “Pipe blank for seamless thin-walled pipes from alloys 36NKhTYu (EI702) and 36NKhTYu5M-VI (EP51-VI). Technical specifications""; TU 14-1-2740-2010; TU 14-1-2785-79; TU 14-1-279-71 “Cold-rolled strip and cold-drawn wire from alloy 36NKhTYUM8. Technical specifications""; TU 14-1-279-72 “Cold-rolled strip made of alloy 36НХТУ8М (EP52). Technical specifications""; TU 14-1-2880-80 “Cold drawn wire from alloy 36НХТУ8М (EP52). Technical specifications""; TU 14-134-270-90; TU 14-134-357-96 “Rolled products from alloy 38NХМ-VI (ChS129-VI). Technical specifications""; TU 14-1-3853-84 “Cold-rolled strip made of precision alloy 12KhNKMTU (SP-22). Technical specifications""; TU 14-1-41-71 “Micron wire made of N80ХУД-VI alloy. Technical specifications""; TU 14-1-4456-88 “Cold-rolled strip made of alloy grade 68NHVKTYU-VI (EP578-VI). Technical specifications""; TU 14-1-4470-88 “Rods made of alloy 68NHVKTYU-VI (EP578-VI). Technical specifications""; TU 14-1-4488-88 “Cold-drawn wire from alloy grade 68NHVKTYU-VI (EP578-VI). Technical specifications""; TU 14-1-4722-89 “Cold-rolled strip made of precision alloy grade 12KhNKMTU (SP-22). Technical specifications""; TU 14-165-301-89 “Spring blanks for wind-up toys made of alloy 12HNKMTU (SP-22). Technical specifications""; TU 14-19-106-90 “Rods made of corrosion-resistant steel grade 60Х13С-ШД with standardized carbide sizes. Technical specifications""; TU 14-3-379-75; TU 14-1-2899-80 “Alloy rods. Grade 49KFA-VI vacuum induction smelting. Technical specifications""; TU 14-1-314-72 “Hot-rolled and forged rods from corrosion-resistant automatic steel grades 40Х18Н2М (EP378), 40Х18Н2М-ВД (ЭП378-ВД)”; TU 14-1-3177-81 “Cold drawn wire from alloy 38NKD. Technical specifications""; TU 14-1-3761-84 “Cold-drawn wire from alloy KhN50MGYu (EK1). Technical specifications""; TU 14-1-5029-91 “Hot-rolled and forged rods from precision alloy grade 34NKD-VI. Technical specifications""; TU 14-1-5048-91 “Forgings from precision alloy grade 34NKD-ID. Technical specifications""; TU 14-1-604-73; TU 14-1-886-74 “Rods made of non-magnetic automatic corrosion-resistant steel grade 07Х17Н16 (EP626)”; GOST R 51397-99 “Tape and wire made of special alloys for connecting and implantable elements of products for cardiovascular surgery. General technical conditions""; OST 4-020.065-78; ST TsKBA 010-2004 “Pipeline fittings. Forgings, stampings and rolled products. Technical requirements""; TU 14-1-1124-74 “Tape made of precision alloy grade 36NHTYU (EI702). Technical specifications""; TU 14-1-1129-74 “Rods made of alloy grade (EI702) 36НХТУ. Technical specifications""; TU 14-1-1285-75 “Cold-drawn wire from 40KKhNM alloy. Technical specifications""; TU 14-1-2217-2013 “Hot-rolled and hot-rolled rolled products made of alloy structural steel with high cutting machinability””; TU 14-1-2597-79 “Strip made of alloy 10SYU-VI. Technical specifications""; TU 14-1-2858-79 “Sheets made of precision alloy grade 36NHTYU (EI702)”; TU 14-134-433-2009 “Hot-rolled round steel turned with a cutter from economically alloyed steel grade AS18KhGT””; TU 14-1-3727-84 “Hot-rolled strip from precision alloys of grades 42N, 47ND. Technical specifications""; TU 14-1-4098-86 “Cold drawn wire from KhN20YUS alloy (EK11). Technical specifications""; TU 14-1-4312-87 “Cold-rolled strip (roll) in rolls from alloys 47ND and 42N. Technical specifications""; TU 14-1-4464-88; TU 14-1-4618-89 “Cold-rolled strip made of alloy 36НХТУ. Technical specifications""; TU 14-1-469-73 “Thin sheets of 16YUKH-VI alloy of vacuum induction melting. Technical specifications""; TU 14-1-899-74 “Cold drawn wire from 40KKhNM alloy. Technical specifications""; OST 1 90005-91 “Steels and alloys. Indicators of tensile strength and hardness. Layer depth during chemical-thermal treatment""; TU 14-1-1060-74 “Cold drawn wire from alloy 46ХНМ (EP630). Technical specifications""; TU 14-1-2116-77 “Sheets made of precision alloy 46ХНМ (47ХНМ-2, EP630). Specifications" "; TU 14-1-2423-78; TU 14-1-2556-78 “Forged slabs from alloy 46ХНМ (EP630). Technical specifications""; TU 14-1-2572-78 “Cold-rolled strip made of alloy 47ХНМ-VI. Specifications" "; TU 14-1-3074-80 “Rolled products, hot-rolled sheets, alloy wire and strip (EP218) and 45NХТ-P (EP218-P)”; TU 14-1-3123-81 “Slabs from alloy grade 46ХНМ (EP630). Specifications" "; TU 14-1-3124-81 “Sheets made of precision corrosion-resistant alloy. Brand 46ХНМ (EP630). Specifications" "; TU 14-1-3125-81 “Pipe blank made of precision alloy grade 46ХНМ (EP630). Specifications" "; TU 14-1-3264-81 “Rods made of alloy 32NKD-VD for vacuum arc remelting. Technical specifications""; TU 14-1-3494-82 “Rods made of bearing steel grade ШХ15СГ-Ш for railway bearings. Technical specifications""; TU 14-1-3505-82 “Tape made of alloy grade 47ХНМ-VI. Technical specifications""; TU 14-1-4131-86 “Cold drawn wire from alloy 40KNB (EP966). Technical specifications""; TU 14-1-4278-87 “Forged rods and hot-rolled sheets from alloy 12YU-VI. Technical specifications""; TU 14-1-4535-88 “Cold-rolled strip made of N50K10-IL alloy. Technical specifications""; TU 14-1-4605-89 “Hot-rolled rods made of alloy structural steel grades 17ХГ and АЦ16ХГ”; TU 14-1-801-73 “Rods made of ball-bearing steel grade ШХ20СГ. Technical specifications""; TU 14-1-918-74 “Forged rods and hot-rolled sheets from alloy 5Х14В (5ХВ14). Technical specifications""; TU 14-1-999-73 “Rods made of alloy 46ХНМ (EP630). Specifications" "; TU 14-3-1045-81 “Cold-deformed seamless pipes from alloy 46ХНМ (EP630). Technical specifications""; TU 14-3-1082-82 “Hot-pressed pipes from alloy grade 46ХНМ (EP630). Technical specifications""; TU 8009.00.001; TU 8009.00.002; TU 8009.00.022; TU 14-1-2526-78 “Pipe blank made of alloy 36NH-Sh (EP713-Sh). Technical specifications""; TU 14-1-2543-78 “Pipe blank made of alloy 36NH-Sh (EP713-Sh). Technical specifications""; TU 14-1-3125-81 “Pipe blank made of precision alloy grade 46ХНМ (EP630). Technical specifications""; TU 14-131-987-2002 “Rods with special surface finishing made of 42ХНМ alloy. Technical specifications""; TU 14-1-4422-88 “Hot-rolled and forged rods from alloys of grades 32NK-VI (EP475-VI), 32NK-EL (EP475-EL), 32NK-IL (EP475-IL). Technical specifications""; TU 14-1-4425-88 “Hot-rolled sheets, cold-rolled strip made of 32NKA alloy. Technical specifications""; TU 14-1-4743-89 “Pipe blank made of alloy 32NK-IL (EP475-IL). Technical specifications""; TU 14-1-5436-2001 “Rods made of 42ХНМ alloy. Technical specifications""; TU 14-159-215-92 “Seamless cold-deformed and hot-deformed pipes from alloy 32NK-IL (EP 475-IL). Technical specifications""; GOST 21022-75 “Chromium steel for precision bearings. Technical specifications""; GOST 4727-83 “Bearing wire. Technical specifications""; GOST 808-70 “Rolled steel tape for twisted rollers of bearings. Technical specifications""; OST 4-020.030-78; TU 1142-250-00187211-96; TU 14-1-1185-75 “Hot-rolled and forged rods from alloy 49KF. Technical specifications""; TU 14-1-1204-74 “Sheets made of 79NM alloy. Technical specifications""; TU 14-1-1271-75 “High precision shaped steel profiles. Technical specifications""; TU 14-1-1286-75 “Cold-rolled strip (roll) from alloy 29NK. Technical specifications""; TU 14-1-1306-75 “Cold-rolled micro-tape made of alloys 79NM and 77NMD. Technical specifications""; TU 14-1-1328-75 “Cold-rolled strip made of 50NP-IL alloy. Technical specifications""; TU 14-1-1500-75 “Bearing steel grade ШХ15Ф-Ш (ЭИ760-Ш) electroslag remelted. Technical specifications""; TU 14-1-1530-75; TU 14-1-1530-75 “Forgings made of steels and alloys for machine parts. Technical specifications""; TU 14-1-1708-76 “Cold-rolled strip from alloys 77NMD-VI and 80NM. Technical specifications""; TU 14-1-1740-75 “Tape (roll) made of alloy 79NM and steel grade 09Х15Н8У (Х15Н9У). Technical specifications""; TU 14-1-1833-76 “Rolled slabs from steel 09Х15Н8У (Х15Н9У), 65С2ВА, Sv-08Х19Н10Г2Б (ЭИ898) and alloy 79НМ. Technical specifications""; TU 14-1-2032-76 “Hot-rolled strips made of ball-bearing steel grade ShKh15. Technical specifications""; TU 14-1-232-72; TU 14-1-2357-78 “Pipe billet from alloy 29NK-VI and 29NK. Technical specifications""; TU 14-1-2398-78 “Roll rod made of ShKh15 steel, sorbitized from rolling heating. Technical specifications""; TU 14-1-2425-78 “Thick sheet steel. Brand ШХ15. Technical specifications""; TU 14-1-2545-78 “Slabs from precision alloys of grades 79NM and 29NK. Technical specifications""; TU 14-1-2545-78 “Slabs from precision alloys of grades 79NM and 29NK. Specifications" "; TU 14-1-2664-79 “Cold rolled strip in alloy rolls. Brand 79NM. Technical specifications""; TU 14-131-851-92 “Rolled products from precision alloys 79NM, 44NHMT, 52K13F. Technical specifications""; TU 14-132-173-88 “Calibrated ball-bearing steel grade ShKh15 with ground surface. Specifications "" "; TU 14-1-3815-84 “Steel is hot-rolled, trotted, calibrated brand ShH15 in riots. Experimental party. Specifications "" "; TU 14-1-4039-85; TU 14-1-4346-87 “Cold ribbon from an alloy 29K. Specifications "" "; TU 14-1-468-73; TU 14-1-4786-90 “A tape from a precision magnetic soft alloy of a brand 50n. Specifications "" "; TU 14-1-5088-91 “A ribbon from a precision alloy with a given temperature coefficient of linear expansion of the brand 29NK. Specifications "" "; TU 14-1-5358-98 “The rental is cold and with a special surface finish made of steel of the brand SHX15-V for cold landing. Specifications "" "; TU 14-1-699-73 “A blank of steel of the brand ShH15. Specifications "" "; TU 14-1-841-73; TU 14-1-878-74; TU 14-19-18-87 “Steel sheet hot-rolled brand shh15. Specifications "" "; TU 14-22-139-99; TU 14-3-1203-83 “Bearing pipes from vacuum steel SHX15-B. Specifications "" "; TU 14-3-256-74 “Pipes Special-Wrong-resistant cold-deformed from an alloy of brand 50n. Specifications "" "; TU 14-3-335-75 “Pipes seamless hot-rolled from steel brand ShH15. Specifications "" "; TU 14-3-972-80 “Cold-formed pipes of 29NK and 29NK-vi alloys”; TU 14-4-1112-80 “Cold ribbon made of steel SHX15 for parts of electric writing machines. Specifications "" "; TU 14-4-563-74 “Round wire made of steel of the brand ShH15-SSR for super-carbon dash bearings” ”; TU 14-1-4979-91 “Cold ribbon from the alloy of the Ev6 brand. Specifications "" "; TU 14-1-4081-86 “Pipe workpiece from the heat-resistant alloy of the brand KhN55MVC-VI (ChS57-VI)”; TU 14-1-4747-89 "Eucks from the heat-resistant alloy of the brand KhN55MVC-VI (ChS57-V)"; TU 807.2634.388-2012 “Processions processed from the alloy KhN55MVC-VI (ChS57-VI) and HN55MVC-DID (ChS57-DID)”; TU 14-1-3663-83 "Forged rods from the heat-resistant alloy of the brand KhN55MVC-vi (ChS57-VI)"; TU 14-1-4392-2013 “Skorolistovaya Cold-rolled rental from an alloy of the KH55MVC-VA brand; TU 14-1-4400-88 “Hot carpet rental from the alloy of the KhN55MVC-VA brand”; TU 14-134-436-2008 “Holstolistova rental from the heat-resistant alloy of the KhN55MVC-VA brand;

Material 40ХН2МА Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells 40ХН2МА material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, 40ХН2МА material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Heat treatment

Steel 40ХН2МА – medium-carbon alloyed hypoeutectoid steel.

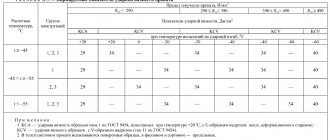

Heating hardened steels to temperatures not exceeding A1 is called tempering. Complex heat treatment consisting of full hardening (steel is heated to a temperature above A3) and high tempering

(500-680 °C) structural steels are called improvement. Improvement of this steel, in contrast to normalization, provides an increased yield strength in combination with good ductility and toughness, and high resistance to crack development. In addition, the cold brittleness threshold is reduced.

For this steel, the optimal heat treatment mode is quenching at 850°C. Hardening is carried out in water, followed by tempering at 620°C in oil.

Ac3 (820 o C)

Ac1 (730 o C) water 620 o C Mn

F+P M Sotp

Rice. 1. Heat treatment mode for steel 40ХН2МА

Decoding

Decoding of steel 40ХН2МА includes information:

- 40 – 0.4% carbon;

- X – less than 1% chromium;

- H2 – 2% nickel;

- M – up to 1% molybdenum;

- A – high quality steel (minimum amount of sulfur and phosphorus in the composition).

This is a strong, tough metal, which during heat treatment is calcined to a considerable depth. Alloying components are designed to improve strength and durability, and molybdenum facilitates heat treatment.

Chemical composition

The alloy contains a maximum of:

Each of the components improves the characteristics of 40ХН2МА steel. Chromium and nickel provide hardness and corrosion resistance, copper - viscosity and thermal conductivity, manganese and silicon - bind free iron, reduce the influence of sulfur and phosphorus.

The main physical characteristics of the metal are:

- electrical resistivity;

- Young's modulus;

- density (7850 kg/m3);

- heat capacity;

- coefficient of thermal conductivity and thermal expansion.

Depending on the heating during testing, the results may vary. This allows you to determine the optimal area of operation of the structure.

Application

Structural steel 40ХН2МА is not subject to brittle fracture after tempering, which is due to the presence of molybdenum. Due to its high strength, the material can be used for the production of structures used in production and operating under heavy loads.

The following products are widely used:

- rolls for cold rolling of alloys;

- disks and loaded parts;

- brackets;

- claw couplings;

- hardware;

- solid rolled rings;

- fittings for pipelines;

- products for the aircraft industry operating at +500 degrees.

Specifications

The high mechanical properties of 40ХН2МА are due to:

| hardness | 270 MPa; |

| yield area | 930 MPa; |

| density | 7850 kg/m3; |

| tensile elongation | 12%; |

| tensile strength | 1080 MPa. |

The cost of steel is at least 50 rubles/kg. The final price depends on delivery conditions, release form and volume.

Assortment

Products made from this alloy include:

- gears;

- bolts with a high class of responsibility;

- connecting rod shafts and covers for them;

- valves;

- crankshafts.

Production is carried out in accordance with the requirements of regulatory documents. Manufacturing involves performing a large number of technological processes, one of which is mechanical processing. It is designed to increase mechanical strength and the required appearance. In our company you can choose any type of rental.