Metals are most widely represented in the bowels of the earth. All of them, except mercury, are solid substances that have a characteristic metallic luster and the ability to transmit electricity and heat well.

They have a unique combination of strength and ductility. They can be forged, welded, drawn into wire, rolled into sheets and bars, and used for casting. Based on their chemical composition, metals are classified into ferrous and non-ferrous.

This division is based on a very simple principle - ferrous metals and alloys contain iron, while non-ferrous ones do not have it. Naturally, the difference in chemical composition also determines various physical properties.

The meaning and composition of the industry basis

The metallurgical complex consists of enterprises and plants throughout the country that produce various types of metals. For its efficient operation, about 25% of fuel and energy are used, and it accounts for up to 30% of transport traffic.

The two main directions of development of the complex are ferrous and non-ferrous metallurgy, which together represent up to 90% of all metals. The production complex consists of a number of industrial processes:

- mining, beneficiation, agglomeration and other types of ore preparation;

- activities for processing cast iron and steel;

- rolled metals and pipes;

- production of alloys;

- processing of residues from production activities.

The metallurgical industry differs from others in its rather complex production process and disproportionate scale of the work cycle. Thus, in order to obtain some types of products, it is necessary to perform 15–18 processing operations.

In addition, the metallurgy field has a well-established logistics system not only with other factories and enterprises in Russia, but also in the countries of the former Soviet Union. The complex is also distinguished by the fact that its production involves the largest number of labor resources. Now there is no larger production in the world than metallurgy.

Iron ores

In its pure form, this element of the periodic table is found in fairly small quantities in the earth's crust (only 5.5%). But there is a lot of it in various iron ores.

The most significant deposits (reserves amount to more than 30 trillion tons) are layers of ferruginous quartzites, which are more than two billion years old. They are distributed mainly in places such as South and North America, Africa, India and western Australia.

Leading heavy industry

The basis for the functioning of manufacturing production for the manufacture of various machines is ferrous metallurgy. This industry includes the receipt of raw materials, the preparation of fuel and additional elements for the production of rolled products with the products of subsequent metal processing. The main activities include:

- mining, beneficiation and agglomeration of iron, chromium and manganese ores;

- production of steel, cast iron and rolled products;

- creation of electroferroalloys;

- alloy processing process;

- coal coking;

- production of fire-resistant components;

- obtaining minor elements (magnesite, limestone, etc.);

- production of industrial products.

The main activity of enterprises consists of piggyback work, and the rest are secondary, but no less important. Today Russia occupies a leading position in the world in terms of the degree of saturation of ferrous metals production. Russian metallurgical plants produce most of the world's rolled steel and cast iron.

The bulk of large enterprises on the geographical map are located in the Siberian and Ural regions. In this territory there are 7 plants that produce 4/5 of all steel, 9/10 of cast iron and more than 4/5 of rolled products. Every year, these enterprises process 2/5 of scrap metal and 9/10 of iron ore.

The plants that produce heavy metals are much larger, but in terms of production modernization they lag behind non-ferrous metallurgy enterprises. The peculiarity of modernization is to solve the problem of production waste and reduce costs.

Many enterprises use a combined production method, for example, coking of coal is carried out together with processing.

In Russia, almost all coke (95%) is produced at metallurgical enterprises. Today, in terms of their characteristics, almost all large plants are metallurgical and energy chemical plants.

In some cities of Russia there are small factories that are engaged in conversion activities without producing pig iron. There are also small workshops that produce steel and rolled products directly at machine-building plants. If we consider all types of industry, then ferrous metallurgy with a full production cycle is the main factor for regional formation.

Ferrous metallurgy

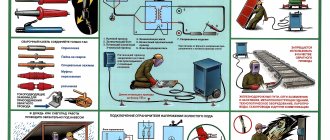

Ferrous metallurgy is based on the processing of iron, namely the ores in which it is contained. Most iron ores are natural oxides. That is why the first stage of production is the separation of iron from the oxide. Large blast furnaces are used for this. This method of producing cast iron is carried out at temperatures above 1000 degrees.

Ferrous metallurgy

In this case, the properties of the resulting raw materials directly depend on the temperature of the blast furnace and the melting time. With further processing of cast iron, steel or foundry cast iron is obtained, with the help of which blanks and products are cast.

To produce steel, iron and carbon are used, the addition of which gives the resulting alloy the desired properties. Various alloying components can also be used to achieve certain characteristics of the steel.

There are several methods for producing steel, which are based on smelting the metal in a liquid state. The following should be highlighted: open hearth, oxygen-converter and electric melting.

Each type of steel is called a grade, which indicates its composition and properties. To change the properties of steel, an alloying method is used, that is, adding additional components to the alloy. The elements most often used for such purposes are chromium, manganese, boron, nickel, tungsten, titanium cobalt, copper and aluminum. Typically, such components are added to molten steel.

But there is another method, which consists in pressing fine-grained powder of the components and then baking at high temperatures.

Non-ferrous metals

The main activities of the enterprises include obtaining raw materials, beneficiation, redistribution of non-ferrous, precious and rare metal ores, and diamond mining. The entire functioning of the industry is aimed at producing high-quality and high-tech materials.

This is achieved through the use of modern developments in science and technology in production. The list of metals produced in the non-ferrous industry is divided into classes :

- The main ones are heavy (tin, lead, copper, etc.); lungs (sodium, potassium, aluminum, etc.); small (cadmium, arsenic).

- Alloying agents: tungsten, molybdenum, tantalum.

- Noble ones - gold, silver, platinum with platinum group metals.

- Rare - zirconium, gallium, thallium, etc.

The Russian Federation has the most diverse structure of the color industry. It includes the main industries that produce copper, aluminum and rare metals. In the future development of enterprises, the main emphasis is on creating waste-free production.

Therefore, much attention is now being paid to expanding the combined technology. Thus, many companies, in addition to their main products, began to produce related construction and chemical materials. Unlike the ferrous industry, the non-ferrous industry has a high material consumption, so it is mainly located on the raw material base.

In addition, non-ferrous metal ore has a low content of useful elements. Hence, the entire technological process carried out using a combined method is explained by the need to build production in such a way as to ensure maximum extraction of useful elements from ore.

The efficiency of combining the production process is achieved not only through waste-free activities, but also through careful processing of ore. Unlike ferrous metals, non-ferrous metallurgy has more options for production location, so it does not have a clear dependence on the raw material base and the fuel and energy industry. For example, copper industry enterprises are located close to raw materials, since they contain very low amounts of useful elements.

Main mining methods

Depending on the depth of occurrence of mineral resources, one or another method of their extraction is chosen:

- Career or open path. It is used to extract metal ore, nonmetallic building materials, and coal. This is the most economical, but at the same time quite strong impact on the soil method. Which further reduces its fertility and has a harmful effect on the environment.

- Mine or underground method. It is also called closed. This method is used for deep occurrence of mineral raw materials, ores and polymetals. Its disadvantages are significant costs and a high level of production risk for miners and miners.

- Open-underground or combined method. In fact, it combines the first two and is used in cases where minerals occur both on the surface and deep in the earth's crust.

- Borehole or geotechnological method. It is used to extract raw materials in a liquid or gaseous state. Typically, it is used to extract oil and gas, sulfur and lithium, uranium and phosphorus from drilled wells, resorting to leaching, precipitation and smelting. In order to then extract through pipes the mineral resources that are so needed in the national economy.

- Dredging method. It combines mining and mineral processing. Most often it is used in the development of placer deposits of diamonds, gold, cassiterite and platinum group metals.

Aluminum production

The aluminum industry occupies one of the leading and unique positions in non-ferrous metallurgy. This fact is explained by the fact that higher quality raw materials (bauxite, nepheline) are used for metal production. The central territories where bauxite production is carried out are considered to be Boksitogorsk, Severouralsk and the Severo-Onezhskoye deposit.

Nepheline deposits are located in Kirovsk on the Kola Peninsula and in Goryachegorsk, which is located in Eastern Siberia. The difference between the minerals is that nephelines have a more complex composition. Main stages of the aluminum industry:

- alumina production;

- production of metal aluminum.

Such activities can occur both in one area and in different territories. Enterprises producing alumina try to locate as close as possible to the deposits, since this production is considered more material-intensive.

Aluminum plants are located closer to sources of mass and cheap electricity. Russia is second only to the People's Republic of China in the production of this metal. Comparative table of aluminum production in thousands of tons by countries for 2012 and 2016.

| Place | A country | 2012 | 2016 |

| 1 | China | 21500 | 31000 |

| 2 | Russia | 3950 | 3580 |

| 3 | Canada | 2900 | 3250 |

| 4 | India | 1700 | 2750 |

| 5 | UAE | 1800 | 2400 |

Areas where limestone and cheap fuel are found along with aluminum raw materials are considered optimal for the production of alumina. Such areas include Achinsk-Krasnoyarsk in Siberia and Severouralsko-Krasnoturinsky in the Urals. Enterprises for processing metals and alloys are located closer to consumers and are usually located in large industrial centers.

Fuel and energy minerals

Oil

Our country ranks seventh in the world in terms of the number of proven oil reserves. Deposits estimated at 14.1 billion tons are located in 9 oil and gas provinces:

- Volga-Ural,

- Yenisei-Anabar,

- West Siberian,

- Leno-Vilyuiskaya,

- Leno-Tunguska,

- Okhotsk,

- Pricaspian,

- North Caucasus-Mangyshlak,

- Timan-Pechorskaya,

and in 3 oil and gas regions:

- Anadyrskaya,

- East Kamchatka,

- Baltic.

The leader among domestic oil fields is Samotlor - 7.1 billion tons. The productive period for using the reserves of this liquid hydrocarbon fuel on the territory of our state is estimated at 22 years.

oil

Natural gas

Russia is the undisputed global leader in blue fuel reserves, the total volume of which is estimated at 40 billion tons with a production prospect of more than 80 years.

The largest part of it (over 75%) falls on the deposits of Siberia. The largest among them are: Urengoyskoe – 10 trillion. m3 and Yamburgskoye – 8.9 trillion. m3.

Coal

According to the reserves of this natural resource, estimated at 2.23 trillion. t, Russia is in third place. Moreover, a significant part of the deposits – 69% – is brown coal. Most of the reserves, accounting for 63% of this valuable energy resource, are located in the eastern part of the country:

- The Kuznetsk coal basin is one of the largest in the world, with gigantic reserves of hard and coking coal.

- Kansko-Achinsky (brown coal).

- Pechersky.

- South Yakutsk.

The majority of domestic coal mining - 75% - is carried out using the closed mine method, which significantly increases its cost.

coal

Oil shale

Most of the oil shale deposits are located in the European part of Russia, in the Leningrad and Samara regions. There are also large deposits in the north of the country and in Siberia.

However, they are not actively developed due to competition from more common fuels such as oil and gas. Perhaps it will be started after the main hydrocarbon reserves have been exhausted.

Uranus

In terms of reserves of this natural resource, Russia is confidently in the top ten. According to studies five years ago, its reserves amount to 507.8 thousand tons, which is a tenth of the world's uranium resources. The main deposits are concentrated in Yakutia and Buryatia and in the Trans-Baikal Territory.

Manganese

Manganese is similar to iron in terms of formation conditions and technical applications .

Sedimentary ores

It usually accompanies iron in sedimentary ores and ancient metamorphic deposits. It, like iron, the basis of ferrous metallurgy, is used to produce high-quality steels.

Vanadium

Vanadium

is also important - a frequent companion of titanium in deposits and placers, used for the production of especially strong grades of steel used in the production of armor and projectiles, in the automotive industry, and in nuclear energy.

Here, new combinations of elements in alloys are becoming increasingly important. For example, an alloy of vanadium with titanium, niobium, tungsten, zirconium, and aluminum is used in the production of rockets and in nuclear technology. And new composite materials are also prepared from mineral raw materials.

Titanium

Titanium belongs to the same technical group . It is mined from basic igneous rocks in the form of ilmenite and from placers, terrestrial and very widespread on sea beaches and shelves (Brazil, Australia, India), where its source is titanomagnetite, ilmenite and rutile.

Titanium is used in the production of special grades of steel. It is a heat-resistant, lightweight metal.

Alternative power engineering

As in ferrous metallurgy, the main region for the production of non-ferrous metals is the Urals . There are deposits of copper in the area of the city of Gai, nickel in the Orenburg region, and aluminum ores in Severouralsk. Large production centers are located in Mednogorsk (copper smelting), Kamensk-Uralsk (aluminum production), and Orsk (nickel production). The main production factor here is the availability of raw materials. But many deposits have already been greatly depleted, so enterprises operate on imported raw materials.

The second region, as well as in the iron and steel industry, is the European North . Here, on the basis of its own reserves of nickel ores, production is located in the cities of Nikel and Monchegorsk. Factories in Kandalaksha operate on aluminum ores.

In the north of Siberia there is the largest center of copper-nickel production, as well as gold production, the city of Norilsk. 50% of copper, 90% of nickel and cobalt, and practically all of Russia’s platinum and gold are produced here. The main factor of placement here is the raw material factor.

Rice. 5. the city of Norilsk is the largest center of copper-nickel production

The south of Siberia is a large aluminum production area, both from its own raw materials and imported from the Urals and Kazakhstan. Large metallurgical plants are located here in Bratsk, Krasnoyarsk, Ust-Ilimsk, Sayanogorsk, Shelekhov. The main factor for locating in this area is not so much the extraction of raw materials, but the production of cheap electricity, since aluminum smelting is a very energy-intensive process.

Far East . Lead-zinc and tin ores, as well as gold, are mined here. Tin mining areas are the Deputatskoe deposit and the Ese-Khaya deposit, lead-zinc ores in the city of Dalnegorsk, and gold in Yakutia and the Magadan region. The main factor of placement is raw materials.

Construction Materials

Natural minerals used in construction include:

- Gravel is a small, rounded stone.

- Crushed stone – sharp-angled stones, no more than 70 mm in diameter, used as filler.

- Sand is a fine-grained stone fraction up to 5 mm in size.

As well as minerals used in the production of concrete, cement and other binders.

On the territory of Russia there are 8,500 deposits of more than 100 types of non-metallic building materials. The largest of them are located in the Vyazemsk, Kirov, Moscow and Smolensk regions.

Principles of business location

Enterprises of the mining and metallurgical complex are not located randomly. They depend on the following factors of metallurgy location:

- Raw materials (physical and chemical characteristics of ores);

- Fuel (what type of energy must be used to produce metal);

- Consumer (geography of placement of raw materials, main energy sources and availability of transport routes).

Rice. 2 Fuel factor of metallurgy location