Cold gas dynamic spraying is the latest method in the field of thermal spraying. Compared to conventional thermal spray processes, cold gas dynamic spray has particular advantages because the sprayed material does not melt or melt during the process. Thus, the thermal impact on the coating and the substrate material remains low.

The high kinetic energy of the particles and the high degree of deformation when exposed to the substrate that is connected to it makes it possible to produce homogeneous and very dense coatings. The coating thickness ranges from a few hundredths of a millimeter to several centimeters.

In the resulting metal coatings, the physical and chemical properties are practically no different from the properties of the base material.

With the latest system technology, an inert gas - preferably nitrogen or helium - is supplied to the spray gun at pressures of up to 50 bar (725 psi) and heated to a maximum temperature of 1100 °C (2012 °F) in the gun body.

The subsequent expansion of the heated and highly pressurized gas in a converging-diverging nozzle to ambient pressure results in the acceleration of the process inert gas to supersonic speed and at the same time cooling the gas to a temperature below 100 °C (373 °F).

The atomized powders are injected into the converging part of the nozzle using a powder and carrier gas feeder and accelerated to a particle speed of 1200 m/s in the main gas flow.

In the highly constricted spray nozzle, particles strike the mostly untreated component surfaces, are deformed, and are converted into a highly adhesive/cohesive, low-oxide coating.

Impact of Particle Velocity on Coating Quality and Efficiency

- The coating particle has reached the minimum impact speed, which is necessary to excite the mechanism of interaction with the surface of the substrate (processed sample). This so-called “critical speed” affects the properties of the coating material.

- As the impact velocity is higher than the critical velocity, the deformation and quality of particle adhesion increase.

- If the impact velocity is too high (the "erosion rate"), more material is destroyed than added. No coating is formed.

- To form a dense and well-formed coating, the particle impact velocity must be between the critical velocity and the erosion rate.

Advantages of the technique

Despite the similarity with the gas-thermal method, gas-dynamic galvanizing has the following advantages:

- The device allows you to process parts and elements regardless of size.

- The heating temperature of the substrate does not exceed 150 degrees.

- Coating adhesion is 40-100 N/mm2. This is higher than any modern paint. Zinc does not peel off even with impacts or surface deformation.

- The thickness of the galvanizing layer varies over a wide range. Thanks to this, it can be applied evenly, making thickening in areas prone to corrosion.

- Low porosity of the coating - less than 1%

- Zinc covers the iron and acts as a protector. 50 microns of zinc provide corrosion resistance for 10 years.

Galvanization is carried out in accordance with GOST 9.316-2006 and 51163-98. The work uses guidance documents relating to zinc coatings of marine equipment and pipes of ship systems.

Individual processing

Each individual material is processed individually.

Material processing requires individual adjustment of gas temperature and pressure. The combination of these two physical parameters determines the particle speed and the quality of the coating. The range of optimal spray velocity, limited by the critical velocity and the erosion rate, is called the deposition range. Within this range, the quality of coating application is influenced by parameters.

Candidates of physical and mathematical sciences O. KLYUEV and A. KASHIRIN.

When the first metal tools appeared, it turned out that, although hard and durable, they often deteriorated under the influence of moisture. As time passed, people created mechanisms and machines, and the more advanced they became, the more difficult conditions their metal parts had to work in. Vibrations and alternating loads, enormous temperatures, radioactive radiation, aggressive chemical environments - this is not a complete list of “tests” to which they are subjected. Over time, people have learned to protect metal from corrosion, wear and other phenomena that shorten the service life of parts. Essentially, there are two approaches to providing such protection: either alloying elements are added to the base metal, which give the alloy the desired properties, or a protective coating is applied to the surface. The operating conditions of machine parts dictate the properties that coatings must have. The technologies for applying them are varied: some are common and relatively uncomplicated, others are very subtle, allowing the creation of coatings with unique properties. And restless engineers continue to invent new coatings and come up with ways to obtain them. The fate of these inventions can be happy if the coating is much superior to its predecessors in useful properties or if the technology provides a significant economic effect. The development of physicists from Obninsk combined both of these conditions.

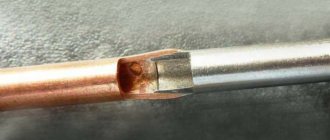

Metal particles flying at enormous speed upon collision with the substrate are welded to it, and ceramic particles compact the coating (a); stuck ceramic particles are visible on the thin section of the metal layer (b).

Diagram (above) and general view (below) of an apparatus for spraying metal coatings.

Using the device, you can apply coatings in any room and even in the field.

A negative pressure zone appears behind the critical section of the nozzle, and powder is sucked in here. Thanks to this phenomenon, it was possible to simplify the design of the feeder.

Defects in body parts (left) and the result of spraying (right): a - crack in an automatic transmission; b - cavity in the cylinder head.

Tools coated with a layer of copper or aluminum can be used in fire hazardous areas: when they hit metal objects, they do not create a spark.

TEMPERATURE PLUS SPEED

Of the methods for metallizing surfaces in modern technology, the most commonly used are galvanic deposition and immersion in a melt. Vacuum deposition, vapor deposition, etc. are used less frequently. The closest thing to the development of Obninsk physicists is gas-thermal metallization, when the applied metal is melted, sprayed into tiny droplets and transferred to a substrate with a gas stream.

Metal is melted with gas torches, electric arcs, low-temperature plasma, inductors and even explosives. Accordingly, metallization methods are called flame spraying, electric arc and high-frequency metallization, plasma and detonation gas spraying.

In the flame spraying process, a metal rod, wire or powder is melted and sprayed in the flame of a burner operating on a mixture of oxygen and flammable gas. In electric arc metallization, the material is melted by an electric arc. In both cases, metal droplets are moved to the sprayed substrate by air flow. In plasma spraying, a plasma jet generated by plasmatrons of various designs is used to heat and spray the material. Detonation gas spraying occurs as a result of an explosion that accelerates metal particles to enormous speeds.

In all cases, particles of the sprayed material receive two types of energy: thermal - from the heating source and kinetic - from the gas flow. Both of these types of energy are involved in the formation of the coating and determine its properties and structure. The kinetic energy of particles (with the exception of the detonation-gas method) is small compared to thermal energy, and the nature of their connection with the substrate and among themselves is determined by thermal processes: melting, crystallization, diffusion, phase transformations, etc. Coatings are usually characterized by good adhesive strength to the substrate (adhesion) and, unfortunately, low uniformity, since the spread of parameters across the cross section of the gas flow is large.

Coatings created using gas-thermal methods have a number of disadvantages. These include, first of all, high porosity, unless, of course, the goal is to specifically make the coating porous, as in some parts of radio tubes. In addition, due to the rapid cooling of the metal on the surface of the substrate, high internal stresses arise in the coating. The workpiece inevitably heats up, and if it has a complex shape, it can “lead.” Finally, the use of flammable gases and high temperatures in the work area complicate measures to ensure worker safety.

The detonation-gas method stands somewhat apart. During an explosion, the particle speed reaches 1000-2000 m/s. Therefore, the main factor determining the quality of the coating is their kinetic energy. Coatings are characterized by high adhesion and low porosity, but explosive processes are extremely difficult to control, and the stability of the result is almost impossible to guarantee.

SPEED PLUS TEMPERATURE

The desire to create more advanced technology has been around for a long time. The engineers had a goal - to preserve the advantages of traditional technologies and get rid of their shortcomings. The direction of the search was more or less obvious: firstly, coatings should be formed mainly due to the kinetic energy of metal particles (the particles should not be allowed to melt: this will prevent heating of the part and oxidation of the substrate and coating particles), and, secondly, the particles should acquire high speed not due to explosion energy, as in the detonation-gas method, but in a jet of compressed gas. This method was called gas-dynamic.

The first calculations and experiments showed that it is possible to create coatings with quite satisfactory characteristics in this way if helium is used as the working gas. This choice was explained by the fact that the gas flow speed in a supersonic nozzle is proportional to the speed of sound in the corresponding gas. In light gases (hydrogen was not considered due to its explosiveness) the speed of sound is much higher than in nitrogen or air. It is helium that would accelerate metal particles to high speeds, giving them kinetic energy sufficient to attach to the target. It was believed that the use of heavier gases, including air, was doomed to failure.

The work of experimental sputtering installations gave good results: particles from most industrially used metals, accelerated in a helium jet, adhered well to the substrate, forming dense coatings.

But the engineers were not completely satisfied. It was clear that equipment using light gases would inevitably be expensive and could only be used in enterprises that produce high-tech products (only there there are lines with compressed helium). And compressed air lines are available in almost every workshop, every car service center, and repair shops.

Numerous experiments with compressed air seemed to confirm the worst expectations of the developers. However, intensive search allowed us to find a solution. Coatings of satisfactory quality were obtained when the compressed air in the chamber in front of the nozzle was heated, and fine ceramics or hard metal powder was added to the metal powder.

The fact is that when heated, the air pressure in the chamber increases in accordance with Charles’s law, and therefore the flow rate from the nozzle also increases. Metal particles that have gained enormous speed in a gas stream are softened when they hit the substrate and welded to it. Ceramic particles play the role of microscopic sledgehammers - they transfer their kinetic energy to the underlying layers, compacting them, reducing the porosity of the coating.

Some ceramic particles get stuck in the coating, others bounce off it. True, this method produces coatings only from relatively ductile metals - copper, aluminum, zinc, nickel, etc. Subsequently, the part can be subjected to all known methods of mechanical processing: drilling, milling, sharpening, grinding, polishing.

THE MAIN CONDITION IS SIMPLICITY AND RELIABILITY

The efforts of technologists will be in vain if designers cannot create simple, reliable and economical equipment in which the process invented by technologists would be implemented. The basis of the apparatus for spraying metal powders is a supersonic nozzle and a small-sized electric compressed air heater capable of raising the flow temperature to 500-600 o C.

The use of ordinary air as a working gas made it possible to simultaneously solve another problem that faced the developers of light gas systems. We are talking about introducing sprayed powder into a gas stream. To maintain tightness, the feeders had to be installed up to the critical section of the nozzle, that is, the powder had to be fed into a high-pressure area. Purely technical difficulties were aggravated by the fact that, passing through the critical section, metal particles caused wear of the nozzle, worsened its aerodynamic characteristics, and did not allow stabilization of coating application modes. In the design of the apparatus with an air jet, engineers used the principle of a spray gun, known to everyone from school experiments in physics. When a gas passes through a channel of variable cross-section, its speed in a bottleneck increases, and the static pressure drops and may even be below atmospheric pressure. The channel through which the powder came from the feeder was located in just such a place, and the powder moved into the nozzle due to air suction.

As a result, a portable apparatus for applying metal coatings was born. It has a number of advantages that make it very useful in various industries:

to operate the device, you only need an electrical network and an air line or a compressor providing a compressed air pressure of 5-6 atm and a flow of 0.5 m 3 /min;

when applying coatings, the substrate temperature does not exceed 150 o C;

coatings have high adhesion (40-100 N/mm 2) and low porosity (1-3%);

the equipment does not emit harmful substances and radiation;

the dimensions of the device allow it to be used not only in the workshop, but also in the field;

Coatings of almost any thickness can be sprayed.

The installation includes a sprayer itself weighing 1.3 kg, which the operator holds in his hand or secures in a manipulator, an air heater, powder feeders, a unit for monitoring and controlling the operation of the sprayer and feeder. All this is mounted on a rack.

We also had to work hard to create consumables. Industrially produced powders have too large particle sizes (about 100 microns). A technology has been developed that makes it possible to obtain powders with grains of 20-50 microns in size.

FROM SPACE VEHICLES TO SEEDERS

The new method of spraying metal coatings can be used in a wide variety of industries. It is especially effective during repair work, when it is necessary to restore areas of products, for example, to repair a crack or a sink. Thanks to the low temperatures of the process, it is easy to restore thin-walled products that cannot be repaired in any other way, for example by surfacing.

Since the spraying zone has clear boundaries, the sprayed metal does not fall on defect-free areas, and this is very important when repairing parts of complex shapes, such as gearbox housings, engine cylinder blocks, etc.

Sputtering devices are already used in the aerospace and electrical industries, at nuclear power facilities and in agriculture, in auto repair plants and in foundries.

The method can be very useful in many cases. Here are just a few of them.

Restoration of worn or damaged surface areas.

Using spraying, parts of gearboxes, pumps, compressors, lost wax casting molds, and molds for the production of plastic packaging that are damaged during operation are restored. The new method has become a great help for workers at auto repair plants. Now, literally “on their knees,” they repair cracks in cylinder blocks, mufflers, etc. Without any problems, they eliminate defects (cavities, fistulas) in aluminum castings.

Elimination of leaks.

The low gas permeability of coatings makes it possible to eliminate leaks in pipelines and vessels when sealing compounds cannot be used. The technology is suitable for repairing containers operating under pressure or at high and low temperatures: heat exchangers, car radiators, air conditioners.

Application of electrically conductive coatings.

Sputtering makes it possible to apply copper and aluminum films to a metal or ceramic surface. In particular, the method is more cost-effective than traditional methods for copper plating of current-carrying busbars, galvanizing of contact pads on grounding elements, etc.

Anti-corrosion protection.

Films made of aluminum and zinc protect surfaces from corrosion better than paint and varnish and many other metal coatings. The low productivity of the installation does not allow processing large surfaces, but it is very convenient to protect such vulnerable elements as welds. By spraying zinc or aluminum, it is possible to stop corrosion in places where “bugs” appear on the painted surfaces of car bodies.

Restoration of plain bearings.

Babbitt liners are usually used in plain bearings. Over time, they wear out, the gap between the shaft and the bushing increases and the lubricant layer is damaged. Traditional repair technology requires either replacing the liner or welding defects. And spraying allows you to restore the liners. In this case, ceramics cannot be used to compact the layer of sprayed metal. Solid inclusions will cause the bearing to fail within a few minutes after the start of operation, and the surfaces of both the bushings and shaft will be damaged. I had to use a special design nozzle. It allows the coating of pure babbitt to be applied in the so-called thermokinetic mode. Powder particles immediately beyond the critical section of the nozzle are accelerated by a supersonic air flow, then the flow speed sharply decreases to transonic. As a result, the temperature rises sharply, and the particles are heated almost to the melting point. When they hit the surface, they are deformed, partially melt and adhere well to the underlying layer.

NOTE FOR SPECIALISTS

Literature

Kashirin A.I., Klyuev O.F., Buzdygar T.V. Device for gas-dynamic application of coatings from powder materials.

RF patent for invention No. 2100474. 1996, MKI6 S 23 S 4/00, publ. 12/27/97. Bulletin No. 36.

Kashirin A.I., Klyuev O.F., Shkodkin A.V. Method for producing coatings.

RF patent for invention No. 2183695. 2000, MKI7 C 23 C 24/04, publ. 06.20.02. Bull. No. 17.

The contact details of the developers and the conditions for purchasing their technologies or products can be found in the editorial office.

Purchase and sale of business equipment

- home

- Information articles

- Technologies

- “Defense Industry” shared a method for restoring metal products

By the way, Obninsk engineers have already developed several modifications of DIMET installations. Considering the wide demand for this equipment, both manual and automated cold gas dynamic spraying devices are now being mass-produced, which allows them to be used in industry, the oil and gas industry, as well as in small businesses for processing small parts. Moreover, there is nothing particularly complicated in the technology itself. To operate the complex (in addition to the material for spraying), only compressed air is required (supplied at a pressure of 0.6-1.0 MPa and a flow rate of 0.3-0.4 m3/min.) and a 220 V power supply.

Now let's talk about the advantages and disadvantages of the method. Metal spraying equipment from China? Firstly, unlike the gas-thermal method, CGN can be effectively used at normal pressure, in any temperature range and humidity level.

Secondly, it is absolutely environmentally safe. Thirdly, due to its high speed, it can also be used for abrasive cleaning of surfaces. Well, the only drawback of the technology is the ability to apply coatings only from relatively ductile metals, such as copper, aluminum, zinc, nickel, etc.

Methods of galvanizing metal structures

Six methods are used to galvanize a metal surface:

- Hot galvanizing. Steel and cast iron products are dipped into molten zinc and then removed. The remaining layer of 40-80 microns on them reliably protects the metal. Before the operation, the surface is thoroughly cleaned and coated with flux, which ensures the adhesion of zinc.

- Cold galvanizing. The method involves applying an electrolytic solution of zinc in a volatile liquid - galvanol, zincnol, cynottern, cynotane - to the parts. The coating is applied to the steel using a spray gun. The solvent evaporates, and the zinc settles on the surface. This method provides a high degree of adhesion without mandatory fluxing. Surface preparation consists of removing dirt and rust. This way you can galvanize structures and parts without any size restrictions. The only drawback of the technique is the matte gray color of the surface.

- Galvanic galvanizing. Zinc plates (anodes) and steel parts (cathodes) are immersed in a bath of electrolyte. Under the influence of current, zinc ions dissolve in the electrolyte and settle on the iron in a layer 4-20 microns thick. The resulting surface has an attractive appearance, but is not protected from abrasion. Galvanic (electrolytic) galvanizing has a low price and is used to protect fasteners, decorative elements and other metal products. It is used for galvanizing aluminum.

- Diffusion galvanizing. The technique is based on the ability of zinc to evaporate from the powder and penetrate into the upper layer of iron, forming a reference. The phenomenon of diffusion is observed under two conditions: a temperature of 290-400 degrees and connecting steel parts as an anode. The process takes place at reduced pressure (0.1 MPa). Thermal diffusion galvanizing is used only with small objects, and the zinc merges with the metal and does not form a shiny film.

- Gas thermal galvanizing. Zinc in the form of powder or wire is fed to the burner nozzle, melts in the gas stream and settles on the surface of the steel or cast iron product. The drops are deformed when they hit the surface and form a porous “scaly” coating. Paint is used to fill micropores. This combined coating has high adhesion and is highly resistant to aggressive environments.

- Gas-dynamic galvanizing of metal structures in a compressed gas flow. This new method is similar to the gas-thermal method, but has significant advantages. specializes in it. The technology deserves detailed consideration.

Scope of application of CGN

I would like to dwell in more detail on the areas of use of cold gas dynamic spraying technology with powder materials in order to clearly show how in demand it is today.

Elimination of defects, restoration of surfaces and sealing

All of this is work that even small businesses can do. For example, in small workshops you can repair parts made of light alloys (parts of an automobile structure, for example), primarily aluminum and aluminum-magnesium. Moreover, defects that arose both during the production process and during operation are easily eliminated.

And the absence of strong heating and low energy of the method make it possible to repair even thin-walled products.

CGN is also excellent for restoring worn surfaces. For example, such a labor-intensive process as “building up” metal in bearing seats can now be carried out even by small enterprises, not to mention restoring sealing (when the use of liquid sealants is impossible) in pipelines, heat exchangers or vessels for working gases and liquids.

High-precision restoration of parts of various mechanisms, current conduction

CGN

very effective in repairing complex products that require precise restoration of geometric parameters, elimination of hidden defects, but at the same time maintaining all operational characteristics, as well as presentation. That is why this method is actively used in the military-industrial complex, railway and aviation industries, agriculture, gas pumping, etc.

You cannot do without this technology in creating contact pads. Prices for metal spraying equipment? Due to the possibility of easy coating on any metal, ceramic and glass surfaces, CGN is also used in the production of electrical products. For example, in copper plating processes, creating power current-carrying networks, applying current leads, making sublayers for soldering, etc.

Anti-corrosion treatment and elimination of deep defects

Spraying a so-called anti-friction coating is a highly effective way to get rid of local damage (deep chips, burrs, scratches). This allows you to avoid the procedure of complete refilling or even replacing the product, which, of course, is not economically profitable.

And in anti-corrosion treatment and protection against high-temperature corrosion of various communications, this method has no equal at all. By the way, various modifications of DYMET ®

provide high-quality processing of the inner surface of pipes with a diameter of 100 mm and a length of up to 12 m.

Additional Information:

Heat-resistant coatings are applied using the gas-dynamic method, which provide protection up to 1000-1100 degrees Celsius. Electrical conductivity is on average 80-90% of the electrical conductivity of the bulk material. Corrosion resistance depends on the characteristics of the aggressive environment.

The operation of DYMET equipment, developed and mass-produced by the Obninsk Powder Spraying Center (OTsPN LLC), is based on the effect of fixing metal particles, if they move at supersonic speed, on the surface upon impact with it, gas-dynamic spraying of metals DYMET. The technology makes it possible to apply metal coatings not only to metals, but also to glass, ceramics, stone, and concrete. To date, DYMET technology makes it possible to apply coatings of aluminum, zinc, copper, tin, lead, babbitt, nickel and apply them not only to metals, but also to glass, ceramics, stone, and concrete.

Plakart specialists produce coatings using the gas-dynamic method for industrial equipment (for example, in the photo - anti-corrosion coating of a heat exchanger without dismantling). In addition, we supply turnkey cold gas dynamic spraying plants (setup, service, training).

Depending on the composition of the consumable material (powder) and changes in its application modes, you can obtain a homogeneous or composite coating with a solid or porous structure and its own functional purpose. This can be: restoration of the geometry of the product, strengthening and protecting the metal from corrosion, increasing the thermal and electrical conductivity of the material, as well as the formation of a wear-resistant coating that can withstand exposure to chemically active environments, high thermal loads, etc.

In the description of Browning's invention, these problems are discussed, but not resolved. A way out of this situation is the spraying method, in which the powder is not heated to a molten state. The idea of the possibility of “cold welding” of small metal particles during high-speed collision with a hard surface was expressed in Shestakov’s invention back in 1967. The proposal for cold welding of particles in a dynamic mode was not developed at that time.

Equipment for cold gas-dynamic spraying of metals? Because To implement the cold spraying mode, new proposals for the design of the nozzle assembly were needed.

Gas-dynamic spraying is a technology for applying a metal coating to various materials and products for protective or decorative purposes, in which the formation of a surface layer occurs due to the impact of particles of the applied substance on the surface of the coated workpieces. Gas-dynamic spraying can be cold (CGN) and pulsed (IGN). In the first case, the particles are not heated, and their acceleration is ensured using a supersonic gas flow. In the second, average heating and acceleration of particles occurs by a series of shock waves of a fixed frequency.

Why galvanizing

Zinc differs from iron by a higher negative potential (0.2-0.3 mV). Therefore, the zinc coating acts as an anode and protects the steel at the electrochemical level. This metal dissolves very slowly in electrolytes contained in urban and industrial atmospheres, sea water, and wet concrete. Therefore, it plays the role of an effective protector, applied in a thin layer over the surface of the structure that requires protection.

The thickness of the layer is determined based on the degree of aggressiveness of the environment in which the product must be used. Additional anti-corrosion resistance is obtained using a paint coating laid on a layer of zinc. This solution greatly increases protection and provides an attractive appearance.

Enterprises in the Moscow region

Moscow region, Sergiev Posad, Red Army Ave., 212B, bldg. 8

Experience (years): 11

Employees:

20

Area (m²):

1400

Machines:

30

Slotting Tool sharpening Countersinking holes Gear shaping Gear hobbing Gear grinding work Jig boring work Thread rolling Thread cutting Surface grinding work Reaming holes Locksmith work Automatic lathe work Electrical discharge machining Hardening ka HDTV Volume hardening Aluminizing Anodizing Gas-dynamic spraying Oxidation Cementation Laser cutting Plasma cutting Gas welding Gas-press welding Diffusion welding Arc-press welding Resistance welding Forge welding Robotic welding Manual arc welding Submerged arc welding Thermite welding Powder coating Working with stainless steel Ultrasonic testing

Moscow region, Istra, st. Panfilova, 11

Experience (years): 61

Employees:

500

Area (m²):

10000

Machines:

86

Horizontal boring work Countersinking of holes Jig boring work Cylindrical grinding work Mechanical processing on a machining center Thread rolling Thread cutting Surface grinding work Broaching Reaming holes Thread grinding work Drilling holes on CNC machines drilling holes on universal machine tools Locksmith work Turning on CNC machines Turning on universal machines Automatic lathes Milling on CNC machines Milling on universal machines Honing Slitting milling Electrical discharge machining Dispersion hardening High-frequency hardening Normalization Volume hardening Metal annealing Metal tempering Surface hardening Sorbitization Metal improvement Boroalitizing Gas dynamic spraying Gas thermal spraying Electroplating with copper (copper plating, copper plating) Electroplating with nickel (nickel plating) Electroplating with chromium (chrome plating) Electroplating with zinc (zinc plating, galvanizing) Carbonitration Nitrocarburizing Thermal diffusion galvanizing Metal etching Chemical phosphating Chromoalitizing Chromosiliconization Laser cutting ka Shaped cutting of pipes Rolling of sheet metal metal Profile rolling Rolling of rod metal Profile bending Bending of rod metal Pipe bending Argon (argon arc) welding Gas welding Gas press welding Contact welding Metal cutting Sheet stamping Metal perforation Metal punching Rolling Manufacturing of parts according to customer drawings Manufacturing of non-standard metal structures Laser engraving Aluminum processing Titanium processing Painting brush painting spray gun Powder painting Working with stainless steel Working with galvanized steel

Moscow region, Mytishchi district, Krasnaya Gorka village, st. Shkolnaya, 38

Experience (years): 6

Employees:

?

Area (m²):

?

Stankov:

?

Turning on CNC machines Disperse hardening High-frequency hardening Cryogenic treatment Normalization Volume hardening Metal annealing Metal tempering Surface hardening Sorbitization Metal improvement Nitriding Aluminizing Anodizing Boriding Boronating Gas dynamic spraying Gas thermal spraying Electroplating with copper (copper plating, copper plating) Electroplating with nickel (nickel plating) Electroplating chrome (chrome plating) Electroplating with zinc (zinc plating, galvanizing) Carbonitration Multi-layer plating with copper and nickel Multi-layer plating with copper, nickel and chromium Nitrocarburizing Oxidation Plating Siliconizing Thermal diffusion galvanizing Metal pickling Chemical phosphating Chromo-alitizing Chromo-silicining Cementation Cyanidation Electrochemical metal polishing Gas/gas-flame /oxygen cutting Waterjet cutting Laser cutting Plasma cutting Transverse cutting of coiled steel Longitudinal cutting of coiled steel Longitudinal-transverse cutting of coiled steel Cutting reinforcement Cutting on a band saw Cutting with press shears Cutting on guillotine shears Figured cutting of pipes Rolling of sheet metal Profile rolling Rolling of bar metal Pipe rolling 3D bending pro sheet metal bending dies Press bending Profile bending Rod metal bending Pipe bending Argon (argon arc) welding Gas welding Gas press welding Diffusion welding Arc press welding Contact welding Forge welding Laser welding Surfacing Soldering Semi-automatic arc welding Robotic welding Manual arc welding Reinforcement welding Explosion welding Semi-automatic welding flux layer Friction welding Welding pipes Thermite welding Ultrasonic welding Chemical welding Cold welding Electron beam welding Drawing Metal cutting Forging Sheet stamping Volume stamping Metal perforation Straightening of flat rolled metal Metal pressing Metal punching Metal rolling Rolling-drawing Rolling-pressing Punching Rolling Metal cutting on a coordinate-punching press Khudozhe natural forging Visually -measurement control Manufacture of parts according to customer samples Manufacture of parts according to customer drawings Manufacture of non-standard metal structures Manufacture of standard metal structures Inspection by penetrating substances Laser engraving Magnetic particle testing Plasma marking Aluminum processing Tumbling drum processing Titanium processing Rewinding of metal rolls Sandblasting Brush painting Spray gun painting Powder forged painting Working with reinforcement Working with stainless steel Working with galvanized steel Development of 3D models from drawings Ultrasonic thickness gauging Ultrasonic testing Chemical analysis

Gas dynamic spraying

The main goal of gas-dynamic metal spraying is to impart certain properties to the surfaces of workpieces. This procedure is performed not only for metal workpieces, but also for other materials. It is aimed at increasing strength characteristics, electrical and thermal conductivity. This technology provides protection against corrosion and restores geometric dimensions. Enterprises providing gas-dynamic metal spraying services in Moscow

, cope with this task perfectly, because they have high-tech equipment at their disposal.

In most cases, surfaces are metallized, and the applied coatings have excellent adhesive properties. The adhesion to the base is as reliable as possible, and the products gain additional strength. Only metal powders or substances containing, in addition to metal, also a ceramic component in certain dosages can be sprayed. This significantly reduces the cost of the powder coating formation technique and does not affect its characteristics. The essence of the cold gas-dynamic spraying technique is to apply and fix solid metal particles or mixtures of materials on the surface of elements. Their size is 0.01-50 microns. They accelerate to the required speed in air, ozone or helium. Such material is called powder.

These are aluminum particles, nickel particles, combinations of aluminum with zinc. The medium used to mix the material can be hot or cold. In the first case, the maximum heating is 700 degrees. When interacting with the surface of the product, a lamellar transformation takes place, the kinematic energy is transformed into adhesive and thermal energy. Due to this, a durable surface layer is formed. The powder is applied not only to metal surfaces, but also to concrete, glass, ceramic, and stone. This significantly expands the scope of use of the technique for forming surfaces with specific properties.

Gas dynamic spraying can be high or low - this depends on the pressure level. In the first case, the working medium that moves the powder is nitrogen and helium. Moving metal particles have a pressure of over 15 atm. In the second case, compressed air is used, supplied at a pressure of no more than 10 atm. The differences between these types also lie in the heating power and the consumption of the working medium. Spraying is performed in several stages, including:

- Preparing the surface for applying powder (using a mechanical or abrasive method).

- Heating the working environment to the required temperature.

- Supply of heated gas into a special nozzle under the required pressure (gas is supplied along with the powder).

- The powder acquires enormous speed and comes into contact with the surface of the product.

The cost of gas-dynamic metal spraying services in the Moscow region is quite affordable.

Supersonic electric arc metallization

The cost of restoring parts using electric arc metallization (EDM) is 2.5...6 times lower than using thermal spraying methods. The heating of engine crankshafts during EDM does not exceed 100...120 °C. The process is highly productive.

The research and production enterprise "Motor" (Kazan) has developed an electric arc metallizer, which includes a wire feed mechanism, a spray head, and a control panel.

The metallizer has increased electrical power, which is necessary to create an energy-intensive two-phase (air - particles of sprayed material) jet. The high speed, temperature and concentration of the metallization jet is ensured by the spray head. Various options for creating metallization jets with high temperature and kinetic parameters were tested, including the use of propane combustion in a special chamber. As a result of the work and gas-dynamic calculations, a spray head was created that provides a highly concentrated supersonic metallization jet with a half-angle of expansion of 4.5...6° and uses only compressed air.

Flux-cored wires containing chromium, aluminum, manganese and other alloying elements are used as sprayed material. The use of flux-cored wires allows one to widely regulate the chemical and phase composition of coatings and, accordingly, the performance properties of coatings.

The results of studies of the properties of coatings depending on the speed of air flow from the nozzle are given in Table. 1.

Table 1. Properties of coatings depending on the speed of air flow from the nozzle of a supersonic electric arc metallizer

| Coating properties | Unit | Estimated speed of air outflow from the metallizer, m/s | |||

| 210 | 372 | 520,5 | 609,3 | ||

| Hardness | H.R.C. | 56 | 46 | 42 | 39 |

| Adhesion | MPa | 32 | 43 | 59 | 68 |

| Porosity | % | 12,1 | 5,8 | 3,9 | 3,6 |

| Carbon content | % | 0,32 | 0,21 | 0,13 | 0,11 |

As can be seen from table. 1, the adhesion of the coating increases with increasing flow rate of the metallization jet.

The microstructure of the coating undergoes significant changes with increasing particle speed. At subsonic air flow velocities, the microstructure of the coating is coarse-grained, with a large number of pores. Most particles have an elongated, deformed shape. As the air flow rate increases, coatings have an increasingly fine microstructure, and porosity decreases. The thickness of the coating has a uniform structure, the transition zone is dense. Thin oxide films are observed.

Research has established that the coating obtained under optimal spraying conditions has wear resistance no lower than hardened steel 45.

Supersonic electric arc metallization is used to restore diesel crankshafts with wear of up to 4 mm per side. The cost of restoration is 25...40% of the cost of a new crankshaft.