Features of application technology

Using dot-impact markers, indelible, clearly visible markings that are resistant to aggressive environments are applied. No surface preparation is required; they can be smooth, convex or concave. After coloring, the information remains readable. It is applied by point impact on the surface of a carbide needle (carbide, tungsten carbide). The movement of the needle is ensured by an impact drive built into the marker, which can be:

- electromagnetic;

- pneumatic.

The equipment is controlled by a controller - automated striking of points occurs according to a predetermined software-controlled algorithm. Wear is determined by the intensity of use of the marker, air pollution in the room, and the hardness of the surfaces being treated. With regular maintenance (lubrication/cleaning of parts), the service life of the device increases significantly.

When operating impact-point equipment, the material does not evaporate, chips and debris are not formed, and the weight of the product does not decrease. The diameter of the recesses depends on the size of the working tool - many models provide the ability to change needles.

Advantages of impact dot marking

• the method is applicable to most products that are used in industrial production; • it is impossible to destroy the stamp without damaging the surface, which the buyer will immediately notice; • high resistance to environmental influences during storage, transportation and operation; • the code can be colored – this will not interfere with the identification of the product; • the surface does not need to be specially prepared; • can be marked on dirty, wet and uneven surfaces; • fast way. Immediately after labeling, products can be stored or prepared for transportation; • hot surfaces can be marked; • no deformation or heating of the product, which is important for plastic; • no consumables are required, because the needle life is very high - up to a million strokes; • the equipment does not require special operating conditions different from the conditions of the production premises in which it is located.

Software

Computer software has significantly expanded the capabilities of needle-impact marking: • editing old images and creating new ones; • storing in memory a large amount of information by type; • full automation of equipment built into the production line. The operator only enters the required type of mark and also carries out maintenance; • the program independently changes operational information by time, date, shift number, etc.; • some devices are equipped with chips that inform about a breakdown or remind you to carry out maintenance.

Differences in application technologies

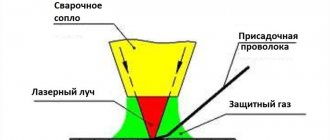

The impact-point method is based on several technologies for applying information:

- point – separate depressions of a given depth are formed;

- continuous - thanks to the vibrating movement of the needle, many indentations are made with a minimal step between them (the points merge into a line);

- deep - high impact power allows you to increase the depth of penetration of the needle tip, this technology is used when working with products made of very hard metals and with parts that will subsequently be painted;

- drawing - the impact-point equipment does not make individual indentations, but draws a line (other needles are used, shavings are formed in a small amount, the image is clearer).

Benefits of technology

The needle impact force is programmable, which allows you to take into account the characteristics of the material being marked. Other advantages of the technology:

- it is suitable for products made from materials of varying degrees of hardness;

- the marking is not erased and cannot be changed;

- the information is easy to read even after applying a coating (varnish, paint) to the marked surface;

- It is allowed to apply information to hot surfaces and to products of different shapes;

- work is possible in dusty conditions - there are no increased requirements for the room where the equipment is used.

Appendix 1 (recommended). DESIGNATIONS OF CONTENTS AND METHODS OF APPLYING MARKINGS AND STAMPS

DESIGNATIONS OF CONTENTS AND METHODS OF APPLYING MARKINGS AND STAMPS

1. The contents of the marking are indicated by the letter designations given in Table 1.

Trademark, name of the manufacturer

Product designation according to the main design document

Product serial number*

Heat number, serial number in the heat

Signs of polarity, direction of rotation, direction of fluid flow, etc. data necessary for installation

________________ * The product number also refers to the batch or series number.

2. The contents of the mark are indicated by the letter designations given in Table 2.

Tests (control): mechanical, hydraulic, pneumatic, electrical, hardness, etc.

3. Methods of applying markings or brands are indicated by the letter designations given in Table 3.

Method of applying markings or stamps

By casting or pressure (pressing, stamping, etc.)

Note. If a marking or stamp can be applied in any way, then the method of application is not indicated.

4. Designations and methods of applying markings and stamps are indicated on the inclined section of the leader line.

AN EXAMPLE OF APPLYING on a drawing the designations of the serial number of a product by impact and the mark of final acceptance with paint, if all the data on marking and stamping are available in the technical specifications for the product, is shown in Drawing 1.

In this case, in the technical requirements of the drawing, an entry is made like: “3. Mark and brand according to specifications. ".

AN EXAMPLE OF APPLYING on a drawing a designation of a material grade - with paint, a product designation, its serial number and a trademark - using the foundry method, if it is necessary to indicate in the drawing data on the location, method of application and font of the marking that is not in the technical specifications, is shown in Figure 2.

In this case, in the technical requirements of the drawing, an entry is made according to the type:

a) if the markings are made in different fonts, -

"4. Mark according to specifications. font GOST. ".

"5. Mark according to specifications. Chl - in font. GOST. Nl - in font. GOST. ".

"6. Mark according to specifications. font GOST. ":

b) if the markings are made in the same font, -

"4. Mark according to specifications. font GOST. ".

APPENDIX 1. (Introduced additionally, Amendment No. 1).

Types of markers

Manufacturers produce industrial equipment that differs:

- dimensions and weight;

- window sizes;

- the force of impact (depth of the point), the step between the recesses;

- range of supported fonts;

- power consumption;

- image format.

The following types of markers can be distinguished:

- portable - they run on battery or mains power, are lightweight, and are suitable for marking large items and working in hard-to-reach places;

- stationary (desktop) - such models are installed permanently (on a column), suitable for serial and individual marking of small and medium-sized products, information is applied to flat and cylindrical workpieces;

- integrated - such models are built into production lines, they are characterized by high productivity (marking speed is about 5 characters per second), work is carried out with products made from materials of different hardness.

MARKING

IPC PUBLISHING HOUSE OF STANDARDS Moscow

INTERSTATE STANDARD

MECHANICAL ENGINEERING AND INSTRUMENT ENGINEERING PRODUCTS

Marking

Machine building and instrument making products.

MKC 01.080.30 OKSTU 4108, 4109

By Decree of the USSR State Committee on Standards dated February 18, 1986 No. 366, the implementation date was set as 01/01/87

This standard applies to the marking of mechanical and instrument engineering products (hereinafter referred to as products), applied directly or in the form of applied elements to products of all climatic versions in accordance with GOST 15150-69.

The standard establishes technical requirements for marking and methods for quality control of marking.

This standard establishes requirements for products manufactured for the needs of the national economy and export.

DEFINITIONS, CLASSIFICATION

1.1. Marking - trademarks, symbols, inscriptions and images applied to the product and providing passport, warning, instructional and other brief information about the product and its manufacturer, as well as data necessary for the installation and operation of the product.

1.2. Trademarks are designations registered in accordance with the established procedure that serve to distinguish the goods of one enterprise from similar goods of other enterprises. Trademarks can be verbal, figurative, three-dimensional, combined and others. A trademark must be originally designed and have an identifying, representative and advertising character. Registration of trademarks in the USSR and abroad is carried out in the manner established by the USSR State Committee for Inventions and Discoveries.

Labeled materials

Work is carried out with the following materials:

- any types of metals and alloys, including cast iron and steel;

- hard plastics.

Using impact-point equipment the following are applied:

- VIN codes;

- logos;

- letters and numbers;

- various symbols;

- barcodes and QR codes.

Plates, cases, cylinders, nameplates, pipes, barrels, storage tanks, bearings, as well as other parts and other finished products are marked.

TOP 5

Industrial markers are produced by different companies. The products of Sic-marking, Markn'Stamp, Brady, Rusmark are popular among consumers.

Sic-marking e10-c153

A high-performance stationary marker from SIC-Marking allows you to work with any type of surface. The maximum height of the workpiece is 25 cm (the device is suitable for marking parts of different heights). Depth – 0.5 mm.

Information is applied at a speed of 5 characters per second. Up to 3,000 markings are performed throughout the day, with the possibility of increasing this number to 4,500. The equipment is easy to install and has a low vibration level. Objects are fed automatically or manually.

Sic-marking e10d-p123

Another Sic-marking development is the portable model e10d-p123. It is mobile and can be used to apply information to large-sized elements. Feature of the model: the ability to place more information on the part or increase the size of the symbols (this is ensured by the size of the marking window). The reinforced module increases the marking depth to 0.9 mm. LED lighting is provided. Software included.

Rusmark PMK-DC

The Rusmark company offers consumers a pneumatic desktop marking machine designed for marking medium and small metal objects. Optionally, the equipment can be supplemented with a rotation axis for working with cylindrical parts and sign holders. The devices are equipped with (optional) control controllers for operation:

- autonomous;

- from PC.

Application speed – 3-5 characters per second.

Rusmark EMK-EC

In the category of portable point-impact markers, the EMK-EC model produced by Rusmark has good recommendations. The device is used for applying inscriptions to metal products - flanges, pumps, parts, pipes, etc. It can optionally be equipped with electromagnetic clamps for fastening to the surface being processed. There are 2 types of control controllers (to choose from). Software included. The hardness of the material is up to 62 HRC. It is possible to develop fonts yourself.

Simple Marker

The Markn'Stamp company offers a desktop pneumatic dot-impact marking machine that provides high accuracy of information application. This is the first model based on Wi-Fi - wireless communication is supported with a computer, phone, laptop. The user has the opportunity to create a design layout using a mobile application and transfer it to the device (software is included in the basic kit). Autodata, auto series, Data Matrix, QR codes, logos in DXF format are marked. Access to the device is protected by a password system. The device is equipped with an electromagnetic drive. Marking speed – 3 characters per second, depth – up to 0.8 mm (9 modes are provided).

Labeling equipment ensures the most accurate product identification. The risk of accidental erasing of the inscription and the appearance of unreadable areas is eliminated. The inscription can only be erased by removing a layer of surface equal in thickness to the depth of penetration of the needle.

Of all the existing modern technologies for marking on metal (paint, laser, drawing, dot-impact), automated dot-impact marking is considered the most effective, having the optimal combination of “marking reliability/price”.

In foreign sources, the dot-impact marking technology is called: Dot peen marking. The term “Direct Part Marking” is also often used: “Direct Part Marking” – DPM (Direct Part Marking) (note: Russian sources use the term “Direct permanent marking on the product”, emphasizing the high reliability of the marking).

The most important advantage of dot-impact marking is its durability, resistance to adverse environmental conditions and aggressive environments (in fact, we are talking about the durability of the material of the product being marked) and the ability to effectively apply information even on a small area of the surface of the product.

The applied symbols are formed by a sequence of points obtained as a result of plastic, residual deformation of the metal at the point of impact of the marking needle.

In this case, there is no weakening of the metal - metal sampling is excluded. Thus, the marking obtained when using SIC Marking equipment is not a stress raiser and does not impair the strength characteristics of the product.

This marking technology is considered permanent, since to destroy the marking it will be necessary to remove a layer of material from the surface of the product to a depth greater than the depth of the marking.

Labeling equipment

For operation of most models of SIC Marking dot-impact markers, only an AC power supply of 85…260 V / 50…60 Hz is required; energy consumption is extremely low - only 300 W.

A marking needle made of tungsten carbide steel reliably and efficiently applies markings up to 0.5 mm deep on steel products whose surface hardness does not exceed 45 HRC; on aluminum alloys – up to 0.7 mm.

Equipment for deep impact dot marking allows marking with a depth of up to 0.9 mm on materials with a hardness of up to 40 HRC.

At the same time, the maximum hardness of the metal of the marked products can reach 62 HRC.

The service life of a marking needle* depends on the hardness of the metal being marked, the volume of marking and the parameters of the marking process.

*We can calculate the average needle life after providing the marking text, the height and width of the characters, as well as indicating the hardness of the material being marked.

Each marking machine model has a very reliable and extremely simple design, which allows complex repairs to be carried out by the owner’s company - any replacement units and parts can be supplied from the manufacturer’s factory.

SIC Marking equipment can operate in highly dusty air conditions in the work area.

An especially high degree of protection is available for integrated equipment that has protective curtains that reliably protect the movement mechanism of the marking module from dust and moisture.

The frequency of preventive maintenance is determined by the load - the number of marking cycles per day/shift and the level of contamination of the room. Moreover, even if the marking equipment operates in a room with a high dust content in the air, for 16-20 hours a day, weekly preventive maintenance (i.e., planned equipment downtime) will amount to no more than 2 hours required for lubrication marking mechanism and replacing the needle and return spring.

Type of information applied:

- Symbolic – alphabetic (Cyrillic and Latin letters) and numeric, as well as various signs (for example: №$%.,/, etc.)

- Graphic information (for example, company logo)

- 2D Data Matrix ECC200 code

Marking parameters:

Set for each line of the marking file, the entire file, or for all marking files

- Font type – 8 fonts in total, including machine-recognizable fonts (OCR)

- Height and width of letters, numbers and various symbols

- Marking text around a circle, at an angle, in a mirror image

- Quality (pitch/density of marking points) – from 0.05 mm to 1.0 mm

Consumables:

One of the main advantages of SIC Marking marking equipment is the minimum range of consumables for all models of marking machines (note: consumables for impact marking and marking by tracing are different).

This allows a company operating various models of SIC Marking impact marking machines to minimize the cost of maintaining a stock of consumables.

Consumables include needles, return springs, impact modules.

Types of products marked using SIC Marking point impact equipment (sample list):

- Pipes – metal and polymer

- Pipeline fittings (gate valves, taps)

- Gas cylinders

- Metal constructions

- Metal tanks

- In metallurgy: slabs, ingots, rolled products, etc. semi-finished products

- All types of transport: metal components and parts

- Weapon

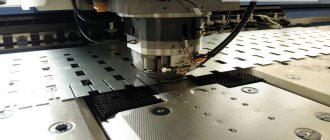

Organization of marking area (examples)

Using SIC Marking dot-impact marking equipment, products of various configurations and any strength groups can be marked - quickly, efficiently and safely.

The marking section can be installed on a conveyor or be autonomous.

An autonomous marking section can be located both in the conveyor line and in any place in the workshop convenient for marking.

The most important advantage of autonomous marking is mobility - the marking area can be permanent or move, if necessary, throughout the workshop/enterprise.

At the same time, the greatest flexibility and versatility are achieved when using portable markers, since they allow you to immediately begin marking pipes of any diameter without reconfiguration.

Automated marking as part of a conveyor is possible using both integrated and stationary marking machines, but it is preferable to use integrated devices due to their design and the presence of metal protective curtains.

The marking process can be fully automated by connecting the control controller to a computer installed at the marking site or to the central computer of the enterprise. For these purposes, the manufacturing company SIC Marking provides the Marking Controller Data Exchange Protocol. The data exchange protocol will allow programmers of the customer enterprise to write their own software, adapted for specific tasks.

Portable/handheld markers Provide the user with mobility and autonomy (when using a battery cart or E-mark series markers) in work. Designed for marking a wide range of products, including those whose dimensions and weight do not allow them to be freely moved around the company’s territory.

Portable markers are divided into two series:

- Commercial series – metal marking depth up to 0.3 mm, simplified control controller, number of markings per day – several dozen

- Industrial series - reinforced design, metal marking depth up to 0.9 mm, number of markings per day - up to 300, expanded control controller capabilities.

Commercial series

- e1-p63c, marking window 60x25 mm

- e1-p123, marking window 120x40 mm

- E-mark - autonomous (battery) marking machine, marking window 60x25 mm

- E-mark XL - autonomous (battery-powered) marking machine, marking window 120x40 mm

Industrial series:

- e10-p63, marking window 60x25 mm

- e10-p123, marking window 120x25 or 120x40 mm

Integrated Markers

Designed for integration into automated production or repair lines (conveyors) under the control of automated process control systems. Allows you to label a large number of products per day. All models are distinguished by a design of increased reliability and protection of internal mechanisms from damage, dust or moisture using a casing or metal protective curtains, which allows minimizing conveyor downtime during periodic maintenance of markers.

- e10-i53, marking window 50x20 mm

- e10-i83, marking window 80x70 mm

- e10-i141, marking window 150x100 mm

- e10-i113D, for deep marking, marking window 110x60 mm (connection requires a compressed air source of 6 bar)

Stationary markers

These markers are ideal for marking both small-sized products (when using portable markers is not possible) and products with a height of up to 270 mm. At the same time, the marking head can be removed from the column for integration into automated production or repair lines (conveyors) under the control of automated process control systems.

The reinforced design of the column and the mechanism for moving the impact module makes it possible to mark a large number of products per day. They have built-in illumination of the marking area. Ideal for applying two-dimensional Data Matrix code. The optionally installed rotation axis allows circumferential marking of products weighing up to 35 kg.

Industrial series:

- e10-c153, marking window 160x100 mm

- e10-c303, marking window 300x150 mm

- e10-c153 za, with autosensing function - automatic determination of the position of the product and automatic movement of the marking head, marking window 160x100 mm

Commercial series:

- e1, marking window 120x100 mm

Controller

A special feature of the industrial series dot-impact markers is the ability to use a control controller in two versions:

- e10 – desktop version (standard equipment for markers)

- e10R – vertical design for installation in a standard industrial rack for use in harsh industrial environments