Classification and characteristics

Two-pipe heating circuit with forced circulation of coolant

According to the manufacturing method, iron pipes can be seamless, made by hot or cold drawing and electric welded. Solid-drawn steel is more reliable and designed for higher pressure. The choice of such pipes entails an increase in the cost of installing the heating system, since their cost is significantly higher than that of electric welded ones.

The main characteristics include:

- Size and weight. The size of the product is determined by the internal and external diameters, nominal diameter, wall thickness and pipe length. All these physical quantities, including the mass of 1 linear meter. m of pipe, regulated by GOST and TU. Using them, you can easily make a choice in favor of one or another type of rolled metal. Diameters and wall thicknesses are measured in millimeters, lengths in meters, and weights in kilograms or tons.

- Strength. Strength characteristics include the ability of a pipeline to withstand a certain pressure (working, nominal, test, excess) and medium temperature. Pressure is measured in pascals and temperature in degrees Celsius or Kelvin. These are the main characteristics that guide the design of heating systems.

- Material. It can be carbon steel, stainless steel, carbon cast iron, alloy and non-ferrous metal.

Classic high temperature welding

How to weld heating from an iron pipe in accordance with building codes is indicated in GOST. Both the diameter of the pipes and the length of the system matter. SNIP will indicate how to properly weld heating pipes in each specific case: private household, multi-storey building or industrial water supply line.

When using a gas welding machine, creating high-quality seams will require considerable practical experience. Electric welding can also create welded joints of impeccable quality, but in this case you will need not only experience, but also high-quality electrodes, the correct current level and “arc feeling”. High-quality electric welding of heating pipes is available only to real professionals.

Metal pipes are the most common material for heating systems

The strength of metal pipes is more than sufficient for the water supply system and for the heating circuit. It is the connection sections that have to be implemented in order not to deviate from the design documentation that are the “weak link” of the system. How to weld a heating pipe using electric welding is described in detail in outdated training materials and articles. In modern construction, the cold welding method is more often used for heating pipes.

Every qualified installation engineer knows how to weld a heating pipe correctly. There are a number of rules that must be followed:

The weld should not consist of scale. This happens if you weld a pipe by electric welding using low-quality electrodes. To weld metal with an electric welding machine, you must use the multilayer metal melt method

Primary weld scale is removed before the next welding layer. It is important to choose the correct current level - low current does not guarantee the strength of the weld. Excessively high current during welding is also unacceptable. If the butt welding method is used, the electrode metal or molten wire is used as the reinforcing material. Electric welding of metal pipelines and other elements of heating and plumbing systems is prohibited near flammable objects.

Gas welding is a universal method for creating a strong connection between metals; metal parts of different sizes can be connected in any combination.

For traditional welding you need to have special equipment and welding experience

The high temperature of the burning gas stream allows you to melt the metal in the area of local heating, and cook the metal at the molecular level. Requires expensive equipment and highly qualified welders.

How to install a heating register

Every owner can install a heating register without involving a specialist in the work. To simplify assembly operations, it is first necessary to prepare each element of the heating system according to the project.

One of the main requirements is a high-quality connection of the register with pipelines. It must withstand the maximum permissible load - 10 MPa. If the joining is done by welding, you need to monitor the quality of the seams.

It is recommended to place registers along one wall. In this case, a minimum slope in the direction of movement of the coolant is required - up to 0.05% of the length of the device.

Heating registers must be located closer to the floor surface. The larger the diameter of the main pipe, the less resistance there will be for the circulating coolant.

The efficiency of the device depends on a large number of factors, including the heating area, which is directly proportional to the length and diameter of the pipes. The most widely used models in everyday life are those with the following characteristics:

- Recommended pipe diameter – from 25 to 160 mm

- Connecting jumpers for sectional models – from 30 mm

- Distance between main pipes – from 50 mm

- Maximum pressure – 10 MPa

- Material – high carbon steel

We make a register with our own hands

Anyone who knows how to work with a welding machine is able to make a heating register on their own. The simple design can be filled with antifreeze or oil.

Introductory video on production

To make a heating device with your own hands, it is recommended to follow the instructions:

- It is necessary to prepare pipes of suitable diameters and cut the blanks

- The inside of the pipe is checked and, if necessary, cleaned to reduce the already high resistance to the circulating coolant

- Plugs are welded at the ends, holes are drilled in some of them

Tubes of a smaller diameter (vertical) are connected to thicker ones (horizontal). It is necessary to install taps to remove air that will accumulate from the edges. All seams are carefully and efficiently cleaned, the surface is painted with oil paints.

In portable structures, it is necessary to install a heating element with a power of 1.5 to 6 W, which will operate from a regular outlet. If the system is powered by a heating boiler, the efficiency of the registers can be increased by installing a powerful circulation pump.

Types of electrodes

An electrode is a thin metal rod that is coated with a special compound. It protects the metal from the occurrence of corrosive deposits and determines how the weld will turn out. To figure out which electrodes to weld pipes with, you need to consider the properties of each of them. The main parameters by which electrodes are classified are the type of coating and the type of core. Products come with a melting and non-melting core.

- To make a melting core, welding wire with different diameters is used, which is selected depending on the type of work.

- To make a non-melting core, tungsten, graphite or electrical coal are used.

The electrodes are coated with cellulose, rutile, rutile-acid or rutile-cellulose coating.

Selecting a welding machine

There are three types of welding machines. Which one to choose depends on the welding method and the material being processed. Device types:

- Step-down welding transformers. This is a reliable device that is used for welding carbon steel. The quality of the seam is average.

- Welding rectifiers. Suitable for carbon and aluminum materials, as well as stainless steel. The seam quality is high.

- Welding inverters. A universal device that is suitable for any material.

You cannot use damaged equipment when welding heating pipes using electric welding. Therefore, before starting work, the equipment is carefully checked.

Work technology

First you need to prepare the workplace and protective equipment. To figure out how to properly weld heating pipes, you need to practice on a separate piece of metal. To do this, you will need a thick pipe and a universal electrode with a diameter of 3 mm and above, since it is easier to learn how to make seams with it. Work process:

- One welding cable has a holder. An electrode is inserted into it, then the cables are connected.

- The device has 2 cables and 2 current outputs with positive and negative polarity. The end of one cable is equipped with a clamp that connects to the part, the end of the second is a holder for the electrode. Polarity is chosen depending on the type of work. The best heating of the metal occurs with straight polarity.

- There are 2 ways to light an arc. To do this, the tip of the electrode is tapped several times on the part or drawn along the seam (chirping).

- The type of weld on the pipe depends on the inclination of the electrode. The main inclination is 30-60°. To deeply heat the metal, the electrode is tilted at a “backward angle.” In this case, the bath and molten metal flow behind the electrode. If surface heating is required, then the angle of inclination is changed in the opposite direction.

Each material and type of seam has its own electrode movement. For homework, it is enough to master some of them

During work, it is important to monitor the size and condition of the weld pool. To do this, movements are accelerated or slowed down

How to weld pipes quickly and easily for novice welders

Watch this video on YouTube

How to weld plastic pipes

Welding of plastic pipes takes place using a special technology, because due to the high temperature, sagging often forms inside them. Therefore, welding work must be performed carefully. But if the temperature is too low, the parts will not be fixed. Work order:

- The welding machine is placed on a stand and heated to 260° C.

- The end of a plastic pipe and a fitting of a suitable diameter are inserted into the welding nozzle so that they are located in the same plane.

- If the pipe is thick, then the temperature level is increased. When the parts warm up, they are removed from the device and connected.

When the seam hardens, the pipe is checked for leaks. Products with a large diameter (over 63 mm) are soldered joint-to-joint. The cut of the end pipes is melted and connected, while pressing strongly on each other. For coupling and socket soldering, hand-held instruments are used. They are equipped with a centering element and attachments that hold the workpieces. All pipeline parts are driven into a heated welding machine and soldered. To ensure that the parts are connected, all work is carried out quickly.

Possible errors in the process

The quality of the finished product may be poor due to a defect in the weld. The defect can be located inside or outside the product, and can also be through. The reasons why it occurs during welding of metal heating pipes and other products:

- due to cheap low quality material;

- due to poor quality equipment;

- when the technological process of work is disrupted;

- due to the inexperience of the welder.

Sometimes welders reinforce the seam up to 4 mm. Because of such an error, it becomes fragile. The height of the reinforcement should not exceed 2 mm, then the seam will have maximum strength.

Preparation of material and welding of parts

The process of argon metal welding.

To install heating devices in the form of registers, it is necessary to prepare pipe and consumables:

- smooth steel pipes with a diameter from 76 to 159 mm;

- pipes with a diameter of 32 mm for jumpers;

- inlet and outlet pipes for welding, threaded or flanged type with a diameter of 35 mm;

- threaded fitting for connecting an air vent (Mayevsky valve);

- plugs for pipe diameters;

- floor supports made from corners or brackets for mounting to the wall.

For the manufacture of such heat exchangers, pipes with diameters of 76, 89, 108 and 159 mm are most often used. Products with profile, rectangular or square sections are also used.

Tools you will need:

- welding machine;

- gas key;

- grinder (grinder);

- hammer, electrodes;

- roulette, level;

- welder protective equipment.

Heating register device.

The joining surfaces of the parts are cleaned and degreased before welding to avoid defects in the seams. The ends of the pipes must be perpendicular to their axes. Large-diameter pipes are processed using milling machines or gas-acid cutting.

The pipes are cut into pieces of calculated sizes, the ends are cleaned with a grinder. On horizontal pipes, holes for jumpers are marked and cut out; the pipes must fit into the hole.

Jumpers inserted into the holes are welded to horizontally laid pipes in accordance with the dimensions. Plugs are welded to the ends of the register elements. The inlet and outlet pipes are welded into pre-cut holes at two ends (diagonally).

At one of the upper ends a threaded pipe is welded for installing a Mayevsky tap. All seams are cleaned with a sander to give an aesthetic appearance. Racks are welded to the structure (if the device is installed on the floor).

To check the register for leaks, the lower outlet for the coolant outlet is closed with a plug. The structure is filled with water and inspected for leaks. When they are detected, the water is drained and the problem areas are boiled again. The seams are cleaned again and the register is painted.

Recommended reading:

Heating pipe welding guide

- Connection of plastic pipes

- Welding pipes made of metal

- Welding heating pipes in an existing pipeline

To create a good and practical heating system in the house, the heating system is welded. The connection between metal and plastic pipes is slightly different and is determined by the purpose or units used.

Errors when butt welding pipes.

Connection of plastic pipes

The connection of polypropylene components of the heating system is carried out in two ways:

- socket welding, when one end of the pipe fits into the other;

- sleeve welding using an additional part - a coupling.

Pipe connection by butt welding.

The polypropylene parts of the heating system are connected using diffusion welding, which is the process of heating individual parts of the system with a specialized soldering iron with a power of 1500 V and operating at a voltage of 220 V. The average heating time is 5 s. Due to its own physical properties, polypropylene begins to melt at a temperature of 270°C. The required heating value is set on a special temperature controller that is equipped with each device.

Welding of polypropylene also varies depending on the period of the year. In winter and during outdoor work, the heating time must be extended. The same rule applies to large-diameter elements, for which the heating time is at least 30 s.

The soldering iron nozzles simultaneously heat the parts intended for connecting the heating elements (pipe and coupling). When heated, “flanges” appear on the parts. After heating is completed, the parts are removed from the nozzles and combined together, pressing equally on both sides. Heated parts must not be moved or rotated after joining, as this will cause damage to the joint seam. To ensure a strong coupling, the connected parts are held for at least 30 seconds.

If the surface of the pipes has acquired a cinnamon color, this indicates excessive heating and combustion.

to come back to the beginning

Welding PP pipes: 1. Fitting socket. 2. Chamfer on the pipe cut. 3. Limit clamp. 4. Heating device sleeve. 5-6. Weld seam.

Metal structures that are part of the heating system are combined using electric welding. To implement this option, iron electrodes are used that conduct alternating current and perform the function of an “additive” that fills the weld seam.

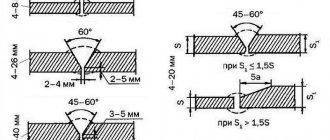

Before making the connection, the parts must be cleaned of sand, dirt and debris. If necessary, straighten the deformed ends or cut them off. To carry out arc welding, the surfaces at the edges of the parts are cleaned to a width of at least 10 mm. The connection of parts around the circumference takes place in a continuous mode.

The number of layers of arc welding is determined by the thickness of the walls of the heating pipes. 2 layers - thickness up to 6 mm, 3 layers - 6-12 mm, 4 layers - more than 12 mm. Each completed layer is cleaned of slags before the next one.

For the first layer, stepwise surfacing is used. For layers - solid. When connecting, the stepwise surfacing is broken down into certain sections, and they are connected through one.

Installation of a heating complex requires great attention and responsibility regarding the first layer. In another case, the defective area will have to be cut down and all the work done again.

When applying further layers to the first layer, the pipes are turned more slowly and equally. The next layer should be started by moving a small (1.5-3 cm) distance from the beginning of the previous one. The last layer should slowly blend into the key metal and be even and smooth.

to come back to the beginning

Welding heat supply under pressure causes considerable difficulties, since pipe lines are often placed in a narrow channel or very tightly near the walls of a building. To perform welding work, a hole is cut to weld the surface inside. And then they boil the other surface of the pipe.

Start the process from the center of the section at the bottom of the pipe. The electrode is placed perpendicularly for good execution of the ceiling seam. To connect vertical seams, you need to adjust the location of the electrode. It must be directed at an upward angle. Vertical seams can be made using spot welding.

Calculation of the required number of registers in the house

When choosing registers for heating, you need to pay special attention to the pipes used in the design and their diameter. The most suitable option for this parameter is considered to be a size of 31-32 mm

Experts do not recommend installing registers from pipes whose diameter exceeds 82 mm. This is due to the fact that heating boilers will not be able to provide the required amount of coolant.

In terms of heat transfer, aluminum radiators are better than steel ones.

For each individual building, it is necessary to very accurately determine the number of pipes and their diameter in the register. Therefore, installing these heating systems in a house requires taking into account the following factors:

- The number of doors and windows in the building.

- Wall thickness.

- Materials from which windows and doors are made.

To calculate the required number of pipes, one main indicator should be taken into account - the heat transfer of 1 m of pipeline. The cost of installing a heating system using radiators and registers is not much different. The differences in price depend only on the number of joints, the cost of welding work and pipes, and the size of the devices. In multi-story and one-story buildings, it is best to use registers for lower pipe routing.

Installation of a heating circuit using cold welding

Cold welding is the joining of two or more elements without heating them. The connection is formed due to chemical reactions occurring in the adhesive. Plasticity, high adhesion and rapid solidification into a monolithic mass are the distinctive features of components used for cold welding.

The adhesive composition may include various elements to improve the mechanical characteristics of adhesive joints. The compositions are usually based on epoxy resin and a filler - a hardener. The packaging indicates whether heating pipes can be cold welded, or whether this is a composition for repairing plastic pipes of the cold water supply circuit.

Cold welding is a plastic mass that provides a tight connection of pipes

There are two types of components for cold welding:

- A plastic two-component substance, which must be thoroughly kneaded immediately before use to mix the components. The advantage of this type of cold welding: the composition is quickly prepared, stored for a long time, and requires minimal preparation before use. Disadvantage: hardens quickly, must be applied very carefully, it is recommended to use as soon as possible after preparation.

- Liquid components. Before starting application, you need to combine the substances in the proper proportion, and the glue is ready for use. Advantages of a liquid composition for cold welding: the adhesive easily penetrates deep into the joint, forming a durable layer that is resistant to mechanical stress when hardened. Disadvantage: requires special conditions for long-term storage. Different materials - plastic, metal - require different chemical components.

The main advantage of any type of cold welding is the ability to quickly repair a section of a plumbing, heating or sewer system without turning off the water supply. Welding, or in this case gluing, components can be done in conditions of increased fire hazard.

As a repair composition for cast iron heating radiators, the surface should be carefully prepared for cold welding. Despite the strength of the connection, the repaired area may not withstand the maximum pressure test.

For plastic plumbing systems, the cold welding method is recognized as one of the best solutions for local repairs when it is impossible to replace the damaged element. Cold welding is also successfully used to restore the tightness of butt seams on plastic water pipe fittings.

Cold welding is an effective method for urgent repair of any pipes

Waiting time for the finished cold welding composition: from 2 to 20 minutes, depending on the intended purpose. Temperature range – from 0 to 1300 degrees.

It is enough to read the instructions for use in detail, and the installation of the system will be successfully completed. To work you will need:

- container for preparing the composition;

- gloves to avoid contact of the composition with the skin. It is recommended to moisten them with water;

- thin spatula for applying a viscous composition to the area of use;

- compliance with safety rules when working with chemical components.

If the composition gets on the skin or in the eye area, it is recommended to rinse the affected area of the skin and if a burning sensation occurs, consult a doctor, having with you the packaging of the “cold welding” components.

Reduced heat transfer.

In order to save energy, it becomes important to reduce the heat transfer of pipes in those sections of communications that are not used for their intended purpose, for example, when moving from one building to another or in an unheated room.

There are many options for using thermal insulation materials for this. Manufacturers offer a fairly wide range to choose from, ranging from cheap fiberglass to more expensive types of polystyrene foam. You can purchase pipes with insulating elements already built into them.

To summarize, we conclude that the use of such calculations helps to significantly save money and avoid many technical obstacles when designing water and heat supply systems.

Actually, you are a desperate person if you decide to undertake such an event. The heat transfer of a pipe, of course, can be calculated and there are a great many works on the theoretical calculation of the heat transfer of various pipes.

Let's start with the fact that if you decided to heat your house with your own hands, then you are a stubborn and purposeful person. Accordingly, a heating project has already been drawn up, pipes have been selected: either metal-plastic heating pipes or steel heating pipes. Heating radiators have also already been looked at in the store.

But, before acquiring all this, that is, at the design stage, it is necessary to make a conditional relative calculation. After all, the heat transfer of heating pipes, calculated in the project, is the key to warm winters for your family. There is no room for error here.

Methods for calculating heat transfer from heating pipes

Why is the emphasis usually placed on calculating the heat transfer of heating pipes? The fact is that for commercially manufactured heating radiators, all these calculations have been made and are given in the instructions for use of the products. Based on them, you can easily calculate the required number of radiators depending on the parameters of your home: volume, coolant temperature, etc.

Tables.

This is the quintessence of all the necessary parameters collected in one place. Today the Internet contains a great many tables and reference books for online calculations of heat transfer from pipes. In them you will learn what is the heat transfer of a steel pipe or cast iron pipe, the heat transfer of a polymer or copper pipe.

All that is needed when using these tables is to know the initial parameters of your pipe: material, wall thickness, internal diameter, etc. And, accordingly, enter into the search the query “Table of heat transfer coefficients of pipes.”

This section on determining the heat transfer of pipes also includes the use of manual reference books on heat transfer of materials. Although they are becoming more and more difficult to find, all information has migrated to the Internet.

Formulas.

The heat transfer of a steel pipe is calculated according to the formula

Qtr=1.163*Str*k*(Twater - Air)*(1-efficiency of pipe insulation), W where Str is the surface area of the pipe, and k is the heat transfer coefficient from water to air.

The heat transfer of a metal-plastic pipe is calculated using a different formula.

Where is the temperature on the inner surface of the pipeline, °C; t

c is the temperature on the outer surface of the pipeline, °C;

Q—

heat flow, W;

l

—pipe length, m;

t

—coolant temperature, °C;

t

inc—air temperature, °C;

a n is the external heat transfer coefficient, W/m 2 K; d

n - outer diameter of the pipe, mm;

l—thermal conductivity coefficient, W/m K; d

in

-

internal diameter of the pipe, mm; a int - internal heat transfer coefficient, W/m 2 K;

You understand perfectly well that calculating the thermal conductivity of heating pipes is a relative value. The formulas include the average parameters of certain indicators, which may, and do, differ from those that actually exist.

For example, as a result of the experiments, it was found that the heat transfer of a polypropylene pipe located horizontally is slightly lower than that of steel pipes of the same internal diameter, by 7-8%. It is internal, since polymer pipes have a slightly thicker wall thickness.

Many factors influence the final figures obtained in tables and formulas, which is why the footnote “approximate heat transfer” is always included. After all, the formulas do not take into account, for example, heat loss through the building envelope made of different materials. There are corresponding tables of amendments for this purpose.

However, by using one of the methods for determining the heat output of heating pipes, you will have a general idea of what kind of heating pipes and radiators you need for your home.

Good luck to you, builders of your warm present and future.

Surface preparation

Before electric welding pipes, you need to prepare them for the joining process. Surface preparation sequence:

- Pipes must comply with all parameters specified in the project. They should have uniform wall thickness along their entire length, and the cut should be round.

- The pipe is cut at an angle of 90° and cleaned to a shine at a distance of 1 cm from the cut.

- Then the cut is degreased. To do this, remove all oil stains and clean off rust. If there is paint, it is removed.

If necessary, the end is further processed. The edge of the pipe cut should have an opening angle of 65° with a blunting value of up to 0.2 cm. Such a cut will help to qualitatively connect the products.

Coil

Unlike a sectional one, a coil heat exchanger consists of one long pipe, bent in the shape of the letter S. It uses pipes of a similar cross-section, and there are no areas of narrowing.

Thanks to the special shape of the design, the heat transfer of heating registers of this type increases and the hydraulic resistance of the coolant decreases.

In most cases, heating registers are made of smooth-walled high-carbon steel pipes. However, you can also find devices made of stainless or low-alloy steel, as well as cast iron.

Thanks to the use of heating registers, even if they are of a compact size, high heating efficiency can be achieved. In this regard, these devices are actively used in large industrial and warehouse premises.

Types of welding

The essence of the process is this: when heated, the metal or alloy is deformed - melts, and when joined to the edge of another metal product, mutual penetration of particles of the material occurs. The new bonds formed in this way are molecular, which ensures high strength of the seam.

According to the welding method, welding is classified into three groups.

- Thermal – fusion welding (arc, laser, etc.).

- Thermomechanical – carried out using a magnetically controlled arc (butt).

- Mechanical - through friction or explosion.

Various elements act as a heating source; depending on their nature, pipes can be welded using 4 methods:

- arc welding;

- gas;

- laser;

- plasma.

The process itself can be manual, automated or mechanized. At the same time, the share of the manual method, even in enterprises, is at least 20–30%, and when installing ready-made heating systems in buildings, it increases sharply.

Instructions for making registers yourself

The easiest way to make your own is a steel heat exchanger, although its assembly will require skills in working with welding and grinding equipment and following certain rules.

- Before installation, it is necessary to perform calculations and a drawing, which will indicate the dimensions of pipes and connecting elements, the location of fittings and connection points. The drawing will help you accurately calculate the quantity and parameters of consumables.

- The clearance between sections is taken to be 1.5D or D+0.5 cm, where D is the diameter of the pipe. The distance between parallel sections of the coil register is calculated depending on the arc element used or the turning radius (R) when using a pipe bender. In the first case, the distance is equal to twice the difference between the height of the arc element (F) and the diameter: 2(FD). In the second case, the distance will be 2R-D. With a smaller distance, heat transfer decreases.

- Since welding and grinding equipment is used during installation, be sure to wear protective clothing and shoes, and protect your face with a special mask or goggles.

- For efficient operation of the register, strict parallelism of its sections is necessary; a level, plumb line and construction angle will help to control this parameter during the work.

- An air vent is installed at the top point of the register, farthest from the supply pipe, to get rid of air pockets in the circuit. When installing a parallel heat exchanger with collectors, air vents are placed at the top point of each collector.

- To secure the register you will need stands and brackets. The more massive the structure, the more fasteners will be required.

Work order

- The work area is being cleaned.

- The register elements are marked and cut in accordance with the drawing.

- The inner and outer surfaces of the pipes, as well as the edges of the holes, are cleaned of debris and rust with a steel brush.

- The plugs are cleaned of debris and plaque. Holes are drilled in two plugs for connection to the heating circuit.

- Plugs, jumpers and connecting pipes or manifolds are welded in accordance with the drawing. The parallelism of the sections is checked after joining each element.

- Welds are cleaned.

- The tightness of the resulting register is checked: the outlet hole is hermetically sealed, and water under pressure is poured through the input hole. If even small drops appear on the seams, it is necessary to drain the liquid and further boil the seam.

- If necessary, coat the heat exchanger with heat-resistant metal paint.

- The register is secured to supporting and hanging elements.

- Connected to the heating system.

Replacing heating batteries using a threaded connection.

Proponents of this method of replacing the heating system note that the use of threaded connections of its various parts has a number of advantages.

- Easy installation of the entire heating system. As a rule, in every apartment you can find places that are quite difficult to reach for welding. And in this case, only a highly qualified welder can perform welding work at a high level. And the use of a threaded connection reduces the entire work process to the elementary screwing of parts into each other according to the principle of a conventional construction set.

- Dismantling a heating system with a threaded connection is also quite simple - there is no need to cut the pipes, but simply unscrew them from each other.

- The threaded connection also increases the safety of installation work, since it does not require the use of high temperature, and therefore cannot lead to an accidental fire.

- When using a threaded connection, all work on installing a heating system takes much less time than when using welding. In some cases, this time difference can reach 70%.

- The cost of such installation is also lower than the cost of a qualified welder.

But no matter how great the advantages of this method of installing a heating system, the number of people using gas welding in this case is quite large. And there are quite simple explanations for this.

Simple ways to increase heat transfer from radiators

We improve air circulation. The batteries transfer heat to the air, which, when heated, rises, and then, when cooled, falls down. This is how air circulates, and the room becomes as warm as the heat transfer of the battery and the air flow speed allow. Therefore, in order to increase the temperature inside the room, first of all, you need to ensure good air circulation. To do this, you should free up the space around the battery as much as possible: remove the protective screen, raise the curtains, move the furniture, and so on.

We accelerate air circulation using a fan. The faster the air moves, the more thermal energy it can take from the battery. On the coldest days, you can turn on the fan, directing it to the center of the radiator to cover as much area as possible. To ensure the autonomy of such a system and ensure its quiet operation, computer fans can be placed. They are quiet, low-power, and when placed directly under the battery, they do not disrupt the natural direction of air movement in the room. The fans will allow you to raise the temperature in the room by 3-10 degrees, and their low consumption makes it possible to blow on the battery all winter long without significantly damaging your wallet. Calculate for yourself: the power of ordinary fans is about 40 Watts, computer fans – no more than 5. Total consumption: 40 * 24 (hours) * 30 (days) = 29 Kilowatts = about 95 rubles per month. In the case of computers, it’s even less – about 23 rubles/month. when connecting 2 at once.

We install a heat-reflecting screen. Heat from the radiator emanates in all directions, and in order not to heat the walls, but to direct thermal energy into the room, you need to install a heat-reflecting screen behind the radiator. For these purposes, you can use foil-isolon (foam base with foil on one side), gluing it to the cleaned wall behind the battery with any suitable means (tile adhesive, universal glue 88, silicone, etc.). Ideally, the area of the heat-reflecting screen should be larger than the area of the battery.

If the battery is cold you need to bleed the air. To do this, you need to unscrew the regular or “Mayevsky” tap at the battery.

It will not be superfluous to keep a container or towel under the valve, because as soon as the air comes out, water will flow in a thin stream. Once this happens, the valve can be closed. The procedure should be repeated for each battery in the house.

Advantages

- Cold welding for batteries and pipes provides reliable results for sealing cracks and leaks in the domestic water supply system;

- The embedding process does not require additional technical devices or other devices;

- Using cold welding is a safer process than hot welding;

- The cost of applying one suture is much lower than other methods;

- When creating a seam, pipes are not subject to heat treatment, which does not damage them, and also does not create stress and deformation on the metal;

- There is no difficulty in carrying out work with different thicknesses of products;

- Cold welding is suitable for plastic pipes and other products, as it is a universal fastening agent;

- The speed of repairs is relatively high and everything does not take much time;

- Cold welding for heating pipes is available in many places where relevant products are sold and can be purchased without any problems at any time.

Features of pipes for the heating system

For water supply systems designed for cold water, heating and hot water supply systems, there are separate types of polypropylene pipes that differ significantly in their technical characteristics.

Therefore, you should not use pipes intended for cold water to install a heating system, since their material cannot withstand high temperatures.

If you need to purchase pipes for installing heated floors, then you should choose special products that are well adapted for these purposes.

Advantages of polypropylene pipes

This building material has received a wide range of applications due to its incomparable characteristics, namely:

- affordable cost;

- maintainability;

- ease of installation;

- resistance to chemical influences and corrosion;

- durability;

- environmental friendliness;

- reliability, etc.

In addition, mineral deposits do not settle on the inner walls of such pipes, and heating welding using them has a low price.

The only drawback of polypropylene is its low fire resistance. It easily ignites and is unstable to very high temperatures.

How to weld heating from iron pipes Metalworker's Guide

When installing heating pipes, you often have to connect them by welding. Of course, in some cases a threaded connection may be suitable, but the percentage of this method is much smaller.

Welding metal heating pipes

As for welding steel pipes, this method has several varieties. For example: manual electric arc, gas welding (semi-automatic, automatic). To connect steel heating elements, the first type of welding is often used.

To weld steel pipes using manual arc welding, you need to use special electrodes that perform the function of an additive. They perform two functions: they conduct current to the arc and fill the seam. Their composition, dimensions and other characteristics are established by GOST. Today on the Internet you can find quite a few videos showing how this or that type of welding is performed.

Heating registers made of steel pipes.

The manual arc technology is quite simple, so you can do it yourself. It all starts with preparation.