Purpose of vibrating plates

A vibrating plate is a mechanism designed to compact loose soils and bulk building materials. In addition, such a mechanism is widely used for vibration processing of semi-dry concrete mixtures and asphalt when constructing floors and paving surfaces. The use of such a tool is very effective when working on a small plot of land and in cramped spaces.

Homemade electric vibrating plate.

The construction of sidewalks, garden paths, driveways and parking lots near a private house using a vibrating plate is carried out much faster, while ensuring high quality of work. Compacting the bottom of the trenches when laying utilities eliminates their possible damage in the event of subsidence of loose soil. These and other advantages encourage many home craftsmen to make such equipment themselves and use it in construction work.

Operating principle of vibrating plate

The impact action exerted on the surface by the working mechanisms of the vibrating plate, which produce a certain number of movements in contact with the ground, is how we can describe the operating principle of the equipment we are considering. At the moment of impact, the kinetic energy of the working mechanisms is converted into other types of energy. There is an instant increase in pressure on the contact surface and an equally rapid decrease. That is, in addition to the force effect (like a roller), there is also an effect of speed and frequency of impact.

Advantages of a homemade tamping machine

The main advantage of a home-made vibrating plate is its low cost and the ability to perform high-quality and efficient work. The simple design ensures the reliability and durability of the mechanism. In addition, a homemade vibrating plate allows you to:

- Safely tamp any surfaces;

- reduce the amount of manual labor when performing work;

- improve the quality of footpaths and platforms;

- It is good to compact dry cement and semi-dry concrete mixtures when laying them.

Having a mechanism for compacting loose soils and bulk materials will allow you to carry out any amount of landscaping and exterior design work.

Review of purchasing options.

Mechanism design

The main working element is a heavy metal platform, which can be made of gray ductile iron or steel. The vibration effect on it is transmitted from a mechanical vibrator driven by a gasoline, diesel or electric engine.

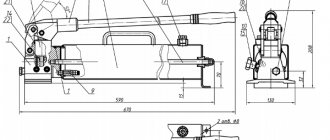

Drawing of a homemade vibrating plate.

A durable handle is provided to control the vibrating plate as it moves across the work area. Additionally, the design may include a fuel tank or starting electrical equipment. The engine and vibration device are installed on a frame, which is mounted directly on the tamping platform.

Do-it-yourself vibrating plate: with an electric motor, gasoline, homemade, drawings, how to make it yourself

Compaction of soil, backfill layer or concrete casting during construction work requires the participation of special equipment. In private construction, problems often arise related to deformation or subsidence of the foundation.

The cause of these events is poor compaction of the sand backfill layer. According to the technology, the density should correspond to the condition of a long-used country road. Checking the quality of the compaction is usually done by walking along the compacted area - if there are no traces of shoes left, the job has been done to the proper standard.

Soil compaction is required not only in critical areas. Conventional tiling of garden paths requires the creation of a layer of sand cushion, which also requires the maximum degree of compaction, otherwise the coating will begin to fail and move apart. It is impossible to achieve high quality work manually, and a vibrating plate comes to the rescue.

For home use, not everyone can purchase a ready-made device, since the cheapest sample will cost 20 thousand rubles. People who are able to operate metalworking tools and a welding inverter prefer to make their own vibrating plates, which saves money and brings the desired result.

Operating principle

The operation of a vibrating plate is based on the use of a rotating shaft with an eccentric, which generates strong vibration. The shaft is mounted on a massive metal base, which with its weight acts on the soil, compacting it due to its weight.

On the same base, a motor is installed, which is necessary to drive the eccentric shaft into rotation. To control the structure and give the installation the desired direction, a long handle is installed.

There are several types of vibrating plates:

- electrical;

- diesel;

- gasoline.

By weight they are divided into:

- light (up to 75 kg);

- universal (from 75 to 90 kg);

- medium-heavy (from 90 to 140 kg);

- heavy (140-200 kg or more).

There are also different ways to move the vibrating plate:

- upright, capable of moving only forward and requiring a platform of sufficient size to turn around;

- reversible, capable of moving both forward and backward, which makes them more convenient in conditions of limited space.

Lightweight and versatile vibrating plates are used for compacting paths, paving slabs, and landscaping work. During construction and foundation work, medium-heavy and heavy-duty installations are required that provide maximum compaction combined with high productivity.

Important! The weight of a vibrating plate created at home should not be too large, otherwise it will be difficult to move it and there will be a danger for the worker servicing the installation.

Mechanism design

Device

The main element of the vibrating plate, from which the creation of the installation begins, is the metal base.

There are steel and cast iron samples, however, the use of cast iron at home is not advisable.

It is capable of cracking, cannot be welded, and is fragile.

Typically, steel sheets with a thickness of 8 mm or more are used. Additional elements are installed on the surface of the base to increase the mass.

They also serve as the basis for installing the engine and vibration mechanism. In most cases, this is a regular shaft mounted on two bearings, on which a load is attached in the longitudinal direction. The rotation of the shaft creates a driving force, which, due to its own weight and inertial force, forms frequent short-term loads on the ground. Drawing

The operating efficiency of a vibrating plate depends on the weight, base area and rotation mode of the eccentric shaft. A slab that is too spacious is not capable of generating high pressure, since the weight of the installation is distributed over the area and reduces the specific pressure.

A small base gives greater efficiency, but it acts too selectively, pointwise. This mode does not allow uniform compaction of the soil over the entire area of the site.

The rotation of the eccentric shaft creates a significant load on all structural elements.

Too intense vibration can destroy the vibrating plate, have a negative impact on the operation of the engine, and negatively affect the well-being of the worker.

An example of a drawing of a gasoline vibrating plate:

Engine selection and installation

The rotation of the shaft is ensured by a motor installed on the base at the rear of the vibrating plate (close to the handle).

Different types are used:

- electric motor;

- diesel;

- petrol.

The choice of vibrating plate motor type is determined by several factors:

- owner capabilities;

- availability of connection to the electrical network;

- specifics of the upcoming use of the installation.

Vibrating plates with a gasoline engine are convenient because they allow you to gain complete independence from network resources (electricity).

They can be used on sites located at a considerable distance from the nearest housing or buildings, in the field, etc.

The only inconvenience is the need to carry a supply of fuel, which may be needed a lot during long-term operation and high engine power. This is excess weight and expense.

A homemade electric vibrating plate is limited in mobility by the length of the connecting cable. At the same time, it only needs to be connected and no longer requires any additional actions.

The main disadvantage of the electric motor is its constant rotation speed, which creates a strong starting torque and overloads the network.

The solution to the problem is to assemble a soft start regulator, which avoids mechanical and electrical overloads.

Attention! Electric motors do not require special care or maintenance, whereas gasoline or diesel units require constant attention.

The motor is mounted on the base of the vibrating plate using rubber cushions that reduce vibration and protect the motor from mechanical destruction.

Plate and frame

The plate is a sheet of metal, the thickness of which can provide sufficient rigidity.

Typically, steel sheets of 8 mm and thicker are used.

The average size of the working surface of the stove is 60*40 cm, although there are other options.

The front and rear edges of the slab are raised for unhindered movement along the surface of the site.

The frame consists of a stand for the engine and eccentric shaft. It also serves as an additional load, which gives the vibrating plate greater efficiency and increases the amount of forcing force. Another task that the frame solves along the way is strengthening the rigidity and strength of the base, compensating for mechanical loads from the rotating rotor.

The design of the homemade frame can be anything. The main task is to strengthen and weigh the slab, so they use pieces of channel bars, rails and other massive and durable elements. The only thing to remember is that the vibrating plate must sooner or later be placed in storage, which may require carrying it manually. Excessive weight will create difficulties.

Vibration mechanism

The vibration mechanism of a vibrating plate, or vibration exciter, can have two design options:

- unbalanced, which is a rotor unbalanced relative to the axis of rotation;

- planetary, using the energy of moving elements that move along special closed paths.

Making a planetary mechanism at home is impractical, since it is difficult both to create and to maintain. It is difficult to make an unbalanced vibrator, and the magnitude of the driving force is the same in both cases, so the choice is obvious.

The eccentric rotor is mechanically connected to the engine via a drive belt. To do this, pulleys located in the same vertical plane are installed on both elements. With their help, you can adjust the gear ratio and change the vibration frequency of the installation.

Additional items

Additional elements are:

- handle (carrier) used to guide the vibrating plate during operation;

- a trolley on which the device is installed when moving from one place to another;

- tension mechanism, which ensures tight contact of the drive belt with the pulleys of the engine and vibration mechanism.

The handle is a long U-shaped bracket made of a tube. It is attached to the plate through a swivel joint, which partially compensates for vibration and protects the worker from its effects.

The trolley is a separate element, although rigid mounting options are available. It is brought under the stove, the unit tilted towards itself by the handle, supported on a trolley and transported to the desired location. When rigidly mounted, the legs with wheels are installed on the base in an inverted position. If it is necessary to move the vibrating plate, the installation is turned over and transported to another location.

The tensioning mechanism ensures tight contact between the drive belt and pulleys. It is important that the roller has a groove that matches the groove of the pulleys. This will help extend the life of the belt.

If the vibrating plate roller is installed on the outside, the groove size must match the back of the belt.

For tensioning, an adjusting screw is used, which allows you to loosen the belt for replacement or tighten it to working condition.

How to do it yourself: step-by-step assembly

Let's look at the process of how to make a homemade vibrating plate for soil compaction. Procedure:

- Using a grinder, a slab (base) is cut out. The size is chosen based on your own ideas, it is recommended to stick to the average value of 60*40 cm.

- Along the edges, cuts are made at a distance of 7 cm (front) and 5 cm (back), to a depth of about 5 mm. Along the line of cuts, the edges are bent upward by 25° so that the slab does not cling to the ground and does not get stuck.

- Two pieces of channel are welded onto the top of the slab, reinforcing the base and edges. It is necessary to ensure that they are in the same plane.

- On the back side, holes for mounting the engine are drilled or burned with a welding electrode in the channels. If necessary, a metal platform with mounting holes is pre-welded.

- The engine is installed using rubber cushions.

- Eyelets are installed for attaching the handle.

- The rotor with the eccentric is manufactured separately and installed on the plate in finished (assembled) form. It is a shaft installed in the hub. One of them is blind, the second is through. A section of shaft passes through it, onto which the pulley is installed. It is necessary to ensure the alignment of the pulleys, otherwise the drive belts will have to be changed every shift.

- The tensioning device is attached to the frame in a convenient place for use. It is usually installed in the middle, between the pulleys, at the point of maximum belt sag. It is important to ensure that all pulleys and the tension roller are placed in the same plane.

- It is recommended to cover the rotating rotor with a protective cover to prevent injury.

- The handle is installed, a test run of the vibrating plate is made, and the functionality is checked. Detected problems or flaws are eliminated and necessary amendments are made.

Putting the vibrating plate into operation is possible only after all defects have been completely eliminated. It’s rare that anyone manages to get the expected result the first time, but after corrections, the installation usually starts working in the desired mode. The main setting is to determine the optimal eccentric size and select the speed mode of operation.

A homemade vibrating plate, no matter how it turns out, will provide a much better result than trying to compact the backfill layer manually. All detected deficiencies will be eliminated, and additions or improvements to the design will appear as operation progresses. The final result can compete with industrial designs, if not outstrip them in terms of efficiency and quality of work.

The main advantage of homemade devices is the ability to correct or change the design at any time, or add additional elements.

Such actions are impossible with ready-made vibrating plates, since the design of such technical means rarely allows for changes.

The quality and speed of labor-intensive operations with bulk materials is worth the effort and time spent on creating homemade plants.

Making a tamping plate

The plate for the vibrating tamper can be manufactured at the factory or made by hand from a metal sheet with a thickness of at least 8 mm. A homemade vibrating plate should provide such a weight to the device that it will give a tight fit to the surface being treated.

Its dimensions should not exceed 800 x 500 mm, excluding the curved edge, which will ensure convenient operation and the ability to use the device without additional assistants.

A flat steel plate, when moving over soil or concrete mixture, will constantly cling to an uneven surface. To avoid this, the front and rear edges of the slab are slightly bent upward, resulting in a structure reminiscent of a sled. To do this, stepping back a little from the edge, you need to make a cut in the metal to a depth of 5-6 mm using a grinder and bend the strip. Repeat this operation on the other edge of the sheet. The contact line after the bend must be welded using electric welding.

Making a tamping plate.

To install the motor and vibration mechanism on the platform, you need to secure the support frame. It can be made from two installed pieces of metal channel. They must be installed parallel to each other transverse to the axis of the tamping platform. Drill mounting holes for the motor and vibrator in them and weld them with electric welding.

Making a vibrating plate with your own hands

A vibrating plate is one of the necessary tools in construction work. Usually purchased tools are used, but if you make a vibrating plate yourself, you can also use it to level surfaces.

Requirements for the tool to operate

The characteristics of a vibrating rammer depend on the quality of the material of the vibrating plate itself. Steel is used to make the frame, and steel or cast iron is used for the device plates.

A device made using a cast iron plate must be chosen more carefully: if the material is of low quality, cracks may appear on it during operation.

The size of the working surface determines the pressure of the plate on the surface being processed. This, in turn, determines the quality of the vibratory rammer. For example, it is better to compact the soil using a vibrating plate with a smaller surface area.

Vibration force is important for high-quality operation of the tool. The compaction density of the surface depends on this indicator. The greater the vibration force, the better the tool will cope with its task. To compact dense surfaces, you need a vibrating plate with a high vibration force.

For example, for laying tiles, the vibration force of a tool weighing 75-90 kg should not exceed 20 kN. Otherwise, the tile will be pressed too hard into the ground, and in the worst case, damage will occur. A vibratory rammer with a force rating above 10 kN is suitable for laying asphalt.

The ease of movement of the plate depends on the power of the engine. If it is powerful enough, the plate itself will move. If the power of the slab is small, difficulties will arise when working downhill, and the tool will begin to bury itself in the ground.

Assembly materials

The design of a homemade vibrating plate is quite simple, so it can be assembled with your own hands.

To make the plate you will need a motor that will provide vibration. Of all the components that make up the tool, this is the most expensive. Area vibrators operating from a household network are quite suitable. You can choose a model that operates from a 220 V network, such as, for example, IV-99E or IV-98E.

There are 380 V models available for sale. Such a motor is also suitable for making a machine, but it is difficult to provide three-phase power on site, so it is not recommended to use it.

Gasoline engines can also be used, such as the three-stroke single-cylinder engine from Honda. An engine from an old or no longer used chainsaw is also quite suitable. A motor from a drilling machine can be used as an electric drive.

The next step is to find material for the work platform. A steel sheet is quite suitable, the thickness of which should be at least 0.8 cm, weight - at least 60 kg. The sheet size should be 80x45 cm. There should be no irregularities on the surface of the sheet.

If all the main parts are found, you can collect additional ones:

- plastic wheels from the trolley - 2 pcs.;

- M10 bolts;

- M12 bolts;

- channels - 2 pcs.;

- elastic cushions for the handle - 2 pcs.;

- pipe sections;

- hollow pipe - 1.2 m;

To work you will need tools:

- hammer;

- locksmith tools;

- Bulgarian;

- welding.

Stages of assembling a vibrating plate

The cover must be removed from the motor to adjust the vibration strength.

The edges of the slab are slightly bent inward. 10 cm before the edge you need to make 0.5 cm cuts and use a hammer to bend it 20-30 degrees. Protect the places where the cuts were made with a welding seam. This simple measure will prevent the slab from burying itself in the ground during operation.

Next, you need to weld the channels so that they do not extend beyond the edges of the surface. The correct location is determined by the center of the work surface and the location of the engine. The channel needs to be welded efficiently, preferably using transverse lines.

Next, the engine is secured. For this purpose, holes are made in the channels. The engine is installed using a level, secured with M10 bolts (if the engine is gasoline, then M12). An eccentric is used to create vibration in the drive device.

Elastic cushions must be installed at the base of the stove, where the control handle is fixed. This will help dampen vibration and the tool will not be pulled out of your hands. Then the wheels and hollow tube are welded to make the tool easier to transport.

At this point, the assembly of the vibratory rammer is considered complete.

I also recommend reading:

How to check if the level is working correctly

Chainsaw lawnmower: how to make it yourself

How to make an electronic latret with your own hands?

Engine selection and installation

When making a vibrating plate with your own hands, diesel engines are usually not used. Yes, they are reliable and durable, diesel fuel is cheaper than gasoline, but these engines are too expensive and bulky for a small home machine. The most popular mechanisms are those with a gasoline internal combustion engine and with an electric drive.

The gasoline engine makes it possible to perform work regardless of the presence of a nearby energy source. This vibrating plate is in demand among small construction teams performing contract work on private development sites.

To carry out work within the personal territory, it is better to use a tamping machine with a 220V electric motor. It operates much quieter, does not require refueling, and the power supply can be easily provided through an extension cord that can be extended to any location on the site.

The electric motor is fixed to a welded channel using bolts and connected to the vibration mechanism using a belt drive. If the vibrator eccentric is connected to the motor with a rigid connection or mounted on a shaft, then the motor bearings will constantly fail due to vibration effects.

The structure of the model with a gasoline engine.

The center of gravity of the engine must be on the central axis of the vibration platform. If this is not done, then during operation the vibrating plate made by yourself will constantly move to the side and you will have to make additional efforts to keep it in the desired direction. Vibration-damping pads made of thick rubber must be placed under the motor feet.

We assemble a 220V electric vibrating plate with our own hands

Home craftsmen perform construction work as economically as possible. In this case, a pre-assembled homemade tool helps. Components for it are usually selected from available materials.

Recently, a do-it-yourself vibrating plate with an electric motor has been in demand. It is used for laying paving slabs, compacting fine soil, and during the process of laying the foundation.

Main components of the vibrating plate design

Before you make a vibrating plate on your own in a garage, you will need to prepare a diagram or even draw up drawings to scale to simplify further assembly. The main components in the design are the following parts:

- frame frame;

- base metal platform;

- electric motor;

- transmission system;

- suspension;

- management block.

The base plate is selected from a thick-walled steel sheet or ductile cast iron so that there is no destruction of the material during operation.

This is facilitated by the relative viscosity of the metal and minimal fragility. It is strictly forbidden to assemble cast iron of questionable quality with a large number of cracks or casting cavities.

When working with sand and gravel mixtures, it will be destroyed by external influences.

The thickest sheet metal will be needed to make the base and weight for the eccentric

It is important to initially have the correct geometric dimensions of the base, since if you make a vibrating plate with your own hands in accordance with this rule, the site will self-clean from soil adhesion. The area is also selected optimally, without unreasonable increase. A small working surface contributes to high-quality compaction of the site.

Popular drawings demonstrate a fairly simple design of a homemade vibrating plate with an electric motor. According to the kinematic diagram, a vibrator is based on the platform, and an electric motor is mounted above it.

To connect these elements together, a V-belt drive or coupling is provided. In fact, the motor provides rotation transmitted to the vibrator, and it further forms the oscillatory process.

Scheme of the simplest vibrating plate design

The resulting energy is transferred to the slab, and from it passes to the compacted soil. During compaction for laying paving slabs or for other purposes, particles of material fill the voids in the embankment. The result is a dense, even coating.

Types of vibrating plates used

Homemade designs require the presence of a power plant that provides the main work. Three types of motors are often used:

- diesel;

- petrol;

- electric 220V.

Diesel engines are appropriate when a lot of effort is constantly required. In everyday conditions they are hardly justified. Although it is not uncommon to find a vibrating plate made from a walk-behind tractor with an installed two-stroke engine.

Devices with a gasoline engine, like previous designs, are autonomous, but extremely noisy in operation. An economical engine with a power of several watts is selected for them.

Recommended engine power is 1.5-2 kW at 4000-5000 rpm. Less power will not provide the required shaft rotation speed, and accordingly, the vibration force will be insufficient

The optimal solution for many is a self-assembled electric vibrating plate. It is enough to connect electricity to the place of work on the site and you can start compacting the soil. A positive factor is the absence of exhaust gases during the process.

According to classification, it is customary to divide products into several groups:

- light – weight less than 70 kg;

- universal – up to 90 kg;

- medium weight – 90-140 kg;

- heavy group – more than 140 kg.

The first group is appropriate for processing the local area, where a layer of no more than 15 cm is expected to be pressed. The universal one is relevant for processing 25 cm. Heavier devices are designed for 50-60 cm.

The larger the compacted layer, the heavier the machine should be

It is important to correctly select the electric motor for the vibrating plate. After all, a too weak model on a massive slab will sink into the layers of soil. The optimal ratio is considered to be 5 hp per 100 kg of mass. or 3.7 kW.

Preparing the necessary kit

To make a vibrating plate at home or in a garage, you do not need to look for any rare or expensive parts. In the process, the following tools will be in demand:

- welding machine and a pack of electrodes 3 mm in diameter;

- half a kilo hammer;

- angle grinder with metal discs;

- set of wrenches and screwdrivers.

The components for the device will include the following set:

- An area motor with the ability to be connected to a 220 V household power supply. A new vibrator for a vibrating plate will be quite expensive, so it is recommended to purchase Soviet devices at disassembly sites or radio markets. Sometimes craftsmen even install motors from old washing machines, but the disadvantage of this method is the lack of vibration control.

Vibrating plate device

- Sheet metal 8-10 mm thick. The area is selected taking into account the fact that the edges will bend. The optimal parameter for domestic conditions is 50x80 cm plus allowance for bending. You can find the sheet on metal plates.

- A pair of 80 mm channels or pieces of a building profile that will be welded across the structure. They are needed to mount and hold the electric motor.

- Metal pipe with a diameter of 20 mm. Its length is calculated based on the user's height. The optimal handle for average height is 120 cm, so you will need about 3 m of workpiece.

- A set of hardware for mounting the motor, including M10-M12 bolts, nuts for them, and always locking washers to minimize the influence of vibration.

The degree of influence of vibration on the operator can be reduced with the help of built-in additional devices. Often, automotive suspension elements are used for this. Without them, everything will also work, but the operator will get tired faster.

VIDEO: Making a vibrating plate with your own hands, step by step, with errors and their solutions

Step-by-step algorithm for assembling a vibrating plate with your own hands

At the initial stage, a base platform is prepared from a metal sheet using a grinder and a welding machine.

We measure 10 cm from the front and back edges and cut the angle grinder to half the sheet thickness of 4-5 mm. Using a hammer or mallet, we bend the workpiece along this line by about 30-40 degrees.

Such a slide will reduce the likelihood of the platform burying in the ground, and will also allow you to move the installation in the desired direction.

The cuts should be strengthened by welding. Using electrodes, we form an internal stiffening rib that fixes the bend in the desired position. We position the channels across the stroke so that their approximate axis corresponds to the distance of the engine mounts. We weld the strips to the inner surface.

There are two ways to mount the motor. In the first case, drilled holes are used in the channel to thread bolts through them. In the second case, the bolts are welded to the channels and the engine is placed on top. This method is considered more reliable, however, it requires very strict adherence to center distances.

When installing the electric motor on the site, it is worth knowing that the Soviet IV-98 models have an internal eccentric for the vibrating plate. It can be adjusted to the optimal vibration strength parameters. We tighten the nuts, having first placed the bushings under them.

The crucial step is attaching the handle. To dampen vibration on it, silent blocks from domestic or foreign cars are useful. We weld the L-shaped elements to the bent part of the platform. We put rubber elements on them, through which the handle will be connected.

At home, it is possible to assemble a model weighing 40-50 kg. This is enough to compact 10-12 cm of soil.

When operating a homemade machine for a long time, individual parts of the electrical circuit may overheat, so it is necessary to use an RCD.

VIDEO: How the Germans prepare a site for laying paving slabs and paving stones

Vibration mechanism

The simplest device for creating vibration vibrations can be made from a piece of metal circle with a diameter of 40-65 mm. To do this, a hole with a diameter of 12-14 mm is drilled parallel to its axis along the entire length. It should be offset from the center by about half the radius. A metal rod of the appropriate diameter must be inserted into this hole and firmly secured with nuts.

Bearings or bronze bushings are installed on the same shaft-rod on both sides, mounted on racks welded to the channel. The height of the stands depends on the diameter of the vibrating roller. On the belt drive side, a pulley is attached to transmit rotational motion from the electric motor to the vibrator. Rotating at high speed, this roller with a shifted center of gravity will create oscillatory movements and transmit them through the racks to the vibrating platform.

Electric vibratory rammer circuit diagram.

You can use a factory-made vibration mechanism. This will provide a higher level of machine reliability, but will entail additional costs.

Do-it-yourself vibrating plate: making products from a walk-behind tractor and others, operating principle, video and photo

Concrete is the most commonly used building material. Due to its performance properties, concrete is used in almost all stages of house construction: the foundation, blind area, floor surface, walls and partitions.

To achieve strength and durability, concrete must be made from a quality mixture and the right tools.

If the concrete solution is properly compacted, the finished surface will be free of cracks.

The most important tool when working with concrete is a vibrating screed.

Technical characteristics and operating principle

The tool has a very simple design, and making it yourself will not be difficult. A vibrator for the vibrating plate is placed on a heavy base, which is connected to the motor using a belt drive. The rotational motion from the power plant of the tool is transmitted to the vibrator, which converts it into oscillatory motion, which leads to compaction of the soil.

Using a homemade vibrating plate you can get an even, dense coating. More sophisticated tools have a reverse function, allowing them to be used in trenches.

Cast iron or steel is used as the material for the work plate. Among the main technical characteristics of the unit it is worth noting:

- Weight of the structure (ranges from 50−200 kg).

- Surface compaction depth. In garden plots, lightweight and versatile units are most often used, capable of compacting soil to a depth of 10 to 25 cm.

- Dimensions are determined by the width of the working platform and have a direct impact on work productivity.

- The disturbing force shows the force exerted on a surface and is measured in newtons.

- The vibration frequency affects the speed of passes and the smoothness of the compacted soil. The more often the blows are applied, the better the top layer of the surface is smoothed, but the speed of work decreases.

All units can be divided into groups in accordance with the power plant used. The most popular are gasoline tools, but for your personal plot you can make a vibrating plate with an electric motor with your own hands.

There are no significant differences between these types of tools in terms of productivity and quality of work. The only drawback of electric vibrating plates is the need for power supply .

There are also diesel units, but they have a high noise level.

Surface

Before making a homemade vibrating plate, it is necessary to analyze the intended surface of the tamper. If the device will work on colored surfaces, an increased vibration frequency will be required.

Sand, gravel and crushed stone are most effectively compacted with just such a slab.

If the working surface consists mainly of soil deposits, then a plate with a high vibration amplitude will help make the operator’s work easier.

The higher the amplitude, the better and easier the soil compaction occurs. But this homemade stove has a significant drawback - the need to install a shock-absorbing system.

Advantages of a homemade tool

Owners of personal plots often doubt the advisability of creating a vibrating plate with their own hands. It is worth remembering that a homemade device will work no worse than its purchased counterparts. Among the main advantages of a unit assembled on its own, the following can be noted:

- There is no need to purchase expensive materials and spare parts.

- The simplicity of the design allows you not to worry about the ergonomics of the tool.

- The manufacturing process is simple; you do not need to strictly monitor the dimensions.

- You can use any type of power plant, and you don’t have to buy it specially; any engine from decommissioned equipment will do.

- The tool is created taking into account the specific tasks and characteristics of the owner. It is often difficult to select a branded unit with the necessary technical characteristics.

Secure the shoe

Check the fit of the steel plate on the beam, if necessary, tap the metal or sharpen the wood. The shoe should fit snugly against the end on all planes. Drill holes for screws in one wing, pointing the drill at a slight angle into the wood, and tighten the screws.

Turn the beam over to the opposite side and fasten the other wing in the same way. Make sure that the shoe does not move away from the end.

When drilling subsequent holes, guide them past the already screwed in screws.

Manufacturing recommendations

All branded units of this type are quite expensive, and making it yourself can save a lot of money. The quality of work performed using a homemade tool will be high. To make a vibrating plate you will need the following materials:

- Sheet metal 8 mm thick for making the base of the working platform.

- Two channels.

- Soft cushions made of elastic material (2 pcs.) for installation on tool handles.

- Bolts for fastening the power unit.

- Metal pipe.

First you have to decide whether the tool will be portable, or whether it is better to make a wheeled version. In the second case, it is worth adding 2 wheels to the number of necessary materials. The portable unit is as simple as possible to manufacture and consists of 4 main elements: a power unit, an eccentric, a platform and a handle.

As an example, it is worth considering just this version of the tool, because it is perfect for use on a personal plot.

Procedure

The tool is assembled in the following sequence:

- In a steel sheet, using a grinder, it is necessary to make blind cuts at a distance of 10-15 cm from each edge. As a result, the design can be shaped into skis. Otherwise, the tool will not be able to move along the ground and will constantly bury itself in it. The edges of the sheet are folded, and the joints are thoroughly boiled.

- In the middle of the slab, a platform for the power plant will be installed, and it is best to use channels as the material.

- After installing the engine, you need to balance it. When the center of gravity shifts during operation, the tool will constantly move towards the maximum weight, and considerable physical effort will have to be made to hold it.

- The power plant is selected based on personal preference. If possible, you can use an electric motor from decommissioned equipment, which will significantly save on the cost of the tool.

Read also: Wheel for polishing a car using an angle grinder

Torque transmission

It is recommended to use a soft V-belt drive as a transmission to transmit torque from the engine to the vibration mechanism. It will ensure reliable rotation of the eccentric and protect the motor bearings from the effects of vibration.

It is recommended to use double-belt pulleys. This will give greater grip to the belts and ensure trouble-free operation in the event of a break in one of the belts.

To protect against possible injuries, the belt drive must be covered with a protective cover, and if this cannot be done, then a bumper guard must be installed.

Control handle and vibration damping system

During operation, thanks to the front location of the eccentric and the resulting vibrations, the platform with the engine installed on it begins to move along the surface independently. But to set the correct direction of movement, a control handle is needed.

According to its design, it can have one or two inclined posts with a transverse handle-crossbar. It is recommended to install a vibration damping device in the upper part of the handle so that vibrations are not transmitted to the hands during operation. You can use springs as protection; the stand itself can be made of two pipes, one of which will go inside the other. The springs are fixed by steel rings installed on the pipes.

If you have the financial opportunity, then instead of a homemade spring structure, you can install silent blocks from a passenger car. This will provide sufficient vibration damping, and the structure itself will be less noisy.

The role of the control knob in the vibrator plate device

In a device such as a vibrating plate, when the market is replete with various models, often differing only in design, it is important to think about the safety of workers. Honestly, it would be better if the model had no handle at all. But such devices will have a significant impact on your wallet and will weigh from 700 kg, but they are controlled remotely. If the handle is present, then it is necessary to ensure that it is equipped with a vibration-proof pad.

Look

All advertisements for the sale of vibrating plates

The device of the vibrating plate does not involve complex schemes and mechanisms of action. But since this equipment is often actively used in difficult conditions, it is necessary to pay attention to proper care of it. Replacement of vibrating plate filters, spark plugs, oil, timely maintenance - and your vibrating plate will serve faithfully for many years.

Bomag vibrating plate device

Possibility of reverse movement

Movements of a homemade vibrating plate made as described above are only possible in one direction. Therefore, after walking a certain distance, you have to turn it around and only then move in the opposite direction. This reduces the speed of work and requires additional physical effort on the part of the operator.

Another drawing of a variant with a gasoline engine.

In order to provide the vibration machine with the ability to reverse movement, it is necessary to install a device that changes the direction of rotation of the motor. After its installation and connection, the vibrating plate will be able to move in two directions.

When the edge of the treated area is reached, the operator turns off the engine and starts rotating it in the opposite direction. The vibrator eccentric will also become reversible and provide the machine with a return movement.

Final work

After assembling the slab, all metal parts must be primed and painted to protect against corrosion. Securely fasten the supply cable to the control handle to prevent the possibility of running over it. The engine switch must be located on the structure itself to provide an emergency stop during operation.

After this, the vibrating plate made by yourself must be tested. Freshly dug soil is best suited for this. Testing on bulk material will not allow you to test operation at full load.

As you can see, it is quite possible to make a vibration machine yourself. But for this you need to have basic knowledge and experience in plumbing and welding.