Decorative Sequins Luxart Glitter Bronze 20 ml

100 ₽ More details

Natural colored jute ribbon (width 7cm, length 4.5m)

292 ₽ More details

Wall curtain rods

Arranging your own home and the surrounding area is an important and responsible task. One of the indispensable attributes of any private home is a basement or cellar. This is a great place to store food. During its construction, the owner will be faced with the problem of arranging a convenient entrance. This is due to the fact that the stairs will take up too much space for a comfortable descent.

The descent, made in the form of a hatch cut into the floor and a vertical ladder for descent, is compact, but extremely inconvenient. The way out of the situation is to build a small lift that will take you and your cargo to the basement with all the convenience. We will learn below how to make a metal elevator to the basement with your own hands and what types of elevators there are.

Build an elevator to the basement

Features of manufacturing a cellar elevator

An elevator is a fairly heavy structure; its fixation area is a load-bearing wall.

When planning the manufacture of a home elevator, you need to understand that this is a heavy structure that needs a strong, reliable support and foundation.

When making a cellar lift with your own hands, you must follow these rules:

- Follow the manufacturers' instructions for the components that will be used during assembly.

- Build a powerful foundation designed to support the weight of the frame, equipment, people and cargo, plus a reserve of at least 30%.

- The guides can only be attached to concrete or brick walls with a thickness of two stones or more.

- Have sufficient space to accommodate the cabin and platform. These are quite voluminous structures that require a lot of space.

The possibility of a power outage or sudden failure of one of the mechanisms should be considered. For such cases, a portable or stationary ladder and a battery-powered light source should be prepared. Another effective solution is a hand winch. The ascent and descent will be slower, but the elevator will remain operational.

How to make it yourself

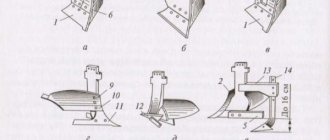

You can make a cantilever lift with your own hands. First, drawings of the main components of the mechanism are made, indicating the dimensions of the parts. This design consists of three inclined supports located at an angle of 70º. The axles are connected to each other at the top. An inclined support is made from a rectangular metal pipe measuring 30x50x2 mm. The lower edge of the pipe is cut at an angle of 70º and a metal plate (support paw) measuring 5x130x150 mm is welded to it.

A through hole with a diameter of 14 mm is drilled in the plate. The upper assembly consists of a thrust plate and a guide clamp. These parts need to be welded together. The thrust plate is made of metal sheet. The guide clamp is made from a rectangular metal pipe measuring 40x60x5 mm. The lift should have a height of 3098 mm, the distance between the centers of the holes of the support legs should be 2280 mm. Such a unit will have a load capacity of 850 kg.

To manufacture the device, install an M20 bolt in the hole of the upper unit and secure it with an M20 nut. Then the supports are installed in the guide clamps. Then the axle is installed in the holes of the clamps and supports and clamped on both sides with M12 nuts. The supports need to be separated. Then the tripod is placed on the ground. Steel crutches are hammered into the holes of the support legs. A chain hoist with a lifting capacity of 850 kg is hung on the bolt.

A manual cable winch with a lifting capacity of 200 kg is installed on the support. Install the hook, carabiner and cable. A load is suspended from the gripping element and the pulley. Apply force to the winch and lift the load. The structure is ready, it needs to be checked for functionality and the strength of fastening of the connections. If everything is in order, then the cantilever lift is installed in the required location and the structure is tested to lift the load. After this you can start using it.

Requirements for a home lift

The main criterion for an elevator is its load capacity.

To make a cellar elevator with your own hands, you need to carefully study the structure of this structure and the requirements that apply to it.

Standard elevators consist of the following parts and mechanisms:

- Lifting device. Operates by manual force or electricity.

- Platform. A base used to accommodate a movable fragment.

- Cabin. Designed to accommodate a person and cargo. Can be open or closed.

- Rails. They are mounted on the wall and serve as guides for the movement of the cabin.

- Controls. These include starters, relays, fuses and other parts that regulate the operation of the structure.

A homemade elevator to the cellar must meet the following criteria:

- safety;

- sufficient load capacity;

- ease of use;

- efficiency;

- availability of an insurance system;

- aesthetics;

- durability;

- Possibility of DIY installation.

When choosing a control method, it is recommended to use a remote control with lifting, lowering and emergency stop buttons.

Common models

Of the domestic models, the most popular are the single-seater branded 3449b and the double-seater 3851b. They have one and two consoles. The first lift is more common. It is used on buildings up to 150m high and can lift weights up to 500kg. The lifting mechanism consists of a winch and two drums located under the platform deck. The device is equipped with a 2.2 W electric motor.

A load weighing 500 kg can be lifted at a speed of 5.5 m/min. Domestic models are distinguished by reliability, ease of maintenance and long service life. For installation, consoles are first mounted, counterweights are fixed on them, then a platform is installed on 4 cables on the consoles. Counterweights are suspended from below. If the cable breaks, the brake system is automatically activated.

Common imported models are produced by a Chinese company under the ZLP brand. The most popular lift is the ZLP-630. It has a load capacity of 630 kg and a lifting height of 200 m. ZLPs are also more powerful, for example the ZLP-800. The main advantage is that their design is collapsible.

The platform consists of three sections, so the length of the platform can be changed depending on the number of passengers and cargo that will be lifted.

The platform is made of steel or aluminum. The height of the console can be adjusted. ZLP 630 can adjust the length of the console reach from 120 to 170 cm.

Types of elevators to the basement

Lift with electric motor

The basement lift can be equipped with various types of drives, differing in the operating principle of the applied force.

Electrical structures are equipped with a motor, gearbox and winch. The movement of the cabin is carried out by winding and unwinding the cable from the drum. To ensure smooth movement and reduce the load on the motor, the platform is equipped with a counterweight, the mass of which matches the moving part or slightly exceeds it. The system is reliable, but subject to rapid wear due to the presence of many parts that rub under load. The device produces a loud noise that can be heard in all corners of the building.

Hydraulic elevators operate quietly; the load is lifted by a piston into which a special liquid is pumped through a high-pressure hose. The power plant can be located below, above, even to the side of the shaft. In case of power outages, provision is made for the installation of hand pumps. The downside of this solution is the likelihood of hose ruptures and oil contamination of the entire basement.

The pneumatic elevator moves by creating a vacuum in one of the chambers under the influence of pressure pumps. The devices are safe, reliable, but rarely used. This is justified by their high cost, insufficient power and difficulty in maintenance.

As an option, you can consider mechanical lifts. To move the cabin, muscular force is applied to the drum. To increase torque, extended handles or large steering wheels are used.

Safety

Be sure to periodically inspect the elevator parts.

We pay special attention to the cable, checking: • presence of lubricant; • uniform laying on the drum; • no kinks or breaks in weaving threads; • serviceability of the cable fastening units on the drum and elevator frame

•

presence of lubricant;

•

uniform laying on the drum;

•

no kinks or breaks in weaving threads;

•

serviceability of the cable fastening units on the drum and elevator frame.

Electromechanical elevator motor with winch

It would be useful to make a simple but effective safety system in case the main cable breaks. To do this, we simply take a pair of ratchets from the inertial seat belts of a passenger car and install a drum with a safety cable between them. Assembling and fastening such a mechanism will not cause any particular difficulties, and its reliability is quite sufficient to support the significant weight of the elevator with a passenger.

In a control unit for a do-it-yourself elevator, it is preferable to use buttons without locking. According to the principle: “pressed - it goes, let go - it doesn’t go.” And be sure to provide an emergency power off button. power supply in case of “stuck” control button.

In addition, be sure to ensure reliable grounding of the elevator electrical equipment.

Leave your tips and comments below. Subscribe to our newsletter. Good luck to you and good luck to your family!

Preparation for installation

To make an elevator with your own hands, you will need a welding machine.

The success of all subsequent actions largely depends on the correct execution of the preparatory stage of work. First you need to choose the type of elevator, decide on its installation location, and draw up a detailed diagram. Then you need to make calculations and purchase the necessary property.

To build an elevator to the basement with your own hands you will need the following tools:

- welding machine;

- Bulgarian;

- perforator;

- screwdriver;

- spanners;

- electric drill;

- roulette;

- square;

- soldering iron;

- screwdrivers;

- level;

- paint brush.

Worm gearbox

Material list:

- channel;

- rails;

- steel corner;

- drum;

- cable;

- worm gear;

- rollers;

- telpher;

- Electrical engine;

- winch;

- power cable;

- actuator;

- profile pipes;

- anchor bolts;

- mounting boxes;

- acrylic paint;

- anti-corrosion agents.

You need to think through safety issues in advance. Effective ventilation and lighting should be provided, and a respirator, helmet, safety glasses and gloves should be prepared.

Comments

Hmm, well, making a homemade elevator is definitely not for a beginner. I would like to, of course, but I feel that my own knowledge is not enough. Maybe someone who is inexperienced like me has already tried to do this and share their experience?

Hmm, well, making a homemade elevator is definitely not for a beginner. I would like to, of course, but I feel that my own knowledge is not enough. Maybe someone who is inexperienced like me has already tried to do this and share their experience?

Alexey, an elevator in the basement is a very convenient thing, a friend of mine had it done by professionals, but if you really want to, I’m thinking of doing it yourself, but everything needs to be planned out very carefully, everything needs to be taken into account down to the smallest detail. Then everything will work out!

Alexey, an elevator in the basement is a very convenient thing, a friend of mine had it done by professionals, but if you really want to, I’m thinking of doing it yourself, but everything needs to be planned out very carefully, everything needs to be taken into account down to the smallest detail. Then everything will work out!

The elevator to the basement is convenient. Otherwise, in our basement you have to climb an ordinary wooden ladder and are constantly afraid that the crossbar under you will break off. Valery Ivanovich, where did your friend find these professionals? Who makes elevators like this anyway? Tell.

The elevator to the basement is convenient. Otherwise, in our basement you have to climb an ordinary wooden ladder and are constantly afraid that the crossbar under you will break off. Valery Ivanovich, where did your friend find these professionals? Who makes elevators like this anyway? Tell.

This is definitely a good idea. But here you either have to be a jack of all trades to build this on your own, or have a good friend to do this. What about companies that do similar things. Does anyone know these?

This is definitely a good idea. But here you either have to be a jack of all trades to build this on your own, or have a good friend to do this. What about companies that do similar things. Does anyone know these?

Place for arranging an elevator

The corner is the best place to install a lift.

A finished lift should provide comfortable conditions for operation. The design should help and not hinder economic activity.

First of all, it is necessary to provide for the issues of ensuring and maintaining the strength of the load-bearing structures of the building. The total weight of the elevator along with its cargo can reach a ton, and this is a large load on the floor and walls of the cellar. The best option is considered to be a monolithic box made of reinforced concrete, where all components have a sufficient margin of safety, and the additional weight is evenly distributed over the slab. The minimum thickness of the slab is 10 cm. If this figure is less, then the base will need to be reinforced.

There are these options:

- Make an external tunnel under the foundation. Place several large stones in it and fill them with cement mortar.

- Drill four holes in the slab and make an extension on top. Fill the wells with reinforcement and fill them with concrete.

- Place an additional screed 5-10 cm thick on top of the existing base.

- Fix and putty the rebar grid on the walls. Another way is to screw two reinforced concrete columns with anchor bolts.

The best place to install an elevator is the corner of the cellar. There the floor is stronger and there are two walls for attaching the guides.

Rules and instructions

Oddly enough, there are many emergency and dangerous situations that have already happened more than once. Sometimes hands or feet get stuck in the cracks of the door, or the cabin falls from a height. And children's games with elevators never bring positive stories. All this is taken as a basis in the process of installation work and installations. Such a unit should not cause problems for the owner.

Many people do not agree to ready-made installations due to the need to create a non-standard cabin. But these dimensions should not be made too high. It is much easier to remake a finished structure than to create a full-fledged new elevator that will fully cope with its purpose. Of course, an elevator to the second floor in a private house is a reality, but you shouldn’t forget about safety.

Of course, every person believes that comfortable living conditions should be in any private home. Today, creating a lifting device is not so difficult, but only if all the rules are followed.

Installing an elevator in a private house yourself

Lift Project

Installing the lift may require the help of a partner, since you will have to deal with quite heavy objects, and you will also need support for attaching them.

Construction should be carried out in the following sequence:

- In accordance with the project, apply markings to the floor, ceiling and walls. Double-check their accuracy, compare horizontals and verticals.

- Make a frame for the movement of the cargo compartment. A closed loop is made, which is rigidly attached to the supporting structures of the building. Rails are attached to the frame as guides for the rollers.

- Assemble the cabin. A channel is used for the frame and a reinforcement grid for the floor. The structure is equipped with railings and a swing door. If necessary, the walls are covered with steel mesh.

- Install the support beam onto the frame. Then attach the power mechanisms of the engine, gearbox, winch and clutch to it.

- Connect the lifting device and the cabin. Attach the cable and band brake.

- Check the quality and reliability of connections, eliminate curvature and play.

- Clean the metal from scale and rust. Treat it with anti-corrosion agent and paint.

- Supply electricity. Make channels for the cable, secure mounting boxes, remote controls and switches.

- Test the device in different operating modes, with maximum load. Check the operation of the protection when the light goes out and the operation of the emergency braking device.

Upon completion of installation, you need to go upstairs and lower the cabin to the bottom position to remove the load from the supporting structures.

Characteristics

The console lift has the following technical parameters:

- Lifting height - 15 m.

- Load capacity - 2 tons.

- Travel speed - 1 m/sec.

The main parts of a cantilever lift are:

- self-supporting steel console;

- loading platform guides, which are fixed to the console;

- basket with fence;

- lifting loading platform;

- lifting mechanism;

- electric motor;

- pump;

- hydraulic cylinder

The design may also include additional parts, for example, a fence in the form of a railing and a gate in it, a cabin, and a control panel.

A cantilever cargo lift is installed in the opening of floors in buildings. You can install such a structure outdoors, but then you need to provide a device for protection from precipitation. A hydraulic cantilever lift is used to lift loads in warehouses, construction, and industrial enterprises. There are also types such as a cantilever mast lift and a cargo mine lift.

Design advantages:

- ease of operation and maintenance;

- no need to make a shaft to install the structure;

- Only one wall is needed for installation;

- The lift is equipped with a safety shut-off valve to protect against accidents;

- reliability of design;

- low cost.

Lift-tilter

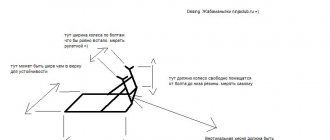

To avoid costs and a lot of complications, you can give preference to a simple garage lift-tipper. The device will allow you to tilt the car to one side, and the tilt angle can vary from 45° to 60°. This is quite enough for most repair work.

To build such a unit, you will have to create and connect a number of parts: the front pillar, beams (top, bottom, rear), shoe. Various connecting elements will also be required. You will need to work a lot with metal, so you must have a special tool - welding, a grinder and a drill with a set of metal drills. The main material for work is 4 mm steel sheets, angles and bushings.

Creating a Top Beam

Next, proceed directly to creating the top beam. For this, take two 1.5 m corners and weld them into a U-shaped profile. It is also necessary to weld a metal insert in the middle, which will ensure the fixation of the jack. The beam will be ready when you weld a plate of the appropriate length and height to the profile. The result is a rectangular beam. One end of it must be welded tightly - the bushing will be attached to it, and the guides for the jack are welded to the other end.

The platform for the beam is created from a steel sheet. You can bend its sides to get something like a box, or weld the walls of this very structure. Inside the site there will be a piece of wood of the required size, which is fixed with fasteners, and rubber is mounted on top of the wood. The platform is attached to the beam using a pre-welded eye.