A car wheel is an integral element of the vehicle's design. Tires and wheels give the car various performance characteristics. For example, they affect cross-country ability and speed performance. At the same time, such a simple parameter as the total weight of the wheel plays an important function. Let's figure out what the weight of wheels and tires affects when operating a car.

Calculation of the mass of a copper cylinder

Let's consider a simple problem. You need to find the mass of a cylinder made of copper. To be specific, let the cylinder have a diameter of 20 cm and a height of 10 cm.

Before you begin solving the problem, you should understand the initial data. The radius of the cylinder is equal to half its diameter, which means r = 20/2 = 10 cm, and the height is h = 10 cm. Since the cylinder considered in the problem is made of copper, then, referring to the reference data, we write down the density value of this material: ρ = 8 .96 g/cm3 (for temperature 20 °C).

Now you can start solving the problem. First, let's calculate the volume: V = pi*r2*h = 3.14*(10)2*10 = 3140 cm3. Then the mass of the cylinder will be equal to: m = ρ*V = 8.96 * 3140 = 28134 grams or approximately 28 kilograms.

Attention should be paid to the dimension of units when using them in the corresponding formulas. Thus, in the problem all parameters were presented in centimeters and grams.

Description

We constantly monitor innovations in the service sector and offer them to our clients. The rolled metal calculator allows suppliers to simplify their work as much as possible and save valuable time. It makes it possible to calculate the theoretical weight of almost all types of rolled metal; this calculator can be used to calculate products made from ferrous steel, stainless steel and non-ferrous metal.

Each visitor to our website can download a calculator and quickly calculate any rolled metal. For example, the calculation of a profile pipe is carried out by entering data on the height, width, wall thickness and required length of the product. When calculating the corner, you also need to indicate its height, width, thickness and length. Other types of rolled metal are calculated in a similar way.

A simplified calculation is also possible when calculating the channel and beam weight. To do this, you need to indicate the product number and its length in the calculator; the program will indicate the rest of the data itself.

All rolled products, depending on their shape, can be divided into four main groups:

a) grade steel;

b) sheet steel;

d) special types of rental.

Rolled sheets of steel and non-ferrous metals are used in various industries and construction. In this regard, sheet steel, for example, is divided into automotive, transformer, roofing tin, etc. The production of sheet steel with tin, zinc, aluminum and plastic coatings, polymer coating, as well as flat, smooth and profiled: corrugated sheets, expanded metal, perforated.

Sheet steel

divided into groups depending on the thickness of the section. Sheets more than 4 mm are classified as thick sheet steel, and sheets less than 4 mm are classified as thin sheet metal. In this case, there are the following types of sheet steel: shipbuilding, boiler, electrical, tin, acid- and heat-resistant, armor, etc. The qualitative characteristics of flat products are determined by mechanical properties, chemical composition, molecular structure, use for further processing and, finally, smelting method. When producing rolled sheets, the thickness may have plus or minus tolerances, which entails changes in the actual weight of a square meter of sheet. The larger the dimensional tolerance for a given flat product (the difference between the maximum and minimum dimensions of the flat product), the greater will be the difference between the theoretical weight of the sheet steel and the actual weight.

Hot rolled sheet of ordinary quality is made from thin sheet steel (thickness 0.5 mm - 3.9 mm) GOST 16523-89 and thick sheet steel (thickness 4 mm - 160 mm) GOST 14637-89. Flat rolled sheets are widely used in the production of steel containers.

The range of steel sheets corresponds to GOST 19903-74, the chemical composition of steel corresponds to GOST 380-88. The assortment for cold-rolled sheet steel provides for the supply of sheets with a width of 600-1400 mm and a thickness of 0.2-3.9 mm. Sheet length 1200-3500 mm. Assortment standards for cold-rolled steel coils provide for the supply of strips with a width of 200-2300 mm and a thickness of 0.2-4 mm. The current standards stipulate specific gravity, tolerances for sheet thickness and thickness variations, depending on the dimensions of the sheet or tape and delivery conditions. The standard includes standards for tensile strength and elongation. The permissible warpage per 1 linear line is also specified. m along the length and width of the sheet and control for decarbonization. In some cases, the technical conditions stipulate tighter tolerances than in the standards.

Read also: What a manual milling machine can do

Rolled sheets are divided into cold-rolled and hot-rolled.

Cold-rolled sheet with a thickness of 1 mm, 1.2 mm, 1.5 mm, 2 mm, 3 mm, available from steel grades 08KP, 3SP/PS.

Hot rolled sheet thickness 2mm, 2.5mm, 3mm, sheet 4, 5, 6mm, 8-10mm, 12mm, 14-16mm, 18mm, 20-32mm, 35mm, 36mm, 40 mm, 45 mm, 50 mm, 60 mm, 65 mm, 70 mm, 80 mm, 90 mm, 103 mm, available in grade st 3SP/PS, steel 09G2S-12; thickness from 4 mm to 50 mm steel grade 45.

Galvanized sheet thickness 0.5 mm, 0.55 mm, 0.6 mm, 0.7 mm, 0.8 mm, 0.9 mm, 1 mm – galvanized iron + polymer coating.

Cold rolling has two great advantages over hot rolling: firstly, it allows the production of sheets and strips with a thickness of less than 0.8-1 mm, down to several microns, which is unattainable by hot rolling; secondly, it ensures products of higher quality in all respects - dimensional accuracy, surface finish, physical and mechanical properties. These advantages of cold rolling have led to its widespread use in both ferrous and non-ferrous metallurgy.

In the production of hot-rolled steel sheet, the metal is first heated and then deformed using special rolling mills by rolling. Cold rolling ensures uniform sheet thickness and also improves its properties by hardening the surface.

Hardening is formed as a result of changes in the structure of the steel sheet

.

sheet, metal

grains are stretched and oriented along the direction of plastic flow of the metal with axes of greatest strength.

A metal sheet

acquires different properties along and across, i.e.

along the length and width of the steel strip

.

At large degrees of plastic deformation, all metal grains are almost identically oriented in the structure of rolled steel sheets

.

Plastic deformation during rolling of a steel sheet

causes hardening of the metal - cold hardening or, in other words, cold hardening. In this regard, to restore plastic properties it is necessary to carry out annealing.

Hot-rolled and cold-rolled sheets are used in mechanical engineering, construction, mining and other industries. The actual scope of application determines the requirements for sheet metal. For the manufacture of products by stamping, sheet metal is used: cold-rolled, hot-rolled, cold-rolled coil, galvanized steel in coils, strip metal.

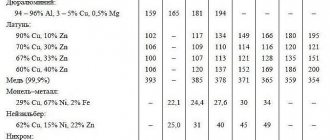

This table is used when calculating the mass of rolled sheets based on the specific gravity of a square meter of sheet metal.

Homogeneous and hollow cylinders

From the result obtained above, it can be seen that a copper cylinder with relatively small dimensions (10 cm) has a large mass (28 kg). This is due not only to the fact that it is made of heavy material, but also to the fact that it is homogeneous. This fact is important to understand, since the above formula for calculating mass can only be used if the cylinder is completely (outside and inside) composed of the same material, that is, it is homogeneous.

In practice, hollow cylinders are often used (for example, cylindrical water barrels). That is, they are made of thin sheets of some material, but are empty inside. For a hollow cylinder, the specified formula for calculating mass cannot be used.

Volume and surface area

As can be seen from the above, a cylinder is determined by two parameters: the height h and the radius of its base r. Knowing these parameters, it is possible to calculate all other characteristics of the body in question. Below are the main ones:

- Base area. This value is calculated by the formula: S1 = 2*pi*r2, where pi is the number pi equal to 3.14. The number 2 in the formula appears because the cylinder has two identical bases.

- The area of a cylindrical surface. It can be calculated as follows: S2 = 2*pi*r*h. It is simple to understand this formula: if a cylindrical surface is cut vertically from one base to another and unfolded, you will get a rectangle, the height of which will be equal to the height of the cylinder, and the width will correspond to the circumference of the base of the volumetric figure. Since the area of the resulting rectangle is the product of its sides, which are equal to h and 2*pi*r, the formula presented above is obtained.

- Surface area of a cylinder. It is equal to the sum of the areas S1 and S2, we get: S3 = S1 + S2 = 2*pi*r2 + 2*pi*r*h = 2*pi*r*(r+h).

- Volume. This value is easy to find; you just need to multiply the area of one base by the height of the figure: V = (S1/2)*h = pi*r2*h.

Metal calculator

With relative accuracy, you can calculate the weight of rolled metal and the amount of steel reinforcement. By entering dimensions and lengths, you can calculate the weight of the products. The calculator works in online mode for quick weight calculation, for this you need:

- select the required steel grade;

- select rental category;

- Enter the dimensions and dimensions of the sides.

Our resource specialists periodically update the steel grade for accurate and up-to-date calculations of products. In the calculation process, the specific gravity of rolled metal (calculator table) steel and size (metal thickness, sheet width, pipe wall diameter, etc.) are used.

Sometimes when the grade of steel from which it is made is unknown, in this case you can use universal grades such as St10 and St20. If you still have suspicions about the raw materials, you can perform a chemical test. metal analysis.

Online metal calculator

When you need to buy rolled metal, you need to know which transport will be more convenient to transport it. The tonnage of cars or other vehicles for delivery depends on the total mass of metal products. Therefore, the question arises of how to calculate the mass of the required amount of rolled metal.

Once upon a time, solving this issue took a lot of time even for highly qualified specialists. After all, to perform the necessary calculations, it was necessary to know the theoretical mass of the weight of various metals, formulas for calculating the volume of various rolling forms, etc. Such computational complexity required the search for new solutions. This solution was the online metal calculator.

Now, when drawing up any construction specifications, a rolled metal calculator is used instead of many tables, formulas and painstaking calculations. Using our online rolled metal calculator service, you can calculate the mass of the following metals: – steel; – cast iron; – aluminum; – bronze; – brass; – magnesium; – nickel; - copper; – tin; - lead; – titanium; – zinc.

Read also: The process of perception underlies the aspect of communication

In order to make the calculation, you need to select the type of metal and type of rental in the drop-down menu of the Free Online Metal Calculator program. The calculation is made for the following types of rental: – corner; – leaf; - pipe; – circle/wire/wire rod; – square pipe; – rental; – channel; – tape/strip; – beam; - hexagon.

For each type of metal, it is possible to select a specific brand. For example, when steel is selected in the “Metal Type” drop-down menu, then in the “Grade” drop-down menu, to the right of the metal type field, you can select any of the standard steel grades. The program also includes all existing grades of metals from which rolled metal is produced.

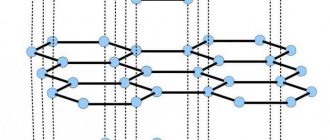

Next, having selected the type of rolled product, the type of metal and its grade, all that remains is to indicate the main parameters of the product itself. The program clearly displays which parameter needs to be entered for the calculation. Each type of rolled metal is accompanied by a graphic image of its cut with the name of each face, shelf, etc. displayed in the form of letters. The type of rolled metal itself is also shown. You probably won’t confuse the “sheet” type with the “strip” type, or the “square pipe” with the “square” type. For convenience and ease of measurement, the graphical representation of a rolled metal cut shows the names of each shelf, for example, a, b, c. For example, if you are calculating the mass of an aluminum corner, you need to indicate the height and width of its shelves, as well as the wall thickness (thickness of the metal sheet). To calculate the mass of a copper pipe, you need to indicate its total diameter and wall thickness. The fields in which you need to enter specific dimensions have the same name as the names in the graphic image.

This data is entered into the metal calculator in millimeters. In addition, indicate the length of a specific metal product in the appropriate field; the length is indicated in meters. Now all that remains is to click on the “Calculate” button and in the “Mass” field the program will display the value of the mass of the specified rolled metal in kilograms, accurate to the nearest gram.

To calculate the total mass of various metal products with different dimensions, perform the calculation for each type of product separately. Then simply add up the results - and you will find out the exact mass of the entire amount of rolled metal you need.

It is also possible to specify the required weight of rolled metal (for example, when you know that you can transport metal using a truck with a certain carrying capacity) and, knowing its basic measurements, determine the total length of the product.

A site about pipes. Calculations, master classes, sewerage

A metal calculator for stainless steel products will help you calculate the weight and cost of products based on given overall dimensions and specified steel grades.

The widget allows you to get the weight of products of almost any steel grade used today: black, non-ferrous, stainless steel. In particular, the non-ferrous rolled metal calculator will help in calculating products made from alloys of copper, bronze, aluminum and others. In the product catalog you can buy the following types of rolled metal: pipes, long products (angle, circle, channel, beam), strip, wire rod, hexagons and sheets.

Calculation of the mass of a hollow cylinder

It is interesting to calculate how much mass a copper cylinder will have if it is empty inside. For example, let it be made of a thin copper sheet with a thickness of only d = 2 mm.

To solve this problem, you need to find the volume of the copper itself from which the object is made. Not the volume of the cylinder. Since the thickness of the sheet is small compared to the dimensions of the cylinder (d = 2 mm and r = 10 cm), then the volume of copper from which the object is made can be found by multiplying the entire surface area of the cylinder by the thickness of the copper sheet, we obtain: V = d *S3 = d*2*pi*r*(r+h). Substituting the data from the previous problem, we get: V = 0.2*2*3.14*10*(10+10) = 251.2 cm3. The mass of a hollow cylinder can be obtained by multiplying the resulting volume of copper required for its manufacture by the density of copper: m = 251.2 * 8.96 = 2251 g or 2.3 kg. That is, the considered hollow cylinder weighs 12 (28.1/2.3) times less than a homogeneous one.

Determination of cylinder mass

Finally, it’s worth going directly to the topic of the article. How to determine the mass of a cylinder? To do this, you need to know its volume, the formula for calculating which was presented above. And the density of the substance of which it consists. Mass is determined by a simple formula: m = ρ*V, where ρ is the density of the material forming the object in question.

The concept of density characterizes the mass of a substance that is located in a unit volume of space. For example. It is known that iron has a higher density than wood. This means that in the case of equal volumes of iron and wood, the former will have a much greater mass than the latter (approximately 16 times).

Table of theoretical mass of round brass pipes according to GOST and TU

| Pipe name and dimensions | Diameter, mm | Wall thickness, mm | Pipe meter weight | Meters per ton | Density, kg/m³ | Standard |

| Pipe 3x0.5 | 3 | 0.5 | 0.0334 kg. | 29940.1 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 4x0.5 | 4 | 0.5 | 0.0467 kg. | 21413.3 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 4x0.8 | 4 | 0.8 | 0.0720 kg. | 13888.9 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 4x1 | 4 | 1 | 0.0840 kg. | 11904.8 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 5x0.8 | 5 | 0.8 | 0.0940 kg. | 10638.3 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 6x0.5 | 6 | 0.5 | 0.0734 kg. | 13624 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 8x2 | 8 | 2 | 0.3350 kg. | 2985.1 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 15x3.5 | 15 | 3.5 | 1.1250 kg. | 888.9 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 16x1 | 16 | 1 | 0.4000 kg. | 2500 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 16x4 | 16 | 4 | 1.3410 kg. | 745.7 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 19x1 | 19 | 1 | 0.4800 kg. | 2083.3 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 20x1 | 20 | 1 | 0.5310 kg. | 1883.2 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 20x5 | 20 | 5 | 2.0960 kg. | 477.1 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 22x5 | 22 | 5 | 2.3750 kg. | 421.1 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 25x2 | 25 | 2 | 1.2860 kg. | 777.6 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 25x6 | 25 | 6 | 3.1870 kg. | 313.8 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 37x2.5 | 37 | 2.5 | 2.3020 kg. | 434.4 m. | 8500 | GOST 494-2014 (x/d) |

| Pipe 47x3.5 | 47 | 3.5 | 4.0630 kg. | 246.1 m. | 8500 | GOST 494-2014 (p) |

| Pipe 72x3.5 | 72 | 3.5 | 6.3980 kg. | 156.3 m. | 8500 | GOST 494-2014 (p) |

| Pipe 104x2 | 104 | 2 | 5.7010 kg. | 175.4 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 108x4 | 108 | 4 | 11.6300 kg. | 86 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 114x7 | 114 | 7 | 20.9300 kg. | 47.8 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 125x4 | 125 | 4 | 13.5300 kg. | 73.9 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 129x2 | 129 | 2 | 7.0900 kg. | 141 m. | 8900 | GOST 617-2006 (x/d) |

| Pipe 300x8 | 300 | 8 | 65.2800 kg. | 15.3 m. | 8900 | GOST 617-2006 (x/d) |

Metal weight calculator

How to calculate the weight of rolled metal using formulas that describe the geometry of the cross-sectional area, for example, a profile pipe? You need to multiply this same area by the length of the pipe - we get the volume. Next, we multiply the volume by the density of the metal - this will be the theoretical weight of the entire product. It should be noted here that the density is different for different grades of steel and can greatly influence the final result. The metal weight calculator can calculate the mass using the base value of steel density 7850 kg/m3, corresponding to the most common grade of rolled metal - steel 40 GOST 1050-88, from which, for example, VR-1 wire is made. If you need to calculate the weight of rolled steel of another grade of steel, you can enter your density value taken from the tables. You can download density tables for non-ferrous and ferrous metals on our website. When calculating mass through geometric formulas, a slight error appears due to the product’s shape not fully matching the elementary mathematical figures. Therefore, for I-beams and channels, standardized parameters have been introduced by product number, taking into account the tabulated, rather than calculated, weight. The convenience of a metallurgical calculator is that you can determine not only the mass, knowing the length, but also the footage, knowing the weight of the rolled metal, i.e. how many linear meters are in one kilogram or ton. Using this calculator, you can quickly and easily calculate the mass of a profile pipe, angle, channel, beam, circle, square, hexagon, rod. The calculation can be made for steel, cast iron, copper, aluminum, magnesium, titanium and other alloys

Read also: How to insert a metabo drill switch button

But you can find out the exact weight of such products much easier on our website.

We bring to your attention a universal interactive mass calculator for independently calculating the mass of products of various shapes from cylindrical or sheet materials. Its peculiarity is that it allows you to find out the weight of a part or product not only made of rolled metal and alloys, but also any other materials: wood and MDF, plastics and polymers, paper, cardboard, rubber, concrete, brick. This can be done simply by entering the overall dimensions of the part, minus the sizes of holes and slots, as well as the density coefficient of the material from which the part is made. The exact data can be found in the adjacent table.

The mass of a cylindrical part is calculated as follows:

• In the appropriate fields of the mass calculator, enter the dimensional indicators: diameter, length and reference density of the material - the calculator will calculate the total mass of the product. • The second step - if the product has protrusions or steps - you need to add their dimensions. • And the third step is to subtract the dimensions of the holes, recesses, slits. • The result is the exact calculated mass of the cylindrical part.

The mass of a sheet part is calculated as follows:

• In the appropriate fields of the mass calculator, enter the dimensional indicators: width, length, thickness and reference density of the material - the calculator will calculate the total mass of the product. • The second step - if the product has protrusions - you need to add their dimensions. • And the third step is to subtract the dimensions of the rectangular or round holes. • The result is the exact calculated mass of the sheet metal part.

Our product weight calculator will be useful both for the designer and for customers, because it allows you to very quickly and with almost 100% accuracy obtain the necessary data regarding the weight of the product without complex mathematical calculations and weighing procedures.

Please note that the default weight in the calculator is steel grade 40 GOST 1050-88.

Source

Rolled metal weight table

The calculation formula determines the weight of 1 mm of rolled steel multiplied by the length (if the weight is calculated based on the length value). In the case when the initial data is weight and a table of rolled metal from tons to meters is required, the cross-sectional area of the rolled metal multiplied by the specific gravity is first determined, after which the weight is divided by the value obtained by multiplication and we obtain the required length by weight.

It should be noted that the weight table of rolled metal depends on the temperature of the calculated rolled product, so, at different steel temperatures, its density changes significantly. Based on this, the calculation uses a universal steel temperature of 20 °C. For non-ferrous metal products, other temperature values may be used, please pay attention to this.

In real life, the sizes of rolled products produced, especially in large-volume batches, may differ significantly from the calculated values. This is due to the fact that the table of mass of rolled metal does not take into account deviations from the exact geometric parameters of the product, which necessarily exist, especially for large volumes.

When it becomes necessary to find out the weight of rolled metal (angle, channel, profile pipe, beam, etc.), its dimensions, assortment, it is convenient to use special tables, where, according to GOSTs, dimensions, steel grades and other details are described. The table of rolled metal weights shows the theoretical weight of rolled metal and allows you to determine dimensions by weight and weight by dimensions. You can download the metal weight table on our website. However, the calculation of mass can be done using the “Metal Weight Calculator”. It allows you to determine the weight by footage and dimensions, as well as the number of linear meters for a given weight.

Lately there have been unscrupulous manufacturers trying to deceive consumers. In particular, it was noticed that Chinese rolled metal has the declared thickness only at the edges, where measurements are taken, and the metal is thin towards the middle of the product. This can be clearly seen in the figure. Knowing the theoretical weight, you can determine how high-quality products are offered by certain manufacturers. According to the production method, rolled products can be hot-rolled, cold-rolled and bent. Hot-rolled metal is bent by passing a hot billet through rolling shafts under pressure; cold-rolled metal is bent from a cold sheet on roll forming equipment or using a rolling mill. Of all types of metallurgical products, hot-rolled metal is the most durable.