The technology for connecting steel pipes in polyurethane foam insulation provides for additional protection of the joint area using heat-shrinkable sleeves, shells or filling. The design of the pipeline elements allows these elements to be welded into a single system without any problems. Or insert various types of fittings into the highway:

- valves,

- taps,

- valves,

- metering and control devices.

But after welding, insulation of the joints of PPU pipes is required - installation technologies are described below.

Note! If the pipeline is laid underground without a channel, the joints are protected using heat-shrinkable sleeves. It is also possible to use metal casings, over which a layer of thermal tape is wound. If the gasket passes above the surface, then a galvanized steel coupling is used for insulation. This is permitted by GOST 30732-2006. As thermal insulation methods, polyurethane foam shells or filling with polyurethane foam components are used.

Preparatory work

Before installing the heat-shrinkable coupling, each pipe in the joint area is cleaned of rust and dirt residues. To do this, use a cord brush (for metal). If the shell or pipe is very dirty, they can be washed and dried with a gas torch. At the same time, make sure that the coupling placed on one of the working edges is covered with a protective film. The film can only be removed at the time of isolation.

Important to remember:

- the coupling is selected according to the diameter of the shell;

- if the shell interferes with welding, it is additionally removed;

- the total length of the free ends of the pipes is up to 300 mm (for lines with a diameter of 57-291 mm) or up to 450 mm (for lines with a diameter of 273 mm).

To eliminate the possibility of damage to the shell and leakage of the medium, an ODK system (operational remote control system) is installed at the preparatory stage. Before shrinking the thermal couplings, the edges of the PU foam shells of already welded pipes are cleaned and degreased. In this way, an absolutely clean surface is achieved on which the coupling will move and on which it will be seated - this is required by the instructions for insulating joints of polyurethane foam pipes.

Installing an insulating layer for the joint

Before starting connection work, it is necessary to prepare the pipes. To do this, before welding the joints, it is necessary to install an insulating coupling of a certain diameter on one end of the pipe.

At the same time, it is important not to disturb the protective layer on the surface of the waterproofing of polyurethane foam pipes. Work must be carried out gradually and carefully. After carefully installing the coupling, you can begin joining the pipes and their further welding.

At the end of the welding processes, the welds should be tested for tightness. Next, it is necessary to combine the lines for the remote monitoring system, which also needs to be checked for reliable integrity of all connections.

Having waterproofed the joints, you can begin installing thermal insulation.

Standards for work

The performance of production work on insulating the connecting seams of polyurethane foam pipes is controlled by VSN 11-94 and 29-95. Also, the standards are determined by SP 41-105-2002. According to these standards, installation is permitted at ambient temperatures down to -14°C. If precipitation is observed, additional shelter must be installed.

Important! Even before the joints are insulated during the installation of polyurethane foam pipes, the tightness of the seams is checked. To do this, use a pressure test. Coupling protection is chosen as the optimal thermal insulation option. It meets the requirements of GOST 30732-2006, reduces the frequency of repair work on this section of the highway, and is a technologically advanced and durable material.

Types of pipe joint insulation

When installing main pipelines of urban heating networks, as well as when installing autonomous heating systems, several methods are used to seal the joints of polyurethane foam pipes:

- shell;

- coupling;

- pouring.

Each of them fits certain pipeline criteria: installation method, expected service life and operating conditions, type of outer insulating layer, design values of coolant pressure and temperature, and others.

Stages of work on insulating joints

Preparation

Taking into account the diameter of the line, the edges of the pipes are cleaned. The total length of the clean section should be 300 or 450 mm (to allow room for the coupling and its movement). Corrosion, dirt, and deposits are removed from the metal surface. The installation area is degreased, as well as the working ends of the shells and the inner surface of the coupling.

Important points:

- the surface of the shell itself is cleaned to a depth of 15 cm from each end. Be sure to degrease;

- at ambient temperatures below 0°C, it must warm up to 30-45°C (should become hot);

- the coupling is positioned in the center of the joint. Appropriate markings are made on the surface of the shell with a marker (not chalk!).

Make sure that the coupling surface is dry and clean. Remove the protective film and drill a hole with a diameter of 25 mm (it will be needed to check the tightness of the joint). The hole should be located at the top and 150 mm from one of the edges.

Preparing the edges of the insulation

Prepare the clean edges of the insulation - heat it with a burner to 50°C and stick on a mastic-based tape. They plan to overlap the tape with the coupling up to 10 mm. Remove the protective film from the mastic tape and make sure that no dirt or dust gets on the adhesive strip. Then slide the coupling over (guided by the markers) with the hole facing up and place it on the mastic tape. The circumference is heated with a burner until the PU shell is tightly compressed. As a result of correctly performed work, a tightly compressed barrel-shaped coupling is obtained.

Tightness

Now check the tightness - install a crimping device in the coupling hole. Air is pumped through the hole until pressure builds up. If necessary, repeat crimping. Difficult areas with air leaks are reheated with a burner and sealed. The edges of the coupling are then sealed with adhesive tape followed by heat shrinking.

GENERAL PROVISIONS

Since the couplings included in the insulation kit are one-piece, they must be pre-installed (pushed) onto the pipeline before welding the pipe metal.

Delivery of couplings to the site must be carried out only in protective polyethylene packaging to ensure their safety!

When sealing a joint using a heat-shrinkable sleeve, third-stage quality control is carried out:

- visual inspection of the coupling along its entire circumference.

- air pressure testing with excess pressure of 0.5 bar, checking for leaks around the entire perimeter using a soap solution.

- re-checking the tightness with the pressure generated as a result of the reaction of the foam components during pouring.

Work on sealing butt joints must be carried out in accordance with STO 18929664.01-2014 “Heat networks. Thermal and waterproofing of joints on pipelines of heating networks in polyurethane foam insulation. Constructions. Technologies. Materials. Quality control"

Repair of metal and polyurethane foam (PPU) pontoons and thermal insulation

⇐ PreviousPage 16 of 27Next ⇒4.9.1. Preparation for repair work in a tank with a polyurethane foam pontoon consists of the following operations:

— cleaning the tank;

— washing the surface of polyurethane foam;

— degassing of the tank, incl. forced ventilation method.

4.9.2. The surface of the pontoon is washed with a washing solution of type ML (0.1% concentration at a temperature of 60 0C). It is prohibited to direct a jet of live steam at a pontoon made of polyurethane foam.

4.9.3. To repair only the PPU pontoon, the concentration of hydrocarbons is reduced to sanitary standards. In this case, the pontoon shutter must be pressed around the perimeter from the tank wall without causing mechanical damage using wooden wedges or other pressing devices.

4.9.4. Sampling of the steam-air mixture is carried out from the following points under the pontoon: from the cavities of the PSR protective pipe, a perforated pipe for level measurement and sampling, the central pillar and in several places directly under the gate.

4.9.5. The concentration of vapors of harmful substances should not exceed the permissible values according to GOST 12 1.005.

4.9.6 During repair work in a previously cleaned and degassed tank with a polyurethane foam pontoon, defective areas are cleaned (around cracks, breaks, etc.). Metal, plywood and other floorings covered with grease or plastic film are placed under the breaks. Then the defective areas are sprayed (filled with polyurethane foam).

4.9.7. Cuts and parts of the valve that do not fit tightly to the wall and other elements of the tank are repaired by gluing sectors and segments of elastic polyurethane foam of the appropriate configuration. A strip of plastic film is placed between the valve and the tank wall to prevent the valve from sticking to the wall. Repaired carpet and shutter surfaces, as well as worn pontoon coverings, are coated with latex.

For the support posts of a monolithic pontoon made of polyurethane foam, the operation of the retractable parts is checked, followed by repairs. Then, as with the stationary support, the anti-corrosion coating is restored if necessary.

4.9.8. When repairing the thermal insulation of tanks and pipelines made of polyurethane foam, defective areas (delamination, crumpling, etc.) are cleaned to bare metal. Then the metal is cleaned, coated with a primer, and polyurethane foam is sprayed onto it. Cracks in thermal insulation made of polyurethane foam are repaired in the same way. When repairing thermal insulation on the upper chords of tanks, cradles of various designs or car lifts are used.

Defective areas of thermal insulation from polyurethane foam on pipelines of small diameter are removed; The metal of the pipe is protected and covered with an anti-corrosion coating. A longitudinal sector is cut out of the cylindrical shell, which, after installing the shell on the pipeline, is glued into place.

For pipes with a diameter of 250 mm, the thermal insulation can be restored by spraying. Repaired sections of pipeline thermal insulation made of polyurethane foam are wrapped with film and covered with a casing made of metal or other material.

4.9.9. Carrying out welding work and other hot work with an open flame during the period of repair of the pontoon is not allowed.

4.9.10. Before performing hot work on a tank with a polyurethane foam pontoon, all measures must be taken to ensure fire safety, including instructing workers carrying out repair work.

4.9.11 If thermal insulation or a pontoon made of polyurethane foam catches fire, it is strictly prohibited for workers to be on the leeward side.

4.9.12 When repairing a pontoon, lighting is provided with explosion-proof lamps.

4.9.13 When removing and correcting defective areas of the roof, tank body, welding collars of the RPS protective pipe, pipes for level measurement and sampling, central pillar, sealing the upper morning corner using hot work, measures must be taken to prevent hot metal from entering the pontoon .

The surface of the polyurethane foam must be protected from welding spatter using various means: felt felt, sheet asbestos or paronite, metal sheets, air-mechanical foam, etc.

4.9.14 Repair work on pontoons made of polyurethane foam is carried out in protective clothing. In addition, when gluing the shutter parts and applying the latex coating, a respirator is used, and when spraying, filter gas masks are used.

4.9.15 Persons who have undergone preliminary training and medical examination are allowed to repair pontoons made of polyurethane foam.

EQUIPMENT, MECHANISMS AND MATERIALS FOR REPAIR

TANK

5.1. When carrying out repairs, the following equipment, devices and tools can be used:

— lifting mechanisms (winches, cranes, jacks, hoists);

— rigging equipment and equipment;

— devices and devices for working at height (inventory scaffolding, scaffolding, cradles hung and attached to the roof of the tank, stepladders, etc.);

— equipment and tools for cutting metal, welded joints;

— welding equipment and tools for performing welding work (manual electric arc welding, semi-automatic welding, etc.);

— construction equipment for carrying out work to remove sediment from the reservoir, strengthen and compact the bases and foundations;

— auxiliary installation devices and tools (wedges, staples, cables, couplers, turnbuckles, hammers, sledgehammers, etc.);

— materials (channels, angles, T-beams and I-beams and other section steel);

— devices and instruments for testing strength and tightness (vacuum chambers, pumps, pressure gauges);

— measuring instruments (tape tapes, calipers, calipers, etc.);

— personal protective equipment and protective clothing (installation helmets, safety belts, etc.).

5.2. To repair tanks, you should use devices and tools that are commercially produced and have factory markings. It is advisable to use the most advanced technological equipment, which ensures high productivity of repair and installation work and significantly reduces the use of manual labor.

5.3. Lifting mechanisms, rigging equipment and equipment must be subject to technical examination within the time limits established by the instructions and departmental services of the State Mining and Technical Supervision Authority of Russia.

The terms and dates of inspection, permissible loads, and carrying capacity are indicated on the registration plates installed on the relevant equipment and mechanisms.

5.4. Work on lifting, moving, and transporting goods must be carried out in accordance with GOST 12.3.009-76 and GOST 12.3.020-80.

5.5. Equipment for cutting, welding, and electrical equipment must be operational, in good condition, checked before carrying out work, and also meet the requirements of electrical and fire safety, labor protection rules, and PUE.

5.6. Instruments for measuring geometric, mechanical and electrical quantities, volume, flow, level and others must have verification certificates (calibration certificates) and be verified within the time limits determined by Rosstandart or the metrological service of the enterprise (organization).

5.7. For repair and replacement of defective sections of the wall, bottom edges, load-bearing structures and stiffening rings, roofs of tanks (including high pressure), pontoons and floating roofs of tanks operated in areas with different design outside air temperatures, depending on the capacity of the tanks, it is recommended to use required steel grades, which must meet the requirements of state standards or technical specifications and be certified by certificates from supplier factories.

5.8. To repair the wall and bottom of horizontal welded tanks, steel grade VSt3sp3 should be used in accordance with GOST 380-94 “Ordinary quality carbon steel. Stamps."

To repair the walls and bottoms of tanks with a capacity of 3 and 5 m3, as well as for stiffening rings, triangular support diaphragms and clamping clamps of tanks of all containers in areas with a design temperature of up to minus 30 °C, the use of grade St3kp2 steel according to GOST 380-94 is allowed.

5.9. When repairing the thermal insulation of tanks and pipelines made of polyurethane foam, defective areas (delamination, crumpling, etc.) are cleaned to bare metal. Then the metal is cleaned, coated with a primer, and polyurethane foam is sprayed onto it. Cracks in thermal insulation made of polyurethane foam are repaired in the same way. When repairing thermal insulation on the upper chords of tanks, cradles of various designs or car lifts are used.

5.10. To repair and eliminate defects using epoxy compounds, the following materials should be used: epoxy resin ED-20, low molecular weight polyamide resin L-20, polyethylene polyamine, dibutyl phthalate, fiberglass, aluminum powder PAK-1, technical acetone, sandpaper N 3-5, putty EP-0010, technical toluene, gasoline, hexamethylenediamine, solvent R-4.

⇐ Previous16Next ⇒

What does the IS operation and maintenance department do? Responsible for the safety of data (copying schedules, copying, etc.)…

What makes your dreams come true? One hundred percent, unshakable confidence in your...

WHAT IS CONFIDENT BEHAVIOR IN INTERPERSONAL RELATIONSHIPS? Historically, there are three main patterns of differences that exist between...

WHAT AND HOW THEY WRITTEN ABOUT FASHION IN MAGAZINES AT THE BEGINNING OF THE XX CENTURY The first issue of the Apollo magazine for 1909 began, in fact, with a policy statement from the magazine’s editors...

Didn't find what you were looking for? Use Google search on the site:

Price

| Name of couplings | Price |

| Heat-shrinkable coupling 110*500 | 300 rubles |

| Heat-shrinkable coupling 125*500 | 330 rubles |

| Heat-shrinkable coupling 140*500 | 420 rubles |

| Heat-shrinkable coupling 160*500 | 480 rubles |

| Heat-shrinkable coupling 180*500 | 530 rubles |

| Heat-shrinkable coupling 200*500 | 610 rubles |

| Heat-shrinkable coupling 225*500 | 680 rubles |

| Heat-shrinkable coupling 250*500 | 850 rubles |

| Heat-shrinkable coupling 280*500 | 940 rubles |

| Heat-shrinkable coupling 315*500 | 1200 rubles |

| Heat-shrinkable coupling 355*700 | 1600 rubles |

| Heat-shrinkable coupling 400*700 | 2050 rubles |

| Heat-shrinkable coupling 450*700 | 2500 rubles |

| Heat-shrinkable coupling 500*700 | 3000 rubles |

| Heat-shrinkable coupling 560*700 | 3400 rubles |

| Heat-shrinkable coupling 630*700 | 4000 rubles |

| Heat-shrinkable coupling 710*700 | 5100 rubles |

| Heat-shrinkable coupling 800*700 | 6300 rubles |

| Heat-shrinkable coupling 900*700 | 7800 rubles |

| Heat-shrinkable coupling 1000*700 | 9300 rubles |

| Heat-shrinkable coupling 1200*700 | 14,000 rubles |

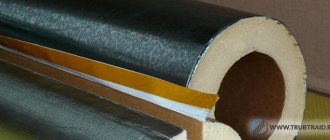

Design features and advantages of heat-shrinkable couplings

The internal diameter of the installation coupling installed at the pipe junction with a certain allowance must be commensurate with the PE shells being connected, therefore these products are produced in a line of standard sizes for all diameters of PU pipes (110 - 1200 mm). Convenient and quick installation of the heat-shrinkable sleeve is ensured by the special properties of the polymer from which it is made. This material is subjected to dosed exposure to gamma radiation, as a result of which the bonds of the molecules that form it are modified, and polyethylene acquires the ability to irreversibly decrease in size when heated.

The advantages of the technology for sealing welded pipe joints using dimensional cylindrical couplings are based on their multitasking. Installation of a heat-shrinkable coupling , capable of tightly compressing the surfaces of the shells of connected pipes, allows not only to ensure reliable waterproofing with minimal labor costs - its cylindrical surface is also a form for the manufacture of thermal polyurethane foam insulation. In addition, the modified polyethylene from which the couplings are made has the same physical characteristics as the shell material of PE PPU pipes, which ensures the tightness of their connection throughout the entire service life of the pipeline.