Steel nitriding process

The essence of the nitriding process is that the surface layer of a steel object is saturated with nitrogen by heating the product in an ammonia-saturated environment.

Steel nitriding, or nitriding, began to be used in industry not so long ago. A similar method of processing the outer surface of steel products was proposed by Academician Chizhevsky. As a result, the steel alloy is significantly improved:

- increases hardness and wear resistance;

- the durability and endurance of the metal increases;

- corrosion resistance is enhanced.

Anti-corrosion qualities are maintained in a humid environment and when exposed to steam.

Scheme of the steel nitriding process

This is interesting: Pipe flaring: subtleties of technology and basic tools

What is nitration

Nitriding of steel alloys is often compared to carburization. Despite the fact that the result is somewhat similar, nitration has more advantages. Nitriding of steel is currently used as the main method for increasing the resistance of the metal to various factors.

During nitriding, steel elements are not subjected to significant heating, but during this process the surface layer becomes much harder. These properties of the technology allow it to be used when processing parts that have been hardened and already ground. Nitriding is also called nitriding, which does not affect the outcome of the procedure in any way. After nitriding, steel parts can be polished or treated in other ways.

Nitriding plants come in different sizes depending on the production. The nitriding installation diagram consists of the following parts:

- power supply;

- hinges with details;

- vacuum chamber;

- rotameter;

- filters;

- gas cylinders;

- fore-vacuum pump.

All elements of the installation are designed for long-term operation.

The essence of the process is that steel is heated in an environment of ammonia materials. Due to processing in this environment, the metal has the following changes:

- since the hardness data of the surface layer changes, the wear resistance of the steel part improves;

- there is an increase in the fatigue strength of elements;

- the surface becomes resistant to rust and the effect is maintained when the elements come into direct contact with liquids, vapors or moist air.

Nitriding is the only optimal method that allows you to achieve stable steel hardness indicators. Unlike elements that have been carburized, nitrided parts retain their hardness parameters at a temperature of 550-600 degrees. After nitriding, the strength of the metal increases by one and a half to two times compared to hardening or carburization.

Steel grades for nitriding

Alloy and carbon steels containing C in the range from 0.3% to 0.5% are processed with this type of chemical treatment.

Particularly high performance is provided by alloying components that are capable of forming high-strength and thermally resistant nitrides, for example, aluminum, molybdenum or chromium. However, components that increase the hardness of the surface layer often do not allow applying a sufficiently thick layer of nitrogen to the surface. For nitriding, it is recommended to use the following grades of low-alloy and alloy steel:

- 38Х2МУА, containing aluminum, which reduces the workpiece’s resistance to deformation and at the same time helps to increase hardness and wear resistance after processing;

- 40X and 40HFA, which are low-alloy alloys, which, after surface treatment with nitrides, are widely used for the production of machine tools and equipment with non-standard characteristics;

- 30Kh3M, 38KhGM and 38KhNMFA, which are used in the manufacture of parts operating under regular bending loads;

- 30Х3МФ1, intended for the production of workpieces with increased requirements for the accuracy of parameters (the alloy can be enriched with silicon in order to create structural elements of fuel equipment).

Which steels are nitrided?

For nitriding, both carbon and alloy steels are used, in which the proportion of carbon is 0.3-0.5% . The best results can be obtained by using steel with alloying metals that form the most heat-resistant and hard nitrides. Thus, the nitriding process is most effective for alloy steels that contain aluminum, molybdenum, chromium and similar metals. Steels with this composition are called nitralloy. Molybdenum, in particular, prevents temper brittleness caused by the slow cooling of steel after the nitrogen saturation process. Characteristics of steel after nitriding:

- Hardness of carbon steel - HV 200-250;

- Alloyed - HV 600-800;

- Nitralloyev up to HV 1200 and even higher.

At the same time that the hardness becomes higher through alloying compounds, the thickness of the nitrided layer becomes lower. The thinnest layer is formed by steels with elements of chromium, tungsten, nickel, and molybdenum.

Recommended steel grades

The use of a particular grade of steel depends on the subsequent use of the metal element. Recommended grades for nitriding depending on the purpose of the products:

- If it is necessary to obtain parts with high surface hardness, steel grade 38Х2МУА is used. It is worth noting that it contains aluminum, which leads to low deformation resistance of the product. Whereas the use of grades that do not contain aluminum significantly reduces the surface hardness and its wear resistance, although it makes it possible to create more complex structures;

- For machine tool building, improved alloy steel grades 40X, 40HFA are used;

- For parts subjected to cyclic bending loads - steel grades 30Kh3M, 38KhGM, 38KhNMFA, 38KhN3MA;

- For fuel units, the parts of which must be manufactured with high precision - steel grade 30Х3МФ1. To obtain a higher hardness of the nitrogen-saturated layer, this grade of steel is alloyed with silicon.

Features of the technology

To saturate the steel surface with nitrogen, a muffle made of iron is used. The workpiece is placed in it. The furnace in which the muffle is located heats up to 600 degrees. During the heating process, the muffle is filled with ammonia and other gases. When ammonia enters the chamber, it decomposes. This releases nitrogen, which saturates the surface layers of the material.

What factors influence nitriding

The characteristics of the product depend on the conditions under which the process of saturating steel blanks with nitrogen is carried out. Several factors influence nitriding:

- temperature regime maintained during processing;

- the pressure level at which the muffle is filled with gas;

- duration of the procedure.

To speed up the process of saturating the steel surface with nitrogen, a two-stage technology is used. At the first stage, the workpiece is heated to 525 degrees. During the second stage, the part is heated to 600 degrees.

Processing Media Options

To carry out nitriding, various gaseous media are used. The most popular is a mixture of 50% propane and 50% ammonia. The metal surface heats up to 570 degrees. The duration of the process is about 3 hours.

Sometimes nitriding is carried out in liquid media. An alloy of cyanide salts is heated to 570 degrees. The workpiece is lowered into it for 3 hours.

Benefits of Nitriding

The main advantages of the technology include a variety of workpiece saturation modes and versatility of application. Surface treatment with a depth of about 0.2-0.8 mm also makes it possible to preserve the basic structure of the metal part. However, much depends on the organization of the process within which nitriding of steel and other alloys is carried out. Thus, compared to alloying, the use of nitrogen treatment requires less costs and is allowed even at home.

Types of nitriding and equipment used

To carry out the nitriding procedure, you can use several types of equipment, the choice of which depends on the chosen technology for the process of saturating steel with nitrogen.

Product after processing

Gas

Saturation of steel with nitrogen is carried out at a temperature range of 400–1200 degrees Celsius. In this case, dissociated ammonia is used. The characteristics can be changed by increasing or decreasing the heating temperature.

To process the workpiece using the gas method, chamber and shaft furnaces are used. Experienced metallurgists recommend using shaft retort furnaces. This is due to the characteristics of the equipment and the ability to evenly distribute the temperature over the entire surface of the workpiece.

Catalytic gas

This processing method is considered more modified. The working gas composition is dissociated ammonia. The temperature range during nitriding is selected within 200–400 degrees Celsius. The advantage of this method is that lower temperatures are used than with conventional gas nitriding.

Warming equipment is a complex of elements:

- control panel and oven settings;

- water cooling;

- a chamber in which a vacuum is formed after switching on;

- mechanisms that pump out air to create a vacuum;

- a system by which the working chamber is filled with gas.

To change the parameters of steel layers saturated with nitrogen, several methods are used. These include saturation with nitrogen, the addition of methane, argon, and hydrogen to the working environment.

Nitriding using electrolyte solutions

Anodic electrolytic heating is considered one of the fastest methods for processing steel surfaces. This method involves sending pulsed charges of electricity to the workpiece, which pass through the entire part. In this case, it must be in a container filled with an electrolytic solution.

Electrolyte nitriding

Catholic nitriding

The working space in this case is formed by dissociated ammonia maintaining a temperature regime of about 200-400 °C. Depending on the initial qualities of the metal workpiece, an optimal saturation mode is selected that is sufficient to correct the workpiece. This also applies to changes in the partial pressure of ammonia and hydrogen. The required level of ammonia dissociation is achieved by controlling the pressure and volumes of the gas supply. At the same time, in contrast to classical methods of gas saturation, catholic nitriding of steel provides for more gentle processing modes. Typically, this technology is implemented in a nitrogen-containing air environment with a smoldering electric charge. The anode function is performed by the walls of the heating chamber, and the cathode function is performed by the product.

Types of steel suitable for nitriding

Different types of steel are suitable for nitrogen enrichment - both alloy and carbon. With the first type the process is more efficient. Especially if the composition contains alloying elements capable of forming heat-resistant nitrides (chromium, molybdenum, aluminum and others). When cooled, such alloys - nitroloins - will not become brittle, and after that their hardness increases significantly.

How hard will different types of steel alloys be as a result of nitrogen treatment:

- nitroloins – up to 1200 HV;

- alloyed – up to 800 HV;

- carbon - up to 250 HV.

It is also necessary to take into account the grade of steel, which indicates what the product is intended for.

How to mark the steel most suitable for nitriding:

| Brand | Usage | Technological data | Maximum layer parameters | ||

| Core Hardness (HRC) | Maximum temperature (˚С) | Depth (mm) | Surface hardness (HV) | ||

| Hot metal processing | |||||

| 4Х5МФС | Molds, hammer dies, press inserts | 35–55 | 560 | 0,3 | 1100 |

| 3N3M3F | Injection molds, impact die, measuring, cutting tools | 35–51 | 560 | 0,3 | 1100 |

| 5ХНМ | Hot forming dies | 36–44 | 550 | 0,3 | 760 |

| 3Х2В8 | Heavy-duty press equipment | 35–50 | 560 | 0,25 | 1100 |

| Cold metal processing | |||||

| X12 | Cold stamps | 50–55 | 520 | 0,2 | 1100 |

| X12M | Knurling rollers, drawing boards, calibration eyes, dies, punches | 53–60 | 520 | 0,2 | 1200 |

| X12MF | Knives, blades | 56–58 | 480 | 0,2 | 1300 |

| Х12Ф1 | Thin cutting edge tool | 52–60 | 550 | 0,2 | 1250 |

Thanks to heat-resistant nitrides, the steel will become harder, but the thickness of the nitrogen-saturated layer will decrease.

This is interesting: We do resistance welding from a microwave with our own hands

Types of processed steel

Modern metallurgy uses nitriding technology to process carbon and alloy steels, where the proportion of carbon is 0.3−0.5% . The high success rate of the procedure can be seen when choosing alloying metals capable of creating nitrides with high heat resistance and hardness. For example, the process is especially effective when using those structures that contain aluminum, molybdenum, chromium and other similar raw materials. Such steel blanks are usually called nitralloy.

Molybdenum is able to prevent temper brittleness, which is caused by the slow cooling of steel after successful completion of processing. As a result, the material acquires the following characteristics:

- Hardness of carbon steel - HV 200−250;

- Alloyed - HV 600−800;

- Nitralloyev up to HV 1200 and even higher;

Recommended Brands

The choice of specific steel grades is determined by the scope of operation of the metal element. Basically, metallurgists distinguish the following criteria:

- If you need to obtain parts with high surface hardness, choose grade 38Х2МУА. It is characterized by a high aluminum content, which causes low deformation resistance of the product. If there is no aluminum in steel, this negatively affects hardness and wear resistance, although it expands the scope of application and allows the reproduction of the most complex structures and workpieces;

- In machine tool building, improved grades of alloy steel 40X, 40HFA are used;

- If we are talking about the manufacture of parts with a high risk of cyclic bending loads, use products under the brands 30Х3М, 38ХГМ, 38ХНММА, 38ХН3МА;

- As for fuel units, which require the use of complex metal products with high manufacturing precision, it makes sense to opt for the 30Х3МФ1 model;

Processing Media Options

Currently, nitrogen treatment of steel billets in an ammonia-propane environment . In this case, metallurgists have the opportunity to expose raw materials to 570 degrees for three hours. The carbonitride layer formed under such conditions has a minimum thickness, but the strength and wear resistance are much higher than those of those options that were invented using the usual method. The hardness of this layer is in the range of 600−1100 HV.

The technology is particularly indispensable when choosing products made from alloy alloys or steel, which are subject to high requirements for operational endurance.

Also, an equally popular solution is the use of glow discharge technology, when the material is strengthened in a nitrogen-containing discharged environment, connecting metal products to the cathode. As a result, the workpiece acquires a negatively charged electrode, while the muffle has a positively charged one.

The technology makes it possible to reduce the duration of action several times. A discharge appears between plus and minus, and gas ions act on the surface of the cathode, heating it. This effect is carried out in several stages:

- initially cathode sputtering occurs;

- then cleaning the surface;

- then saturation.

At the first stage of spraying, a pressure of 0.2 millimeters of mercury and a voltage of 1400 volts are maintained for 5-60 minutes. In this case, the surface heats up to 250 degrees Celsius. The second stage involves using a pressure of 1-10 millimeters of mercury at a voltage of 400-1100 V. The procedure requires 1-24 hours.

Another very effective processing method is the tenifer process, which involves nitriding in a liquid based on molten cyanide under the influence of a temperature of 570 degrees Celsius.

Benefits of technology

Currently, nitriding technology is considered the most popular solution for achieving the best performance characteristics of metal parts. With the right approach, the best wear resistance is ensured, and the layers obtained as a result of such processing become highly resistant to corrosion. Treated structures do not require additional thermal hardening. Due to these features, nitriding is considered to be a key process for processing elements in mechanical engineering, machine tool building and other areas where high demands are placed on components.

However, in addition to numerous advantages, the technology also has disadvantages, which are the high cost and duration of the procedure. At a temperature of 500 degrees Celsius, nitrogen can penetrate 0.01 millimeters. In this case, the total duration of the process reaches one hour.

The essence of technology

Nitriding of steel, when compared with such a popular method of processing this metal as carburization, has a number of significant advantages. That is why this technology began to be used as the main way to improve the quality characteristics of steel.

When nitriding, the steel product is not subjected to significant thermal effects, while the hardness of its surface layer increases significantly. It is important that the dimensions of the nitrided parts do not change. This allows this processing method to be used for steel products that have already been hardened with high tempering and ground to the required geometric parameters. Once nitriding, or nitriding as the process is often called, has been completed, the steel can be immediately subjected to polishing or other finishing methods.

Scheme of a glow discharge nitriding installation

Nitriding of steel involves heating the metal in an environment characterized by a high ammonia content. As a result of this treatment, the following changes occur with the surface layer of the metal, saturated with nitrogen.

- Due to the fact that the hardness of the surface layer of steel increases, the wear resistance of the part improves.

- The fatigue strength of the product increases.

- The surface of the product becomes resistant to corrosion. This stability is maintained when steel comes into contact with water, moist air and air-steam environment.

Microstructure of a high-quality nitrided layer of steel grade 38Х2МУА

Nitriding allows you to obtain more stable steel hardness indicators than carburization. Thus, the surface layer of a product that has been subjected to nitriding retains its hardness even when heated to a temperature of 550–600°, while after carburization, the hardness of the surface layer may begin to decrease when the product is heated above 225°. The strength characteristics of the surface layer of steel after nitriding are 1.5–2 times higher than after hardening or carburization.

Strengthening nitriding

Nitriding of steel

Saturation of steel with nitrogen is called nitriding. Nitriding, like carburizing, is a method of surface hardening of steel. However, compared to carburization, nitriding has a number of advantages:

1. higher surface hardness, which is maintained when heated to high temperatures (600-650°C), while the hardness of the cemented layer with a martensitic structure is maintained only up to 200-250°C;

2. greater resistance to wear and alternating loads;

3. corrosion resistance in atmosphere, water, steam;

4. less deformation and warping;

5. does not require subsequent heat treatment;

The disadvantage of nitriding is the significantly longer duration of the process, because it is carried out mainly for alloy steels and at lower temperatures compared to carburizing. Nitriding is widely used for gears, cylinders of powerful engines, many machine parts, pump bushings, etc. Nitriding is most often carried out in an atmosphere of ammonia NH4, which dissociates at elevated temperatures

2 NH3→ 2N (atom) + 6H

with the formation of active nitrogen atoms. Nitrogen atoms are adsorbed by the surface of the steel and diffuse into the interior, forming ferrous-nitrogen phases.

In the Fe-N system the following phases can form:

→- nitrogen ferrite 0.42%N at 590° and 0.01%N at 20°;

→- nitrogenous austenite exists at t > 590 °;

→ — Fe4 N nitride containing 5.7% N;

→ - Fe2N nitride, containing from 8.1 to 11.1% N.

If nitriding is carried out at t1 < 5900 C, then phases corresponding to the Fe-N diagram will form in the surface layer.

Main goals of nitriding:

1. increasing the hardness and wear resistance of the surface;

2. increasing fatigue strength;

3. Increased corrosion resistance.

The choice of process mode depends on the purpose of nitriding, and the depth and composition of the nitrided layer depends on the latter. There are strengthening nitriding and anti-corrosion nitriding.

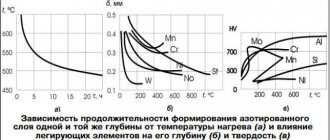

When iron is saturated with nitrogen, no increase in hardness is observed; Therefore, pure iron is not subjected to nitriding. When steel is saturated with nitrogen, carbonitride phases Fe4 (N,C), Fe3 (N,C) and Fe2 (N,C) are formed on the surface. Nitrogen forms nitrides with many alloying elements (Mn, Cr, Ti, Al, V, Mo, Zr, etc.) Dispersed solid nitrides of alloying elements (VN, Cr2N, etc.) prevent the movement of dislocations and thereby increase the hardness and strength of the nitrided layer (Fig. 81).

At low nitriding temperatures, nitrogen segregation forms in the solid solution; at higher temperatures, dispersed nitrides form. The nitrides A1, Cr, Mo, and V are most strongly strengthened during nitriding (Fig. 81a). Strengthening nitriding is applied to steel with an average carbon content of 0.25-0.4% C. The greatest hardening is caused by nitriding of steels alloyed with Cr, Al, Ti, Mo, etc.

If high hardness and wear resistance are required from the nitrided layer, then nitraloy steel alloyed with molybdenum and aluminum is used.

The technological process for manufacturing parts from nitral steel includes:

1. Preliminary heat treatment (improvement) to increase the strength and toughness of the core of parts: 1st order. = 900-950°C, cooling in oil, high tempering at t = 600-675°C, exceeding the nitriding temperature;

2. Mechanical processing of parts, up to grinding;

3. Protection from nitriding of individual parts of the part that are not subject to nitriding, with tin (0.01 -0.015 mm) or liquid glass;

4. Nitriding at t = 500-520°C, holding time to obtain ? = 0.3-0.6mm from 24 to 90 hours;

5. Final sanding.

The higher the nitriding temperature, the lower the hardness of the nitrided layer, which is caused by the coagulation of nitrides of alloying elements.

To speed up the nitriding process, stepwise nitriding is carried out: 1st stage at t = 500-520°C, 2nd stage at 540-600°C. An increase in the nitriding temperature causes an increase in deformation, without a significant decrease in hardness, the total time during nitriding in a glow discharge (ionic nitriding) is significantly (2-3 times) reduced, and the speed of nitriding under the influence of ultrasound increases by 1.5 times.

Nitriding of steel

Saturation of steel with nitrogen is called nitriding. Nitriding, like carburizing, is a method of surface hardening of steel. However, compared to carburization, nitriding has a number of advantages:

1. higher surface hardness, which is maintained when heated to high temperatures (600-650°C), while the hardness of the cemented layer with a martensitic structure is maintained only up to 200-250°C;

2. greater resistance to wear and alternating loads;

3. corrosion resistance in atmosphere, water, steam;

4. less deformation and warping;

5. does not require subsequent heat treatment;

The disadvantage of nitriding is the significantly longer duration of the process, because it is carried out mainly for alloy steels and at lower temperatures compared to carburizing. Nitriding is widely used for gears, cylinders of powerful engines, many machine parts, pump bushings, etc. Nitriding is most often carried out in an atmosphere of ammonia NH4, which dissociates at elevated temperatures

2 NH3→ 2N (atom) + 6H

with the formation of active nitrogen atoms. Nitrogen atoms are adsorbed by the surface of the steel and diffuse into the interior, forming ferrous-nitrogen phases.

In the Fe-N system the following phases can form:

→- nitrogen ferrite 0.42%N at 590° and 0.01%N at 20°;

→- nitrogenous austenite exists at t > 590 °;

→ — Fe4 N nitride containing 5.7% N;

→ - Fe2N nitride, containing from 8.1 to 11.1% N.

If nitriding is carried out at t1 < 5900 C, then phases corresponding to the Fe-N diagram will form in the surface layer.

Main goals of nitriding:

1. increasing the hardness and wear resistance of the surface;

2. increasing fatigue strength;

3. Increased corrosion resistance.

The choice of process mode depends on the purpose of nitriding, and the depth and composition of the nitrided layer depends on the latter. There are strengthening nitriding and anti-corrosion nitriding.

When iron is saturated with nitrogen, no increase in hardness is observed; Therefore, pure iron is not subjected to nitriding. When steel is saturated with nitrogen, carbonitride phases Fe4 (N,C), Fe3 (N,C) and Fe2 (N,C) are formed on the surface. Nitrogen forms nitrides with many alloying elements (Mn, Cr, Ti, Al, V, Mo, Zr, etc.) Dispersed solid nitrides of alloying elements (VN, Cr2N, etc.) prevent the movement of dislocations and thereby increase the hardness and strength of the nitrided layer (Fig. 81).

At low nitriding temperatures, nitrogen segregation forms in the solid solution; at higher temperatures, dispersed nitrides form. The nitrides A1, Cr, Mo, and V are most strongly strengthened during nitriding (Fig. 81a). Strengthening nitriding is applied to steel with an average carbon content of 0.25-0.4% C. The greatest hardening is caused by nitriding of steels alloyed with Cr, Al, Ti, Mo, etc.

If high hardness and wear resistance are required from the nitrided layer, then nitraloy steel alloyed with molybdenum and aluminum is used.

The technological process for manufacturing parts from nitral steel includes:

1. Preliminary heat treatment (improvement) to increase the strength and toughness of the core of parts: 1st order. = 900-950°C, cooling in oil, high tempering at t = 600-675°C, exceeding the nitriding temperature;

2. Mechanical processing of parts, up to grinding;

3. Protection from nitriding of individual parts of the part that are not subject to nitriding, with tin (0.01 -0.015 mm) or liquid glass;

4. Nitriding at t = 500-520°C, holding time to obtain ? = 0.3-0.6mm from 24 to 90 hours;

5. Final sanding.

The higher the nitriding temperature, the lower the hardness of the nitrided layer, which is caused by the coagulation of nitrides of alloying elements.

To speed up the nitriding process, stepwise nitriding is carried out: 1st stage at t = 500-520°C, 2nd stage at 540-600°C. An increase in the nitriding temperature causes an increase in deformation, without a significant decrease in hardness, the total time during nitriding in a glow discharge (ionic nitriding) is significantly (2-3 times) reduced, and the speed of nitriding under the influence of ultrasound increases by 1.5 times.

Main types of nitriding

There are several technologies used to carry out nitriding of steel. Let's take the following list as an example:

- Ammonia-propane environment. Gas nitriding has become very widespread today. In this case, the mixture is represented by a combination of ammonia and propane, which are taken in a ratio of 1 to 1. As practice shows, gas nitriding when using such a medium requires heating to a temperature of 570 degrees Celsius and holding for 3 hours. The resulting layer of nitrides is characterized by a small thickness, but at the same time the wear resistance and hardness are much higher than when using classical technology. Nitriding of steel parts in this case makes it possible to increase the hardness of the metal surface to 600-1100 HV.

- Glow discharge is a technique that also involves the use of a nitrogen-containing environment. Its peculiarity lies in the connection of the nitrided parts to the cathode; the muffle acts as a positive charge. By connecting the cathode, it is possible to speed up the process several times.

- The liquid medium is used a little less frequently, but is also highly effective. An example is a technology that involves the use of a molten cyanide layer. Heating is carried out to a temperature of 600 degrees, the holding period is from 30 minutes to 3 hours.

Ionic nitriding

In industry, the gas medium has become most widespread due to the ability to process large batches at once.

Technological process

Nitriding of steel using gas technology consists of several stages:

- Preliminary heat treatment (metal hardening and high tempering).

- Mechanical processing.

- Provides protection in areas that are not hardened.

- Directly, nitriding. The products are placed in a special sealed muffle, which is subsequently installed in an oven heated within 500-600°C. Ammonia is supplied to the container, decomposing into atomic nitrogen and carbon compounds under the influence of elevated temperature. Nitrogen components penetrate the structure of the steel alloy, forming nitrides, which are characterized by increased hardness.

- The result is secured and oxidation is prevented by cooling the workpiece without removing it from the oven. As a result, a layer of nitrides of 0.3-0.6 mm is formed. No additional surface treatment is provided

At the same time, the process of saturating the surface layer with nitrogen compounds can be accelerated by using a two-stage scheme:

- initial nitriding is carried out at 525°C;

- during the process the temperature gradually rises to 600°C.

There is also a modern analogue of the technology, namely nitriding using the ion-plasma method. The process takes place in a glow discharge: the product being processed is connected to the cathode (electrode with a negative value). A muffle is used as an anode - a container in which the part is placed. The first stage involves cleaning the surface by cathode sputtering, and the second stage involves directly saturating the layer with nitrides.

Catalytic gas nitriding

This type of chemical treatment involves creating a special atmosphere in the stove. Dissociated ammonia is pre-treated on a special catalytic element, which significantly increases the number of ionized radicals. Features of the technology include the following points:

- Preliminary preparation of ammonia makes it possible to increase the proportion of solid solution diffusion, which reduces the proportion of reaction chemical processes during the transition of the active substance from the environment to iron.

- Provides for the use of special equipment that provides the most favorable conditions for chemical processing.

Steel nitriding process

This method has been used for several decades and allows changing the properties of not only metals, but also titanium alloys. The high costs of installing equipment and preparing the environment determine the applicability of the technology to the production of critical parts that must have precise dimensions and increased wear resistance.

Properties of nitrided metal surfaces

Quite important is the question of what hardness of the nitrided layer is achieved. When considering hardness, the type of steel being processed is taken into account:

- Carbon steel can have a hardness in the range of 200-250HV.

- Alloy alloys after nitriding acquire a hardness in the range of 600-800HV.

- Nitralloins, which contain aluminum, chromium and other metals, can achieve a hardness of up to 1200HV.

Other properties of steel also change. For example, the corrosion resistance of steel increases, making it possible to use it in aggressive environments. The process of introducing nitrogen itself does not lead to the appearance of defects, since heating is carried out to a temperature that does not change the atomic lattice.

ION-PLASMA NITRIDATION (INA)

Ion plasma nitriding (IPA) is perhaps one of the most advanced methods for strengthening parts made of cast iron, carbon, alloy and tool steels, titanium alloys, cermets, and powder materials. The use of various gas spheres, which, depending on their composition, influence the properties of the treated surface, makes it possible to achieve high efficiency of this technology. IPA is actively used for mechanical engineering, the aviation and automotive industries, production associated with high precision, in the fuel and energy, oil and gas, and mining industries, since this technology has proven itself in the processing of parts operating in aggressive environments that are subject to friction and chemical corrosion.

Processing using the IPA method improves the characteristics of the surfaces of parts, increases operational reliability, in particular, increases contact strength, resistance to the formation of microcracks, increases corrosion resistance and contact strength.

Advantages of ion plasma nitriding

The main economic and technological advantages of ion plasma nitriding are low energy consumption, increased productivity and increased service life of the part several times.

The IPA process itself saturates the surface layer of the part with nitrogen or a mixture of nitrogen and carbon. This contributes to the formation of a uniform, high-quality coating on the surface with a certain structure and composition.

The processing process for products is reduced by 3-5 times, and for titanium alloys by 5-10 times. Using ion plasma anodizing technology, parts can be processed as if they were blank. Same with through holes. Thanks to the low temperature regime, cooling can be carried out at any speed, which eliminates the occurrence of martensite and structural transformations of steel, and reduces the possibility of damage and fatigue failure. If it is necessary to strengthen and improve performance characteristics without changing the hardness in the core of parts made of alloyed tool, high-speed and maraging steels, the IPA process is carried out at temperatures below 500C.

Ion plasma nitriding technology is excellent for surface finishing, since it maintains the original roughness within the range of Ra = 0.63...1.2 microns, and does not bend or deform the part. In addition, the use of the IPA method is environmentally friendly. Process technology

The technological process of ion-plasma nitriding is carried out under conditions of rarefied atmospheric pressure (0.5 - 10 mbar). Depending on the alloy from which the part is made, either a mixture of nitrogen and hydrogen is supplied into the chamber - for processing steel, cast iron, or nitrogen - for titanium alloys. A glowing charge is formed between the product being processed and the walls of the chamber, which, in turn, promotes the formation of plasma, resulting in the creation of a working environment with charged ions, molecules and atoms, which forms the thinnest nitrogen film on the surface.

The composition of the working gas medium, its temperature and the duration of the IPA process influence the final result, and at the same time depend on the composition of the workpiece.

The ion nitriding method is used to process parts with complex contours and hard-to-reach surfaces of any size and shape, for example, gears, dies, molds, gear rims, drilling and cutting tools, shafts, etc. For some parts, the IPA method is the only technology that allows minimizing defects.

Properties of products after hardening using the IPA method

Using IPA processing, tools and parts of almost all industrial sectors are hardened.

Due to the fact that the nitrogenous surface film does not allow the liquid metal to stick in the area of its supply, high-quality casting of molds is ensured, which significantly extends the service life of the part. The durability of cutting and stamping tools of various steel grades also increases several times. This occurs due to the fact that the nitrogen film on the surface of the tool reduces the coefficient of friction and prevents chips from sticking to the cutting edge. In this way, the cutting speed can be significantly increased.

The Ionmet enterprise produces ion nitriding of steels, tools, products, shafts and various surfaces. The processing mode is selected based on the technical characteristics that need to be achieved in the end. Hardening the surface layer increases resistance to corrosion and wear.

You can check with specialists for a list of parts to be strengthened for processing. Our experts will help you find out whether nitriding can process your large parts with complex contours. To accurately determine the technical conditions for IPA processing and begin cooperation, send us a drawing by email indicating the steel grade and the technology for manufacturing the part.

Scope of application of steel nitriding

Nitriding of steel is one of the frequently used methods for processing alloy products to achieve maximum hardness and durability. Steel parts are not subject to deformation because they do not require subsequent hardening. Corrosion resistance increases significantly, which is important when operating mechanisms in humid environments.

Engineering steels

The use of nitrided steels is relevant not only in the engineering and machine tool industries, but also in the creation of household appliances - after all, consumers are becoming more demanding of the quality of purchased products every year.

This technique allows you to change the characteristics of not only steel, but also titanium alloys. The high cost of equipment and the difficulty of creating the required environment are compensated by the exact dimensions of the output parts and increased wear resistance. But there are also strength indicators that cannot be achieved by nitriding. Then the steel is alloyed, carrying out deep processing of its structure. The disadvantage of this method is the appearance of harmful impurities.

Video on the topic: Chemical-thermal treatment of steel

Treatment with electrolyte solutions

As a rule, anode heating technology is used. In essence, this is a type of electrochemical-thermal high-speed processing of steel materials. This method is based on the principle of using a pulsed electric charge that passes along the surface of the workpiece placed in an electrolyte medium. Due to the combined effect of electrical charges on the surface of the metal and the chemical environment, a polishing effect is achieved. With such processing, the target part can be considered as an anode with a positive potential supplied from an electric current. At the same time, the volume of the cathode must be no less than the volume of the anode. Here it is necessary to note some characteristics in which ion nitriding of steels is similar to electrolytes. In particular, experts note the variety of modes of formation of electrical processes with anodes, which, among other things, depend on the connected electrolyte mixtures. This makes it possible to more accurately regulate the technical and operational qualities of metal workpieces.

Varieties of nitriding methods

Approaches to nitriding may vary. Typically, there are two main methods depending on the metal nitriding conditions. These may include methods for increasing surface wear resistance and hardness, as well as improving corrosion resistance. The first option differs in that the change in structure occurs against a background of a temperature of about 500 °C. A reduction in nitriding is usually achieved by ion treatment, when a glow discharge is excited through anodes and cathodes. In the second option, alloyed nitriding of steel is carried out. This type of technology involves temperature treatment at 600-700 °C with a process duration of up to 10 hours. In such cases, processing can be combined with mechanical action and thermal finishing of materials, in accordance with the exact requirements for the result.

Factors influencing nitridation

The main factors that influence nitriding are:

- the temperature at which such a technological operation is performed;

- gas pressure supplied to the muffle;

- duration of exposure of the part in the oven.

The efficiency of this process is also influenced by the degree of ammonia dissociation, which, as a rule, is in the range of 15–45%. As the nitriding temperature increases, the hardness of the formed layer decreases, but the process of diffusion of nitrogen into the metal structure accelerates. A decrease in the hardness of the surface layer of a metal during its nitriding occurs due to the coagulation of nitrides of alloying elements included in its composition.

The influence of temperature and alloying elements on the formation of a nitrided layer

To speed up the nitriding process and increase its efficiency, a two-stage scheme is used. The first stage of nitriding when using this scheme is performed at a temperature not exceeding 525°. This makes it possible to impart high hardness to the surface layer of the steel product. To perform the second stage of the procedure, the part is heated to a temperature of 600–620°, while the depth of the nitrided layer reaches the required values, and the process itself is almost doubled. The hardness of the surface layer of a steel product processed using this technology is no lower than a similar parameter for products processed using a single-stage method.

Factors affecting nitriding

The main parameters that have a significant impact on the nitriding process are:

- temperature;

- gas pressure;

- exposure duration.

These factors are the main parameters that influence the nitriding process, but there are also other indicators. For example, the degree of dissociation of ammonia components. Usually it is in the range of 15-45%. As the temperature in the gas treatment environment increases, the hardness may decrease significantly, but in contrast, the diffusion processes of nitrogenous components are accelerated. Such parameters are determined by the coagulation of nitrides of alloying components, which are noted in the composition of the metal. These parameters make it possible to reduce processing processes by several times.

If necessary, speed up the nitriding process and increase its efficiency, use a two-stage metal processing scheme. This scheme involves the first stage of processing metal alloys at a temperature that does not exceed 525 degrees. Thanks to the use of this particular temperature, high hardness values are imparted to the steel part. In the second part of the nitriding process, the part is heated to 600-620 degrees. With such temperature parameters, the nitriding process is significantly accelerated, and the depth reaches the required values. The strength data of the surface layer using two-stage technology are not inferior to the corresponding products that have undergone one-stage nitriding.

Classification of nitriding processes

Nitriding processes

Nitriding does not require an extreme increase in temperature, which means that the steel object completely retains its given shape and parameters. This is important when processing parts that have already been ground to the desired size. Upon completion of the procedure, the product only needs to be polished.

This method of thermochemical treatment also has its disadvantages. The cost of the procedure is considerable. Enrichment of steel alloys with nitrogen is a complex and slow procedure. The effect of nitrogen on steel is very slow; it takes up to 2.5 days to process the part. It is carried out in a specially equipped production workshop.

Gas nitriding

Traditionally, nitriding is carried out under the influence of gas. For this type of working medium, ammonia and propane or ammonia and endogas are mixed in equal parts. The nitriding procedure in such an environment is carried out at temperatures up to 570 °C. The diffusion process itself takes about three hours. The steel product receives a thin protective layer, but it is characterized by high hardness.

Gas nitriding

A variation of the traditional type of nitriding is catalytic gas nitriding. In this case, ammonia is pretreated to speed up diffusion and produce a larger number of ionized radicals.

The use of a liquid nitriding medium can speed up the process somewhat.

Sometimes the diffusion itself takes place in half an hour. The working medium here is molten cyanide salts; the process is carried out at temperatures up to 570 °C.

But technology does not stand still. Ion-plasma nitriding is becoming increasingly popular at metallurgical enterprises. It is also called glow discharge treatment.

The main difference of this technology is that a rarefied environment and the effect of electric current are used. A voltage source is connected to the sealed container. The retort acts as a positively charged electrode, and the part itself acts as a negatively charged one. A flow of ions appears between them. The resulting plasma heats the top layer of the steel product, due to which the surface is saturated with nitrogen compounds and becomes harder.

Design features of gas nitriding

Thermochemical process

Nitriding of steel is carried out in a muffle - an iron retort, which is hermetically sealed. Steel parts are immersed in this container, and then it is sent to a special oven. Under the influence of the required temperatures and ammonia released from a cylinder connected to the muffle, the steel is nitrided.

The fact is that ammonia contains nitrogen, and under certain conditions releases it during decomposition. Nitrogen diffusion occurs: atoms of this element gradually penetrate into the upper layer of the material, forming nitrides in the metal structure. These compounds give the surface of the product the necessary hardness and resistance to corrosion. The thickness of the protective layer can reach 0.6 mm. To avoid the oxidation process, the furnace is cooled slowly.

The main factors influencing nitriding are:

- selected temperature mode;

- gas pressure;

- degree of ammonia decomposition;

- the time the muffle is in the furnace.

As the temperature rises, the level of hardness due to coagulation of nitrides may become lower, but the effect occurs faster.

General technology for all types of nitriding

The metallurgical industry does not stand still, and variations have appeared on traditional gas nitriding. But the sequence of technological operations is almost the same:

- Preliminary processing.

- Protection of parts that do not require nitriding.

- Nitriding of parts.

- Final finishing.

At the first stage, the workpiece needs to be hardened. To do this, the product is cooled in oil or water at a temperature of 940 °C. Then comes the tempering process (temperature about 600 °C). The metal becomes harder and easier to cut. Next, the part is machined to clarify all the necessary parameters, for example, it is ground.

Nitriding process technology

The second stage involves applying a protective layer to areas that do not require nitrogen saturation. A thin layer of tin or liquid glass is applied to them by electrolysis. A protective film is created that interferes with nitriding - the atoms of the element cannot overcome it. Next comes the nitriding itself, the product will gradually become harder and more resistant to external factors.

At the final stage , the nitrided parts are ground to give them the exact desired shape. This process does not take a long time, since there is no noticeable deformation of the geometry of the product. The final finishing time depends on the temperature and thickness of the surface that has been treated with nitrogen.

A guarantee of no changes in the steel product is provided by a modern version of the technology - ion plasma nitriding. With it, the part is not deformed at all, since the action takes place at lower temperatures.

Technological scheme of nitridation

Although nitridation can be carried out in various ways, the scheme for preparing materials and technological operations is almost identical. There are several options for nitriding:

- gas;

- innovative plasma;

- ionic.

Despite the type of metal nitriding, the treatment result is aimed at obtaining the most durable and wear-resistant product.

Preparatory heat treatment

This type of processing consists of hardening the product and its high tempering. Hardening of a steel element is carried out at temperatures above 940 degrees. Cooling during preparatory processing is carried out exclusively in oil or water. After hardening the metal at a temperature of 940 degrees, tempering occurs at 600-700 degrees. The processed steel part is endowed with increased hardness.

Mechanical restoration

The operation consists of grinding the finished part. The precise geometry of parts is the key to acquiring the necessary strength properties and long-term operation in the future.

Protection of parts not subject to nitriding

This steel processing step is necessary to protect elements that should not be nitrided. For protection, tin or liquid glass is used, which is applied to the surface of the metal part in a thin layer of no more than 0.015 mm. The electrolysis technology for fastening these materials ensures its reliable fastening on the surface of the steel alloy, as well as high resistance to nitrogenous environments, so the substance does not penetrate into the internal structure of the steel part.

Nitriding

Different grades of steel require a certain heating temperature. The steel is kept at this temperature for a certain number of hours. Thanks to these parameters, a layer is formed at different depths, providing a certain nominal surface hardness. For steel grade 7ХЗ, the heating temperature is 500-520 degrees. The steel is aged for 48-60 hours, a layer depth of 0.4-0.5 mm is ensured, and the nominal surface hardness is 1000-1100.

Final processing

This stage of steel processing allows you to bring the geometric and mechanical parameters of the steel element to the required value. Since the geometry changes are very slight during nitriding, the changes at the finish will be minimal. Despite the fact that the part is subjected to minimal temperature treatment, the elements will still have to be slightly modified, since the nitrogen layer can slightly affect the geometry. In order to avoid any deformation during the nitriding process of the element, you can use a more advanced technology - ion nitriding. The technological process of ion-plasma nitriding involves minimal exposure to temperature conditions on steel parts, and the likelihood of steel deformation tends to a minimum.

Ion plasma nitriding has proven to be extremely positive. Among the advantages, it is worth emphasizing that nitridation occurs at low temperatures, unlike traditional options. In order to carry out ion-plasma nitriding, a replaceable muffle or a built-in part of the installation is most often used. These elements speed up the process of improving the metal, but are not economically justified in all cases.

Types of Nitrided Steels

Both carbon and alloy steels, characterized by a carbon content in the range of 0.3–0.5%, can be processed using nitriding technology. The maximum effect when using such a technological operation can be achieved if steels are subjected to it, the chemical composition of which includes alloying elements that form hard and heat-resistant nitrides. Such elements, in particular, include molybdenum, aluminum, chromium and other metals with similar characteristics. Steels containing molybdenum are not subject to such a negative phenomenon as temper brittleness, which occurs when a steel product cools slowly. After nitriding, steels of various grades acquire the following hardness:

Hardness of steels after nitriding

Alloying elements found in the chemical composition of steel increase the hardness of the nitrided layer, but at the same time reduce its thickness. The thickness of the nitrided layer is most actively influenced by chemical elements such as tungsten, molybdenum, chromium and nickel.

Depending on the scope of application of the product that is subjected to the nitriding procedure, as well as on its operating conditions, it is recommended to use certain grades of steel to carry out such a technological operation. So, in accordance with the technological problem that needs to be solved, experts advise using products made from the following steel grades for nitriding.

38Х2МУА

This is steel, which, after nitriding, has a high hardness of the outer surface. Aluminum contained in the chemical composition of such steel reduces the deformation resistance of the product, but at the same time helps to increase the hardness and wear resistance of its outer surface. The exclusion of aluminum from the chemical composition of steel makes it possible to create products of more complex configurations from it.

40X, 40HFA

These alloy steels are used for the manufacture of parts used in the machine tool industry.

30Х3М, 38ХГМ, 38ХНММА, 38ХН3МА

These steels are used for the production of products that are subjected to frequent cyclic bending loads during their operation.

30Х3МФ1

Products are made from this steel alloy, the accuracy of whose geometric parameters is subject to high demands. To impart higher hardness to parts made of this steel (these are mainly parts of fuel equipment), silicon can be added to its chemical composition.

Characteristics of some steels after nitriding

What metals are subject to nitriding

Nitriding is applied to steel with a carbon content of no more than 0.3-0.5%; they can even be doped, but the concentration of C in any case should not exceed the established limits. The list of main brands:

- 38Х2МУА – acquire strength and special wear resistance;

- 38KhGM, 30KhZM, 38KhNZMA, 38KhNMFA - become elastic, which allows them to withstand more severe bending and torsion loads;

- 40X, 40HFA - age more slowly, even under the influence of cyclic pressures;

- 30ХЗМФ1 – do not lose their linear dimensions during strengthening, the accuracy of which is subject to particularly stringent requirements.

In modern industry, not only nitrided steel is in demand, but also titanium, chromium, aluminum, molybdenum - these and other metals are also processed by gas or thermochemical methods. They also don’t forget about alloys - hardening allows you to get rid of the shortcomings of its weakest inclusions, for example, to normalize the deformation resistance, which Al reduces, or to maintain the desired geometry and shape of complex workpieces (which is also achieved by preliminary alloying with silicon). The main thing is to correctly take into account the concentration of impurities and choose a technology that is optimally suitable for the case and improves, rather than worsens, the performance characteristics of a particular material.

Types of media for nitriding

The process of steel nitriding is actually carried out not using one, but several technologies, hence the variety of types of nitriding. This is due to the fact that for some types of metals nitrogen is absorbed more efficiently in one environment, for others - in another. But that's not the main thing. The medium allows you to obtain a certain surface quality or change the speed mode of the steel nitriding operation. The most common technologies used in enterprises:

- diffusion of nitrogen in a gas environment based on propane and ammonia;

- diffusion of nitrogen when using a glow discharge;

- nitrogen diffusion in a liquid environment.

Ammonia-propane environment

Nitriding in a gas mixture of propane and ammonia is now the most applicable method of strengthening the surface of steel. The ratio of the mixture components is taken equal, the temperature on the Celsius scale is raised to 570 degrees above zero, and the treatment is carried out for three hours.

The resulting surface layer can be characterized as a high-strength hard surface with excellent wear resistance, despite the small thickness of the nitrides. In numerical units, the hardness of the product increases to 1100–600 HV.

Glow discharge

In other words, a glow discharge is an environment of a discharged state during ion-plasma nitriding. A very common method of saturating the surface of steel products with nitrogen. The peculiarity of this method is that, in addition to placing the workpiece in a muffle furnace, where the temperature rises, an electrical contact with a negative potential is connected to this workpiece (that is, a negative electrode is obtained), while the muffle furnace itself acts as a positive electrode.

Ion nitriding creates an ion flow between the furnace and the product, which takes the form of plasma, and it consists of the elements NH₃ or N₂. Thus, nitrogen molecules begin to diffuse into the surface layer, effectively saturating it.

Plasma nitriding takes place in two stages:

- Cleaning the surface of the workpiece by sputtering the cathode.

- Direct saturation of steel with nitrogen.

The main advantage of the method is that with ion plasma saturation the process can be accelerated several times.

Types of media for the procedure

Each material requires its own conditions for the most effective absorption of nitrides. The quality of the final surface and the specific speed of the operation also depend on the environmental parameters. Therefore, we have identified 3 types of them - let’s look at each of them.

Ammonia-propane

It is considered the most frequently used and is characterized by the following features:

- the components for the mixture are taken in equal proportions,

- operating temperature reaches 570 0C,

- The preparations are kept for 3 hours.

The resulting hardening is characterized by high strength and excellent wear resistance. Hardness during nitriding reaches 600-1100 HB, and this is with a relatively small coating thickness.

Glow discharge

Here the environment is in a rarefied state. And future products are not simply placed in an oven, but a negatively charged contact is connected to them. The other electrode, the positive one, is the furnace itself.

As a result, an ion flow runs between the muffle and the parts, which becomes a plasma consisting of nitrides, which, under the influence of temperature, diffuse into the material and saturate it.

The procedure is carried out in 2 stages:

- a cathode is sprayed onto the working surfaces to clean them;

- The strengthening is carried out directly, taking into account the features described above.

The method is good for its speed of implementation and the fact that it is suitable for alloys.

Liquid

There are also cases of using nitriding in solutions of cyanide salts - their components, as a result of mixing particles under heating, also penetrate quite effectively into the thickness of the metal. But they are relatively rare - the method is rarely used, because it is expensive and, most importantly, dangerous to health - inhaling the vapors is prohibited. Although it is productive and does not require strict requirements: for example, the temperature should reach 570 0C (achieving it is not a problem), and the holding time should be 2.5-3 hours, which is quite fast. Hence the conclusion: the final choice of medium is influenced not only by the specifics of nitride assimilation by a specific material, but also by the accompanying conditions of the procedure.