Features of eccentric sanders

The main goal of finishing work is to bring surfaces to perfect condition. This cannot be achieved with mechanical devices. Grinding units will help you do this job quickly and efficiently.

There are several types of such devices, differing in functionality, operating principle, and class. For delicate finishes, an orbital sander is recommended.

Thanks to the soft rubber sole, the device will allow you to accurately perform the following types of work:

- level the primer;

- make grout;

- prepare surfaces for coating.

The main feature of these machines is that in addition to the eccentric rotation of the sole, there is also a radial rotation. This ensures high-quality polishing of planes of various slopes and curvatures.

Design and principle of operation

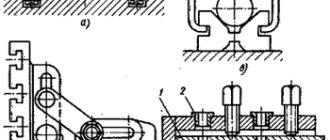

Orbital sanders provide good surface finishing due to their design features. The structure of the unit is shown in the photo:

The rotary-circular and translational movements of the abrasive wheel allow you to perform not only rough, but also filigree polishing of various surfaces.

The operating principle of the tool is not complicated and is represented by the following points:

- the working circle is mounted on the sole;

- the drive is attached to the base;

- when the device is turned on, the abrasive rotates around its axis;

- An impulse is applied to the sole, causing it to vibrate.

Note! Both movements occur in parallel, which is why the trajectory of the abrasive elements does not repeat. Due to this, the quality of polishing is ensured.

Peculiarities

The polishing machine can be used in a variety of areas. In particular, this device is used for final finishing and to improve the appearance of surfaces. The wide functionality of the tool is ensured by changing attachments and pastes. Confidently solve problems such as:

- adding shine to a mirror or window glass;

- improving the appearance of the car;

- polishing wood products.

Regardless of what specific task is being solved, the polishing machine has a fairly typical structure:

- frame;

- drive mechanism;

- a pair of handles;

- removable polishing wheel.

The appearance of such a device is similar to an angle grinder. However, the big difference is the use of completely different disks. It is natural that as the size of the working part increases, the area being processed also increases. Also important characteristics of polishing machines are the grain size of the discs installed and the total power of the device. As the technical characteristics increase, the price also increases.

Types of Grinding Tools

Manufacturers offer several options for eccentric sanders. They are classified according to various parameters, which allows you to choose the appropriate model.

| Type | Peculiarities |

| Household | Designed for light loads. Continuous operation limit – no more than 1 hour per day |

| Semi-professional | Can be used at home and in small businesses |

| Professional | Thanks to the powerful motor, they can withstand heavy loads. Equipped with additional functions |

Grinding tools are also divided according to other criteria:

- power supply – from the electrical network, battery-powered or running on compressed air (pneumatic);

- according to the processed material - metal, wood, plastic;

- by layout - one- and two-handed;

- the diameter of the sole is 125 and 250 mm.

Some models are combined, designed for finishing various types of materials.

Accessories and spare parts

Regardless of the specific model of the polishing machine, its auxiliary equipment plays an important role. Among the attachments, the bag stands out in its role. It allows you to collect maximum debris, dust and waste. As a result, the work is done as cleanly as possible.

Backings formed on an adhesive base allow grinding discs to be secured in holders. Special flexible shafts help to work in hard-to-reach places. For the grinding itself, brushes or rollers made of nylon, metal and special composites are used. Polishing machines are equipped with main and additional handles. But when selecting such components, you need to carefully check that they make the work easier and not complicate it.

The sole for a vibration machine, as already mentioned, can be made in the form of a triangle or a rectangle. The first type works better in limited space, the second - in cases where you need to process a maximum area. If the power cord is initially short, you will have to continuously use an extension cord. Of course, all spare parts and auxiliary components must be purchased only from official manufacturers.

Areas of application of ESM

The orbital sander has found its application not only in the professional sphere - such tools are also used in everyday life. The main purpose is to level surfaces for further finishing. EShMs are used:

- during construction and repair work - for grinding plastered surfaces;

- in the manufacture of new and restoration of old furniture - preparation of surfaces before applying varnishes, paints, primers;

- during car repairs at service stations - to level the primer applied to the car.

The tool can polish natural stone, plastics, and glass. For each type of work, a different abrasive is selected and the wheel rotation speed is set.

Application

On a production scale, the eccentric machine is used in car repair, body repair and finishing work. This device is capable of processing wood blanks, so it is used in the manufacture of furniture. The grinder polishes parts, which makes it possible to use it in work to restore the paintwork and eliminate small scratches and dents on the surface of the product. The most common type of grinder used in industry is a pneumatic grinder. It is easy to operate, has a minimum number of dynamic angles and does not require recharging from the mains or battery, which allows you to save a large amount of electricity.

In everyday life, an eccentric sander is used when processing large surfaces during repair work. When using this device, the following rules must be observed:

- Before preparing the tool, you need to choose the right type of grinding machine, depending on the type of work being performed.

- When assembling the main elements of an orbital sander, it is important that the location of the holes on the tool sole coincide with the location of the holes in the working wheel.

- During the grinding process of a product, it is necessary to adjust the operating speed of the working wheel in order to increase work efficiency. It is not recommended to set it above 20,000 rpm.

- During polishing work, do not put pressure on the main elements of the eccentric grinder, which will help extend the life of the engine and avoid its breakdown.

- Grinding the part must be done in stages and intermittently so that the components of the electric motor do not overheat.

- To reduce the intensity of vibration resulting from the rotation of the working wheel, you need to place your palm on the body of the grinder, reducing the amplitude of the vibration.

- Grinding can only be carried out using proper tools. Before use, it is important to check the condition of the grinding machine elements for structural wear and lack of lubricants, which negatively affects the performance of the device.

- If there is no dust collector, you must purchase a vacuum cleaner or other device that collects dirt and industrial waste in the form of chips;

- After completing the grinding work, you need to carefully remove the tool from the workpiece so as not to damage its surface.

It is not recommended to use an eccentric sander when processing small parts because it is not capable of sanding corners and uneven surfaces. Otherwise, the tool will leave scratches on the workpiece. Instead of an orbital sander, it is better to use engraving devices that have appropriate attachments for grinding relief surfaces.

Specifications

The quality of a tool's performance is determined by its parameters. Before figuring out how to operate an eccentric sander correctly, you need to study its technical characteristics.

| Parameter | Peculiarities |

| Power | Depends on the energy consumed and ranges from 220-450 W. The more powerful the device, the higher the performance |

| Rotational speed | In unregulated devices the fixed speed is 12 thousand rpm. In other models - ranging from 2000 to 20000 rpm |

| Oscillation amplitude | The indicator affects the quality of processing:

|

| Plate diameter | Running parameters – 125 and 150 mm. The more powerful the ESM, the larger the diameter of the circle. There are also non-standard sizes (50, 80, 115 mm). They are used for cleaning corners |

Important! The greater the amplitude, the worse the quality, but the higher the productivity.

Eccentric orbital sanders have to work not only on horizontal surfaces. That’s why another parameter is so important – the mass of the tool. The more powerful the machine, the heavier its engine, the more uncomfortable it is to operate the device in weight. The weight of household ESM is about 1.5-2 kg.

Tools

0 votes

+

Vote for!

—

Vote against!

Creating an ideal surface for varnish or paint is impossible without a sanding machine. Today, for these purposes, you can find several different types of sanders on the market, each of which is good in its own way. For example, even a high-quality and expensive belt sander will not be able to provide an ideal surface for varnishing or staining, unlike an eccentric sander, which was created precisely for this purpose. There are no particular difficulties in choosing an eccentric grinder, even despite the huge assortment from various brands. The main thing is, before choosing an eccentric type sander, determine for yourself what it should be in terms of basic parameters and additional functions.

- Basic parameters of an eccentric sander

- ESM power

- EShM type

- ESM rotation speed

- Amplitude of ESM oscillations

- EShM plate diameter

- EShM weight

- Additional functions of an eccentric sander

- Speed adjustment

- Dust collector option

- Possibility of connection to a vacuum cleaner

- Second handle

- Starting current limitation

- Pressure indicator

- Abrasive mounting option

For those who are going to grind a surface for the first time using an eccentric sander, the following should be explained. An eccentric sander is designed for polishing , coarse and fine grinding. In practice, in most cases it is used only for polishing and fine finishing, followed by varnishing or painting the surface. Such a narrow focus of the machine is due to the peculiarity of its operation. The operating principle is a reciprocating circular motion of the grinding wheel, which achieves high-quality processing.

Basic parameters of an eccentric sander

When choosing an eccentric sander (ESM), you will have to immediately decide how often it will be used. If from time to time and for short-term work, then when purchasing you can take the budget option. But if the loads on this tool are frequent and quite large, then you can safely take a professional electric machine. Of course, if you purchase a tool for yourself and so that it will serve for a long time, then you can look into a professional ESM without hesitation. True, the price for a professional eccentric grinder will be significantly higher than for a regular one.

Having determined whether it will be a regular or professional grinder, it remains to understand the characteristics of the ESM itself. Without this, it will not be possible to determine which of the best sanders you need from the entire possible range. All characteristics can be divided into two categories. The first category is performance characteristics that determine the quality and efficiency of working with a particular eccentric sander. These include power, vibration amplitude, rotation speed, abrasive wheel diameter, weight and power supply option for the tool. The second category is the additional functions of the machine, which provide convenience and comfort when working with the tool. Additional functions include speed control, a dust collector option, the ability to connect to a vacuum cleaner, a second handle, starting current limitation, and a pressure indicator.

ESM power

The main characteristic of any power tool is its power. And eccentric sanders are no exception. This is the first thing you should consider when choosing a grinder. The high power of the ESM allows you to use the tool longer and with greater efficiency. In addition, the quality of the work performed, the rotation speed of the sanding plate, and the weight of the machine depend on this parameter.

The power range of eccentric sanders is from 160 W to 900 W. But low-power and high-power ESMs can be listed on one hand. The most common grinders have power from 300 W to 600 W. the Bosch eccentric grinder . When choosing, you should pay attention to ESM with high power ratings. Moreover, if the difference in power is 20 - 50 W, then there will not be any significant differences in the quality of processing. But if the difference is 100 W or more, then preference should be given to a more powerful tool. The quality of work, its duration and the service life of the ESM will be high.

EShM type

Various energy sources are used to operate ESMs; depending on this, there are several types of eccentric sanders. This could be an electric machine powered by mains or battery power, or it could be a sander using compressed air. This diversity makes it possible to use ESM both where there is electricity and where there is none. When choosing one option or another, you need to clearly understand why and where the ESM will be used.

If everything is more or less clear with electric sanders, then we should talk a little about pneumatic ones. An eccentric pneumatic grinding machine is used mainly on a production scale, as it requires the installation of additional equipment in the form of a compressor or compressed air cylinders. These EShMs serve perfectly in a garage, service station or furniture production workshop. Their main advantages are low weight, it ranges from only 600 g to 1000 g. As well as a small number of moving parts. Since, using compressed air, there was no need for an electric motor, there were correspondingly fewer parts. This affected both the weight and the service life. In addition to all this, the low weight allows you to use the tool itself longer and more comfortably. One of the manufacturers of such ESMs is Dynabrade, with its Dynorbital .

ESM rotation speed

This parameter of an eccentric sander is directly related to its power. The quality of work performed and ease of use depend precisely on the rotation speed. But there is one important point here. When buying, they usually try to choose a machine with high rpm, believing that the higher, the better for work. But this relates more to productivity than to the quality of work. Very high ESM speeds are suitable for rough surface treatment, but for perfect grinding low speeds are required.

There is another feature associated with the rotation speed that should be taken into account. It lies in the fact that the higher the power of the machine, the lower the rotation speed. the Makita bo6040 eccentric grinder has a power of 750 W, and its rotation speed is only 1600 - 5800 rpm. , the Bosch GEX 125-1 AE eccentric grinder has a power of 250 W and a rotation speed of 7500 - 12000 rpm. When choosing an ESM, you need to remember this feature and focus on the purpose for which the machine will be used. It will be a high speed sander for rough sanding or a low speed sander for finishing sanding.

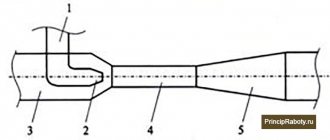

Amplitude of ESM oscillations

The next parameter that affects the quality of surface treatment and depends on the rotation speed is the amplitude of oscillations or, as it is also called, the eccentric stroke of the grinding machine. As noted above, the ESM performs reciprocating circular movements. And if the rotation speed has a greater influence on productivity, then the amplitude of movement of the grinding plate is responsible precisely for the quality of processing.

In fact, the amplitude of vibration and the speed of rotation are related. It is the combination of these two movements that allows for high-quality grinding. There are models on the market with amplitudes from 2 mm to 5 mm. DVT grinders have the smallest amplitude. The presented photo demonstrates the movements of the sanding pad of an eccentric sander; it can be seen how the quality of the surface treatment changes depending on the amplitude of the vibration.

Important! It should be noted that for some pneumatic ESM, reciprocating movements are created using special lever attachments. Depending on which lever is installed, this will be the diameter of the orbit for grinding.

EShM plate diameter

In addition to power, the performance of an eccentric sander also depends on the diameter of the sanding pad. Everything is simple here - the large area of the plate allows you to quickly process a large area at a time. The most common sizes are diameters 125 mm and 150 mm. But you can also find non-standard sizes of 50 mm, 80 mm, 90 mm or 115 mm. Although the eccentric sander is intended for processing only smooth surfaces, the small diameters of the soleplate allow grinding of corner joints.

Non-standard sizes of the grinding pad are very rare. Only a few companies produce them, and among the entire range of eccentric grinders on the market you can find only a few copies. Prominent representatives of ESM with a small plate diameter are the Rupes TA 50 and Metabo SXE 400 .

When purchasing an ESM, in many cases it is enough to look at the model name to determine the diameter of the plate. Most manufacturers indicate the size there. For example, eccentric sander Interskol EShM-150/600E . Looking at the markings, you can immediately determine that the diameter of the plate is 150 mm, and the power of the machine is 600 W. But it wouldn’t hurt to look at your passport or ask the seller. the Makita BO5031 eccentric grinder does not contain such data in its name.

EShM weight

As previously noted, the weight of an eccentric sander directly depends on its power. It's just a matter of the engine. The more powerful it is, the heavier the machine. Weight does not directly affect the quality or productivity of work. But this parameter is important for the comfortable work of the master. So an ESM with a large weight will be more difficult to process vertical surfaces, as well as the ceiling. For processing horizontal surfaces, this parameter has little effect on the comfort of working with it.

Additional functions of an eccentric sander

In contrast to the characteristics of eccentric sanders described above, additional ones have a lesser effect on the productivity and quality of work. But the presence of certain additional functions makes the work more comfortable.

Today, manufacturers are trying to provide their ESM with useful functionality as much as possible. Such functions include speed control, various options for dust collectors, the ability to connect to a vacuum cleaner or an adapter for it, a second handle, limiting the starting current (soft start), and a pressing force indicator. Let's look at each of them in more detail, since some of these functions can play a decisive role when choosing.

Speed adjustment

Today, almost any power tool has this function and the ESM is no exception. Even pneumatic ESMs have the ability to adjust speed, implemented in the form of pressure levers. For eccentric grinders, the ability to adjust the speed makes it possible to use the tool for both coarse and fine grinding. Which in turn allows you to save on the purchase of several sanders.

Dust collector option

The result of the grinding machine is not only a flat and smooth surface, but also a fairly large amount of fine dust. Of course, the manufacturers took care of the presence of a dust collector for it. But everyone has their own one and it’s not always convenient.

For example, Makita eccentric sander is equipped with three types of dust collectors – plastic, rag and paper. But Bosch only have plastic dust collectors with the possibility of replacing them with a vacuum cleaner. When purchasing an EShM, you should always consider the option of a dust collector that will be convenient for everyone in particular. The dust collector itself, of course, does not affect the quality of work, but you don’t want to bother too much when cleaning it.

Possibility of connection to a vacuum cleaner

As already noted, dust removal for various models and manufacturers of ESM is carried out either in a separate dust collector or using a vacuum cleaner. This approach is justified. After all, the dust collector is small in size and doesn’t last long, so you have to clean it often while taking time off from work. Therefore, some manufacturers have provided the ability to connect a vacuum cleaner. Unfortunately, not all models of eccentric sanders have this option. But professional ESMs, such as Bosch , Rupes or Makita sanders, must be connected to a vacuum cleaner.

Of course, there is another option for connecting to a vacuum cleaner, this is a special adapter. Other ESM manufacturers, realizing the importance of connection, decided to leave their grinder models unchanged and began producing special adapters. Therefore, when buying an eccentric machine, realizing that you will have to work hard and for a long time, you should ask the seller about the possibility of connection.

Second handle

The specificity of working with an eccentric machine involves pressure on it from above. Even the very shape of the instrument is entirely aimed at this. But quite often the trigger mechanism and electric motor are located somewhat away from the center, which creates certain difficulties during operation. In this regard, ESM manufacturers have added an additional handle, which compensates for pressure on the other side and makes working with the machine easier. The handle itself can be removable or stationary. It all depends on the model. For example, the Makita BO5040/5041 has a removable handle, while the Bosch PEX 400 AE is equipped with a stationary additional handle. Special mention should be made of DWT . They equipped their EShM with side handles, which provides additional convenience when working with vertical surfaces.

Starting current limitation

The result of the sander should be a flat and smooth surface. But from the moment of launch until the start of work, the master does not always have time to adjust and make the necessary effort. As a result, the surface can be damaged, leaving unwanted grooves that will have to be sanded down. Therefore, many manufacturers equip their grinders with a soft start system. This approach is justified, especially if the wood sander is eccentric. It's all about the vibration that occurs immediately after turning on the machine. The presence of a soft start allows the ESM to gradually reach operating speeds and allow the master to adapt to them.

Pressure indicator

One of the additional functions useful for a beginner is the pressure indicator. This is especially useful for those who have not yet learned to feel their pressure on the instrument. This indicator will allow you to correct the pressure if you apply too much or too little pressure to ensure proper sanding. This feature will also be useful for professionals. It will allow you to evaluate the degree of your skill in working with an electric machine and will facilitate the grinding process itself.

Abrasive mounting option

During grinding work, there is often a need to sweep away the abrasive due to wear or in order to reduce the grain size for a smoother grind. To prevent this simple step from taking too much time, manufacturers have developed several different methods for attaching the abrasive to the sanding pad. The most common is regular Velcro . In addition to it, there is also the Quick-Fit system, which provides a modular replacement, but it is less popular. When choosing an ESM from a particular manufacturer, you need to familiarize yourself with how the abrasive will be attached so that during operation there are no problems with replacement.

In addition to the listed brands Bosch, DWT, Makita, Metabo, Rupes, Interskol and Dynorbital, there are many others, both domestic and foreign, whose products can be easily found on the shelves of large supermarkets and hardware stores. When purchasing an ESM, like any other tool, it is important to know and take into account not only its functionality and characteristics, but also the country of the manufacturer, and the materials from which the tool itself is made. After all, everything that is purchased must serve for a long time, reliably and perform its tasks efficiently.

Additional functions

Some models are equipped with additional functionality, which significantly improves the quality of work and increases its productivity. Often these options are important when deciding which tool to choose.

| Name | Description |

| Speed adjustment | Allows you to use one tool for different types of finishing |

| Dust collector option | The standard equipment is a plastic container. There are also paper and rag |

| Possibility of connection to a vacuum cleaner | Many models are equipped with this function |

| Second handle | Provides convenience for working while in weight. Also necessary for additional pressure |

| Starting current limitation | The “soft start” system makes it possible to adapt to the tool and select the required pressure |

| Pressure indicator | Signals about weak or excessive pressure, which allows you to adjust the effort in time |

| Abrasive mounting option | There are 2 options used - with Velcro and the Quick-Fit system, where fixation is carried out using clamps |

Additional features affect the cost of the grinding machine. But such costs are justified - productivity increases, quality improves, and ease of use is ensured.

Criterias of choice

Comparison of eccentric sanders

Popular manufacturers of orbital sanders (eccentric type)

- Makita;

- Metabo;

- DeWALT;

- BLACK+DECKER;

- BOSCH;

- Hyundai;

- Hammer;

- Einhell;

- PATRIOT;

Power consumption is considered one of the main selection characteristics that affects process performance. It is also necessary to take this indicator into account so as not to overload the power grid. A tool with more power is chosen mainly for rough work, such as grinding concrete and metal. The range varies from 50 to 1200 W.

You need to understand that the more power the EShM model has, the heavier it will be.

The size of the platform stroke, mm - can vary from 1 to 20 mm. The greater the amplitude, the faster the processing process moves.

Disk diameter, mm - can be divided into three types: small 100 - 125 mm, medium 150 -180, large 200-230 mm. Each of them is selected depending on the work being performed. The higher the number in the table, the finer the grain size.

| Type of grinding | Grain |

| Finishing | 180 — 320 |

| Blade finishing | 170 — 220 |

| Round finishing | 60 — 100 |

| Round roughing | 24 — 36 |

| Flat | 16 — 36 |

The equipment is classified:

- P40 – P120 - intended for rough work, for example, initial surface cleaning before sanding wood, metal, etc.

- P140 – P180 – removal of minor flaws.

- P400 – P1000 – polishes products.

Maximum disk rotation speed (revolutions per minute) - this parameter depends on the maximum disk size for a particular model; the larger it is, the lower the number of revolutions becomes.

It is set mainly for a specific material and attachment. The finer the grain size of the skin, the higher the processing speed (from 5,000 to 13,000 rpm).

| Additional functions | |

| Speed adjustment | Allows you to perform work more efficiently. |

| Starting current limitation | Gently accelerates the engine, reducing tool wear and making work safer. |

| Speed stabilization system | Fixes the desired value by dialing the speed and maintaining it. |

| Overload protection | Turns off the motor during overload or jamming, which prevents tool damage. |

| Anti-vibration system | Works as a dynamic counterweight, reducing strong vibration. |

| Rubberized body | The grip becomes more comfortable and there is less vibration. |

| Button lock ON | Prevents the grinder from being accidentally pressed, and also keeps the button ON during prolonged operation. |

| Case | Convenient for carrying tools and storing equipment. |

| Weight | The lighter weight prevents your hand from getting too tired, which improves performance. |

How to choose an eccentric sander

Considering the above information, it will be easier for the master to make the purchase of the tool. It’s not enough to know how an eccentric sander works; you need to decide on the selection criteria:

- Budgeting. For household needs, when the device is used from time to time, it is not rational to buy an expensive professional machine.

- Class. First, the accents are determined:

— for productivity, choose a disk diameter of 150 mm with an amplitude of 5 mm and above;

— for finishing quality – 125 mm with an amplitude of 3 mm.

- Weight. It depends on convenience. If you have to work a lot on vertical surfaces or sand the ceiling, then the tool should be lightweight. It is better to give preference to a device of medium power.

The choice of manufacturer also matters. In order for the ESM to last for a long time, it is recommended to pay attention to brands that have managed to prove themselves in their work on the positive side.

What to look for when choosing eccentric sanders

- hand-held power tools are equipped with many additional mechanical and electronic systems. Their main purpose is to increase the comfort of working with the device, as well as to protect its mechanical part;

- For example, an electronic system for maintaining constant revolutions of the grinding disc is very practical. With its help, the grinding result becomes more uniform over the entire area of the object being processed. Similar systems are found on almost all models of professional ESM;

- It is worth paying attention to the presence in the selected model of the ability to limit the starting current. This limitation eliminates jerking of the grinder at the moment of start-up, and also prevents power surges in the network;

- The automatic brake option will be useful. Instant stop of the disk after turning off the device will save both the operator’s hands and the surface of the material from accidental damage;

- In addition to electronic systems, orbital sanders are also equipped with mechanical devices. Thus, most models have a terminal for connecting a construction vacuum cleaner. As an option - a dust bag;

- When purchasing, you need to pay attention to the material used to make the casing and the sanding pad of the device. If it is metal, then the ESM will last longer and will heat up less during operation;

- It is better to give preference to models with a removable network cable. If the latter is damaged, replacement will not take much time. In addition, the manufacturer’s warranty will remain, since you will not have to open the device case;

- A little more comfort can be added by such features as rubber pads, adjustable additional handles, a lock on the switch, etc. little things.

Video - Comparison of eccentric sanders with different amplitudes

Rating of eccentric sanders

On the working tools market you can find many interesting options for OHM, both Russian and foreign manufacturers. Some of them (judging by the ratings) are more popular among consumers and professionals, others less so.

| Name | Peculiarities |

| From the category of household and semi-professional | |

| Bison 452 | Inexpensive but well-proven model |

| Interskol EShM 125/27 | Compact, lightweight device, easy to use |

| Vityaz OSHM 125/700 | A universal tool used for all types of grinding. Works with various materials |

| Professional devices | |

| Bosch GEX 150 AC | Great for small workshops |

| Metabo FSX-200 | A small-sized lightweight tool from the “pro” category is quite suitable for working at home |

| DeWalt D26320 | If you need to process large surfaces in one go, this is the most suitable model |

| Whirlwind EShM-125E | The powerful device, powered by mains, is equipped with a set of abrasives of various grain sizes. |

If you choose a tool from the professional category for personal use, this review recommends paying attention to models from Metabo and Bosch. They are easy to use, equipped with a large dust collector, and provide high quality grinding.

How to use a sander correctly

Features of using a belt sander

A belt sander is best suited for processing large, flat surfaces.

First of all, you need to put on the tape. The easiest way to do this is when the car is lying on its side. Having first snapped off the fastener, put on the tape, taking into account the direction of movement - indicated by the arrow both on the tape and on the rollers of the machine. This is necessary so that the seam on the tape is positioned correctly. Otherwise, the tape may either break or damage the surface instead of sanding. After this, snap the fastener into place.

The belt in the machine always moves in one direction, so you also need to work in one direction with the tool - pressing it tightly to the surface, moving it towards you. The wood must be processed along the grain with a belt sander. Otherwise, deep furrows may appear. There is no need to press unnecessarily on an already heavy tool - instead of increasing productivity, you can overheat and thereby damage the tape.

To expand the functionality of the belt sander, you can use a frame, stationary mounts (vices), and corner stops. It is the band tool that can be fixed permanently with a vice and moved not by it, but by the surface being processed (for example, a board, a block). This type of tool mount is especially important for grinding small parts. Also, when the machine is stationary, it is very convenient to sharpen notches and curves.

Another way to use the belt tool is when the machine is lying on its side. Its advantage is that in this position a right angle is formed.

Video: how to use an eccentric (orbital) machine

When preparing the machine, you need to pay attention to how dusty the job is expected to be. And if there may be a lot of dust, it is better to connect the vacuum cleaner right away, fortunately many models have this option. The work is relatively clean - a dust collector will do

A respirator will keep you healthy

The work is relatively clean - a dust collector will do. A respirator will help you stay healthy.

Important! During operation, you need to periodically check the dust container and prevent it from overflowing. Otherwise, dust will come out from all the holes. The abrasive disc is attached to the round platform of the machine with Velcro - you simply apply it and press it with your hand

You just need to make sure that the holes on the disk coincide with the dust holes on the platform

The abrasive disc is attached to the round platform of the machine with Velcro - you simply apply it and press it with your hand. You just need to make sure that the holes on the disk coincide with the dust removal holes on the platform.

When processing a plane with a machine, you need to press the platform tightly against it. You need to hold the machine level so that the platform is not pressed against the surface by the edge - otherwise there is a risk of damaging the surface with scars. In order not to remove excess, this is especially true during body work, it is better to check the surface more often with your palm for roughness.

As you work, check the dust content of the nozzle, change it on time so that the work does not go in vain when the grain is “clogged” and the roughness is no longer torn off.

Video: how to use an eccentric sander for body work

There are many ways to use grinding machines. This includes preparing for painting the body, treating floors, sanding wooden parts (even children's toys), and even polishing. The result of work, of course, depends on the skill and perfection of a person’s skills

But no less important is the quality of the tool, as well as how correctly it is selected and used correctly.

Good luck with your work!