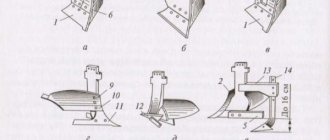

- 1 Types of gutters 1.1 Suspension device

- 1.2 Gutter structures with jibs

- 1.3 Tray for truss-type concrete mixture

Gutters are a structure for draining or mechanically transporting liquid to the desired location. Such a device is a useful, effective assistant both in everyday life and in industrial conditions, in the road system, and the construction industry. It is the construction type of gutters that will be discussed. A construction gutter for concrete is a simple design that you can actually make with your own hands. With such a gutter it is possible to ensure high-quality, uniform placement of concrete mortar during the construction of the foundation for a building.

Types of gutters

There are several types of gutters for pouring concrete:

Return to contents

Hanging device

It is used when transporting concrete mortar over a short distance with a shift to the site of the future foundation. To build this mechanism, you need to take a rope and attach a tray to it using cables threaded through a couple of blocks. One end of the rope is tied to a column or pole. A weight is attached to the other and left on the ground. The load should also be hung on the edges of the cables so that it is convenient to adjust the degree of inclination of this mechanism.

If a massive foundation is being laid for a large project, a fixed angle of inclination of the concrete conveyor should be installed. This can be achieved by increasing the height of the tower or installing additional columns. Actually, the mixture from the central tower will be transferred to these additional pillars.

Return to contents

Gutter structures with jibs

Diagram of a trench for pouring concrete.

Such a device is a mechanism in which the lower edge of the tray is attached to a jib - a lattice structure made of metal, one edge of which rests on the lower slide, the other is connected to the upper ones by means of a lifting cable. To maintain stability of the angle of inclination of the gutter, the lower edge of the structure is attached to the ground using cables. This device is used when delivering concrete composition to the formwork at a distance not exceeding 60 meters.

Return to contents

Truss-type concrete mix tray

The simplest mechanism for delivering concrete to the foundation site of all those listed. It is a design in which the lower edge of the concrete conveyor is attached to a support.

Return to contents

Methods of transporting concrete. Characteristics of concrete mixer trucks

Description of concrete mixer trucks

As you know, gone are the days when concrete was delivered by dump trucks.

Now concrete mixer trucks (ABS or mixer) are used to deliver concrete mixture to the site. The task of ABS according to GOST is to exclude the possibility of precipitation getting into them, disruption of homogeneity, loss of cement mortar, and also to ensure the protection of the mixture en route from exposure to wind and sunlight. The safety and uniformity of the concrete mixture during transportation is ensured by the rotation of the drum. There are spiral blades inside the drum. When rotating in one direction (during loading and transport), the blades drive the mixture deeper into the drum. While the concrete mixer truck is moving with concrete mixture and at temporary stops, rotation of the drum in the opposite direction is strictly prohibited. When rotating in the other direction (during unloading), the Archimedes Screw mechanism is used, with the help of which the mixture is unloaded.

Preparation of the concrete mixture is possible directly in a concrete mixer truck during transportation, when cement, water and aggregates are loaded into the drum. In Russian concreting practice, the more common scheme is to transport ready-mixed concrete mixed at the plant.

Volumes of concrete mixer trucks

The most popular on the Russian market is KAMAZ ABS with a volume of 7 cubic meters, followed by 9 cubic meters.

The top three are closed by small two-axle mixers based on Japanese right-hand drive trucks with a volume of 2 to 5 cubic meters. ABS with a barrel volume of 7 cubic meters. as a rule, it is loaded at 6-6.5 cubic meters, and with a barrel volume of 9 cubic meters. at 8-8.5. Not filling up to full volume is associated with a number of factors:

- Preventing spillage of moving concrete during transportation.

- Reducing the load on tires, frame, subframe and chassis ABS.

- The smaller the vehicle’s loading volume, the more passable it is over rough terrain.

Dimensions of concrete mixer trucks

ABS 7 cubic meters based on KAMAZ 65115 has the following overall dimensions:

- Length - 7800 mm.

- Width - 2500 mm.

- The height of the funnel is 3700 mm.

- Weight without concrete - 12500 kg.

- Weight with a load of 6 cubic meters is 27500 kg.

- The capacity of the water tank is 650 liters.

- The total length of standard gutters (1 gutter + 2 extensions) is 2500 mm.

- The total length of standard gutters (1 gutter + 2 extensions + additional gutter) is 6500 mm.

- The maximum unloading height is 1700 mm.

ABS 9 cubic meters based on KAMAZ 6520 has the following overall dimensions:

- Length - 8800 mm.

- Width - 2500 mm.

- The height of the funnel is 3850 mm.

- Weight without concrete - 14500 kg.

- Weight with a load of 8 cubic meters - 34500 kg.

- The capacity of the water tank is 1000 liters.

- The total length of standard gutters (1 gutter + 2 extensions) is 2500 mm.

- The total length of standard gutters (1 gutter + 2 extensions + additional gutter) is 6500 mm.

- The maximum unloading height is 1900 mm.

Concrete sells concrete at an affordable price and quickly and efficiently delivers the concrete mixture using its own fleet of concrete mixer trucks.

Purpose of concrete trays

Such a structure is intended for pouring mortar into the formwork of the future foundation of the building. From the concrete mixer, the mixture is supplied through a chute to its destination. However, if concrete is poured at the same point, then due to the uneven placement of the mixture, a flat surface of the designed foundation will not be obtained.

In this case, beware of delamination in concrete, when the watery part of the solution flows into the far corners of the formwork, and the denser part remains at the pouring point. By making mistakes when supplying the concrete mixture using a special tray, you can create a low-quality foundation that will soon begin to deform.

Therefore, be sure to create conditions for the smooth movement of the concrete mixer around the construction site so that there is access to any corner of the future structure. If in some places this is not possible, the length of the gutter should be increased in order to reach hard-to-reach corners.

Return to contents

Preparation of materials and tools for creating a gutter

When producing a transport mechanism for a concrete composition, pay attention to some points:

- This device must be in close contact at one end with the mixer, at the other with the formwork, thus connecting them.

- Install the device with a certain angle of inclination so that it is easier for the concrete under its own weight to flow down the gutter into the formwork.

Tools that may be needed at work.

To create such a mechanism, you will need the following tools:

- hacksaw;

- roulette;

- hammer;

- screwdriver;

- square;

- Bulgarian.

To do this you will need to prepare the following materials:

- board measuring 2.5/12 cm;

- a piece of polyethylene, linoleum or tin;

- timber or block as a support;

- nails (you can use screws).

Return to contents

Tips for making troughs for pouring concrete mortar

Before starting the production of a concrete delivery tray, it is worth paying attention to some conditions regarding setting the correct angle of the structure. The degree of the established inclination must be stable and the same throughout the entire working process. As the slope decreases, the flow of the concrete solution slows down . The consequence of this may be premature hardening or clogging of the mixture.

Pouring concrete through a chute into the formwork.

If the angle of inclination of the gutter, on the contrary, becomes even greater, the speed of transport of the solution inside the formwork will increase. This is fraught with the disintegration of the mixture into different parts, which can lead to a significant deterioration in the quality characteristics of concrete. The foundation will lose its performance qualities, become fragile, vulnerable and short-lived.

The angle of inclination for installation of the gutter structure is selected taking into account the level of supply range of the concrete mixture and its density coefficient. For liquid solutions conveyed over a shorter distance, a small level of inclination is permitted. If the composition is sufficiently dense or it is delivered over a long distance, the angular degree of the tray should be increased as much as possible in order to speed up the pouring process and not deform the structure due to the weight of the concrete mass.

The uniformity of the concrete composite is influenced by the shape of the gutter structure. A long, narrow tray, made with your own hands, during the delivery of the solution contributes to a closer connection of its grains. At the same time, the trench should be made quite deep to prevent the concrete solution from overflowing over the edges of the tray while pouring the foundation.

If the manufactured device transporting concrete from the mixer to the formwork turns out to be too narrow, it must be strengthened with horizontal crossbars. This will protect the structure from deformation during the thrombotic process of the concrete mass. If you want to give the structure greater strength, you can increase its hardness by means of corners attached to the tray perpendicularly. The length of such fasteners must correspond to the width of the gutter.

Today, similar mechanisms for laying foundations are produced from 3 to 15 meters in length. Such devices, as a rule, are used for more global purposes - in the construction of large-scale commercial, often multi-level structures.

Under private construction conditions, shorter (up to one and a half meters), convenient gutters are suitable, which are quite possible to make with your own hands. Its weight also depends on the footage of the tray. The longer the structure, the heavier it should be. This will protect the solution conveyor from bending under the weight of the mass entering it.

Return to contents

Device requirements

Formwork diagram for the foundation.

In order for the supply of concrete mass during the construction of the foundation to be as uniform and homogeneous as possible, the gutters must meet certain requirements that apply to them:

The slope of the gutter must remain unchanged throughout the entire period of work during the construction of the foundation of the house. If this condition is not met and the angle of inclination, for example, decreases, then the speed of passage of the concrete mass will also decrease.

This, in turn, would lead to a buildup of solution and blockage of a certain area of the gutter. With an increase in the angle of inclination, and therefore the speed of passage of the mass, the concrete surface will be divided into separate parts, which is completely inconsistent with the existing technology. The foundation will be of poor quality.

The angle of inclination of the gutter relative to the horizon must have a certain size, an increase in which will lead to the concrete mass being divided into parts. The reason for the change in the size of the angle of inclination may be the consistency of the concrete and the degree of its delivery distance.

Solutions of a more liquid consistency, supplied over a short distance, allow gentle slopes; for longer distances, steeper gutters are appropriate.

The process of creating a trough conveyor for concrete mass

Jet chute diagram.

It is not at all difficult to build such a mechanism with your own hands. This is a simple process that does not require professional skills and abilities. First, use a saw to cut the board, adjust it to the dimensions of 2.5 by 15 cm, and knock down a shape resembling the letter “P.” The sides of this structure must be high so that the concrete solution does not stagnate during transportation.

To facilitate the flow of the solution along the tray, the entire inside of the structure must be covered with smooth materials: polyethylene, tin or linoleum. This will ensure better sliding of the solution and reduce its adhesion to the bottom and walls of the conveyor.

After making the trench device for pouring the foundation, it is placed in the required place, supported by four supports. The role of such supports can be perfectly fulfilled by gas silicate or other monoliths that can protect the means of transporting the composite from collapse.

You should know that inside elongated open-type structures, a specific percentage of moisture evaporates from the concrete mixture, thereby disrupting the homogeneity of the solution. Therefore, such transport mechanisms are used only at private construction sites.

When laying foundations for industrial purposes, gutters are used, constructed in such a way that at the bottom of the device, before entering the formwork, the concrete passing through the tray is constantly mixed. This is done with the help of a special trunk pipe, reminiscent of a funnel, through which the solution passes.

Return to contents

Rules and tools

Jet chute diagram.

To build the structure you will need:

- roulette;

- hacksaw or chainsaw;

- hammer;

- Bulgarian;

- screwdriver;

- square

When pouring a foundation with your own hands, it is very important to follow some rules, the main ones of which are the following:

- concrete should be poured with a mixer in small portions, no more than 1.5 m in height, evenly distributing it over the entire surface area;

- the poured mixture must be compacted using a device such as a vibrator;

- pouring concrete using a mixer should proceed until it reaches the control mark, which is made on the surface of the formwork, i.e. then the filling stops;

- the concrete surface is well leveled, and after 3 hours, when the solution has set a little, it is covered with burlap;

- the foundation should not be poured from a mixer in small portions, which, in turn, will lead to the formation of joints that reduce the strength of the foundation, which can subsequently lead to the destruction of the structure;

- if the work is carried out in hot sunny weather, then the concrete surface is periodically moistened for several days.