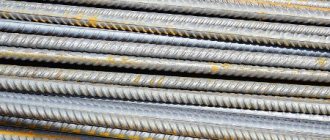

Reinforced concrete structures in construction are the strongest, which is why they are used in the construction of house foundations, load-bearing beams and floor slabs, bridges, columns and other critical objects. Without reinforcement, concrete poorly resists tensile and bending loads, which cause its destruction. This problem is solved simply - they “stuff” the concrete with steel rods, which serve as a rigid frame in its body. The reinforcement, the weight of which is necessary for design calculations and determining the required amount of material, can have different shapes and cross-sectional diameters.

Samples of reinforcement of different diameters Source permglavsnab.ru

Why and how to determine the weight of reinforcement

Most private developers wondered how much 12 mm reinforcement weighs per meter - it is what is most often used for pouring foundations, monolithic basement walls, and armored belts. The answer to this helps solve at least two problems.

- Determination of the carrying capacity of the vehicle required to deliver materials to the construction site.

Not all developers use delivery services, and not all small sellers provide such a service. If you don’t need so many rods, it’s cheaper to pick them up yourself, but you need to know whether the load will be excessive for the car. Since the standard length of the reinforcement is 6 or 12 meters, many people cut it in half right on the spot and transport it on a trunk or in a trailer. Or they select short rods from unmeasured lots.

The number of short rods in unmeasured batches can reach 7% Source prom.st

See also: Catalog of companies that specialize in the design and installation of metal structures (canopies, greenhouses, etc.)

- Determination of reinforcement footage in ton.

Large volumes of rolled metal are sold using not meters or pieces as a unit of measurement for calculations, but a ton. If you know how many linear meters of reinforcing bars are contained in one ton, it will not be difficult to calculate the weight required for ordering and purchasing.

In theory, knowing the diameter of the required products and the density of the steel alloy from which they are made, you can independently calculate their weight. But in practice, such calculations will have a large error, since the reinforcement bars do not have a constant cross-section, but a periodic one, with longitudinal and transverse stiffeners. And they have two diameters - minimum and maximum.

Reinforcement cross-section - drawing Source ugmk.com

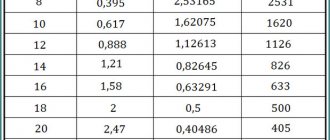

But there is no need to do this. A table compiled on the basis of GOST 5781-82 will help you find out how much the reinforcement weighs. This document regulates all parameters of these metal products. Their mass depends primarily on their diameter.

- The thinnest rods have a diameter of 6 mm and the weight of one linear meter is slightly more than 220 grams.

- The thickest 80 mm reinforcement is much heavier - more than 39 kg per linear meter.

The larger the diameter and denser the reinforcement pattern, the more important it is to know how much a meter of reinforcement weighs. The mass of the metal frame must be taken into account when calculating the load on the base, and an error can lead to unpredictable consequences.

Main categories

The following classes of fittings are popular in Russia: A240, A400, A500C, AT800. Below we will look at them in detail.

A240 (AI)

Reinforcement of this type is made from carbon steels, which additionally contain small amounts of manganese, nickel, chromium, and copper. Brand A240 - smooth fittings. If the cross-sectional diameter is less than 12 millimeters, then A240 can be in the form of large coils held together with wire. Spare parts with a diameter of more than 12 millimeters are made in the form of separate rods of short length (up to 5 meters). The brand is used for the construction of small lightweight structures. It can also be used to reinforce small objects - compact columns, curbs, partitions, walls.

A400 (A-III)

A400 class rods have a round cross-section with a corrugated surface. Corrugation on spare parts appears due to small protrusions, which are located at an angle of 40-45 degrees relative to the central axis of the reinforcement. A400 is made from carbon steel, which includes a large number of filler components. The main additive component is manganese, which makes the alloy more durable and reliable. In addition to manganese, the alloy also includes other components - chromium, nickel, copper. The presence of stiffening ribs provides better adhesion of the A400 to the concrete composition.

Therefore, durable composite parts based on reinforced concrete are often made from the A400 brand - walls, floors, ceilings, inclined surfaces, vertical pillars, beams, bridges. Another area of application is road pavement reinforcement. Welding can be used to connect A400 parts to each other, but it is recommended to do butt welding using the butt welding method or using spot welding machines. Alternative welding technologies are less reliable, and the resulting structure will have low bending strength. This negatively affects the shelf life of the reinforced concrete product.

A500C

The A500C brand appeared on the Russian market relatively recently - in the 90s. Reinforcement of this type undergoes a number of auxiliary technological treatments (hot rolling, thermal hardening). These treatments significantly increase the physical properties of the material - elasticity, strength, stretching. Also, the A500C brand has poor contact with water and air, since it is chemically inert. Interestingly, grade A500C is smelted from ordinary steel containing an average amount of carbon and a minimum amount of alloying additives.

This makes the material cheaper to produce, which will be very useful for the builder. The A500C brand tolerates welding well, and can be joined using almost any welding method - overlap, butt, cross-overlay, and so on. The brand can be used for the construction of both large and small buildings based on concrete. These can be elements of a house or the entire house, bridges, hanging structures, medium-sized hangars, support poles, power lines. The only major drawback of the A500C is the deterioration of physical properties at low temperatures (below -30 degrees). Therefore, parts of this type are not recommended for use in the Far North.

AT800

The AT800 brand belongs to the class of heavy-duty reinforcements that have undergone hot rolling and thermomechanical hardening. The surface of the material is usually corrugated, although smooth varieties of the AT800 brand are also available. The brand is used for the construction of large massive structures based on reinforced concrete. These can be multi-story buildings, bridges, hangars, and so on. Thermo-mechanical hardening performs the following functions:

- Increasing ductility while maintaining the strength of the material (ductility increases by 20-30%).

- Increased fatigue strength, which allows spare parts to retain their shape even during long-term use.

- Improving anti-corrosion properties, minimizing the risk of cracking of the material upon contact with chemicals.

Weight table

In accordance with the current standard, reinforcement of classes A240, A400 and A500C is used in construction. All weight values in 1 linear meter, in a rod 11.75 m long and in 1 ton of timber are summarized in the table. The error is acceptable, but insignificant, no more than a few percent.

Summary table for all diameters Source vezetnerud.ru

Examples of calculations

To find out how much 1 meter of 12 mm reinforcement weighs, just find this diameter in the first column. The following gives the mass of 1 l.m. – 888 grams. And there are only 1126 meters in a ton, or, if you divide this value by the length of the rod, almost 96 pieces.

The design documentation may only indicate the diameter and weight of the reinforcement without indicating the footage. When purchasing individually, you will have to calculate how many pieces you need. For example, you need to buy 1.5 tons of 16 mm reinforcement to install a strip foundation.

- We find from the table how much 1 meter of reinforcement weighs - it is 1.58 kg.

- We convert 1.5 tons into kilograms, multiplying by 1000 - 1500 kg.

- Divide 1500 by 1.58 and we have 950 m.

- Or divide 1500 by 18.56 (the weight of one bar) and get 81 pieces.

These simple calculations will allow you not only to avoid making mistakes when purchasing, but also to check the amount of material delivered to the site.

When you need to find out how much a certain number of rods will weigh, do the opposite: multiply the weight of the rods of the required diameter by their number or footage. For example, you need to buy 30 rods, the thickness of the reinforcement is 20 mm. With a mass of one rod of 29 kg, the total weight will be 30 x 29 = 870 kg.

Delivery status

An area where the private developer almost always faces unpleasant discoveries.

The reinforcement is supplied in coils (up to 22 mm thick) and rods. The skein should consist of one, maximum two segments.

Length of rods: 6 - 18 m. Rods according to standard 34028-16 come in measured length (MD), measured with unmeasured (MD1), unmeasured (ND, 6 - 12 m). In the supply of MD1, no more than 3% of unmeasured rods with a length of at least 2 m are allowed.

Rods of irregular length are cheaper. But the probability of deception here is quite high. If it is not possible to count and measure each rod, you will pay more. Please also take into account that due to the overlap of individual rods, the consumption of reinforcement will increase.

The skeins should unwind freely, and the overlap of the turns should not interfere with unwinding.

Weight of composite reinforcement

Nowadays, fiberglass reinforcement bars are increasingly being used instead of steel reinforcing bars. They have a lot of advantages, including light weight. In addition, fiberglass has better tensile strength than steel, which allows the use of products with a smaller diameter. For example, an 8 mm composite rod is equivalent in its physical and mechanical characteristics to a 12 mm steel rod. Accordingly, the load decreases even more noticeably.

Table for determining the equivalent diameters of steel and composite reinforcement Source luxkompozit.ru

Compare how much a meter of 12 mm steel alloy reinforcement weighs (890 g) and a meter of fiberglass rod with a diameter of 8 mm (110 g). The difference is 8 times.

Corrosion

The surface of a concrete structure must be looked after and any cracks that appear must be eliminated in a timely manner.

Due to the ability of iron to react with oxygen, steel products are inherently sensitive to the atmosphere. The interaction between it and oxygen in the air causes an oxidation process, more often called rust or corrosion.

Surface rust of the reinforcement that is located inside the structure does not affect its properties. The alkaline environment prevents this. It can even increase the bond between the bar and the concrete. However, a long process of surface oxidation (with access to air) can eventually lead to internal corrosion, which will inevitably weaken the steel bar.

The resistance of reinforcement to corrosion is determined by the chemical composition of the steel, the production method, and is designated by the letter K. In this case, the reinforcement is made of stainless steel. In private construction, it is irrational to use such rods.

It's not just about cost. Damage to the surface by metal slings or friction against the steel of the body creates pockets of corrosion.

Ferrous reinforcing metal is protected by hot-dip galvanizing or coating with epoxy resins.

Briefly about the main thing

When starting construction and ordering materials for it, it is important to be able to calculate them correctly and control delivery, without allowing suppliers to deceive you. To do this, you need to know how many kilograms of cement are in a bag, how many boards are in a cubic meter, how many kg are in 1 meter of reinforcement with a diameter of 12 mm. Such knowledge can be very helpful in calculating loads on building structures and in solving transportation issues. In the case of fittings, everything is simple - you just need to look at the table and find the necessary data in it.

Color marking

Symbols of fittings can also be distinguished by the color of the ends - this is applied at the manufacturer when batches are shipped to consumers. For such designations there is also a classification table in which the marking of the reinforcement can be represented by the column “end color”; there is also a column corresponding to it and the steel grade “the number of transverse ribs between the markings”:

| Bar class | Colored (painted) marking of rod ends | Number of transverse edges between markings |

| A III | — | 3 |

| At III | White | 3 |

| A 500s | White and blue | 1 |

| A-IV | Red | 4 |

| At-IV | Yellow | 4 |

| At-IVc | Yellow and white | 4 |

| At-IVk | Yellow and red | 4 |

| A-V | Red and green | 5 |

| At-V | Green | 5 |

| At-Vk | Green and red | 5 |

| A-VI | Red and blue | 6 |

| At-VI | Blue | 6 |

| At-VIk | Blue and red | 6 |

| At-VII | Black | 7 |

As an additional column in the tables, a parameter such as “cold bending test” can also be entered.