Features of fiberglass structure

Polymer composite reinforcement has a couple of main parts:

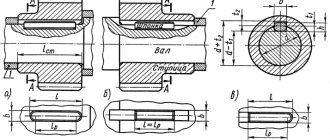

- ⦁ the inner rod is made of fiberglass fibers arranged parallel to each other. The fibers are bound together by a special polymer resin composition. There are options when manufacturers offer reinforcement in which the intra-rod fiber is twisted in the shape of a pigtail. It is important to note that it is this internal rod of fiberglass reinforcement that determines its initial characteristics and is responsible for strength.

- ⦁ the outer layer of the reinforcing rod is made using the type of bidirectional wrapping from fibers of a composite material. Often there are products in which the top layer is made using spraying of fine abrasive powder.

The technical production of fiberglass reinforcement bars is determined by the capabilities, equipment and imagination of the manufacturers. As well as manufacturing technologies for this material, on which the final quality of the product will depend.

Solutions

Fiberglass reinforcement for the pond frame Fiberglass reinforcement “SZS” was used to make the frame for the pond bowl in the “Dachny Otvet” program. Fiberglass reinforcement for the parking lot foundation During the construction of the “Garden with Moonlight,” the Dachny Otveta team used fiberglass reinforcement from SZS to reinforce the foundation under the parking area. Fiberglass reinforcement for the foundation of a greenhouse During the construction of the “radiant garden” by the “Dachny Otvet” program, fiberglass reinforcement from SZS was used to strengthen the foundation of the greenhouse. Fiberglass reinforcement for the terrace foundation When constructing a patio with a moon window, fiberglass reinforcement from SZS was used as a frame for the terrace foundation.

Advantages of composite reinforcement

Fittings made of fiberglass periodically undergo numerous inspections, trials and tests, which demonstrate its rational use, taking into account a number of characteristics. Each time, the data confirms the advantageous difference from other materials of similar purpose.

It is worth considering the advantages of composite reinforcement in more detail:

- Reinforcement bars made of fiberglass are light in weight. The weight of composite reinforcement is up to 9 times less than that of similar metal products;

- In a comparative analysis of corrosion resistance, fiberglass reinforcement is 10 times more reliable than steel reinforcement with similar data. The consumer appreciates the excellent resistance of this material to aggressive environments, such as salty, alkaline or acidic;

- Composite reinforcement conducts heat much less than metal reinforcement, therefore the occurrence of “cold bridges” is minimized;

- In many cases, purchasing composite reinforcement is much more profitable in financial terms - transportation, unloading and longer service life are much more convenient;

- The invaluable advantages of composite reinforcement also lie in its transparency for electromagnetic waves and impediment to electric current;

- It greatly simplifies the work of installing structures - there is no need to purchase equipment for welding and tools for cutting metal;

Comparative table of parameters of reinforcement made of different materials

| Diameter of fiberglass reinforcement ASP | 4 mm | 6 mm | 8 mm | 10 mm | 12 mm | 14 mm | 16 mm | 18 mm | 20 mm |

| Diameter of equivalent steel reinforcement | 6 mm | 8 mm | 12 mm | 14 mm | 16 mm | 18 mm | 20 mm | 22 mm | 25 mm |

| Weight of 1 meter ASP, kg | 0,030 | 0,060 | 0,083 | 0,135 | 0,210 | 0240 | 0,287 | 0,313 | 0,353 |

| Weight of 1 meter of steel reinforcement, kg | 0,222 | 0,395 | 0,888 | 1,210 | 1,580 | 2,000 | 2,470 | 2,980 | 3,850 |

| Footage of 1 ton of ASP, m | 33334 | 16667 | 12048 | 7407 | 4762 | 4167 | 3484 | 3195 | 2833 |

| Meterage of 1 ton of steel reinforcement, m | 4504 | 2532 | 1126 | 826 | 633 | 500 | 404 | 335 | 260 |

| Weight of ASP reinforcement, equivalent to 1 ton of steel, kg | 135 | 152 | 93,5 | 111,5 | 133 | 120 | 116 | 105 | 92 |

Possible sizes of composite reinforcement

We have already pointed out that the dimensions of composite reinforcement can vary depending on the capabilities of the manufacturer.

Also, often this type of fittings is made individually, taking into account the specific requirements of the customer.

Here are the most common sizes of composite reinforcement in demand in the construction market:

- Reinforcement in which the diameter of the rod is from 4.6 to 8 mm is wound into coils, the diameter of the coils themselves is no more than 1 meter;

- A coil of fiberglass reinforcement, which has a diameter of 10 mm, also has a diameter of about 1 meter;

- Reinforcement produced with a bar cross-section of 12 mm is produced and stored in coils whose diameter reaches 1.5 m;

Characteristics of fiberglass reinforcement

| Reinforcement parameters | Profile number | ||||||||||

| Ø4 | Ø5 | Ø5.5 | Ø6 | Ø7 | Ø8 | Ø10 | Ø12 | Ø14 | Ø16 | Ø18 | |

| Outer diameter dн, mm | 4.0 | 5.0 | 5.5 | 6.0 | 7.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 |

| Inner diameter dн, mm | 3.0 | 4.0 | 4.5 | 5.0 | 6.0 | 7.0 | 9.0 | 11.0 | 13.0 | 14.0 | 17.0 |

| Winding pitch t, mm | 15.0 | ||||||||||

| Weight 1 lm, kg | 0.02 | 0.025 | 0.03 | 0.05 | 0.06 | 0.07 | 0.12 | 0.20 | 0.26 | 0.35 | 0.42 |

If you are still in doubt about which reinforcement to choose - metal or fiberglass, we have prepared the following table for you:

Areas of use of composite reinforcement

Taking into account the largely unique operational characteristics, composite reinforcement can be used in a wide range of construction of various building structures. As well as in the repair of buildings and infrastructure.

The following are the most frequently requested areas where the use of composite reinforcement has proven to be most effective:

- If there is no need for prestressing reinforcement and the structure is not multi-story, then it is advisable to use composite reinforcement in the installation of structures of buildings of various types - civil, industrial or residential;

- If there is a threat of electrochemical corrosion created by the influence of stray current, it is reasonable to make certain parts of structures from composite fiberglass reinforcement;

- It is possible to use this type of reinforcement to strengthen the soil during tunneling during mining;

- During the process of repairing a reinforced concrete structure, in a situation where it is impossible to apply a significant layer of mortar;

- For the purpose of installing transverse connecting connections in buildings where the walls are built from various types of building materials. These are most often combinations of gas silicate block and brick, as well as brick and concrete;

- If layered masonry is provided using small-sized elements with flexible connections, as an option it is possible to strengthen the banks of the reservoir with such a reinforcing mesh filled with pebbles or crushed stone;

- In buildings that are particularly strongly affected by an aggressive environment - building foundations, structural parts of chemical and food production buildings and agricultural facilities;

- When strengthening the base for building structures of various types;

- Private low-rise housing construction;

- During road construction, the road surface is reinforced;

- During the construction and strengthening of slopes and embankments;

- To strengthen different parts of the road, such as asphalt concrete and rails;

- Reinforcement of bridges and other spans, such as viaducts;

Vulnerabilities of composite reinforcement

Absolutely every building material, along with proven advantages, also has so-called “weaknesses”.

Composite fiberglass reinforcement also has some disadvantages. They must be taken into account at the design stage of reinforced concrete structures:

- The elastic modulus of this material is low - for example, compared to steel, it is almost 4 times inferior. This negatively affects the performance of fiberglass reinforcement during tension;

- The material is brittle and non-plastic, so changing the shape of the rod rod is problematic without heating. This determines the inconvenience in the process of manufacturing embedded parts and hinges for installation;

- Weakly resistant to high temperatures - strength characteristics are lost even when heated to about 200 degrees;

In general, if we correctly approach the use of composite fiberglass reinforcement, we have a fairly cheap, easy-to-use and reliable material for use in construction.