Question and answer December 14, 2020

In many apartments in the kitchen, rubber hoses are connected from the gas pipe to the stove. Tell me, how long are they designed for? When should they be changed?

PHOTO pixabay

Rubber hoses must be changed immediately after reading these lines. According to the current rules, there should not be any rubber hoses for supplying gas in the kitchen.

Related article:

Residents of St. Petersburg are promised a minimal increase in housing and communal services tariffs in 2022

Of course, they still exist. And more. Preserved since ancient times. Their shelf life at any time is 2-3 years. But it’s worth repeating: according to the new GOSTs, they can no longer be used. So you should contact your gas service as soon as possible and replace them. So far there are no penalties for having rubber pipes. However, it is possible that punishment will be introduced in the future. Too often, citizens forget about safety rules when operating gas equipment.

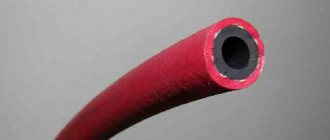

Reinforced hoses have recently replaced rubber hoses. Simply put, it is a rubber hose braided with durable textile threads. Its service life is up to five years. Experts say that it heats up from the inside and gradually cracks.

Further in terms of modernity and advancedness are bellows hoses, reinforced with various metal materials, stainless steel, and polymers. Each type has its own service life. It will certainly appear on the documents that are attached to the hose in the store. From 10 to 30 years. However, in Russian conditions, such a long period does not make much sense, since most gas stoves in service with Russian housewives have a service life of 20 years.

Requirements for all types of gas hoses: they should not be more than one and a half meters long, no narrowing or twisting. During installation, any hose should not touch sharp corners of furniture or kitchen equipment. And, of course, it should not have any cracks or damage, even “cosmetic”.

Experts advise hanging a tag on the hose at the time of installation with the installation date and service life. This is more reliable for memory.

And some more advice from PetersburgGaz employees. Perhaps citizens will take it lightly, but... It is recommended to turn off the gas valve in the apartment not only when the family leaves for a long time, but also immediately after finishing cooking. They say this increases the life of the eyeliner.

#housing and communal services #kitchen #gas

The material was published in the newspaper “St. Petersburg Vedomosti” No. 228 (6826) dated December 14, 2020 under the heading “The hose is not a joke.”

Share on VKontakte Facebook

Cool

Connection instructions and features

Regardless of the type of connection, the connection is carried out according to certain requirements:

- The length of the sleeve corresponds to the distance at which the household appliance will be located from the gas source. The riser has branches that end in taps. The product must not be equipped with additional couplings or connections.

- Before connecting the hose, preparatory work is carried out. The gas supply is cut off at the central riser in the apartment. The household appliance must stand level so that there are no distortions in the hose connection.

- A seal is applied to the hose fitting and it is screwed on when the pipe is released. If the threads on the device and the diameter of the tube do not match, an adapter will be required. A seal is also used for it to prevent gas leakage.

- Checking the tightness of the connection. To do this, apply a soap solution to the joint. If bubbles are not blown in, there is no problem.

Eyeliner cannot be hidden behind furniture, so you should choose a product that will fit into the interior of the house. There should be no branches or extraneous connections from the gas tap. If necessary, an additional tap is removed from the pipe.

Features of choice

The flexible hose should not be more than 3 m according to safety regulations.

To select the correct device, the type of equipment to be connected, its distance from the central pipe, material of manufacture, and recommendations of professionals are taken into account. There should be no intermediate connections along the entire length from the device to the gas source, so the length of the hose is initially calculated.

When choosing, the diameter of the section is taken into account. For good gas permeability, the indicator is 1 cm. For a reliable connection, it is better to choose products with nuts and a fitting.

For home installation

For effective operation of home equipment, a product 1-2 m long is required. In this case, the risk of tube rupture is reduced. If the length is insufficient, it is increased using a metal insert. It is better not to use a rubber hose, but if it is installed, you need to carefully monitor the degree of wear. If cracks appear on the product, it must be replaced immediately. It is best to install a bellows product.

There is no need to buy products in which the fitting and corrugation are fixed together with glue. Optimally one-piece product. When choosing a hose, you need to take into account that there are a large number of fakes on the market.

What do gas services recommend?

The product must be marked that it is intended for gas.

The product should be selected at specialized points of sale, where the seller can provide a quality certificate. Experts recommend purchasing a hose with extra length, since it should not be stretched. The following tips will help you make a choice:

- You should not purchase cheap Chinese-made products, since the wall thickness is small and they are subject to rapid wear;

- there should be a yellow mark on the sleeve, which indicates the purpose of the material (plumbing options cannot be used);

- when choosing, the eyeliner is inspected for cracks or other damage;

- the fittings and nuts must match the diameter of the outlet on the household appliance.

The length of the hose should be such that it does not sag or stretch.

Installation

Connecting gas stoves using a flexible hose is carried out according to a standard scheme, which consists of the following steps: a main pipe - a riser - passes through each apartment of a gasified house. A pipe extends from the riser, called a pipe by experts, at the end of which a gas tap is installed. A gas meter is installed between the tap and the outlet, taking into account fuel consumption. The tap section size is usually 1/2, which corresponds to a diameter of 15 mm. One end of the flexible hose is screwed to the tap, making sure to treat the threaded connection with sealant.

The hose must be screwed directly to the tap; there should be no additional connections or unnecessary bends. The use of adapters is allowed only in cases of extreme necessity, when it is not possible to purchase a hose compatible with the outlets of the faucet and stove. In this case, all connections must also be well coated with sealant and, upon completion of installation, checked using soap foam.

If no soap bubbles appeared on the surface when the gas was turned on, then the installation was carried out correctly and the device can be safely used. In addition, when connecting a flexible hose, it is necessary to install paronite gaskets equipped with a metal mesh and included in the hose kit. The mesh will act as a kind of filter and protect the system from possible contamination.

After the hose is connected to the gas tap, it should be screwed to the stove. To do this, there is an inlet pipe on the rear wall of the device, which can be located either perpendicular to the rear wall of the furnace or at a slight angle relative to it. The angular location of the nozzle is more preferable, since it does not allow the hose to bend sharply and allows you to install the slab almost flush to the wall.

Quite often the inlet pipe has a 3/4 thread. In this case, it is necessary to use a fitting - a special adapter with a diameter of 1/2. The hose is connected to the furnace outlet or adapter using a union nut, which is tightened with an open-end wrench. Upon completion of installation, the connection is coated with a sealant, and after it dries, with a soap solution. Then open the gas tap and test the connection for leaks.

The above installation algorithm is purely advisory in nature, since all work on connecting the stove using a gas hose should only be carried out by a gas specialist

If for some reason you have to do the installation yourself, then you should familiarize yourself with some rules that will help you correctly connect the flexible hose, while observing all safety precautions

- It will not be possible to hide the sleeve in the floor or wall of the kitchen: it must be located in a well-accessible place and be in a free state.

- The hose must not be kinked or bent too much. The maximum permissible bending radius of the hose must be greater than the sum of its three diameters.

- Do not paint the gas hose. The paint causes the rubber to dry out excessively and can cause it to quickly crack.

- Hose connection elements and adapters are often made of different metals, which threatens electrolytic processes and damage to metal parts. To prevent such troubles, only compatible metals can be screwed: copper with brass and steel with steel.

- Over-tightening the nuts may cause them to break and require replacement of the entire hose.

- Installation of flexible hoses longer than 4.5 meters is prohibited. If the gas stove is significantly removed from the main tap, the outlet is increased using steel pipes. Any welding work to extend the “vacation” should be carried out after the house is completely disconnected from the gas supply and only by gas service specialists.

- After connecting the flexible hose, a note is made in the gas subscription book with the exact date of installation. This information will help you not miss deadlines and change your sleeve on time.

Safety regulations

It is recommended to change rubber hoses every 2 years.

The use of bellows gas hoses or other types of products requires compliance with safety rules:

- The sleeve must be changed regularly if it has mechanical damage or has expired. Products with a service life of less than 10 years should not be used. Rubber options are changed every 2 years.

- It is prohibited to carry out welding or soldering work near gas appliances, as well as their connecting elements. It is necessary to protect them from exposure to condensation or its accumulation.

- Leak testing is carried out monthly. To do this, connections and cracks in the hose are treated with soapy water. If there is a leak, bubbles will inflate in these places.

- Metal hoses are insulated. They should not come into contact with wires or household appliances.

- The connecting tube is located in a visible place so that it can be inspected every time.

- The hose must not be painted. In this case, the material cracks faster.

- If the gas pipes are steel, you should not use hoses with copper tips.

- The product must have a coating that will protect it from high temperatures and corrosive processes.

- The hose must meet the characteristics of the gas mixture.

Sleeves must not be twisted or bent.

Gas hose life

The guaranteed service life of the gas hose is indicated in the instructions for use. After its expiration, the product is replaced. Depending on the material of manufacture and technical properties of the tubes, the following operational period is regulated:

- bellows hoses: 15-30 years, changes along with gas equipment;

- rubber-fabric: 2-3 years, if there is the slightest defect, the product requires replacement;

- reinforced: up to 10 years, they use high-strength materials;

- oxygen: up to 5 years, more often used to connect liquefied gas cylinders;

- rubber with metal braid: up to 10 years.

The service life is influenced by various factors: correct installation, correctly selected hose characteristics, product quality.

There are several main types of hoses with which a household appliance is connected to the central pipe, but the bellows version is preferred. With proper installation and operation, the product will last as long as stated in the instructions.

Advantages and disadvantages of gas hoses

The pros and cons of gas hoses depend on their type. Features of different types of products:

- Rubber-fabric. Flexible, easy to install, cheap, available in different sizes. The disadvantage is the impossibility of a rigid connection to a household appliance, short service life, and rapid cracking of the material.

- Rubber reinforced. The product is easy to install, has good flexibility and strength, and a low price. However, it conducts electricity and the inner polymer layer is subject to rapid destruction.

- Bellows. The hose is recommended by gas services, as it fully meets the technical requirements and GOST standards. It is reliably protected from the influence of negative factors, as it is covered with a PVC component layer. The product withstands mechanical stress well. There are no restrictions during operation. The only drawback is the cost.

Oxygen hoses have the advantages of the previous options, but are intended for temporary use.

How to choose?

Before you start buying a hose for a gas stove, you need to pay attention to a number of points and listen to some recommendations. Gas hoses should be purchased in specialized stores that specialize in the sale of gas equipment

Such establishments, as a rule, work with trusted suppliers and sell only certified products. In addition, sales consultants have sufficient knowledge and are well versed in the intricacies of connection. Often in special stores you can submit an application for connecting a gas stove, which will be carried out by trained people

Gas hoses should be purchased in specialized stores that specialize in the sale of gas equipment. Such establishments, as a rule, work with trusted suppliers and sell only certified products. In addition, sales consultants have sufficient knowledge and are well versed in the intricacies of connection. Often in special stores you can submit an application to connect a gas stove, which will be carried out by people trained in this.

In general, the requirements for the materials from which gas hoses are made are much higher than the requirements for the production of the same water hoses. This is because gas hoses need to withstand the very low temperatures encountered when transporting liquefied bottled gas. In addition, gas models should not burn themselves and support combustion, and also have a left-hand thread.

However, the most important requirement for gas hoses is the presence of an insulating insert, which was already mentioned above. The fact is that to increase the anti-corrosion resistance of steel gas pipes located in the ground, they are given a positive potential. And there is no guarantee that one of the residents of the apartment building did not use the gas riser as grounding for their household appliance.

This situation can lead to a short circuit, heating the metal braid of the hose and creating an explosive situation. In addition to the possibility of a spark occurring in the gas pipeline and detonation of the gas-air mixture with dire consequences, a person standing at the stove can receive an electric shock, and with a significant potential of stray charges, even serious electrical injury. To prevent such situations, the set of rules SP 42-101-2003 regulating the equipment of gas distribution networks included clause 6.4 on the mandatory equipping of internal gas pipelines with dielectric inserts, which must be installed even on polyethylene hoses.

Today there are two types of stray current cutoffs. The first is represented by dielectric couplings (MD), made in the form of an insulating fitting, equipped with threads on both sides. Couplings are mounted between the main valve and a flexible hose, and are the most common type of insulator. Dielectric couplings are available in four thread sizes: 1⁄2, 3⁄4, 1 and 1 1⁄4. This variety of diameters makes dielectrics compatible with any type of pipeline fittings used in intra-house networks. Moreover, couplings are available with thread/thread, nut/nut, and thread/nut ends, which makes selecting the right fitting much easier and allows you to adapt to any type of connection.