Exhaust gases from passenger cars are discharged into the atmosphere behind the rear bumper. This is due to the need to minimize the likelihood of them being sucked into the cabin. But in most cases the engine is located at the front, so the pipe with mufflers is too long to remain rigid. To give flexibility, hinged or braided connecting inserts are built into it.

Important nuances

As we have seen, welding the muffler and corrugation for repair is not at all necessary.

But there are some nuances in the above types of repairs. The corrugation must be installed evenly, without distortions. At the end of the work, make sure that all brackets and hangers for attaching the muffler are intact and ensure its stability and immobility.

All three options for replacing corrugations will take no more than an hour. The part must be repaired at the first sign of a malfunction. Do not forget that timely replacement of the part is necessary for the further safe operation of the car.

What to pay attention to

What should you consider before installing a new corrugation? Try to understand the reason for the breakdown of the old corrugation.

When an old part failed due to the fact that a large load was placed on it, but it could not stand it. Then this malfunction should be eliminated in the car. Otherwise, the same fate will befall the new corrugation.

For example, when the engine mount is worn out, when the rubber fasteners of the muffler are stretched. The load on the corrugation is increased, and it may well break and burn out due to the fact that it operates in a mode not intended for its functionality.

Possible repair of a faulty element

Replacing the timing chain on a Chevrolet Niva with your own hands: instructions with video

Due to the tightness of the product itself, repairs in case of severe breaks and burnouts are not possible.

However, in some situations you can save on buying a new part of the system and repair the device yourself.

Temporary measures

The key to successful operation of the exhaust system is its complete tightness.

The same applies to corrugation. In order to quickly eliminate the deformation that has begun, you can use special sealants for mufflers.

These substances perfectly close all holes or cracks, ensuring tightness even at the highest temperatures.

Bandaging

Temporary repairs also include the use of bandages.

A special bandage tape made of thin foil is applied to the pipe.

The tape covers cracks and holes, allowing you to ride this muffler for some time:

Heat-resistant material allows you to extend the service life of the corrugation for some time

How to weld using electric welding

Self-repair using a welding machine is possible if you have experience in welding.

If the car owner is not confident in his abilities or has only basic skills, then it is better not to take risks, as it is easy to damage the muffler pipes.

Sometimes, after hitting an uneven road, the corrugation may “move away” from the pipe - in this case, it is necessary to weld it again.

For these purposes, two types of electrodes are usually used - with a diameter of 3 and 4 mm:

- The corrugation is grabbed along the diameter of the pipe with a 3 mm electrode.

- The correctness of its fixation is checked (the product must be located strictly in the center of the pipe).

- Next, the entire circumference of the pipe diameter is welded with 4 mm electrodes.

- After the weld has cooled, it is necessary to clean it and paint it with heat-resistant paint.

The seam when welding corrugation must be smooth and uniform

When to repair flanges

Do-it-yourself tire studding: instructions with photos and videos

Repairing a muffler flange connection is a popular task for service center specialists. They often encounter it during the restoration of the exhaust system, when they have to remove the muffler. Then it is discovered that the flange has failed for the same reasons as the muffler itself:

- regular temperature changes and, as a result, burnout of the part;

- contact with chemically aggressive exhaust gases;

- changes in humidity that lead to corrosion;

- exposure to dust, dirt, grease, etc.

In some cases, it is enough to perform a “cosmetic” repair of the muffler. But you must understand that this is a temporary measure that will not solve, but only delay the problem. If the flanges are strong enough, you can replace the gasket, fasteners and use a special mounting paste. It is used to seal small damaged areas and make the connection airtight.

Reasons for failure

In addition to the fact that the corrugation takes on powerful mechanical loads, exhaust gases with a temperature of 300-900°C are passed through it. The aggressive chemical environment at this temperature burns through the braids over time. The car will inform you about this with a loud rumble. The burnt part will have to be replaced.

Corrugations, especially not original ones, quickly and inevitably rust until a gap forms in the wicker wall. The lower the vehicle's ground clearance, the greater the likelihood that the corrugation will be damaged mechanically when hitting an edge, stone, etc.

Causes of muffler corrugation malfunction

Easy adjustment of the handbrake with your own hands: video instructions

This element serves to compensate for the vibration load on the exhaust system, so the corrugation may fail due to harsh operating conditions.

Irregularities in the road or large objects on the roadway can lead to physical destruction of the element. Premature failure of this part can also be caused by improperly installed muffler, worn engine mounts and a faulty transmission.

If the wavy fold of the muffler is damaged, then in addition to increased noise, there may be a smell of exhaust gases in the cabin. In this case, you can get severe poisoning, so at the first sign of a malfunction of this part, you must begin repairs.

An easy way to repair

Do-it-yourself muffler corrugation repair without welding can be done as follows:

- An ordinary medical bandage is impregnated with epoxy resin.

- The dampened bandage is wrapped around the vibration compensator of the muffler.

- After the resin has hardened, the car can be operated as usual.

This method is the simplest, but the problem of muffler malfunction can be solved using epoxy resin for no more than 1 - 2 months. Over time, the repaired area will burn out and will need to be restored again.

Repair with high temperature sealant

A special muffler repair sealant can also be used to repair a broken corrugated pipe in a car's exhaust system.

Repairs are carried out in the following order:

- The sealant is applied to the outer surface of the element.

- The part is wrapped several times with thin sheet metal, the width of which should be equal to the length of the corrugation.

- The tin is fixed using ordinary screw clamps at the edges and in the middle.

- After 24 hours, when the sealant has hardened, the car can be used as usual.

This method is also temporary and is designed to operate the car for no more than 1 month.

Reliable replacement method (no welding)

The listed temporary methods for eliminating the malfunction of the wavy fold of the muffler do not allow you to forget about the problem for a long time. Therefore, they can be used in extreme cases when it is not possible to carry out a full repair of the muffler exhaust system.

The most correct and reliable way to install a new spare part is welding with the exhaust pipe. But when it is not possible to use a welding machine, you can use an equally effective method of attaching corrugations.

This part can be installed on threaded connections.

The work is performed in the following sequence:

- The old corrugation is cut off with a grinder or a hacksaw immediately behind the weld.

- Next you need to install a new vibration compensator.

- Make a number of holes with a diameter of 4.2 mm, which should be evenly distributed around the circumference. Holes must be made on both sides of the cut exhaust system.

- Using an M5 tap, threads are cut into the holes that were made in the exhaust system.

- M5 bolts are screwed into the holes, which must be installed on engraving washers to prevent unscrewing.

Cut the thread with a tap

Another effective installation method

This simple method of installing a vibration compensator without welding, if done correctly, allows you to fix the problem yourself. Installation is carried out in the following sequence:

- The old corrugation is cut off.

- The new one is sawed longitudinally at the points of connection to the exhaust system and installed on the exhaust pipe.

- Using clamps, the wavy fold is crimped in the places where the cuts were made.

Epoxy resin

This is also a temporary measure that allows you to restore the functionality of the vibration compensator within an hour. They use it when there is no time to visit a service station. Repairs are performed using a regular medical bandage, preferably an elastic one. It is impregnated with epoxy resin and tightly wound around the corrugation. After waiting for it to harden, use the car as usual. Epoxy resin will last no more than a month. As an alternative, you can use fiberglass or special heat-resistant tape.

Do-it-yourself replacement of car muffler corrugations without welding

Corrugation (bellows, vibration compensator, vibration damper) is installed on almost all modern cars. Its main function is to prevent vibration of the car exhaust system. The part also helps prevent the car from overheating. It connects the intake manifold to the muffler pipes. It looks like a tube made of multilayer metal mesh. Replacing the muffler corrugation with your own hands without welding is possible in all cases where the brand of the car being repaired allows it.

The part takes on the main vibration loads and therefore often becomes unusable. But the use of this spare part in the design of the car exhaust system helps other parts to operate longer. Also, replacing a muffler corrugation is much cheaper than repairing an entire section of the car. Many people are interested in how to replace it themselves, without using welding. After all, this part quite often burns out, and there may not be a welding machine in the garage.

Causes of damage

The corrugation can break through from external mechanical influence. The cause of the malfunction may be impacts on hard objects protruding relative to the roadway - stones, bumps, etc. It also becomes less durable due to natural wear and tear.

Chemical reagents used to clear roads of snow in winter have a destructive effect on metal parts. A clogged catalyst can also damage the spare part. The integrity of the part may be compromised by the presence of additives that increase the octane number in the fuel consumed by the vehicle.

Signs of damage

The most important sign of damage to the corrugation is atypical sounds when turning on the ignition and driving.

- car “sneezing”, popping noises;

- engine power decreases;

- the rhythm of the engine becomes unstable;

- exhaust gases penetrate into the car interior;

- soot appears on metal parts.

The first two methods imply high-quality repairs with further long-term operation of the part. The third is a temporary replacement in order to get to the nearest service station. We will see that welding mufflers and corrugations, although desirable, is not at all necessary.

The first method is corrugation on clamps

Suitable parts for 48 mm Lada cars.

To replace you need to do the following:

- Jack up the car from the rear right;

- Remove the engine crankcase protection;

- Remove the exhaust manifold;

- Saw off the old part with a grinder;

- On the new corrugation, make short longitudinal cuts along the pipes welded to it, this will ensure a tight fit of the part to the exhaust pipe;

- We seal the corrugation and crimp its edges with clamps;

- We install the part in its original place.

After such repairs, the corrugation will not need repairs for a year or a year and a half.

Threaded connection

For repairs, you will need high-temperature sealant and eight M5 threaded bolts.

The old spare part is still cut off with a grinder. In order to install a new part, you must do the following:

- On the rings and exhaust pipe, drill eight holes with a diameter of 4-6 mm around the circumference at the points of contact;

- Using an M5 tap, cut threads in the drilled holes;

- Treat all structural parts with sealant;

- Screw the bolts into the holes;

- Install corrugation.

Temporary replacement of muffler corrugation

Before starting work, the bandage must be treated with epoxy. The resulting material must be wrapped around the damaged part. Such repairs will last no more than a month.

Some craftsmen decide to seal the area of corrugation deformation with high-temperature sealant. But such repairs will be enough for a maximum of two days of car operation.

Important nuances

As we have seen, welding the muffler and corrugation for repair is not at all necessary. But there are some nuances in the above types of repairs.

The corrugation must be installed evenly, without distortions. At the end of the work, make sure that all brackets and hangers for attaching the muffler are intact and ensure its stability and immobility.

All three options for replacing corrugations will take no more than an hour. The part must be repaired at the first sign of a malfunction. Do not forget that timely replacement of the part is necessary for the further safe operation of the car.

What reasons?

There are few reasons why it is necessary to replace the muffler corrugation without welding: natural wear of the material, the passage of gases or mechanical damage. The following reasons can lead to such conditions:

- catalyst damage. If it becomes clogged, thermoregulation disturbances will occur, and during overheating, increased pressure is created in the corrugation;

- significant wear of the shock absorber pads on the power unit. The fasteners of the muffler itself are not able to provide sufficient movement of the unit;

- deformations due to impacts on the surface;

- incorrect installation of the device;

- the destructive effects of chemicals that are sprinkled on roads in winter;

- use of additives to increase the octane number in gasoline.

Replacing the muffler corrugation with your own hands will be required after preliminary diagnosis of the condition of the unit. Initially, failure is determined by the presence of noise during movement. If the element is completely destroyed, there is a risk of a strong deafening sound. Indirect evidence that the corrugated connection needs to be replaced is the presence of a characteristic odor from gases inside the cabin.

If you have enough driving experience, you can determine the malfunction by a significant decrease in the car’s power. The greatest reduction is observed in modern vehicles. The reason for the drop in performance is a malfunction of the oxygen sensor, which is included in the exhaust system.

In each case, you will need to replace the muffler corrugation with your own hands without welding or with it, this will help prevent further damage.

Do-it-yourself muffler corrugation replacement

Choosing the right corrugation

The muffler corrugation is often replaced and sold at a service station, but you can buy the component at a car dealership. If the owner has the time or desire to carry out repairs on his own, he should initially purchase corrugation. The part is not unified; it is developed individually for most cars. The differences are the dimensions. Before going for the unit, you will need to clarify the size of the element; it is better to find out experimentally - from the pit. Before replacement, it is worth restoring the corrugation and doing the work within the next few days.

When taking measurements, it should be taken into account that you will have to cut the corrugation somewhat further than the weld on which it is fixed. New elements are sold with a slightly reduced diameter for stronger fixation and easier scalding. The corrugation is inserted 3 cm into the pipe, this facilitates repeated replacement of the element on the car without structural changes.

Why do you need a muffler corrugation?

This element can be called a kind of fuse that protects the exhaust system from vibration that occurs during engine operation. It takes on the main load and is often the one that fails, thereby saving all other parts, and replacing the corrugation is much cheaper than a complete repair of the entire exhaust system.

In addition, the elastic element in the form of a corrugation allows the power unit to move freely in the longitudinal plane

As a result, the load is also removed from other body parts, which is important

Video - replacing the Chevrolet Aveo muffler corrugation:

In some cases, corrugation is installed during vehicle tuning and allows it to stand out from the background of surrounding cars. From an aesthetic point of view, it does not add beauty to the car, but it protects it from overheating.

A characteristic feature of corrugation is its tightness, as well as the ability to bend, compress and stretch to a certain limit. It can be produced in two versions.

Double braided corrugation is suitable for power units running on gasoline. At the same time, the braiding from the inside provides protection for the inner surface from mechanical damage. The braid on the outside is stronger and serves to protect against strong compression or vibration, which usually leads to failure of the element.

Triple braided corrugation has higher strength and rigidity due to the intermediate layer, which is a flexible tube. This part is suitable for vehicles with both gasoline and diesel engines. It is also relevant for cars that have already traveled more than 100 thousand kilometers.

In this case, three-layer parts are divided into two more types:

- Interlock – the inner layer is made of stainless steel plates.

- Innerbraid - the inner layer is made in the form of a braid made of the same steel.

Based on this, the first type of Innerbraid corrugation has a lower cost and therefore has a short service life. Elements of the Interlock type last noticeably longer, but their price is higher.

Replacing the muffler corrugation

Some time ago, only owners of foreign cars could purchase and use corrugation. Now everything has changed and this element can be installed on almost any domestic vehicle of the VAZ series.

Typically, the muffler corrugation is installed in a car service center using professional welding equipment and tools. Installation is complicated because it is necessary to select a certain temperature regime.

Traditionally, work is carried out in several stages:

- cutting down old corrugation using a grinder;

- welding a new part;

- seam processing.

It is recommended to entrust such an operation to specialists with relevant experience. Otherwise, improper installation may adversely affect the service life of the corrugation.

With your own hands

If there is any malfunction, it is not always possible to contact a car service center or there is a desire to carry out repairs only on your own.

In general, the work of replacing a muffler corrugation is not as difficult as it might seem. Only for ordinary car owners it can take several hours, but professionals will spend much less time on it.

Preparation

To make the process easier, it is best to remove the exhaust system pipe along with the corrugation. Using a grinder, cut off the faulty part as close to the welds as possible. To try on a new element, the exhaust pipe is put in place, but not secured, and a corrugation is tried on it. This must be done to avoid the occurrence of distortions in the future, which will lead to unwanted additional load on the part and its rapid failure.

Video - replacing the muffler corrugation with your own hands:

Having outlined the optimal location, it is worth welding two or three points in order to slightly grab the part to the inlet pipes, and then carefully remove the entire pipe.

Welding

Ideally, have a semi-automatic device, with which you can completely forget about the existence of car services. But in its absence, inverter equipment with electrodes with a diameter of 1.6 to 2 mm will do.

Before work, the pipe must be thoroughly cleaned. The welding itself should be carried out with a minimum current value depending on the selected electrode, simultaneously chipping away the slag. At the end of the work, the welds must be treated with some kind of automotive coating (enamel or primer) or sealant.

Since the use of conventional welding equipment is not provided for in this operation, a little training on a thin sheet of metal will not hurt. A regular tin can works well. In this case, the tightness of the seam is very easy to check. If the result is positive, you can move directly to your main job. Otherwise, you still need to learn. It is worth noting that working with an inverter welding machine is difficult, but possible with a certain skill.

Finally, all that remains is to put the exhaust pipe in its place, at the same time replacing the gaskets of the connecting flanges.

No welding

The exact service life of the corrugation cannot be determined, since the operating conditions of the vehicle are taken into account. If you drive carelessly, the corrugation can quickly fail even with high-quality installation. Therefore, welding is not always the best option and in some cases you can do without it. Craftsmen have found one good and effective way.

Threaded connection

After removing the old corrugation by cutting it with a grinder, the new part is put on the prepared place. Several holes with a diameter of no more than 6 mm are made on the rings and exhaust pipe. Next, you need to immediately cut the thread using a tap. When disassembled, all parts, including bolts, must be treated with sealant.

After this, you can begin assembly. The result is a fairly reliable and tight connection. The number of bolts is selected based on the diameter of the exhaust pipe. Usually this is 6-8 pieces.

Stopgap measure

There are times when a new muffler corrugation has already been purchased, but it is not possible to find a time to stop by a car service center.

In this case, one ancient method will help, which requires a medical bandage. But if you need a delay for a full repair for a month, you should purchase an elastic bandage, which is denser and better fixed.

To facilitate access to the damaged corrugation, it is advisable to drive the car into a pit. The bandage should be thoroughly soaked in epoxy resin, and then tightly wrapped around the torn element.

The maximum you can count on is a month, no more. Otherwise, parts will literally begin to crumble, and repairs will cost significantly more.

Therefore, a full replacement of the muffler corrugation in such a situation should be planned for the very near future.

Removal process

In the process of removing an element of the exhaust system from a VAZ 2107 (injector) for its subsequent replacement. The following tools will be useful to you:

- wrench 13 (open-end type);

- ratchet or crank;

- deep heads on 13 and 10;

- Bulgarian;

- flat screwdriver (can be replaced with a chisel);

- pliers;

- hammer.

To figure out how to remove the muffler from your VAZ correctly and replace it. Please read the following instructions carefully:

- install the car over an inspection hole or on an overpass;

- unscrew (cut with a grinder) the crimp coupling;

- using a screwdriver or thin chisel, bend the flared ends of the pipe;

- using a hammer, which you will use to knock on the pipe, separate the muffler from the resonator;

- Unfasten the hanging pillows.

After this, the product can be freely removed to be replaced with a new one, which is installed in the reverse order.

For this reason, moisten corroded parts with an anti-corrosive agent in advance (motor oil or brake fluid will also work). If you are planning to install a new muffler, it would be a good idea to purchase new suspension rubber bands (1 for the rear and 2 for the center location).

The muffler is stretched along the entire length of the car body and is removed from under the rear to get rid of exhaust gases. The main task of any muffler is to reduce noise levels and convert sound waves into heat waves. That is, without an exhaust system, a car cannot operate in principle. With mufflers for VAZ 2108/2109 cars, the situation is quite complicated: we can say that the pipe for exhaust gases is the most “sore” point of these models. Therefore, the owner must prepare in advance for the fact that sooner or later he will have to deal with malfunctions of the silencer and independently replace this part of the car.

What is a muffler corrugation

The corrugation (or a special connection in the exhaust system) plays an important role in the removal of exhaust gases from the car.

Today, almost all models of foreign cars are equipped with corrugations on muffler pipes.

They have the shape of a barrel and are designed to act as an elastic connection between pipes to reduce vibrations and noise.

The element loses its metallic luster over time, but continues to protect the exhaust system from excessive vibrations

This element in the exhaust system serves for:

- more reliable connection of two pipes to each other;

- reduction of vibration currents that come from a running engine;

- damping vibrations when starting the engine.

That is, roughly speaking, if there is corrugation, all parts of the exhaust system will work for a long time, since they will not be subject to strong vibrations.

What does corrugation consist of?

Depending on the make and model of the car, the elastic connector can be made according to different patterns.

Traditionally, this is a barrel-shaped element that has two or three internal layers, and is also equipped with a double (less often single) braid.

This model has two internal protective layers and one layer of braid

If you look at the structure of this part in section, it will look like a tube that has both internal and external protection made of stainless steel.

The protective layer allows you to minimize vibration currents from the exhaust manifold, due to which the muffler pipes are less susceptible to destruction.

However, the corrugation itself, due to the fact that it takes the “blow”, is destroyed quite quickly.

Design and purpose of corrugation

Corrugation (from the French gaufrer - folds, patterns) or vibration compensator is a flexible element that acts as a flexible connection in the exhaust system. Outwardly, it looks like an elastic tube with metal weaving in the form of a multilayer mesh and is an intermediate link between the exhaust pipe and the exhaust pipe of the muffler. Corrugation is often used as a substitute for a section of a burnt-out exhaust pipe.

Due to its design, the corrugation not only compensates for the vibration that accompanies engine operation, but also dampens vibrations that occur when the car starts.

Corrugation is an elastic tube with metal weaving in the form of a multilayer mesh

The corrugation design can be very diverse. It can consist of two or three layers, and also have a single or double reinforced braid. In any case, the corrugation is made of durable stainless steel.

Despite its strength, the corrugation is quite sensitive to mechanical damage and is subject to wear.

Replacing corrugations

Replacing the corrugation yourself is quite simple. To do this, it is enough to have a garage with an inspection hole or a lift and a standard set of tools.

Choosing a corrugation

The choice of corrugation should be taken responsibly. It is advisable to buy it from trusted sellers.

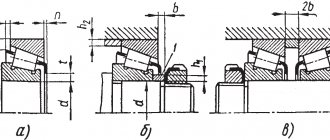

Depending on the type of exhaust system, corrugations are distinguished:

- vertical;

- horizontal.

A vertical corrugation is installed under the exhaust manifold and works for compression. When the engine is running, it does not bend, but contracts and straightens vertically. Such corrugations have a length of about 150 mm and a diameter of 65 mm. When purchasing, a corrugation with the appropriate dimensions is selected.

The vertical corrugation is made of durable and elastic alloys, which allows it to stretch in length

The horizontal corrugation is located below the first elbow of the receiving pipe and bends. It reaches 400 mm in length and 65 mm in width.

When choosing such a corrugation, you should take into account the way it is connected to the exhaust pipe.

Horizontal corrugations are installed on most cars

When replacing, it is recommended to first cut out the faulty corrugation and measure the distance between the two pipes. Only after this can you select a new corrugation.

Any corrugation is installed on the pipe with an overlap of 10–20 mm. Therefore, the new corrugation should almost always be longer than the old one, at least 20–30 mm. In addition, the geometry of the exhaust pipe is taken into account - the new corrugation may not fit into the space between the pipes or noticeably change the angle of inclination of the pipe. The latter can lead to incorrect operation of the exhaust system.

The corrugation should not have bends, and the weld should be more dense

Replacing corrugations using electric welding

Before installing a new corrugation, you need to properly disconnect the old one. To work you will need the following parts:

- a new gasket installed between the manifold and the exhaust pipe;

- muffler mounting rubber bands;

- bracket for fastening the exhaust pipe (if such a mount is available);

- O-rings.

Dismantling the corrugation is carried out in the following order:

- The bolts securing the exhaust pipe and manifold are unscrewed.

- The rubber bands securing the muffler are removed.

- The other exhaust pipe fasteners are disconnected.

- The corrugation is cut off using a grinder.

- The remains of the old weld are removed.

After this, they “try on” the new corrugation. This is an important procedure, since bends and kinks should not be allowed.

After installing the new corrugation, all fasteners should fall into place, and the corrugation itself should not change its geometry

- The two parts of the pipe are connected by corrugation (overlapping the pipe), and the entire system is installed in place.

- The connection points of the corrugations are secured by electric welding. For high-quality welding, 2–3 mm electrodes are used. The best results are shown by argon-arc welding with a non-consumable tungsten electrode with a stainless wire additive. When installing an exhaust pipe, the corrugation must be “grabbed” by welding in several places

- The corrugation is fixed in the desired position by a welding machine at two or three points around the circumference of the pipe.

- After this, the entire pipe is again removed from the fastenings and carefully welded on the ground with a continuous seam. To protect against stones while moving, a protection can be made and welded onto the corrugation

Video: replacing a muffler corrugation using welding

https://youtube.com/watch?v=VQm0NtkJ5yA

After welding work, the gaskets, O-rings and rubber bands for attaching the muffler are changed, and the muffler assembly is installed in place.

Replacing corrugations without welding

The corrugation can be replaced without using electric welding. For this you will need:

- grinder or hacksaw;

- clamps (48 mm is enough);

- screwdriver.

According to the above algorithm, the old corrugation is removed. When attaching the new corrugation with clamps, two small cuts are made on both sides to secure it more securely. Then the corrugation is pulled over the pipes and clamped at the edges with clamps. After this, the exhaust pipe is installed in place.

After installing a new corrugation, the clamps should be periodically tightened

According to reviews from car owners who have carried out repairs in this way, the design is reliable and lasts quite a long time.

Thus, removing the old one and installing a new corrugation with your own hands is quite simple. Even if you were unable to find a welding machine, all work can be done without welding.

Purposeful, with an active life position, competent. A developing personality and just a cheerful and sociable young man! (2 votes, average: 4.5 out of 5)

Recommendations for selection

Depending on how the exhaust system is designed, they can be vertical or horizontal. The first ones are fixed below the exhaust manifold and when the engine is running, they are compressed and straightened vertically without bending. Their length is approximately 150 mm, and their diameter is 65. When choosing, you need to pay attention to the size match.

Horizontal types are placed under the first elbow of the receiving pipe and are bent during operation. Their length reaches 40 cm and diameter up to 65 mm. If you plan to change the corrugation without using a welding machine, its length is chosen a few centimeters longer in order to attach it to the pipes with clamps or a threaded method.

There are three types of vibration dampers offered in stores:

- single-layer, made of metal hose with outer braid,

- two-layer, with an internal braid added,

- three-layer ones are made with an additional corrugated metal hose installed between the braids.

When choosing, you need to focus on the quality you would like to have. When buying corrugation in a single-layer braid, you need to be prepared for its annual replacement. The three-layer version will ensure that there are no problems with the muffler for 8-10 years, even with intensive use of the car.

When choosing, you need to focus on quality

The quality of the material is assessed according to the following characteristics:

- when choosing from parts that are identical in appearance, preference is given to the heavier one,

- the higher the quality, the brighter the steel shines,

- the pipes must have thick walls to ensure a reliable connection of the corrugations,

- On a high-quality vibration damper, the braid is made with minimal gaps.

Muffler diagram

As a rule, in the muffler, in addition to itself, there are also the following components:

- exhaust pipe;

- catalyst;

- resonator.

The gas received by the pipe exits through the intake manifold and is sent to the catalyst. This pipe is an intermediate element equipped with a corrugation that suppresses vibration of the engine, preventing it from entering the system. The load in the system itself is large, relating to both mechanical and temperature effects of thousands of degrees. That’s why cast iron and steel are used here.

The catalyst completes the combustion process of particles, and carbon monoxide is transformed into a less toxic phase. Here, the gas mixture is also purified through chemical reactions.

Front and rear mufflers

The mufflers on the vehicle are located at the very end of the system. They come in front and back. They are necessary to suppress noise, and therefore are not involved in cleaning the gas mixture. Inside they are located gratings and holes that slow down the rate of gases, simultaneously dampening vibrations. A resonant effect will not occur, because there are special materials that absorb unwanted amplitudes.

The front muffler is:

- active. With flat and simple design. They have sound-absorbing material, which tends to become clogged over time.

- reactive. With a more complex design, because they combine expansion and resonator chambers.

The rear muffler is very important, since it is it that finally removes unnecessary sound, while at the same time removing excess gas. The internal structure can be called heterogeneous, containing chambers and fillers.

Features of the structure of direct-flow mufflers

Those drivers who want to increase the power of the vehicle will like direct-flow solutions, because stock ones are not suitable for this. This type converts the exhaust gas into energy. Everything is done due to the gases escaping with a reduced level of resistance. This way the engine wastes less energy, because there is no need to overcome pressure.

Direct-flow mufflers include a perforated tube protected by a casing. The number of chambers and separators is small, and the gas flows unhindered and expands thanks to the perforated pipe structure. The outer casing is responsible for noise suppression, since it is impregnated with absorbing compounds that prevent gas resonance.

Threaded connection

This is an equally reliable way to replace a damaged part without welding. The preparation is the same as when using clamps, but fastening is done differently. Replacement is carried out in the following sequence:

- A new corrugation is installed.

- 6 - 8 through holes (depending on its diameter) with a diameter of 4.2 mm are drilled in the pipe placed on the exhaust pipe. They should be evenly spaced around the circumference.

- Threads are cut into the holes on the pipe using an M5 tap, and the pipe is drilled out to a diameter of slightly more than 5 mm.

- After lubricating the bolts and holes with sealant, one end of the corrugation is secured in place using engraving washers.

- Without securing the second end, the structure is assembled and installed on the car. The line for placing the edge of the pipe is marked to avoid skewing.

- After removal, holes are drilled and the second pipe is attached.

- After final assembly, a test drive is made.

Fastening the corrugation with bolts - the finished result

Replacing electric welding with a threaded connection allows you to do without going to a service station. The quality of the repair does not suffer, since the corrugation successfully withstands longitudinal and transverse impacts.

High temperature sealant as a temporary solution

This type of muffler corrugation repair is used if a new part is not available. The work is carried out in the following sequence:

- the corrugation is covered with a layer of sealant,

- a strip with a width equal to the length of the vibration damper is cut out of tin and wrapped in several layers over the sealant,

- then it is secured with clamps from the edges and in the center,

- After the day required for the sealant to harden, you can drive as before.

Repairing the muffler corrugation with sealant is a temporary solution.

Corrugation repaired in this way will last no more than a month. Some car owners simply cover the damaged area with sealant without wrapping it in tin. In this case, the opportunity to use the car is reduced to two days.

Replacing the exhaust system corrugation at a GSAvto service station

The main principle of our service is maximum savings of client money. Therefore, if it is possible to change the vibration compensator without removing the entire exhaust system, we reduce the standard hours. To weld the muffler corrugation directly on the car, GSAvto uses a special welding machine with reduced sparking. Depending on the installation location, different types of elastic inserts are selected. A more durable vibration compensator is placed in front of the catalysts. And replacing the intake pipe corrugation often requires installing an additional suspension point. This element is softer, and accordingly its strength is lower. Our specialists will determine which corrugation is suitable for replacing the faulty one, and will offer you to choose between economy class or an elite manufacturer. Therefore, if your car’s corrugation is cut, torn or burnt out and you need to replace it, contact the GSAvto car service at the address: Moscow, st. Kubinka, 3/10s3, (JSC, Kuntsevo and Mozhaisky districts, Molodezhnaya metro station, Kuntsevskaya metro station) and our highly qualified craftsmen will make a high-quality replacement of the muffler corrugation in the shortest possible time at affordable prices.