If you have ever used a portable burner with piezo ignition, then you have probably encountered the problem of such a device breaking down. Agree, it would be somewhat inappropriate to throw away an almost new burner due to a malfunction that you can fix yourself.

In order not to spend “extra” money on repairs, for which the technician will demand the cost of the device, you should figure out how to repair a gas burner with piezo ignition with your own hands, and not spend a penny from the family budget.

A gas burner can stop working for completely different reasons, ranging from water or dirt getting inside the mechanism, and ending with a breakdown of the piezo ignition itself. Further in the article, you will become familiar with the main causes of burner malfunction, and learn how to disassemble the mechanism yourself and repair it without the help of an experienced technician.

Features of using a manual gas burner on a cylinder, types of burners and tips for choosing

Both among people who carry out repairs professionally and among home craftsmen, a manual gas burner with a cylinder is very popular. The scope of their application is very wide, there are several varieties. This article tells you how to choose the right gas burner for a cylinder and learn how to use this device, which is not the most intricate design, but extremely useful in many cases when a room is being renovated.

Gas burners for a cartridge with a collet connection represent a separate class of tools. They are used in conditions of high fire safety where serious construction equipment is involved, and the risk of damage to the apparatus is minimized.

The main parameters are temperature and flame shape. In the simplest devices, the combustion temperature is close to the minimum - 700−1000°C. Air comes naturally and there is never enough of it. More expensive products have a special shape of air supply channels, which increases air flow and the flame temperature increases to 1200°C.

The flame has an even higher temperature in ejector burners, in which air is supplied to the hearth due to rarefaction, and the flow force is directly proportional to the operating gas pressure. Thanks to this, the temperature can be increased to 1500−1600°C and relatively smoothly adjusted with the flame length just by turning the tap. There may be several sources of combustion in the apparatus. This tool does not perform delicate work, but it successfully heats large areas.

The threshold temperature of the burners is 2000−2400°C, and it is achieved by concentrating the injected air into the combustion chamber, as well as using methyl acetylene propadiene gas (MAPP). A high-temperature cone is formed in the flame, whose power and temperature can be compared with oxy-fuel welding.

In addition, any type of product can be equipped with a flexible or rotary tube, piezo ignition and a highly sensitive control valve. There is a wide selection of devices based on power and gas consumption .

Travel lamps

Low-temperature devices are used to perform a wide range of work, suitable for both domestic use and professional construction. These blowtorches often replace electric hair dryers where only autonomous operation is possible.

The main disadvantage of burners without an injector is the low flame stability, especially noticeable during sharp tilts and turns. The splashing of liquefied gas does not have a significant effect in more expensive devices that have a special gearbox and heating circuit.

Typically, such devices are not used for soldering. They are mainly used to light firewood and coals or to heat materials that allow the use of an open flame. The lamp is indispensable for thawing pipes, heating car engines, burning paint to remove it, unpacking strips on tow, and other rough work.

The design and purpose of ejector blowtorches is more specific. These devices are used for processing non-ferrous metals. Due to their high temperature and ability to regulate the flame, these devices are excellent for soldering and hardening of metals, and other heat treatments that require high temperature accuracy and a strictly defined cone.

The specifics of the application seriously adjust the size of the nozzles and burners. Miniature devices are used for soldering thin metal and jewelry. Mid-class torches have a cone thickness of 3-9 mm; they are more suitable than others for electrical soldering of cable joints, aluminum and copper tubes.

Due to their high power, larger products can be used in the following areas:

- artistic forging;

- precision stamping and bending of metal.

It is these tools that home craftsmen use as the basis for homemade hardening furnaces and gas forges.

In the case of ejector options, the concept of flame instability is purely figurative, although there is a possibility of periodic flashes of gas, in the core the temperature remains relatively stable. The gas preheating circuit is used more to increase the efficiency of burners, speed them up to operating power, and more accurately control the temperature.

High temperature lamps

- There are devices where MAPP gas is used instead of a propane-butane mixture. The flame temperature in these devices is 2200−2400°C. The main energy is concentrated in a cone, which is quite stable and has a pronounced boundary.

- Such products are used for heating, bending and forging massive parts and high-carbon steels. High temperature allows for better tempering and hardening of metal.

- As for welding and soldering, MAPP gas devices do an excellent job with stainless steel, and even thin parts do not overheat. Another advantage of MAPP is its low boiling point, which allows it to be used at temperatures of -20°C even in products without a heating circuit.

When choosing a gas burner, do not forget about the nuances.

- The simplest, naturally aspirated torch burners are well suited for tourism. Even cheap Chinese products that you don’t really mind breaking or losing will help you light a fire or heat up food.

- For everyday use and minor repairs, amateur series tools are preferred. The design of semi-professional burners is more complex, and there are no shortcomings in it, such as, for example, melting of the plastic lining of the mouthpiece or failure of piezo ignition.

- An additional argument against average prices is the almost universal absence of a normal control valve, which can also be important in the case of rough work.

- If you plan to use the device for delicate work, soldering or welding, additional attention should be paid to balancing and ergonomics. These jobs involve frequent switching on and off of the burner; therefore, the shape of the housing and the placement of the controls should allow one-handed ignition and adjustment.

- The choice of power is dictated by the thickness and material of the parts being processed. Burners with a power of 500-700 W are quite suitable for soldering copper wires or burning paint. Steel products and tubes made of non-ferrous metals up to 3 mm thick can be heated well with a burner with a power of about 1200-1500 W. 2-3 kW burners are used for heating and bending reinforcement up to 14 mm thick.

- And about one more feature: the flame of high-quality, powerful burners can be adjusted for more delicate work, but it will not be possible to heat a massive part with a low-power burner.

Source: https://tokar.guru/stanki-i-oborudovanie/gazovoe-oborudovanie/gazovaya-gorelka-na-ballon-rekomendacii-po-vyboru.html

High temperature lamps

- There are devices where MAPP gas is used instead of a propane-butane mixture. The flame temperature in these devices is 2200−2400°C. The main energy is concentrated in a cone, which is quite stable and has a pronounced boundary.

- Such products are used for heating, bending and forging massive parts and high-carbon steels. High temperature allows for better tempering and hardening of metal.

- As for welding and soldering, MAPP gas devices do an excellent job with stainless steel, and even thin parts do not overheat. Another advantage of MAPP is its low boiling point, which allows it to be used at temperatures of -20°C even in products without a heating circuit.

A gas burner in a can is a necessary thing in the household.

December 11, 2015

A modern person must be prepared for any surprises. Whether the heating pipe or the lock is frozen, the nut cannot be unscrewed, the old paint cannot be removed from the surface, the metal seam is depressurized - a gas burner on a can will help solve these and many other problems. Using its directional torch, you can quickly eliminate any damage that occurs.

Rules for safe operation

Working with flammable materials and open flames is always associated with risk, so when using even a simple hand-held device, you must follow safety rules.

Overheating of the cylinder, which can be caused by the proximity of a heat source, for example, a fire or stove, is unacceptable. The canister may explode and cause injury due to the sharp edges of the torn casing. It is also not recommended to leave it in the sun.

Professional devices that are usually used for a long time require special care. Suppose, in order to preserve the functions of the burner and the power of the torch, after prolonged operation the device is packaged in a catalytic heating pad.

An overview of the best gas-air burners, as well as additional recommendations for choosing a suitable device, are presented in this article.

Homemade burner for a gas cylinder. DIY gas burner: options for household chores

Do you want to learn how to make a burner with your own hands at home? I offer 2 instructions at once: assembling a regular burner for laying roofing materials and making a high-temperature cutter. By making tools according to the proposed schemes, you can heat up roofing bitumen, melt tin and cut low-melting metals.

Everything you need to know about gas burners

- A gas burner

(acetylene or propane) is a tool with which you can create a flame with variable flame temperature and torch size;

- A conventional propane torch

is a nozzle with a regulator connected to a gas supply under pressure; - An acetylene torch

is a cutter that uses an oxygen gas mixture.

Using pressurized gas as fuel will not produce a high temperature. But if you mix propane with oxygen, the flame temperature increases significantly.

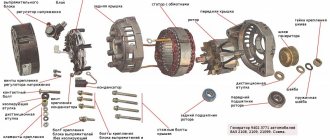

The figure shows two types of burners:

- Injection

- oxygen, due to higher pressure, sucks in gas and directs it to the mixer; - Non-injector

- oxygen and gas are supplied separately, but with the same pressure.

Injectorless cutters are structurally simpler than injection torches. But injection cutters, due to the high pressure of the fuel mixture, are used in welding and cutting metals.

There is also an infrared gas burner, but it is not a cutting tool, but a heater. For uniform heat distribution, the heating element is positioned with the emitter towards the top and transforms thermal energy into infrared radiation. The temperature and heating intensity are adjusted using a control valve.

We assemble a burner for laying roofing felt in 10 minutes

For assembly you will need:

- A nozzle and a tap

from an old gas stove (both parts can be bought on the construction market. The price is cheap); - Gas cylinder

(you can get by with a camping cylinder with a volume of 10-20 liters); - Connecting hose

with cap clamps.

| Illustration | Description of the stage |

| We connect the nozzle with the tap . We connect the tap through the pipe to the nozzle. | |

| We connect the gas cylinder to the burner with a hose . We must tighten the connections with cap clamps. | |

| Trial run . With the tap on the burner closed, open the supply from the cylinder. We bring a lit match to the nozzle and open the gas supply valve. | |

| Torch adjustment . We adjust the flame flow by turning the tap: counterclockwise - more, clockwise - less. |

A homemade gas burner is no worse than a purchased tool in terms of efficiency and safety of use. I am sure that the tool assembled according to the proposed instructions will be useful to you.

Assembling a Portable Cutter for the Home Workshop

This compact tool, despite its low power, produces a flame with temperatures up to +1000°C. To make a gas burner at home, we will need the following materials:

- Pumping needle for inflating balls;

- Thin needle from a disposable syringe;

- Plastic bottle with a volume of 1.5-2 liters;

- Two sets of droppers with clamps;

- Copper wire with a diameter of 0.5 mm;

- Flux and soldering supplies;

- Nipple from a bicycle or car tube;

- Hot glue and gun.

If you liked the article, please share it

Previously on the topic:

Share

Indicators related to the flame of the device

gas burner flame

The burner flame power can be low (fuel consumption is 25-400 dm3/h), medium (400-2800 dm3/h) and high (2800-7000 dm3/h). Knowing the maximum and minimum power of a particular burner, you can calculate the fuel consumption and the amount of energy required to meet technological needs.

According to the number of flames, burners are single-flame and multi-flame. If the first type is used primarily for manual oxygen-acetylene welding, the second is widely used for mechanized flame soldering or heating.

Main characteristics

If you want to purchase this equipment, then you need to know which parameters play the main role.

- Flame type. The flame may resemble a torch or be a swirl type. For spot soldering, a flame in the form of a torch is suitable. This will allow you to influence a small area of the product. But the vortex flame warms up a large surface area well.

- Flame adjustment. Some types of burners do not have a regulator at all. On the rest it is located in different places. The simpler the fire adjustment, the more convenient the work. The variety of positions of the regulator will allow you to process different materials and perform other operations in addition to soldering - metal tempering, heating and others.

Devices with disposable and stationary cylinders

The most convenient and compact device is a mini-gas burner, which is equipped with a disposable cylinder. It is good to use for soldering copper products in hard-to-reach places, and its low weight and compactness make the work more convenient. The fuel in such burners is gas mixtures, acetylene or propane. On the handle of the device there is a valve for adjusting the fire level.

Maximum connection quality can be achieved by using gas burners with stationary cylinders. With their help, you can process even the most refractory metals.

Which one should I do?

Before we begin manufacturing, we will select the appropriate type of burner from the following list:

- atmospheric injection;

- ejection;

- supercharged.

The second and third types are more difficult to manufacture. And to organize pressurization you will need compressed air or oxygen, which means a compressor or another cylinder.

The easiest way to do it yourself is the first type; it’s the one you should prefer..

The atmospheric burner process is controlled by a control valve. Therefore, the choice of type, as well as the model of the device itself, largely depends on which one turns up.

It must be remembered that the combustion of a particular gas depends on the diameter of the nozzle hole. The hydrogen jet has slightly less of it, the propane jet has more.

Designs, diagrams, drawings, assembly technology

First of all, you will need a drawing of the future device, a sketch or diagram of the burner, with dimensions.

It’s easy to find a ready-made one using the Internet . If you understand the general principles of the device’s operation and know how to calculate it, you can develop the project yourself.

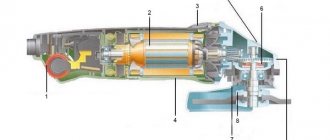

An easy option is to use a valve from a propane or oxygen cylinder, known as model VK-74 (see diagram).

A fitting is machined into the side thread, which will also serve as a handle. You can use a pipe of suitable size. On one side, cut an internal thread, on the other, make a shank for putting on the gas hose.

We screw a plug onto the thread with which it is attached to the cylinder. We drill a hole in its end and cut a thread for the jet. We weld a nozzle to the plug on steel spokes, which will also serve as an injection chamber.

It's even easier if you come across an old acetylene cutter or gas cutter. Essentially, this is a finished burner . It is enough to remove the parts connected with the oxygen supply so that they do not interfere, replace the gas nozzle with a nozzle, and attach the injection chamber-nozzle above it.

Nozzle and handle - manufacturing options

If you look from the outside, the handle and nozzle are, in fact, the entire unit .

The rest is pipes and valves supplying gas. For the nozzle, you can purchase a brass nozzle from gas appliances. They sell without problems and cost pennies.

If you need a special design, you can proceed as follows.

We clamp a suitable workpiece with a vice.

To avoid crushing the thread when clamping the part in a vice, first use a regular wooden clothespin.

Carefully drill a hole with a drill of a suitable diameter, not reaching the end about a millimeter. We grind down the remaining metal until the point left by the very tip of the drill appears.

After this, using a thin drill or a hardened awl, we punch a hole of the required diameter from the inside.

Any suitable object can be used as a handle. A handle from an old soldering iron, a piece of thick-walled hose, or a drilled piece of wood will do.

To fix parts and hoses, we use clamp clamps and hot glue gun.

The burner flame is adjusted and adjusted in the following ways:

- gas control valve - current;

- moving the nozzle (nozzle) along the axis of the injection chamber, changing its opening.

- changing the size and shape of the supply window through which atmospheric air enters.

The last two methods are used when setting up . They do not need to be changed during operation. However, if you are not sure of the accuracy of the design calculations, you should take care of the possibility of adjusting them.

Which is better quality: professional or budget?

So, professional contractors purchase usually expensive professional gas burners that are reliable and safe to use. But for a home craftsman, a small, convenient tool without any additional pretensions will be suitable for equipping and repairing the roof of your own home. Will the quality of work be worse? Not at all! It’s just that such a gas burner is not suitable for industrial work, where it is used almost every day and where uninterrupted processes and absolute safety come first.

It is also not acceptable to have a situation where a team goes to a new facility (and, of course, deadlines are definitely running out), and the burner is defective. There is neither time nor reserve to stop everything and go out to purchase new equipment. Whereas, with careful handling in the hands of a home craftsman, even the most Chinese unit will serve faithfully for decades. Especially if you use it no more than once a season.

And in the end, when working with a massive professional burner or with a regular one, you will get the same result. But no matter how expensive and professional the gas burner is, before each use, be sure to check its connecting hose, the tightness of the connections and the clogging of the mouthpiece. Such problems do not occur often, but if you miss a defect, there is a risk of serious consequences.

Although, if you have an idea to buy the cheapest “lighter” (how much does it cost to cover a garage roof?), then we will hasten to dissuade you. The fact is that if a gas burner has a weak gearbox, then the fire will be no more useful than the same blowtorch. The work will proceed extremely slowly - while you heat one part of the sheet, the second will already have time to cool down. As a result, you will simply have to remove the gearbox and work without it at your own peril and risk.

Mini

A very tiny gas burner can be made from a fitting for inflating basketballs, a syringe needle and a couple of droppers , or as they are called medical “systems” for drip administration of drugs. The homemade product can even work from a lighter refill can.

Adjusting roller clamps will act as valves.

True, we will need a forced air supply for this device; the nozzle diameter is too small for injection of atmospheric air. For this purpose, you can use the compressor of an aquarium or an old refrigerator.

Carefully grind off the tip of the syringe needle and fitting. After this, bend the syringe needle slightly and insert it into the side hole of the fitting, so that the end comes out slightly from the cut tip.

We wrap the needle insertion site with copper wire and solder it well with acid.

The burner is ready. All that remains is to connect gas and air to it.

Soldering tool

A gas heater with piezo ignition is a compact and mobile alternative to a hair dryer. To operate, it does not require a connection to wires; the fuel source is a gas cylinder; in this case, a burner with piezo ignition significantly bypasses a construction hair dryer, which is less convenient to use due to the need to connect wires, which are not always convenient to pull.

Application of gas burner:

The gas temperature during combustion reaches 1300–1800°C. The tool is easy to use with one hand.