Often, autonomous heating equipment is used to heat a private home, and a boiler is used for hot water supply. The only way in this case to minimize the time it takes to move heated water, thereby increasing the efficiency of the systems and avoiding heat loss, is a recirculation pump, correctly installed in the pipeline. Let's look at what it is, what its structure is, its operating principle and purpose, what control options there are, what types it is divided into, as well as how to select and install it correctly.

Recirculation pump in the hot water supply system of a house Source masteravannoy.ru

Device, principle of operation, purpose

Pumping equipment for pumping heated water through a closed pipeline loop in a private house is small in size and consists of the following main elements:

- Housing made of stainless steel, cast iron or bronze and brass.

- A stator that can withstand heating of the pumped medium up to 60-700C.

- A rotor shaft with an impeller, the rotation of the blades of which ensures the injection of water into the pipeline.

- Thermoplastic impeller.

- Squirrel cage steel rotor.

At the same time, the pump is able to exhibit the characteristics laid down in it by the manufacturer, provided that the pumped liquid is technically clean - with a viscosity characteristic of water without the inclusion of mechanical impurities. The device is installed quite simply - without removal from the system, but by inserting it into a pipeline section. Therefore, the use of a bypass is not necessarily necessary.

The principle of operation of a recirculation pump for domestic hot water or heating boils down to the following mechanism:

- Water from the pipeline enters the device into the central part of the impeller.

- An electric drive rotates the blades.

Design of a circulation pump for hot water Source eurosantehnik.ru

- As a result, the resulting centrifugal force pushes water to the outlet pipe, giving the flow a given pressure.

- In this case, an increased injection of incoming water occurs at the entrance to the pump - due to the vacuum created on the back side of the blades.

The use of such equipment is not necessary for the operation of an autonomous water heating system, but it can significantly increase the efficiency and cost-effectiveness of energy consumption. If under normal conditions it takes time for hot water to come out of the tap when opening (since with a slow flow it cools quickly), then when using a pump it flows almost instantly.

This is especially true when the consumer is located at a relatively large distance from the water heater. Another useful function for which this type of recirculator is intended is the return of unused heated water to the heater via the return line. In addition, with a gravity-flow system, the farther the consumer is located, the more noticeable the initial pressure drops.

Option for placing a circulation pump in a heating and hot water system for a private home Source s-proms.ru

The use of a recirculation pump allows you to get rid of this significant drawback. This ensures constant water temperature and pressure at any point in the heating system or DHW circuit - regardless of the distance to the unit.

Important! Only a specially designed pump can be installed in a domestic hot water or heating system. A conventional centrifugal model for pumping water is not suitable, since it is not designed to work in an environment with elevated temperatures and will quickly deteriorate.

Adviсe

Before you start looking for pumping equipment, you need to correctly calculate the device parameters. Only after this can you decide on a purchase and invest wisely. Such data includes the workload of the water supply system, as well as sufficient flow strength. An important point is to take into account the number of taps that can be turned on simultaneously. It is necessary to create the same pressure of the circulation pump so that the pressure remains constant everywhere.

If we talk about the average water consumption at one point, it is about one hundred and eighty liters per hour. If a house or apartment has two bathrooms and a kitchen where taps are located, the best choice would be to install a device with a throughput capacity of at least 0.7 cubic meters per hour. We must not forget about the hydraulic resistance of the overall system. Pressure and pressure are affected by the length and height of the pipeline, so these indicators also need to be clarified. A water column of 0.6 meters uses 10 linear meters of contour. The manufacturer always adds technical documentation to each model and type of pumping equipment, so it is worth studying all the indicators and descriptions.

Thanks to such calculations, it is possible to obtain the average heat consumption of hot liquid through a circulation pump, which will help you quickly make a choice and facilitate the purchase. Of course, an industrial-type device is suitable for pumping water at a large enterprise, but slightly different models are suitable for a home.

Today, calculations can be made online thanks to electronic calculators, where the corresponding indicators are entered, which speeds up the solution of the problem. If a pump is selected for an apartment building or a cottage with a large area, such calculations are carried out only by qualified specialists from design and installation organizations, since they are responsible for the performance of the entire system.

To correctly install the pump in a hot water supply system, you must first study the instructions in detail and strictly follow the manufacturer’s recommendations. In addition, building codes are important and must be heeded.

To complete the installation you will need to complete the following steps:

- the installation location of the circulation device is selected. The module must be installed on the return line, which will prevent air from entering, which in turn will lead to a decrease in the functionality of the entire system;

- a check valve must be installed between the pump and the storage tank;

- shut-off valves are installed before and after the station, their number depends on needs;

- A UPS is used for connection. As soon as the power is turned off, it will ensure that the device operates in autonomous mode. The duration of its operation ranges from several hours to a day.

Of course, it is also necessary to choose an uninterruptible power supply according to certain parameters, taking into account the rules. Uniform distribution of pressure is an important task. For this purpose, special manifolds and pressure-reducing valves are used. You cannot run the electric motor idle, which will negatively affect its performance and the device will quickly fail. After installing the pump in the DHW system, it is necessary to fill the water circuit and do a test run to check the functionality of the mechanism.

The device with a wet rotor is a simple design that does not require regular inspection or even repair, which is one of the main advantages of this equipment. The only thing you need to do is clean and replace the filter if necessary. Glanded rotor pumps require maintenance once every two years. It is necessary to replace the lubricant and clean the housing for the device to operate smoothly. If desired, you can consult with qualified specialists to make the right choice.

In the next video you will find a review of the surface circulation pump GRUNDFOS UP 15-14 B.

This is interesting: Circulation pumps for heating: varieties, selection rules, installation

Control options

Hot water in a private house is used periodically - for washing, washing, cleaning, showering, etc. There is no need to constantly maintain it in the DHW circuit. In addition, such an approach would lead to extremely wasteful consumption of energy resources and equipment.

Circulation pump with temperature sensor Source prom.st

See also: Catalog of companies that specialize in water supply, sewerage and related work

Therefore, in order for the heated water to reach the tap at the right time, 2 special pump control options are used - these are:

- Thermal sensor.

The principle of operation is based on maintaining a given water temperature in the circuit and boils down to the following algorithm:

- The temperature-sensitive element is immersed inside the pipe and is in direct contact with the water.

- As soon as the temperature inside drops below the set value, the sensor instantly sends a signal to the control module.

- The recirculation pump starts and begins to supply hot water to the DHW circuit.

- As soon as the heating level reaches the required value, the pump turns off.

To reduce energy consumption and equipment resources, the pipeline is specially thermally insulated.

- Timer.

Timer operation differs from the above option in that hot water is pumped into the pipes according to a specific schedule. This approach is convenient when it is known exactly during what specific period of time the hot water supply will be used. For example, on weekdays these are the morning and evening hours, when household members get ready for work and come back from it.

Circulation pump with timer Source cok.ru

Modern smart timer models allow you to set up a schedule several days in advance, as well as independently monitor the water consumption schedule and then automatically set the operation of the equipment. In addition, they are able to take into account the parameters of the hot water circuit - the length of the pipes, their capacity, the percentage of heat loss, the cooling time of the water - and, based on this, adjust the time the device is turned on/off.

Recommendations for proper pump installation

To ensure convenient access for servicing the pump, the unit must be connected correctly. In practice, when installing a pump, the following basic installation rules should be taken into account:

After installing the circulation pump, it should always be accessible so that in the event of a breakdown, it can be easily repaired or replaced.

- Both sides of the pumping unit must be equipped with special ball valves, which are necessary when carrying out maintenance of the entire heating system or during the dismantling of the unit.

- It is necessary to equip the entire system with a filter in order to protect the device from exposure to small particles that lead to damage to the installation and its components.

- Since the water passing through the heating system is far from ideal, additional protection will be required for the pumps to function properly. Therefore, the heating bypass on top must be equipped with a valve, which must be installed. You can choose any valve: automatic or manual. Its purpose is to release air pockets formed in the pipes; its terminals should be directed clearly upward.

- Belonging to the type of wet models, the pump must be installed in a horizontal position so that it is completely immersed in water, and not just a separate part. Incorrect installation can cause damage to the working surface of the unit, and the installation will be pointless.

- To increase the operating potential of the structure, it is necessary to specially treat all fasteners and connections in the system with a sealing agent.

- It is necessary to ensure that the sequence is observed when connecting the pump and fasteners.

Varieties

Hot water recirculation pumps are classified according to several criteria. First of all, they are divided according to their purpose in a closed loop circuit into 2 types:

- The servers. Mounted on a direct line for supplying water from the heater.

- Reverse. Installed on the return branch to return cooled water to the heating circuit.

Based on the type of design, pumps are divided into 2 types:

- With wet rotor.

The working part of the device is located directly in the pumped medium. Therefore, both cooling and lubrication of the device is carried out by the pumped liquid, in this case water.

Recirculation pump with a wet rotor Source teploufa.ru

Wilo Star-RS 25/4-180

Photo: https://beru.ru

The German pump Wilo Star-RS 25/4-180 is popular among domestic homeowners. In just 2 months, 2187 people in the nuclear field were interested in this device. The model is designed for small heating systems. The device consumes only 48 W of electricity, delivering a maximum head of 4 m and a throughput of up to 3 cubic meters. m/h. The model looks reliable, the cast iron body and stainless steel shaft will ensure a long service life. The pump earned high marks from experts for its quiet operation and the presence of a speed switch.

Circulation pump Wilo Star-RS 25/4-180 (48 W)

Advantages:

- reliability and durability

- silent operation

- economical energy consumption

- affordable price

Flaws:

- modest performance

Selection rules

In order to choose the right circulation pump for domestic hot water, it is necessary to take into account the following number of criteria:

- Performance. The value is determined by the amount of water pumped per unit of time. For example, for a private house with an area of 100 m2, a model of 80-110 liters/min is optimal.

- Pressure The indicator depends on the location of the water heating installation and the height of the consumer relative to it. So, if the boiler is located in the basement, then a tap on the 2nd floor will require a value of this characteristic of 6-8 m.

- Power consumption. The stronger the motor, the more productive the device will be, but also the more expensive it will cost to operate.

- Control method. By timer or temperature sensor.

- Manufacturer's brand.

- Price.

A circulation pump for a home is selected based on several parameters at once Source byreniepro.ru

Important! Pump selection should be carried out by an experienced designer based on specific application conditions. This takes into account the number of intake points, the minimum and maximum volume of water used, the supply height, and the length of the pipeline.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

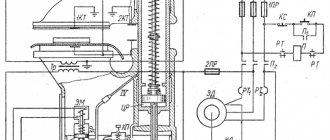

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Video description

Video review of what a DHW recirculation system is and the rules for choosing a pump for it:

In this case, the standard installation procedure in the DHW circuit of a private house is carried out according to the following algorithm:

- Assembling the device in accordance with the technical documentation.

- Determining the installation location in the circuit.

- Shutting off the feed.

- Cutting out part of the pipeline at the installation site.

- Connecting the device.

- Sealing and checking joints for leaks.

- Turning on the water supply, connecting equipment.

- Configuration and performance testing.

Advice! To facilitate equipment maintenance and maintain maximum system functionality, it is best to install the device in a so-called pocket. This is a special outlet separated from the pipeline by shut-off valves. If necessary, the pump can be quickly turned off and dismantled, replaced with a new one or repaired - without stopping the coolant.

Installation diagrams

There are two ways to connect pumps:

- Consistent in the break of the return line of the contour.

- Parallel with the collector.

The first method is good for systems with a small number of consumption devices and with a short total length of pipeline lines. The pump is connected at the end of the circulation circle, into the return line gap.

The second method is used for a large number of circuits (for example, heated floor loops) . It requires a powerful, productive pump, otherwise you will have to install your own device for each circuit, which increases noise and load on the electrical network.

Briefly about the main thing

A hot water circulation pump consists of a housing, a rotor, a shaft with blades, a stator and an impeller. The principle of its operation is that water flows through the inlet pipe to an impeller rotated by a drive. As a result of the resulting centrifugal force, the flow is injected and exits with a given pressure into the system. Thanks to the pump, the water does not have time to cool down in the pipeline and does not lose pressure, regardless of the distance of the tap from the water heater.

Such a pump can be controlled in two ways - by a temperature sensor and by a timer. In the first case, the supply is resumed when the water in the circuit cools, in the second - according to a schedule. Pumping equipment is classified according to several criteria:

- Installation location in the diagram - supply and return.

- Design type - with wet and dry rotor.

- Number of drive speeds.

When choosing a pump, you need to take into account performance, pressure, power consumption, control option, brand, cost. Installation into the pipeline diagram is carried out depending on the purpose and strictly according to a given algorithm.

Unit features

The principle of operation of circulation pumping equipment is based on creating continuous circulation of liquid in the system without changing the pressure indicator

A circulation pump is a device that operates in a closed heating system and moves water in a pipeline. The unit maintains a certain temperature of the coolant in the system. The device does not replenish coolant losses and does not refill the system. The system is filled using a special pump or a certain pressure in the pipes.

The principle of operation of circulation pumping equipment is based on creating continuous circulation of liquid in the system without changing the pressure indicator. Since after installation the device operates constantly, the main requirements for such pumps are low noise level during operation, economical energy consumption, reliability, durability and ease of use.

Important: circulation pumps are compact devices that do not take up much space and do not create noise during operation. The scope of use of circulation units for heating systems is quite extensive.

They are installed:

The scope of use of circulation units for heating systems is quite extensive. They are installed:

- in traditional radiator systems;

- when installing a water heated floor;

- in geothermal systems;

- when organizing hot water supply for cottages and dachas.

Unlike forced circulation systems, this pumping equipment does not require pipes with an increased diameter. In addition, the device has the following advantages:

- speed of heating the room;

- the boiler can be installed in any suitable place;

- coolant losses and air pockets are minimized;

- The thermal relay ensures automatic control of temperature conditions;

- Electricity costs are reduced due to the use of automatic rotor speed control;

- Since liquid is constantly supplied to heating devices, their service life is extended.

How to make the first launch?

The first start-up, as a rule, is made after the device is fully connected, the entire line is assembled and filled with water.

It is prohibited by the instructions to turn on the pump dry. This is fraught with breakdown and failure, as well as refusal of the warranty workshop to carry out repairs.

Before starting, you need to make sure that the system is completely ready for operation . Most designs automatically remove air when a special screw is turned.

You need to unscrew it half a turn (or more) and wait a few seconds until the air comes out and water flows out. For other pumps it is necessary to install a special air venting element (Maevsky valve).

The most common types of breakdowns and how to fix them

The most common type of breakdown is the impeller stopping. The device hums but does not work properly. To solve the problem, you need to turn off the circulation, drain the water, disassemble the device and move the impeller. Typically, the cause is the adhesion of small particles or the entry of foreign objects into the flow.

The second most common type of malfunction is overheating . It occurs due to lack of lubrication on the bearings or due to the regular entry of air into the system. The problem can be solved if the rotating parts are well lubricated and all connections are reliably sealed.

Everything you need to know about hot water is presented in this section of the site.